Porous inert support tubular solid oxide fuel cell with open ends, stack and preparation method thereof

A solid oxide and fuel cell technology, applied in solid electrolyte fuel cells, fuel cells, circuits, etc., can solve problems affecting battery reliability and stability, oxidation of metal connecting materials, and poor electrical conductivity, etc., to achieve convenient battery life. Effects of stack construction, increasing output voltage, and reducing current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

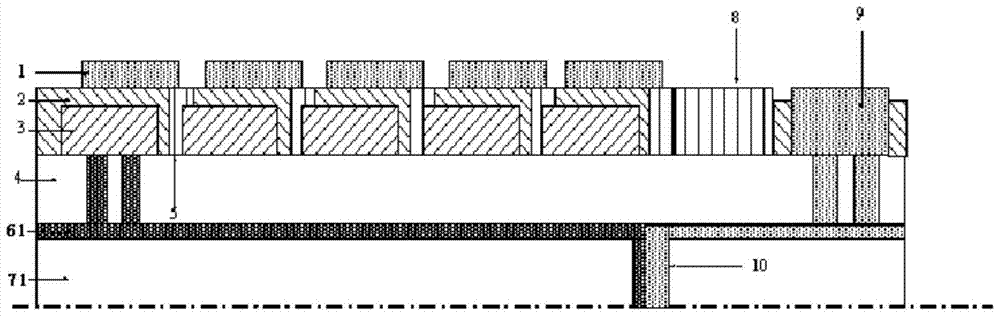

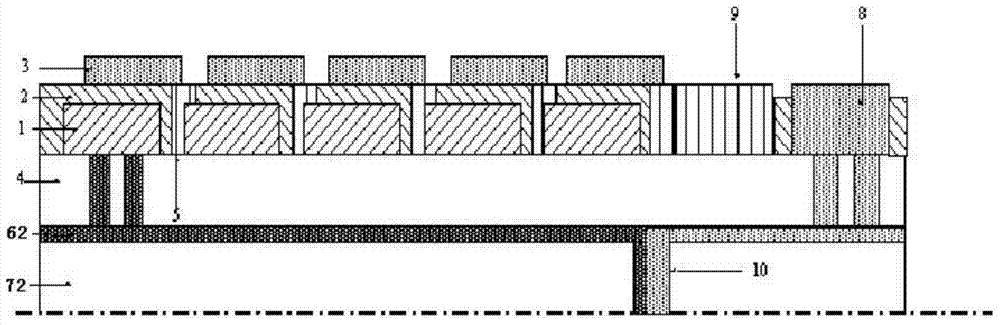

[0032] After mixing magnesia-aluminum spinel, polyvinyl alcohol, starch and deionized water, a porous inert support tube 4 green body with open ends is prepared by extrusion or grouting, and the porous inert support tube 4 green body is suitable Add strontium lanthanum titanate to plug the green body, then open a hole at a suitable position on the tube wall, fill with NiO-YSZ (nickel oxide-strontium doped lanthanum manganite) conductive connection material, and finally put the green body at 1450 ° C Calcined for 5 hours to obtain a porous magnesium-aluminum spinel support tube with both ends open, electronically conductively connected in the tube but airtightly separated. The outer diameter of the tube is 15mm, and the porosity of the tube wall is 42%.

[0033] Add the powder material of each functional section to methyl cellulose and ethylene glycol to prepare corresponding slurry, according to the composition of each functional section and its position in the porous inert su...

Embodiment 2

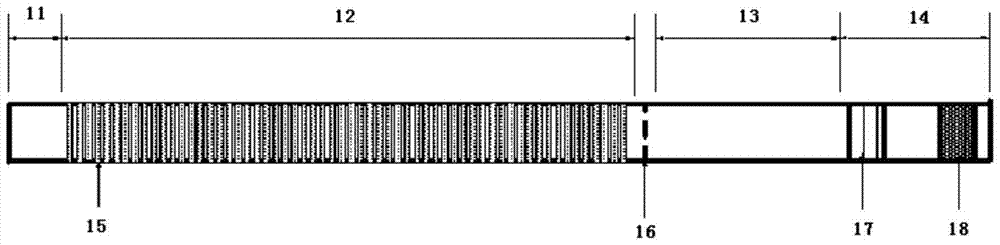

[0036] According to the method described in Example 1, 80 α-cells were prepared. Wherein, the porous inert support tube 4 is a porous alumina tube with an outer diameter of 10 mm and a porosity of the tube wall of 35%. The inlet gas isolation section 11 has a length of 100mm, and the surface is coated with 8mol% yttria-stabilized zirconia dense film. The length of the battery segment 12 connected in series is 1200mm, and the length of each battery is 15mm. The anode is NiO-YSZ (nickel oxide-strontium doped lanthanum manganite), the thickness is 45 μm, the electrolyte is 8mol% yttria stabilized zirconia, the thickness is 20 μm, the connecting body is strontium lanthanum titanate, the thickness is 25 μm, the cathode It is LSM-YSZ (strontium-doped lanthanum manganite-yttria stabilized zirconia), the electrochemical reaction layer of the cathode is 32 μm, and the thickness of the current-collecting conductive layer of the cathode is 50 μm. The heat isolation section 13 has a len...

Embodiment 3

[0039] According to the method described in Example 1, 80 β batteries were prepared. Wherein, the porous inert support tube 4 is a magnesium aluminum spinel tube with a diameter of 15 mm and a porosity of the tube wall of 42%. The inlet gas isolation section 11 has a length of 100mm, and the surface is coated with 8mol% yttria-stabilized zirconia dense film. The length of the battery segment 12 connected in series is 1200mm, and the length of each battery is 15mm. The anode is NiO-YSZ (nickel oxide-strontium doped lanthanum manganite), the thickness is 45 μm, the electrolyte is 8mol% yttria stabilized zirconia, the thickness is 20 μm, the connecting body is strontium lanthanum titanate, the thickness is 25 μm, the cathode It is LSM-YSZ (strontium-doped lanthanum manganite-yttria stabilized zirconia), the electrochemical reaction layer of the cathode is 32 μm, and the thickness of the current-collecting conductive layer of the cathode is 50 μm. The heat isolation section 13 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com