An intelligent lubricating and cooling device for high-efficiency machining of camshafts and its application method

A cooling device and machining technology, applied in metal processing equipment, grinding/polishing safety devices, manufacturing tools, etc., can solve the problem of increasing the cost and difficulty of spare parts allocation and storage management, the degree of automation, intelligence and versatility Insufficient, single type of lubricant used, etc., to achieve the effect of structural strength stability and good versatility, efficient cooling and lubrication operations, and preventing workpiece surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

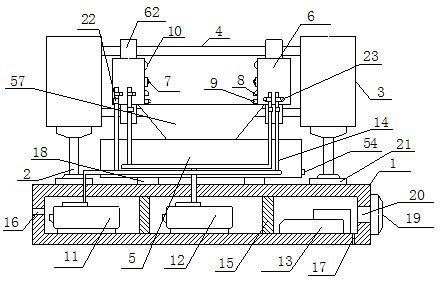

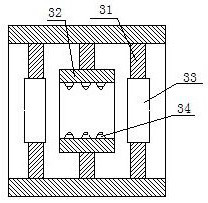

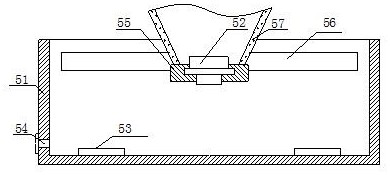

[0027] Such as Figure 1-4 An intelligent lubricating and cooling device for high-efficiency machining of camshafts is shown, which includes a bearing base 1, a lifting drive mechanism 2, a positioning seat 3, a guide rail 4, a collecting tank 5, a slider 6, a distance measuring device 7, and an infrared temperature measuring device. Device 8, lubricant spray port 9, jet air port 10, atomizing spray pump 11, jet pump 12 and control system 13, bearing base 1 is a closed cavity structure with a rectangular cross section, and its upper end surface is passed through a lifting drive mechanism 2 and the positioning seat 3 are connected to each other. There are two positioning seats 3 and they are symmetrically distributed on both sides of the bearing base 1, and the two positioning seats 3 are coaxially distributed and parallel to the upper end surface of the bearing base 1. Two ends are vertically connected to the front faces of the two positioning seats 3, and are parallel to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com