Process and device for recovering and recycling protective gas of bell-type bright annealing furnace

An annealing furnace and shielding gas technology, which is applied in the field of recovery and recycling technology of the bell-type bright annealing furnace shielding gas and its device, can solve problems such as insecurity and waste of energy, and achieve energy saving, novel design, economic benefits and social benefits significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

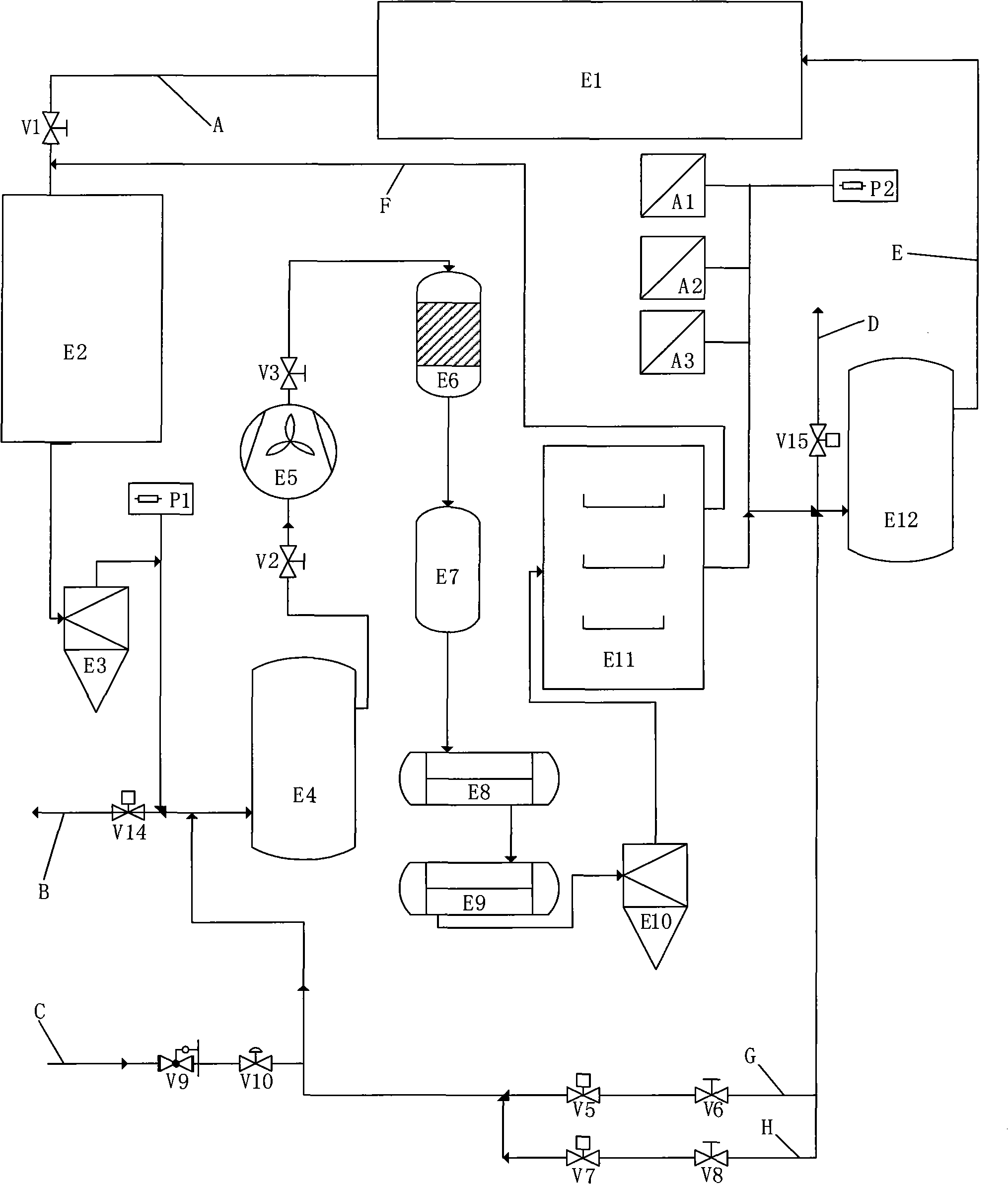

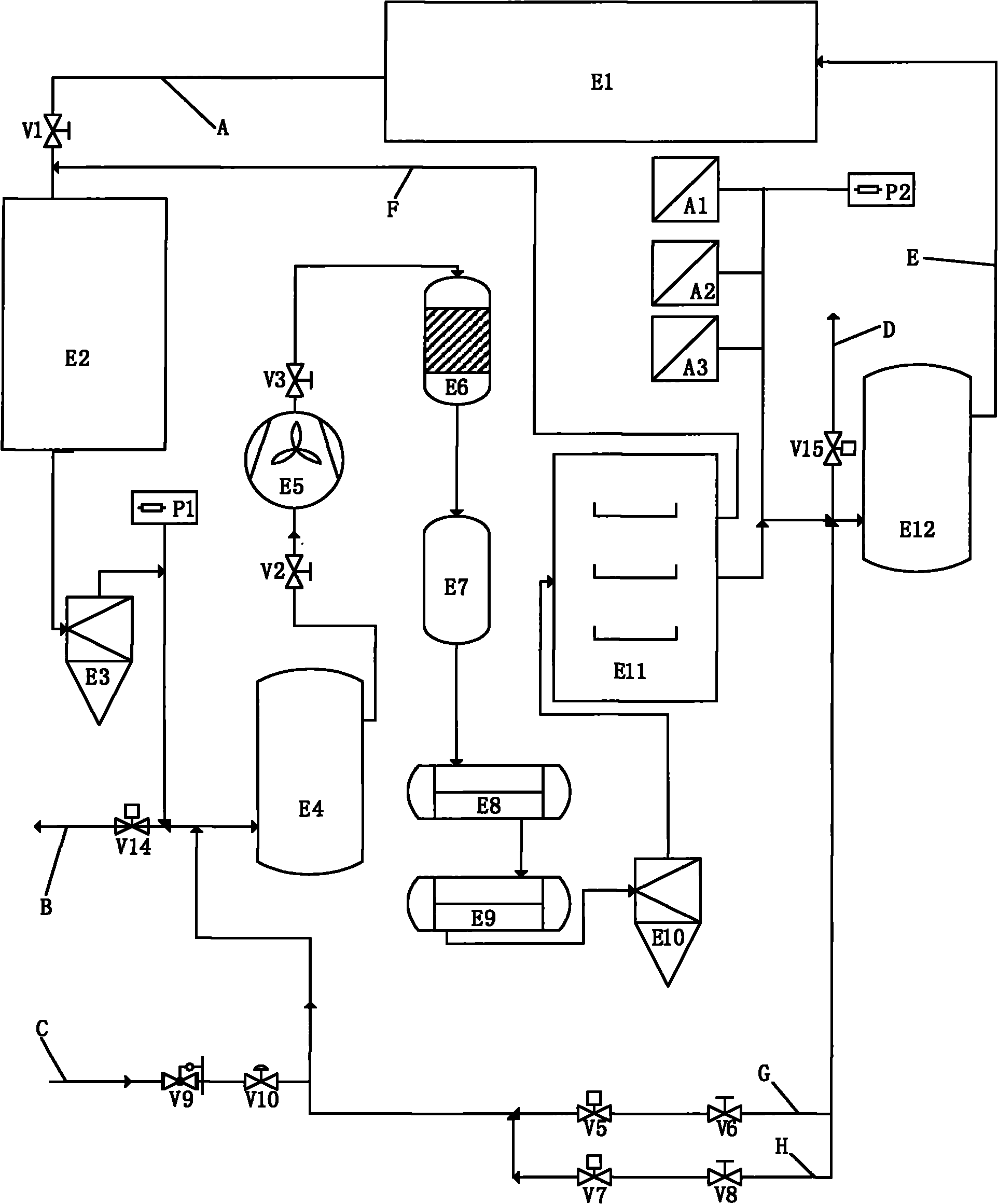

[0019] like figure 1 As shown in the bell-type bright annealing furnace protective gas recovery and recycling device, a cooling condenser E2 is arranged at the backflow protective gas outlet of the bell-type bright annealing furnace group E1, and the bell-type bright annealing furnace group E1 is connected to the cooling and condensing An air inlet valve V1 is installed between the condensers E2, and the air outlet of the cooling condenser E2 is provided with a steam-water separator E3, and the air outlet of the steam-water separator E3 is connected to the pre-stage buffer tank E4, and the air outlet of the pre-stage buffer tank E4 Connected with the inlet of Roots blower E5, Roots blower E5 is connected with frequency converter, the speed of Roots blower E5 is controlled by frequency converter, valve V2 is installed between pre-stage buffer tank E4 and Roots blower E5, Roots blower The outlet of E5 is connected to the oil absorber E6, a valve V3 is installed between the Roots...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com