Patents

Literature

42results about How to "Avoid direct burning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

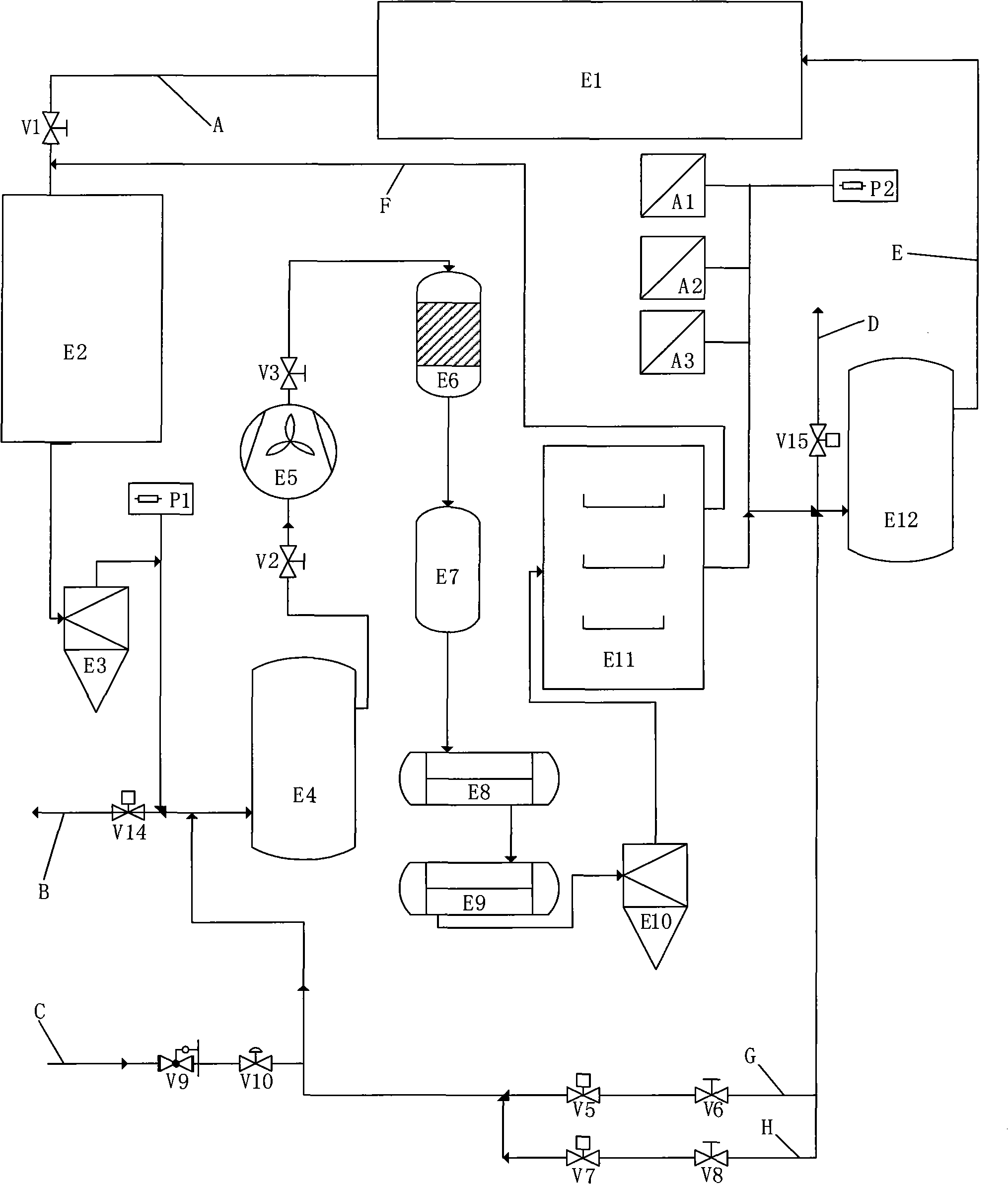

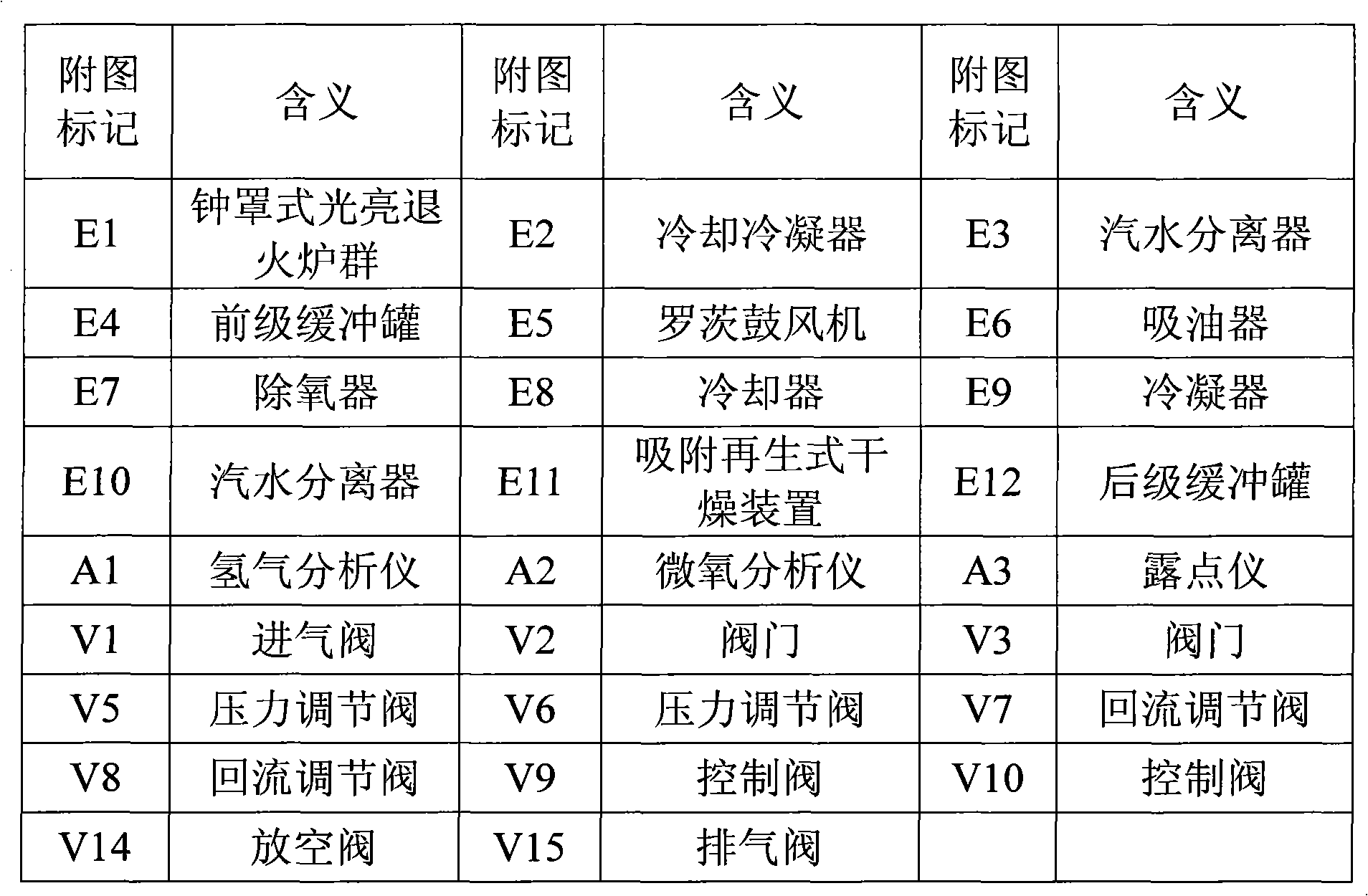

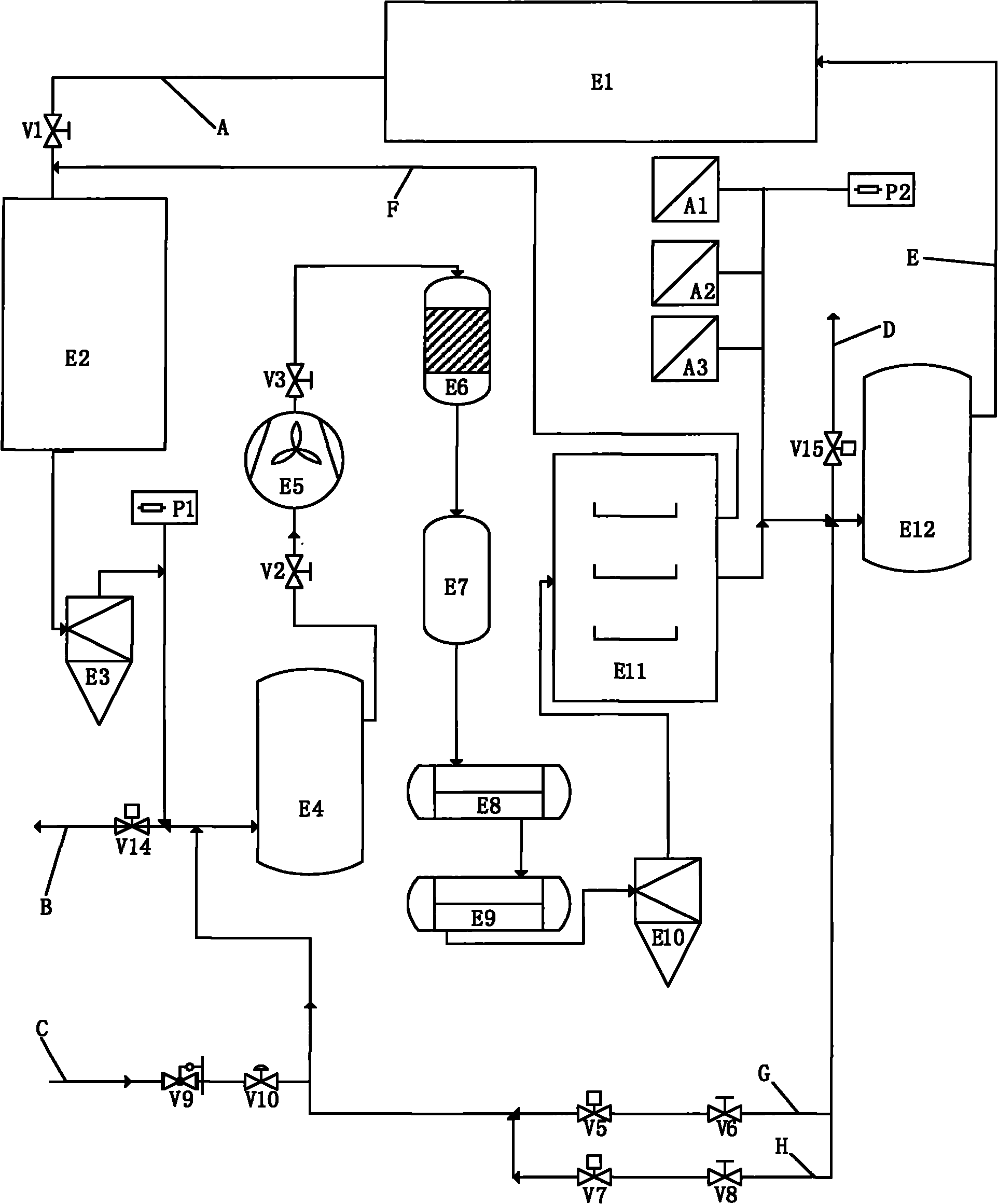

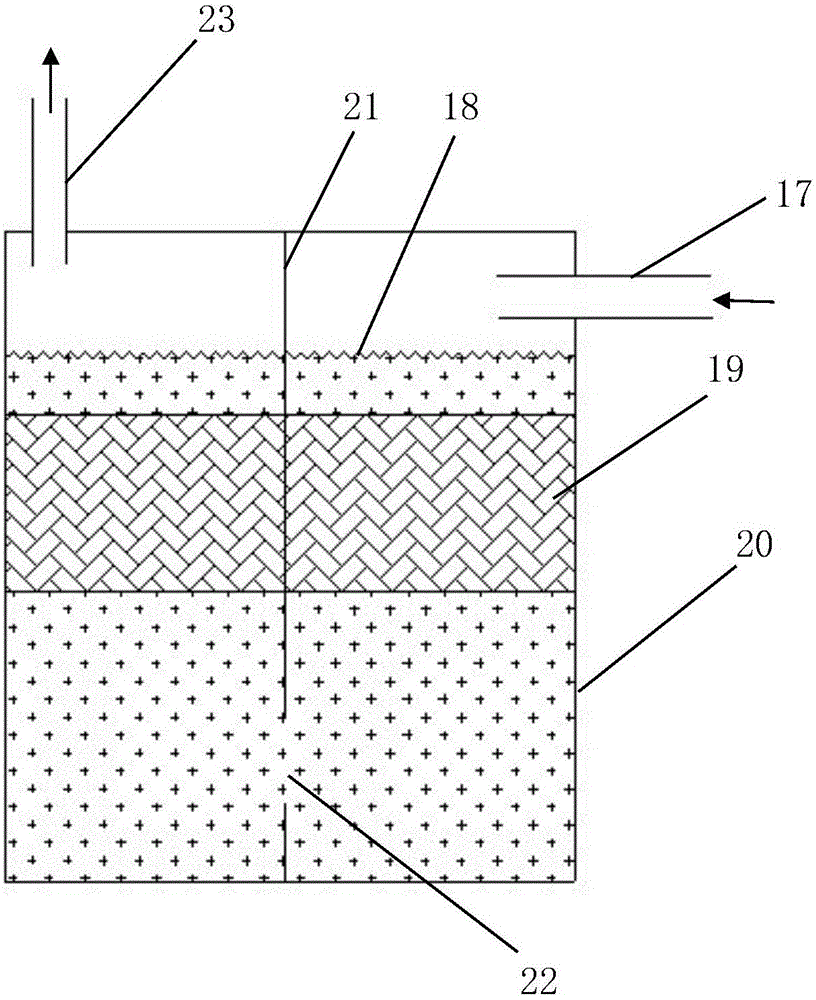

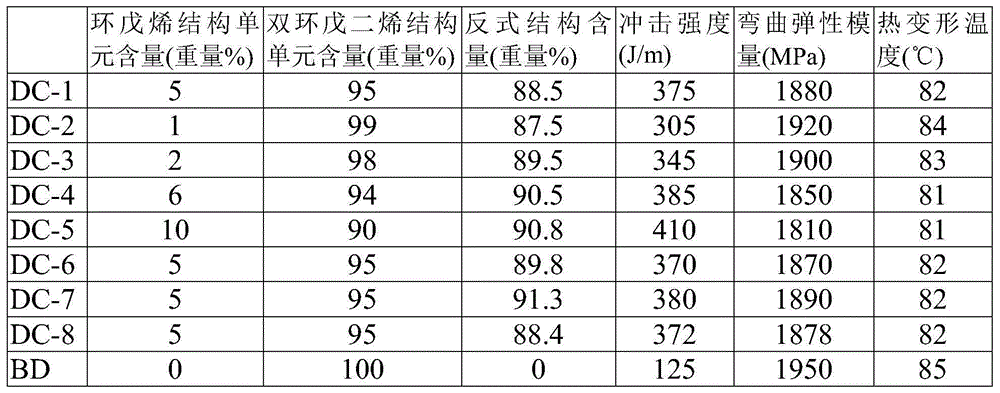

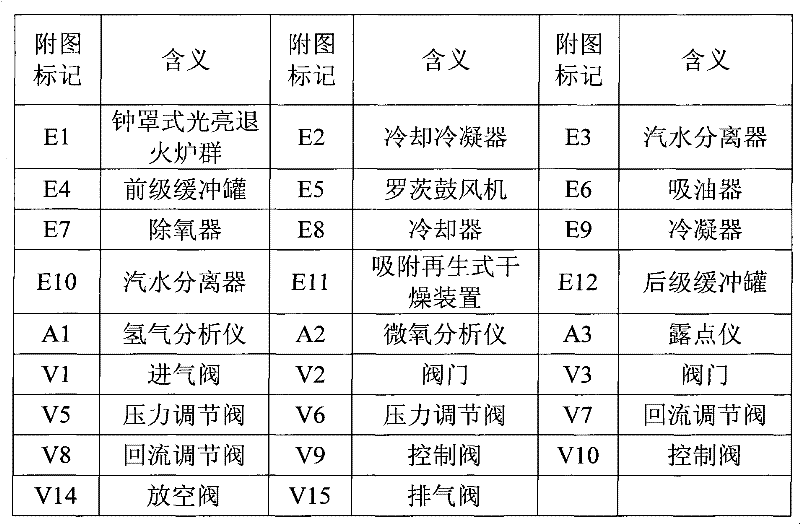

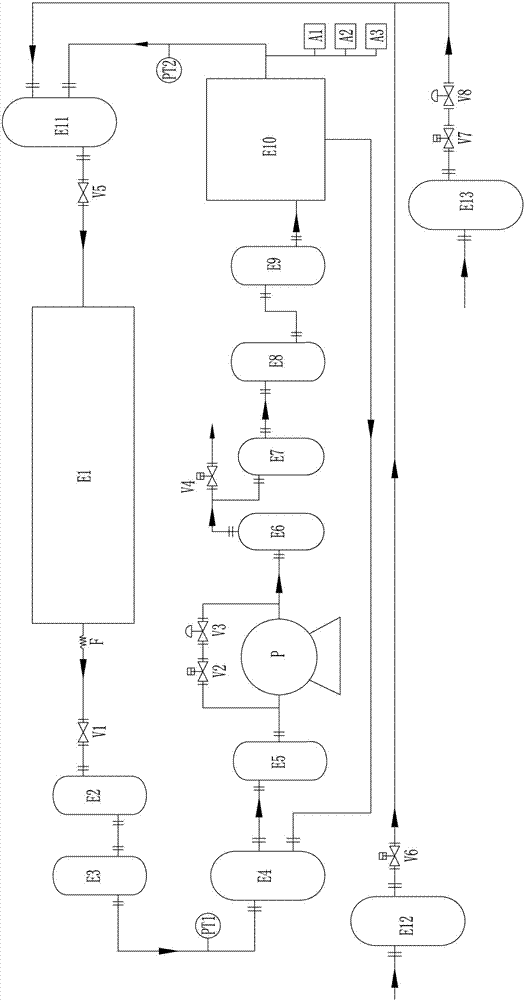

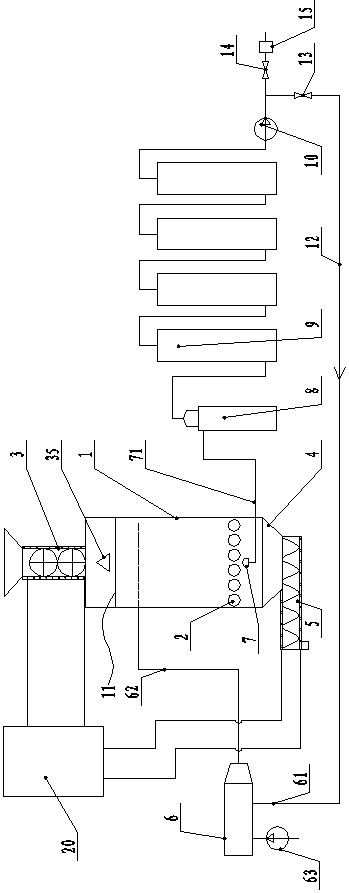

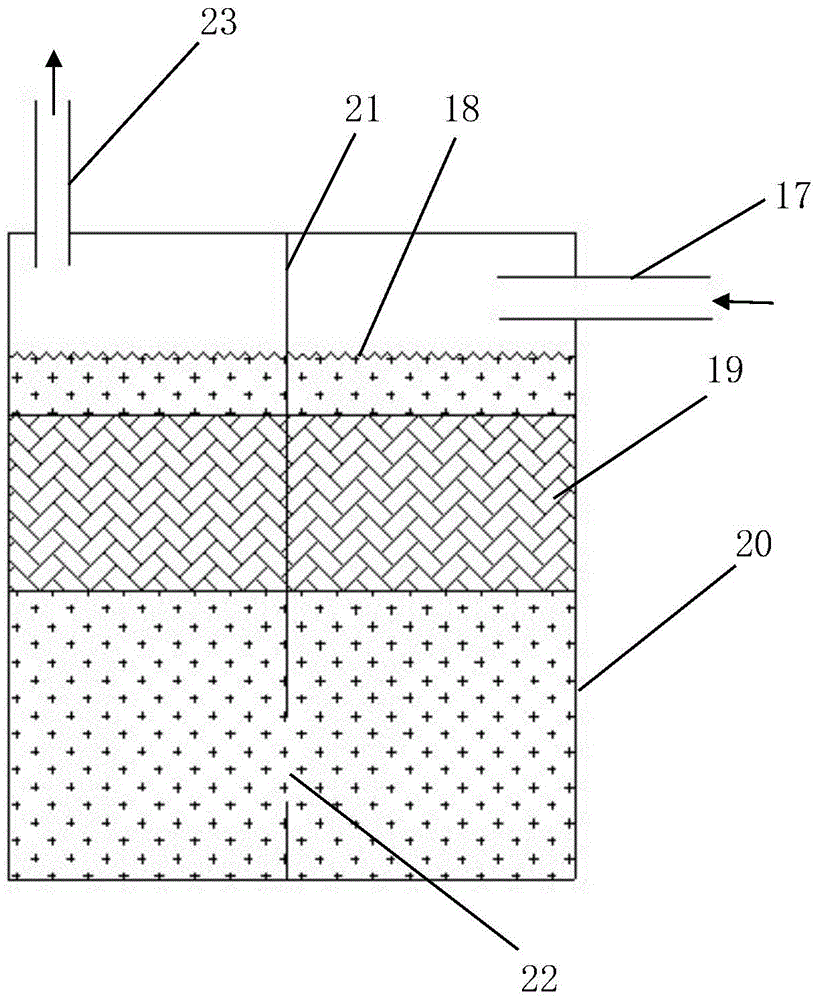

Process and device for recovering and recycling protective gas of bell-type bright annealing furnace

ActiveCN101956061AAvoid direct burningAvoid emptyingMaintainance of heating chambersBell type furnacesBuffer tankDeaerator

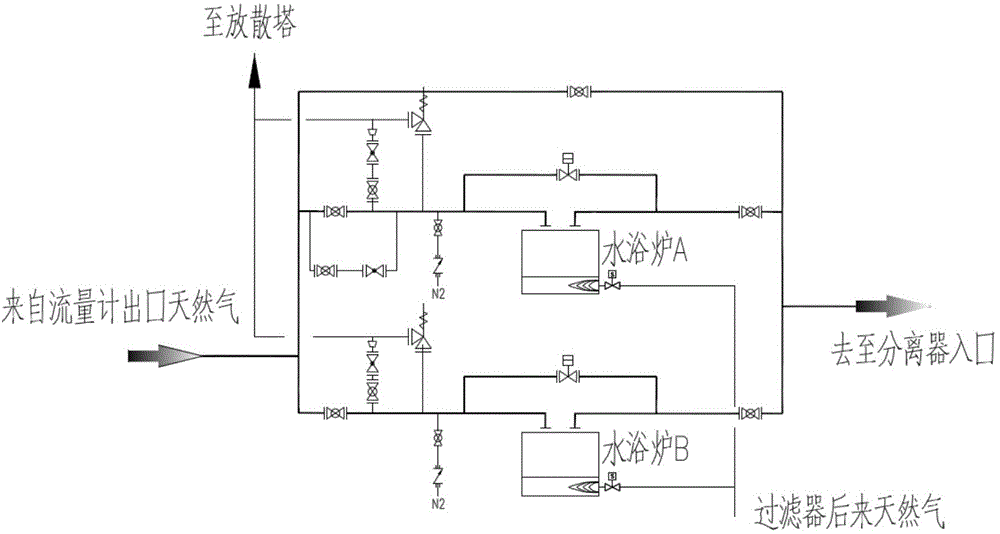

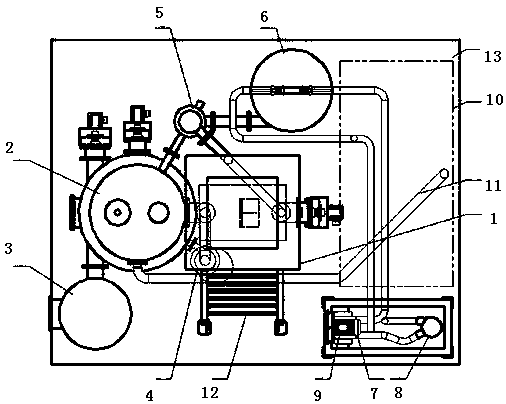

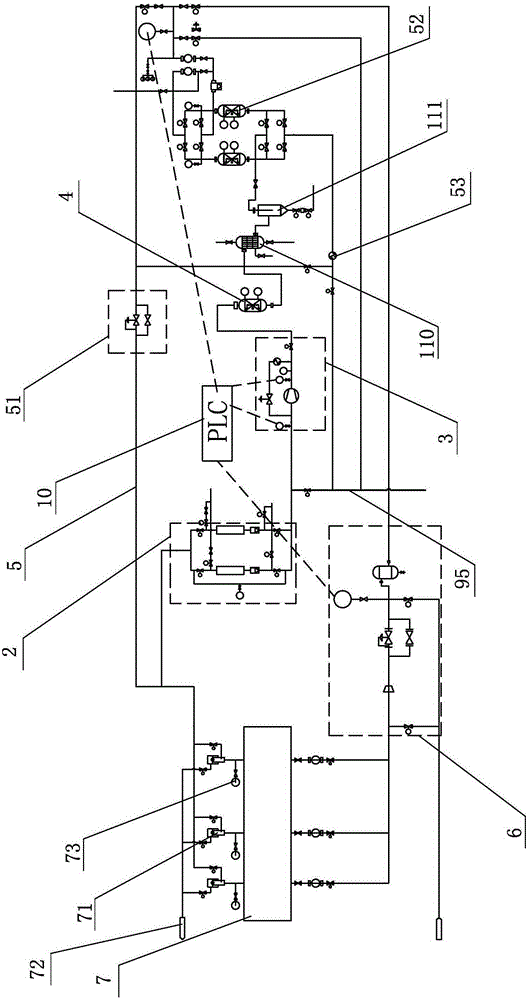

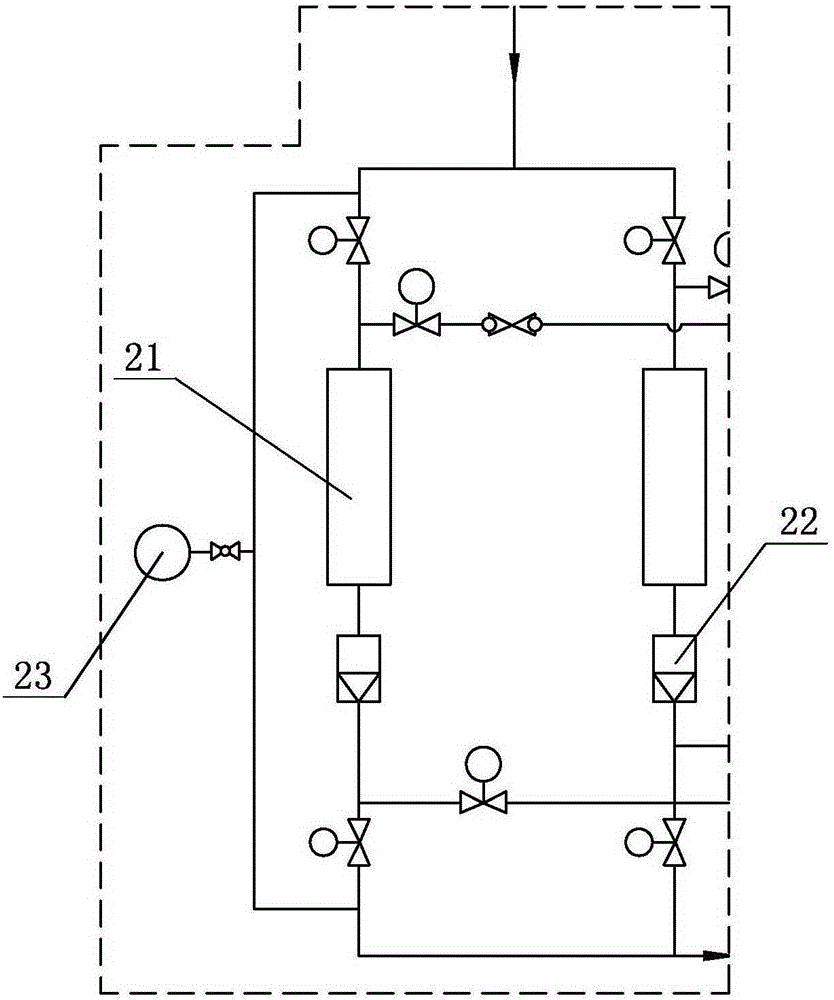

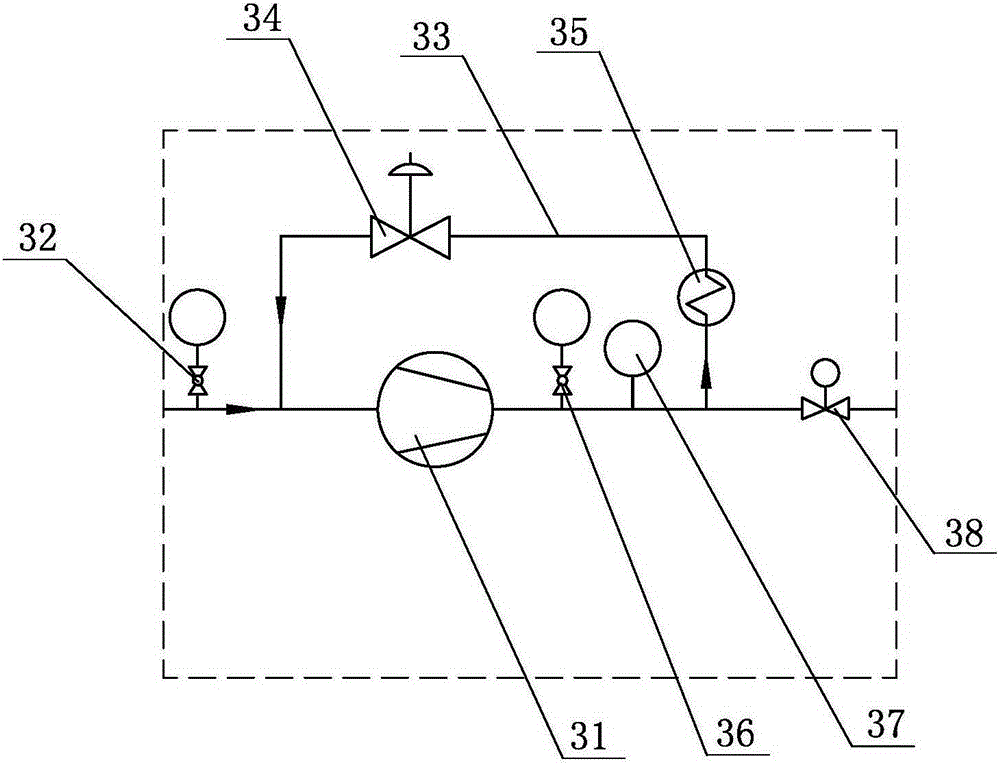

The invention relates to a process and a device for recovering and recycling protective gas of a bell-type bright annealing furnace. The process comprises the following steps of: performing cooling and condensation of oil and gas in refluxing protective gas of a bell-type bright annealing furnace group; allowing the cooled and condensed protective gas to enter a water separator to remove most of water and oil; allowing the cooled protective gas from which the oil and the gas are removed to enter a preceding stage buffer tank; after the protective gas is buffered by the preceding stage buffer tank, pressurizing by using a roots blower; allowing the pressurized protective gas to enter an oil absorption device to remove oil and enter a deaerator to remove oxygen; reacting in the deaerator to generate water and discharge heat; cooling the protective gas by using a cooler and removing water from the protective gas by using a condenser; allowing the cooled and dehydrated protective gas to enter the water separator to separate water; allowing the protective gas to enter an absorption regeneration drying device for removing water and impurities deeply; and performing decompression and voltage stabilization on the purified gas by using a post-stage buffering tank and then supplying the purified gas to the bell-type bright annealing furnace group. Through the process and the device, the refluxing protective gas of the bell-type bright annealing furnace group is recovered and purified and enters the annealing furnace to be recycled as the protective gas again.

Owner:苏州品源气体设备有限公司

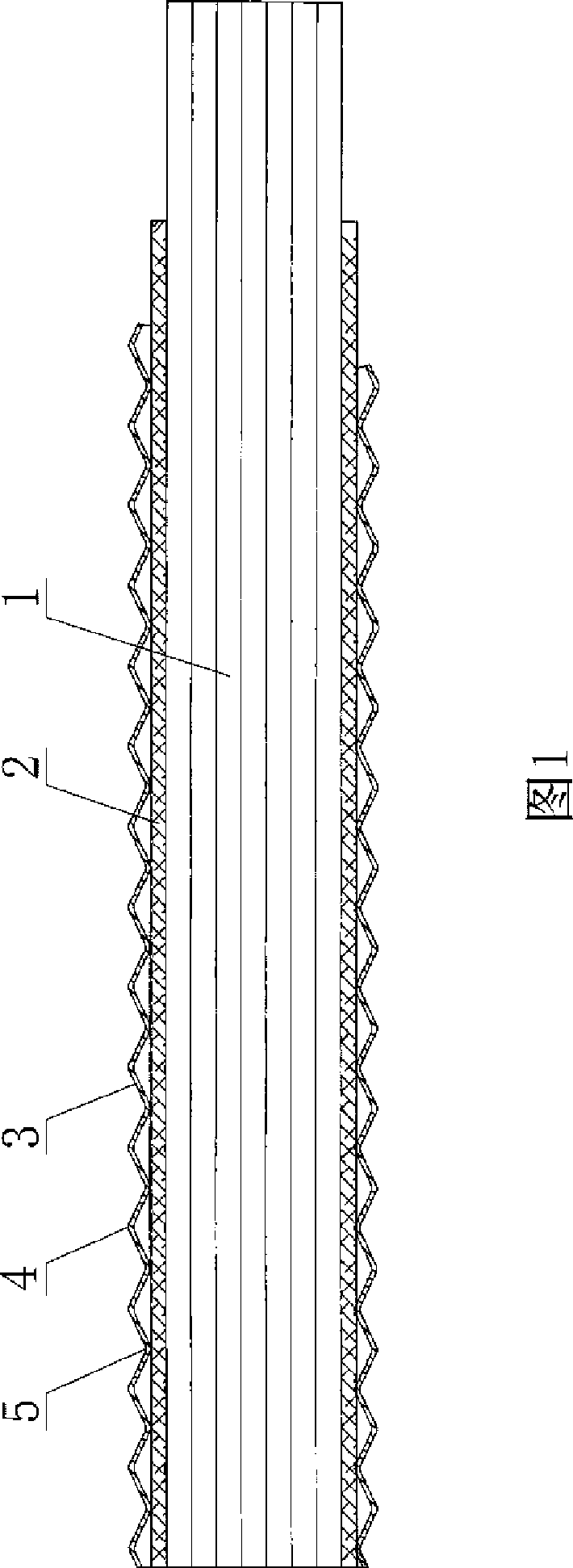

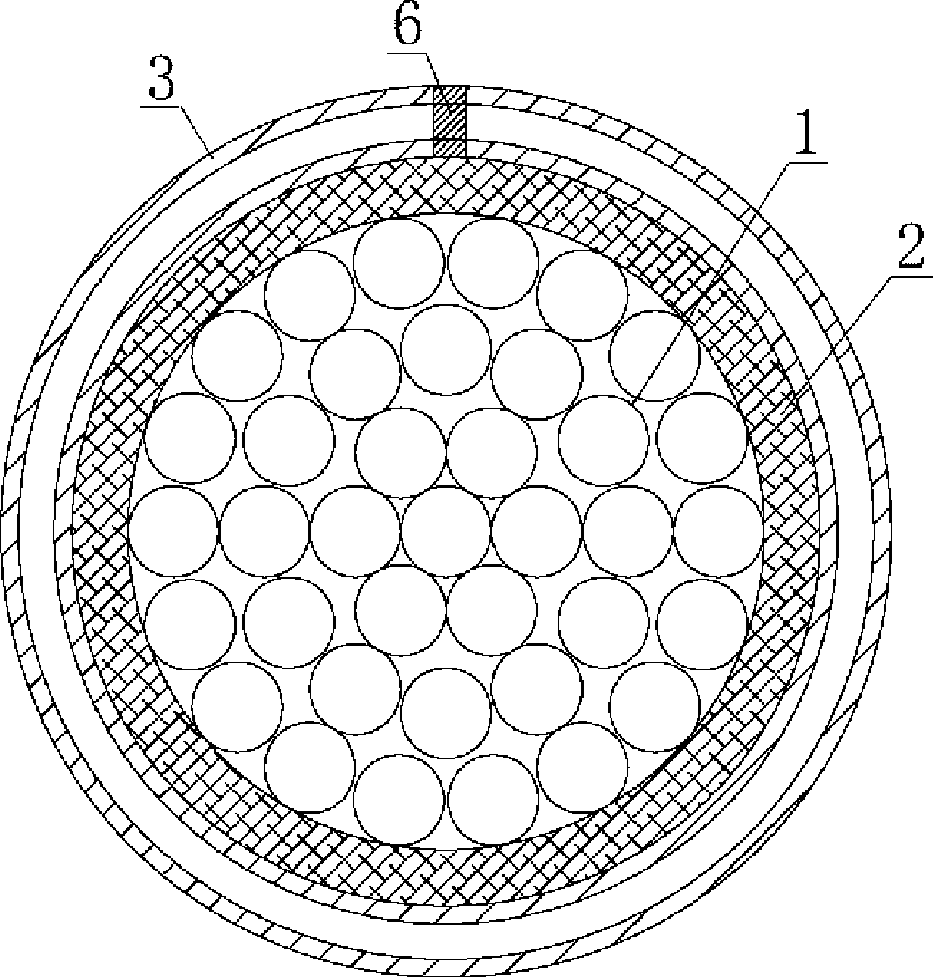

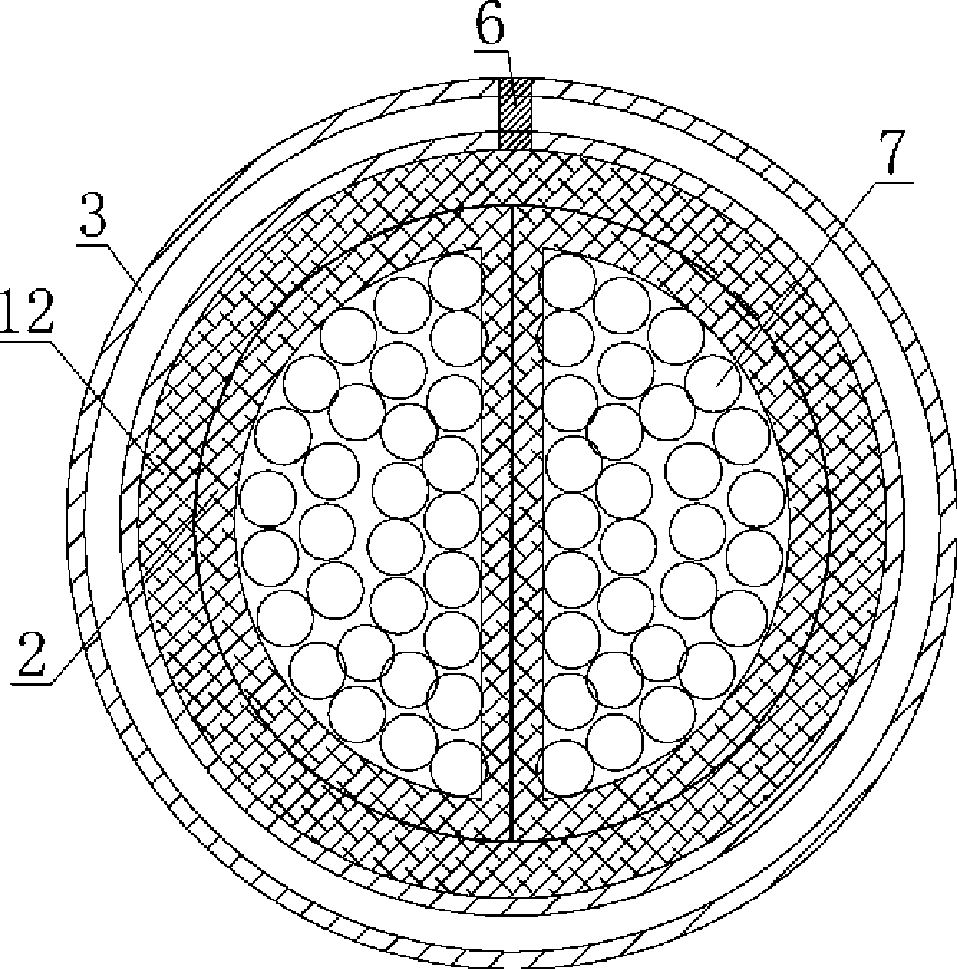

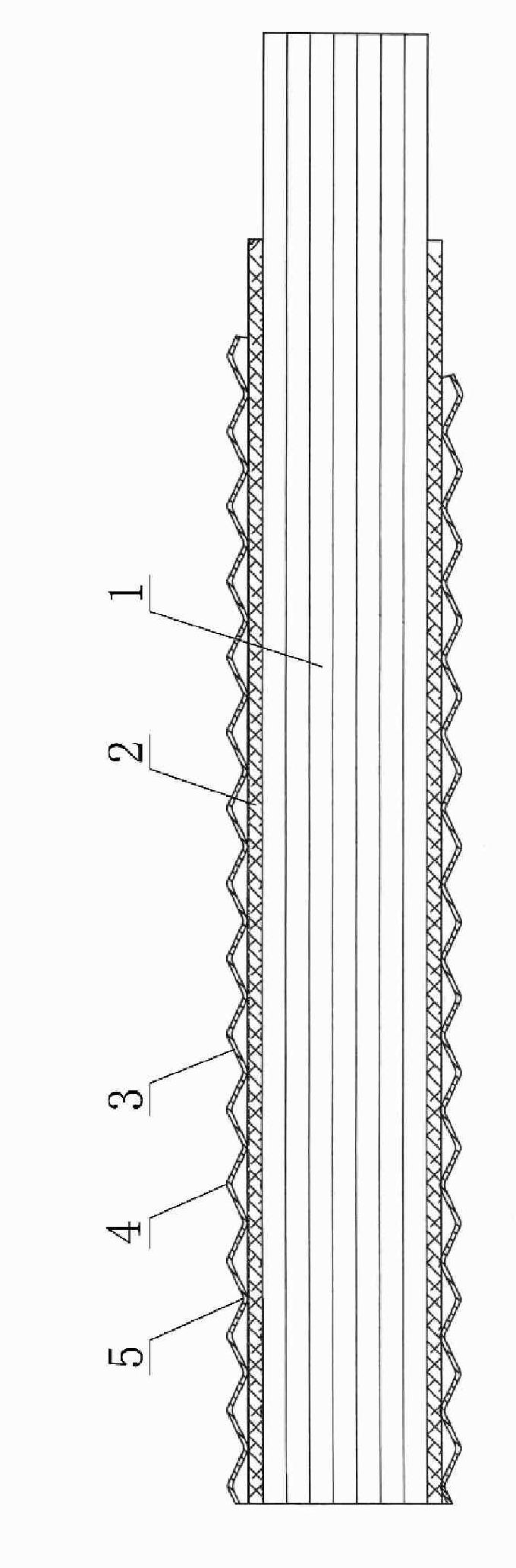

Corrugated metal sheath inorganic mineral insulation cable and method for producing the same

InactiveCN101430947AEasy to bendEasy to installInsulated cablesInorganic insulatorsCopper wireWeld seam

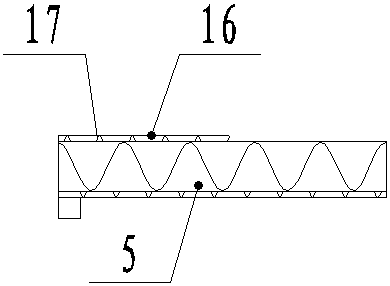

The invention discloses a corrugated metallic sheath inorganic mineral insulated cable and a manufacturing method thereof. The cable consists of an inner cable core, an insulating layer winding the outside of the cable core, and an outermost metallic sheath; the cable core is formed by twisting a bundle of copper wires, the insulating layer is an inorganic mineral insulated tape, the metallic sheath is a copper corrugated tube, corrugation of the copper corrugated tube has upper peaks and lower valleys, the cable core, the insulating layer and the copper corrugated tube have the same length, and the surface of the copper corrugated tube is provided with a welding seam with the same length of the copper corrugated tub along the axial direction. As the cable takes a corrugated shape, the cable is easy to be bent and mounted in a laying field, which lowers the construction cost, can prevent a cable conductor and the insulating layer from being directly burnt by flame, prevents a phase and phase conductor from short circuit, and prevents elevators and fire fighting devices from being incapable of operating without power supply, thus obtaining precious time to facilitate persons to escape in time, and reduce property loss.

Owner:张荣生

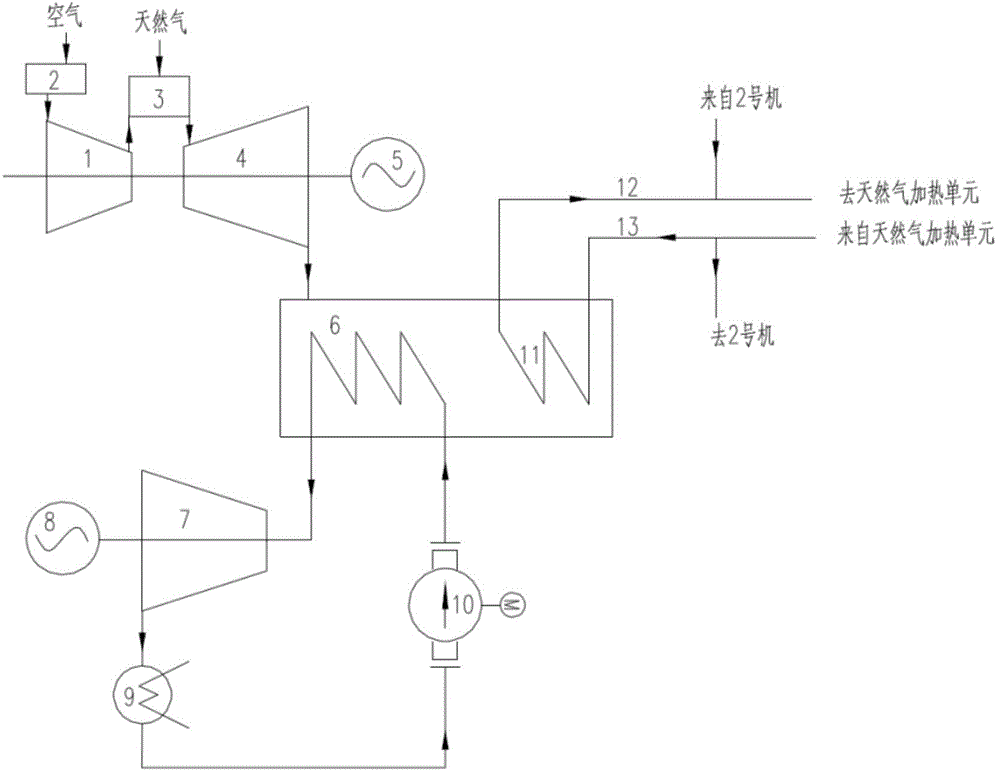

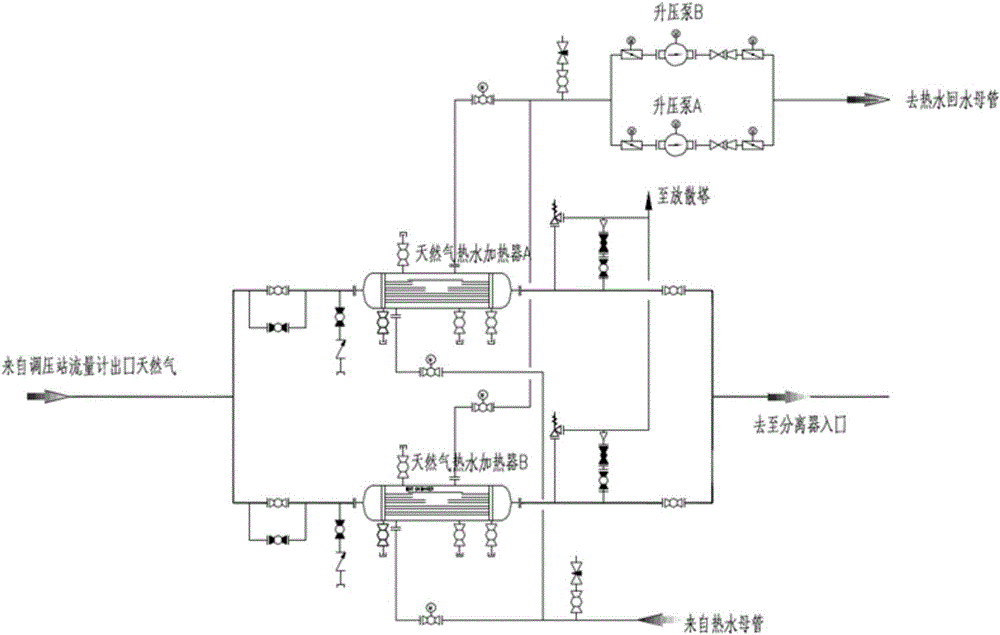

Distributed energy resource waste heat utilization system

InactiveCN104819054AReduce system power consumptionLower exhaust gas temperatureGas turbine plantsSteam engine plantsGas turbinesFlue gas

The invention relates to a distributed energy resource waste heat utilization system which comprises a gas turbine generator set, a steam turbine generator set and a waste heat boiler. The system is characterized in that an exhaust end of a gas turbine is communicated with a gas inlet end of the waste heat boiler, and a steam output end of the waste heat boiler is connected with a steam inlet end of a steam turbine, so that a gas turbine waste heat utilization loop is formed; a steam outlet end of the steam turbine is connected with a water inlet end of the waste heat boiler sequentially by a condenser and a water feed pump, so that a steam turbine waste heat utilization loop is formed; a hot water heat exchanger is arranged at the tail end of the waste heat boiler; a water outlet end of the hot water heat exchanger is connected with a water inlet end of a natural gas heating unit by a hot water supply mother pipe, and a water return end of the hot water heat exchanger is connected with a water outlet end of the natural gas heating unit by a hot water return mother pipe, so that a waste heat cyclic utilization loop of the gas turbine generator set and the steam turbine generator set can be formed. The distributed energy resource waste heat utilization system can be used for solving the problems that a natural gas heating mechanism is high in energy consumption and poor in safety in the prior art, and has the beneficial effects of utilizing the flue gas of the waste heat boiler, reducing the system energy consumption and reducing the flue gas emission.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

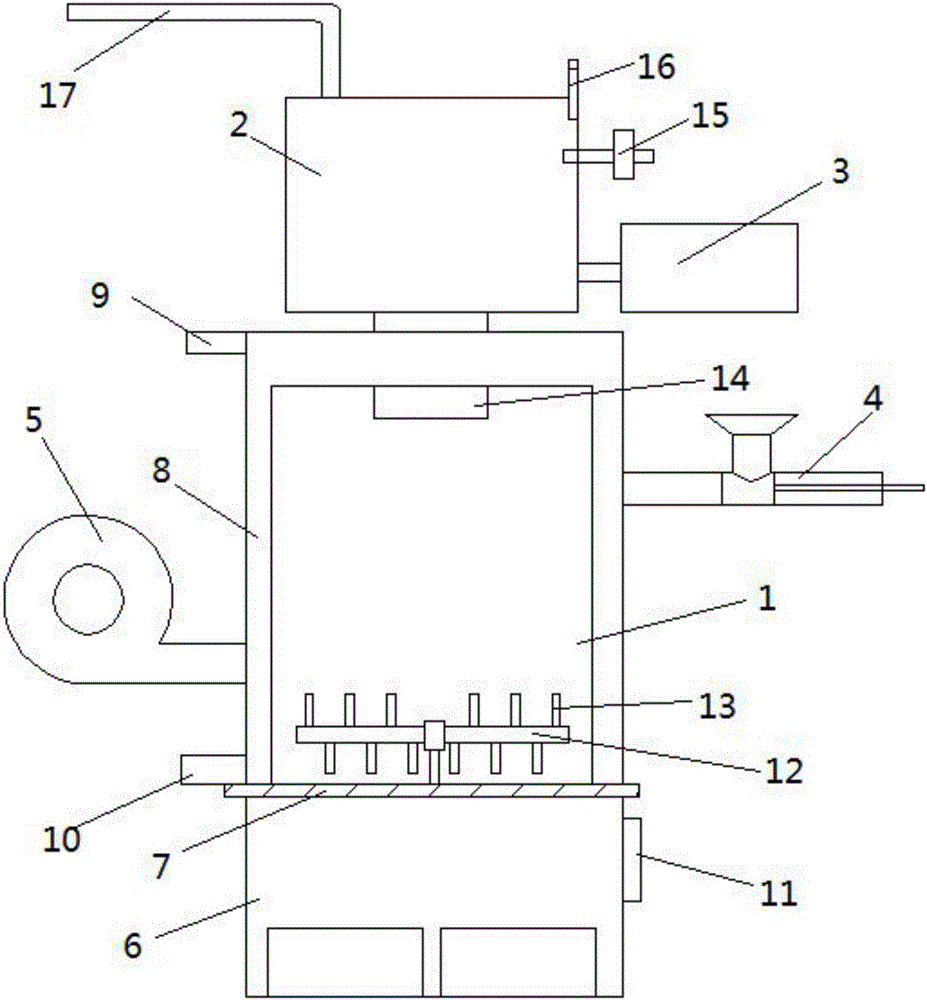

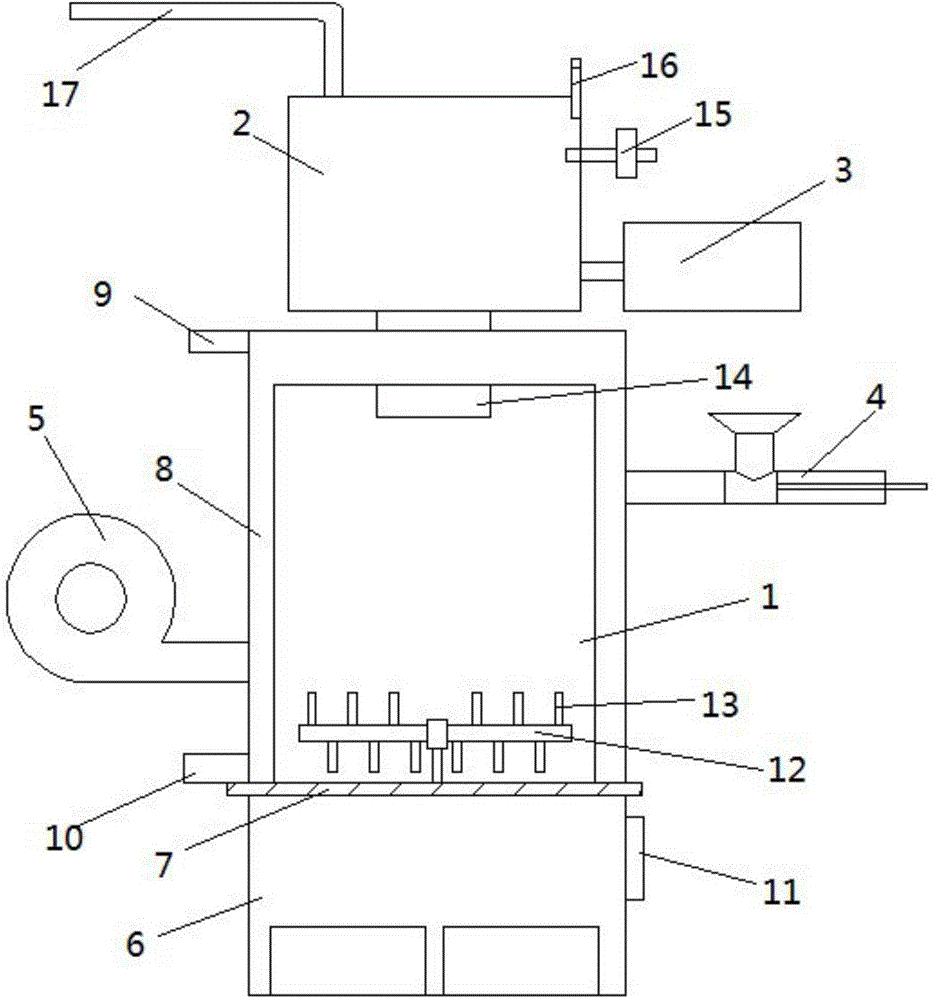

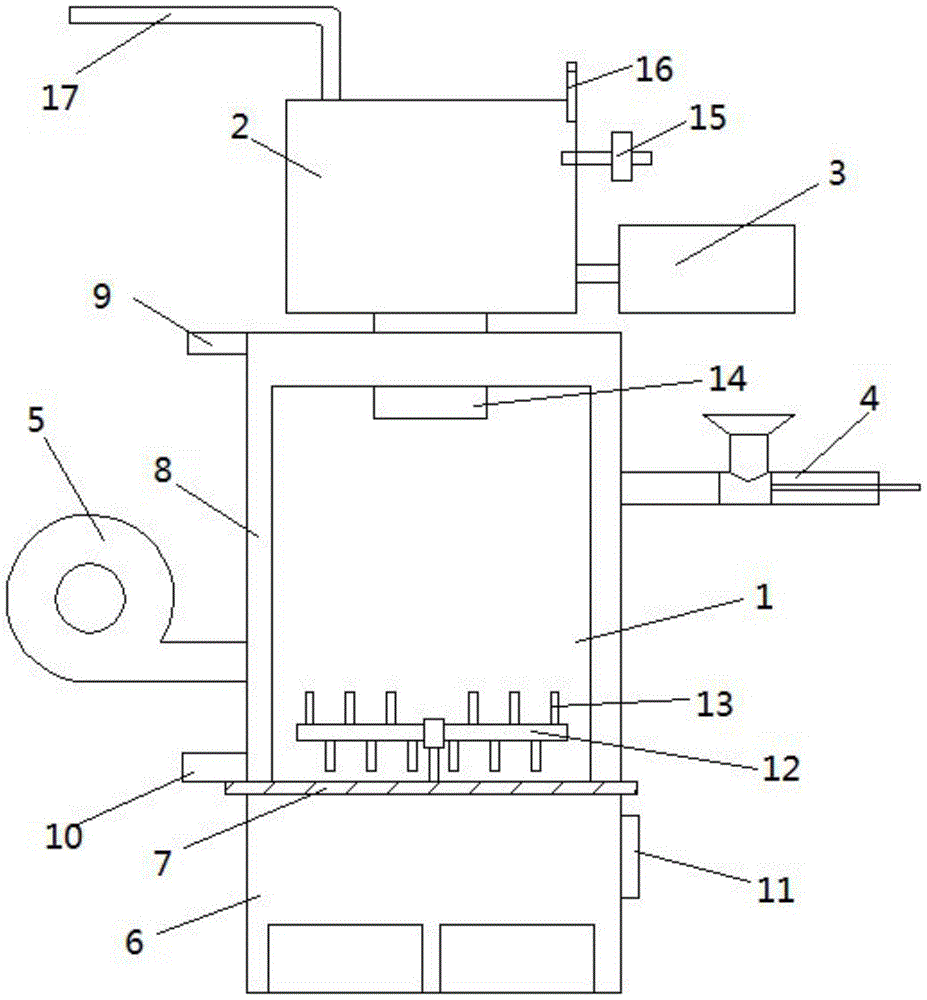

Efficient treatment device for medical waste

InactiveCN106196083AAvoid direct burningAvoid direct combustionSolid waste disposalTransportation and packagingCombustion chamberDirect combustion

The invention discloses an efficient treatment device for medical waste. The efficient treatment device comprises a reaction chamber, a reaction chamber, an air blower, a waste residue chamber and an oxygen-enriched air supply system, wherein the reaction chamber is arranged above the waste residue chamber; the reaction chamber and the waste residue chamber form a device tower body; a filter residue screen plate is arranged between the reaction chamber and the waste residue chamber; and a piston feeding device is arranged at the side of the upper end of the reaction chamber. The medical waste is pyrolyzed under an anaerobic condition in the reaction chamber to generate combustible gases and harmless residues, combustion treatment is carried out on the combustible gases in the combustion chamber, and concentrated collection treatment is carried out on the harmless residues, thus generation of harmful gases due to direct combustion is avoided; an oxygen-enriched gas is conveyed in the combustion chamber through the oxygen-enriched air supply system to adjust an oxygen content in the combustion chamber, thus adequate combustion of the different combustible gases is ensured; and a tail gas after the adequate combustion is filtered through a tail gas treatment device, and then clean air is exhausted and is harmless to environment.

Owner:SUZHOU DUOGU ENG DESIGN CO LTD

Efficient medical waste processing device and manufacturing method thereof

InactiveCN104534484AAvoid direct burningAvoid direct combustionTransportation and packagingSolid waste disposalCombustion chamberDecomposition

The invention discloses an efficient medical waste processing device and a manufacturing method of the efficient medical waste processing device. The efficient medical waste processing device comprises a reaction chamber, a combustion chamber, an air blower, a waste residue chamber and an oxygen-enriched air supply system. The reaction chamber is arranged above the waste residue chamber. A device tower body is composed of the reaction chamber and the waste residue chamber. A residue filtering net plate is arranged between the reaction chamber and the waste residue chamber. A piston feeding device is arranged on the lateral side of the upper end of the reaction chamber. Oxygen-poor pyrogenic decomposition is conducted on medical waste in the reaction chamber to generate combustible gas and harmless residues. In the combustion chamber, the combustible gas is combusted and the harmless residues are collected in a concentrated mode so that harmful gas generated through direct combustion can be avoided. Oxygen-enriched gas is conveyed into the combustion chamber through the oxygen-enriched air supply system, the oxygen content in the combustion chamber is regulated, it is ensured that combustible gas of different types is fully combusted, tail gas which is fully combusted is filtered through a tail gas processing device, clean air can then be discharged, and no harm is caused to the environment.

Owner:寇卫国 +2

Waste gas treatment method

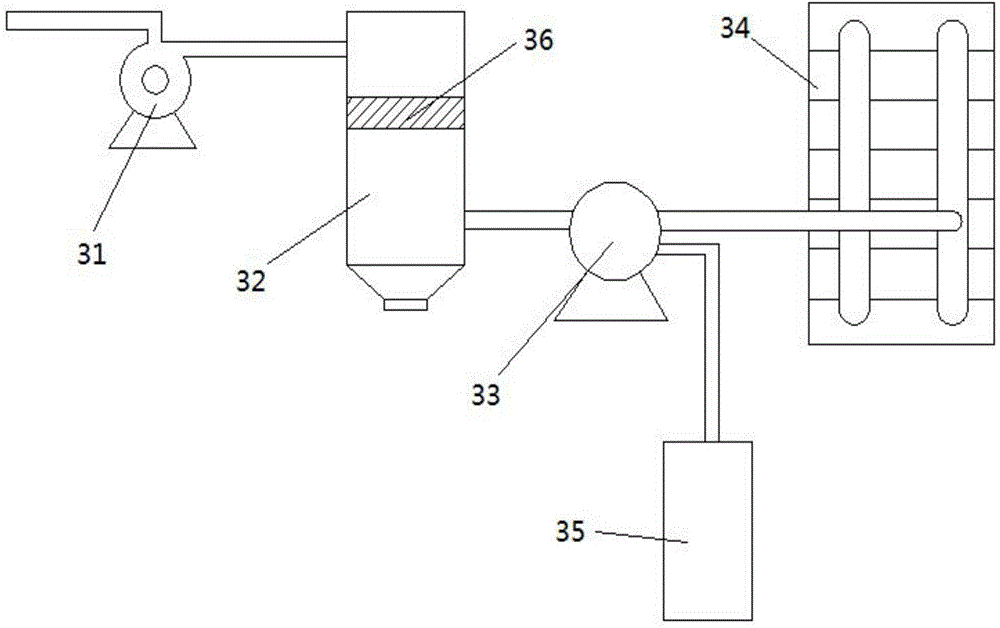

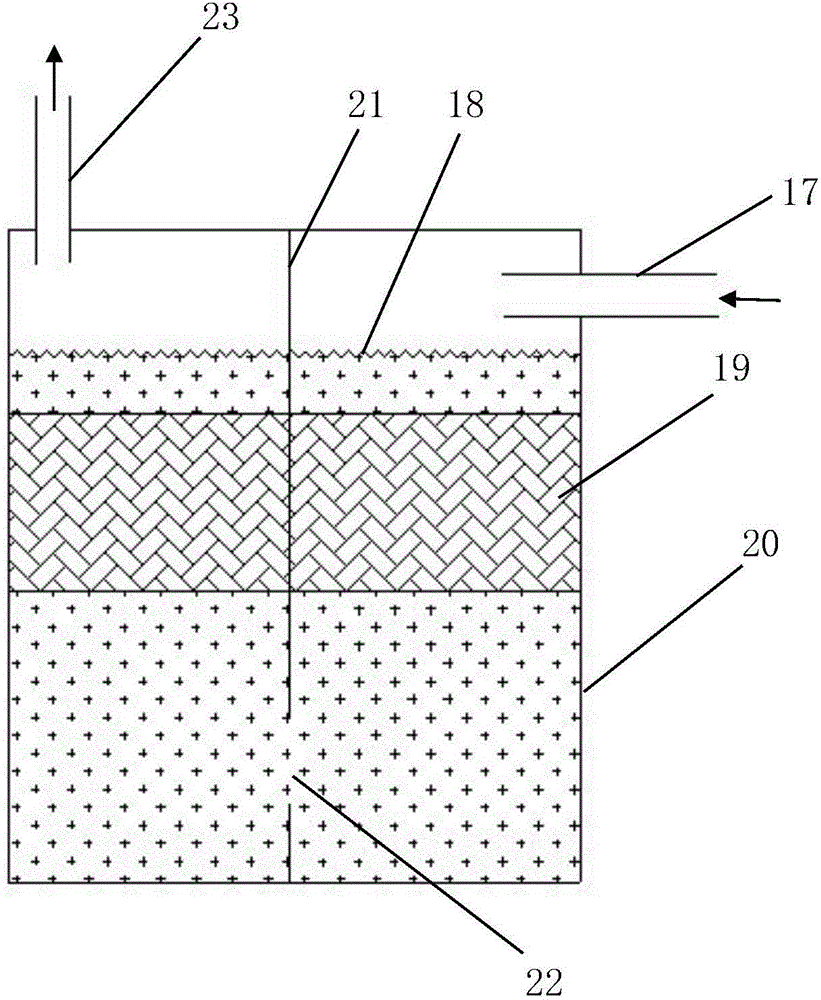

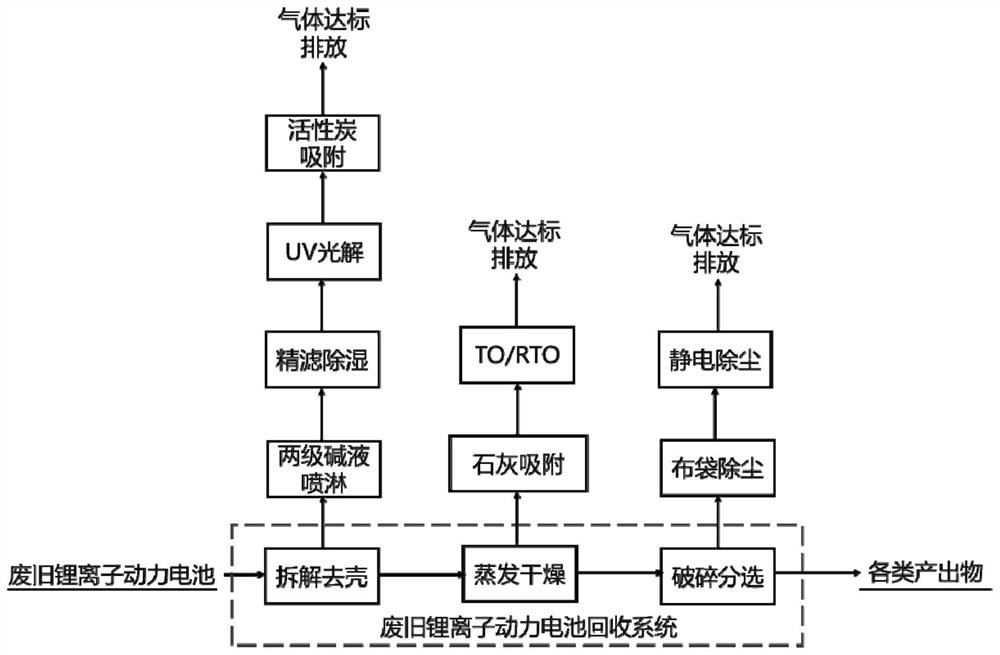

InactiveCN111760435AAchieve emissionsAvoid direct burningCombination devicesGas treatmentPower batteryActivated carbon

The invention discloses a waste gas treatment method. Waste gas is generated in the recovery process of a waste lithium ion power battery; the recycling process of the waste lithium ion power batterysequentially comprises the steps of disassembling and shelling, evaporating and drying, and crushing and sorting. The waste gas treatment method comprises the following steps that: the waste gas generated in the disassembling and shelling process is sequentially subjected to two-stage alkali liquor spraying, refined filtration and dehumidification, UV photolysis and activated carbon adsorption treatment; the waste gas generated in the evaporation drying process is sequentially treated in a lime adsorption mode and a TO or RTO combustion mode; and dust generated in the crushing and sorting process is sequentially removed in a cloth bag dust removal mode and an electrostatic dust removal mode. According to the waste gas treatment method, segmented treatment is carried out in a targeted mode,so that targeted waste gas treatment in the recycling process of the waste lithium ion power battery is achieved, secondary pollution is greatly reduced, the environment-friendly operation cost is reduced, and harmless emission is achieved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY CO LTD CO LTD

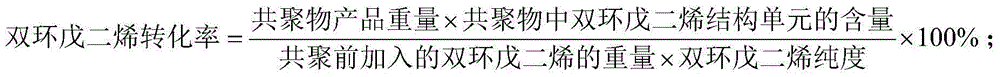

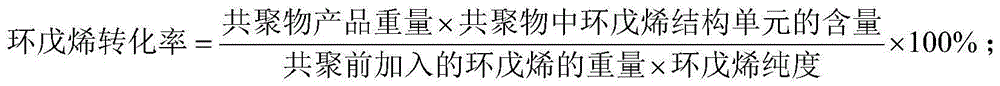

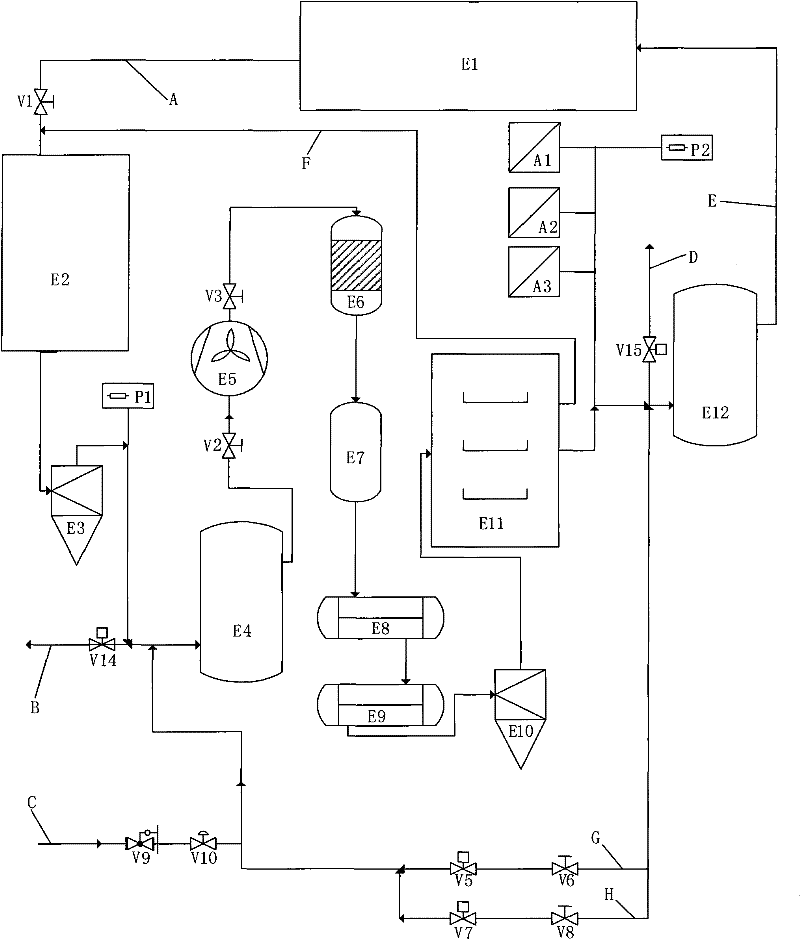

Dicyclopentadiene-cyclopentene copolymer and preparation method thereof

The invention discloses a dicyclopentadiene-cyclopentene copolymer and a preparation method thereof. With the total weight of the copolymer as a reference, the copolymer contains 1-10wt% of cyclopentene structural units, and 90-99wt% of dicyclopentadiene structural units. The dicyclopentadiene-cyclopentene copolymer provided by the invention has high polymerization conversion rate. A prepared product has no odor, good heat resistance, and especially excellent impact resistance. With the preparation method, the impact resistance of the material is improved from approximately 100J / m of a prior polycyclopentene diene homopolymer material to 300-400J / m. The material can be used as various impact-resistant engineering materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process and device for recovering and recycling protective gas of bell-type bright annealing furnace

ActiveCN101956061BAvoid direct burningAvoid emptyingMaintainance of heating chambersBell type furnacesBuffer tankDeaerator

The invention relates to a process and a device for recovering and recycling protective gas of a bell-type bright annealing furnace. The process comprises the following steps of: performing cooling and condensation of oil and gas in refluxing protective gas of a bell-type bright annealing furnace group; allowing the cooled and condensed protective gas to enter a water separator to remove most of water and oil; allowing the cooled protective gas from which the oil and the gas are removed to enter a preceding stage buffer tank; after the protective gas is buffered by the preceding stage buffer tank, pressurizing by using a roots blower; allowing the pressurized protective gas to enter an oil absorption device to remove oil and enter a deaerator to remove oxygen; reacting in the deaerator togenerate water and discharge heat; cooling the protective gas by using a cooler and removing water from the protective gas by using a condenser; allowing the cooled and dehydrated protective gas to enter the water separator to separate water; allowing the protective gas to enter an absorption regeneration drying device for removing water and impurities deeply; and performing decompression and voltage stabilization on the purified gas by using a post-stage buffering tank and then supplying the purified gas to the bell-type bright annealing furnace group. Through the process and the device, therefluxing protective gas of the bell-type bright annealing furnace group is recovered and purified and enters the annealing furnace to be recycled as the protective gas again.

Owner:苏州品源气体设备有限公司

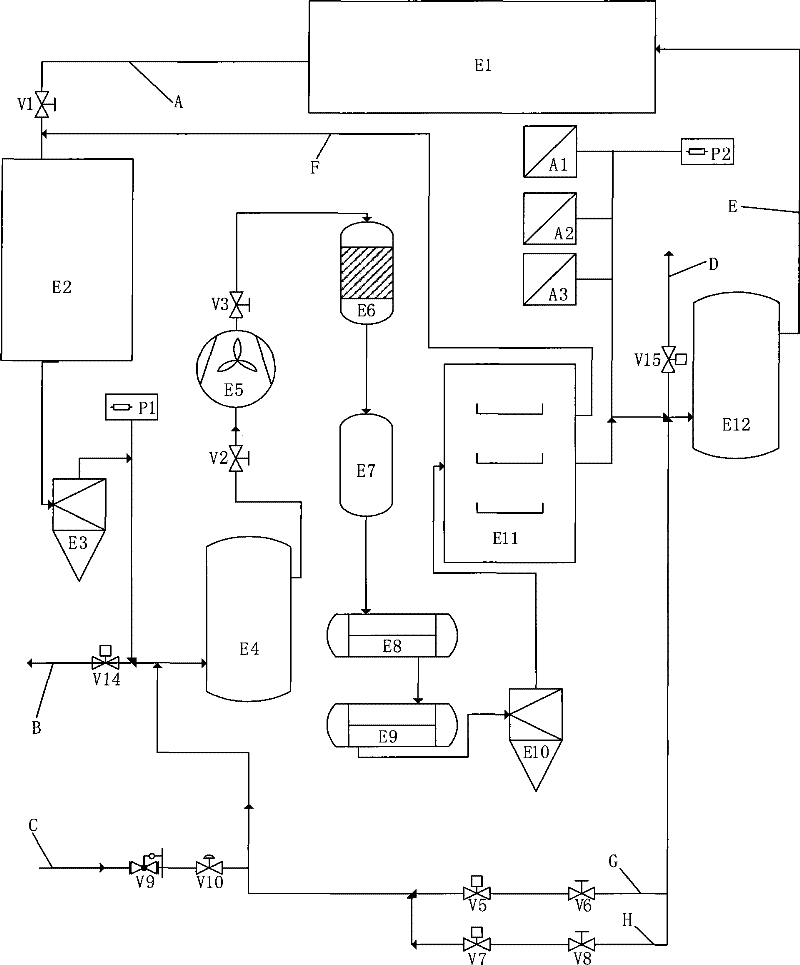

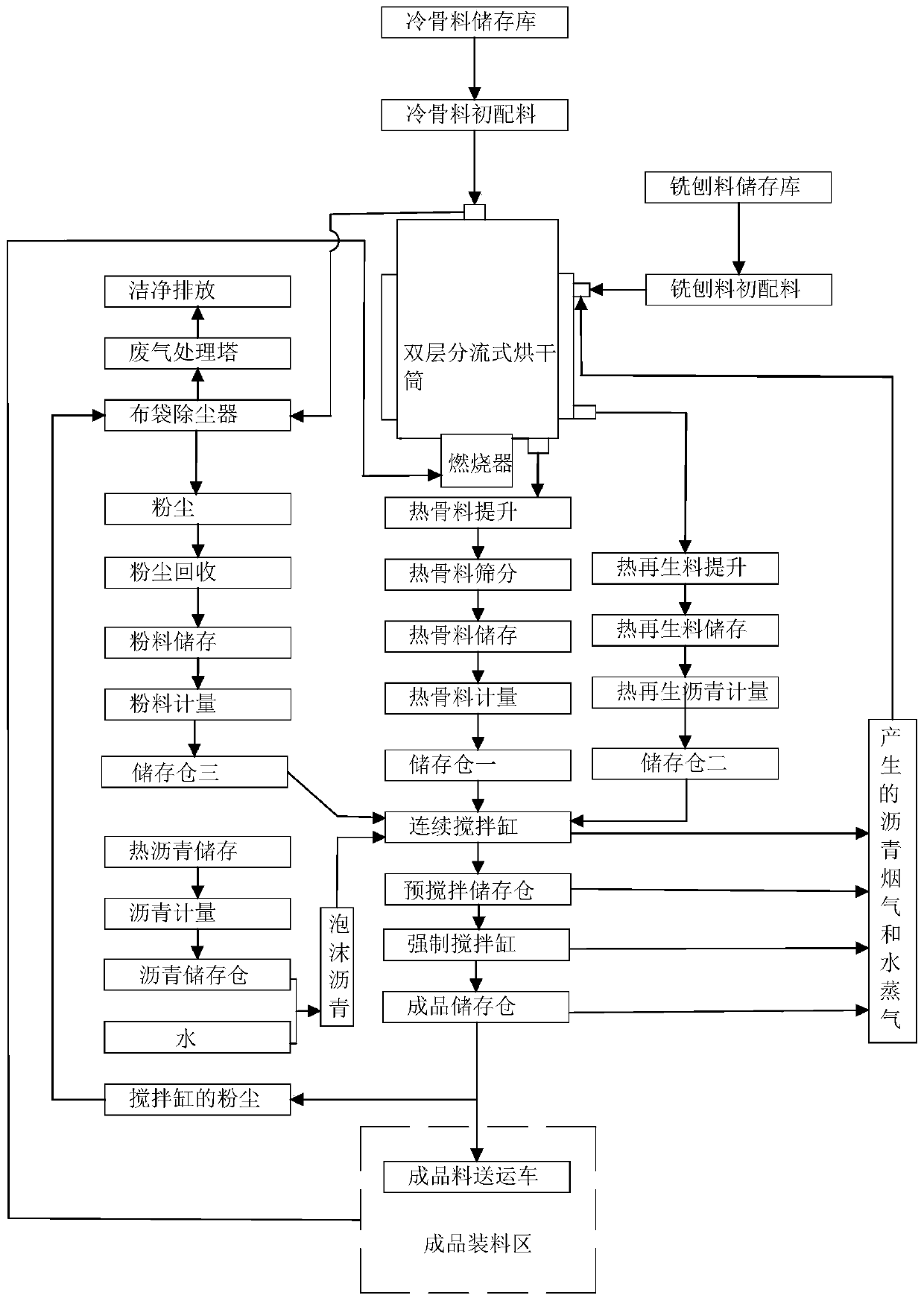

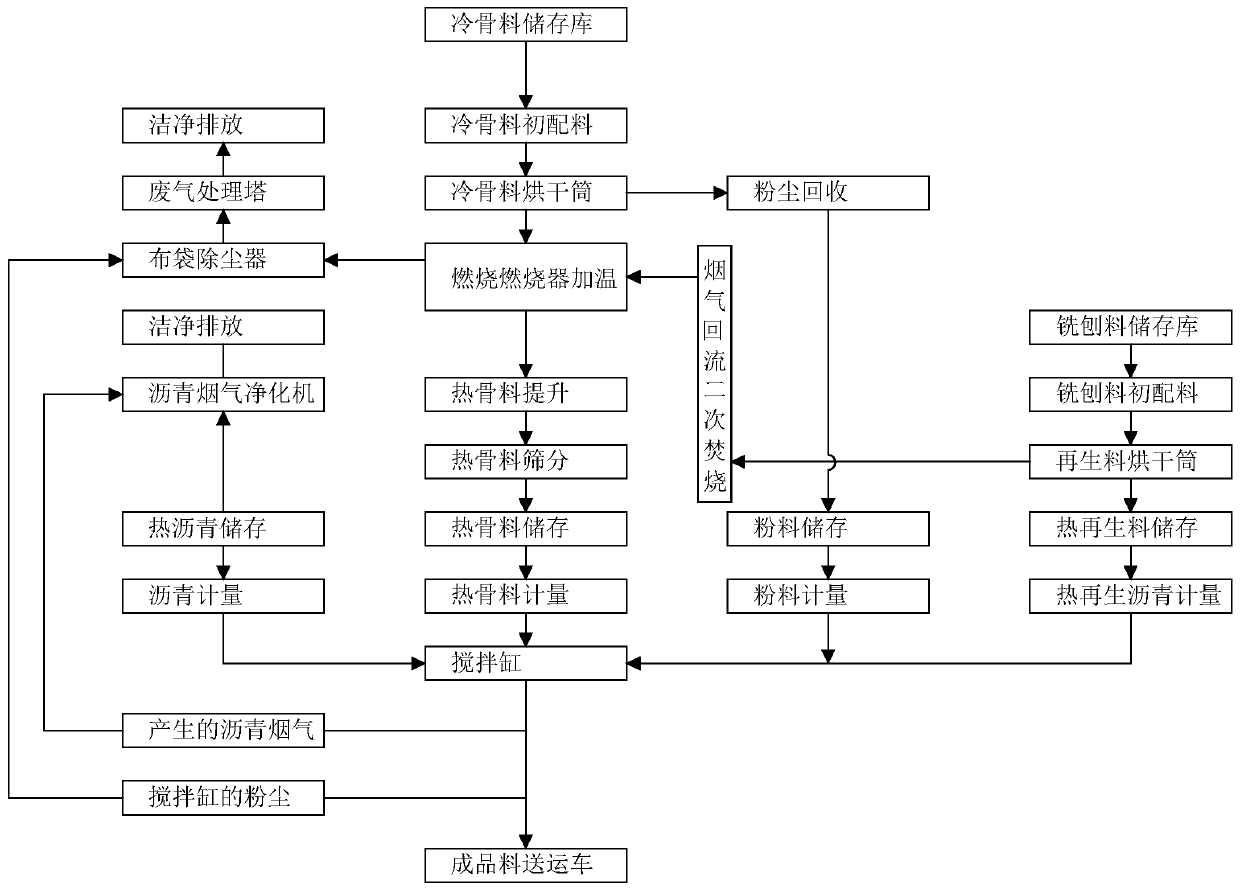

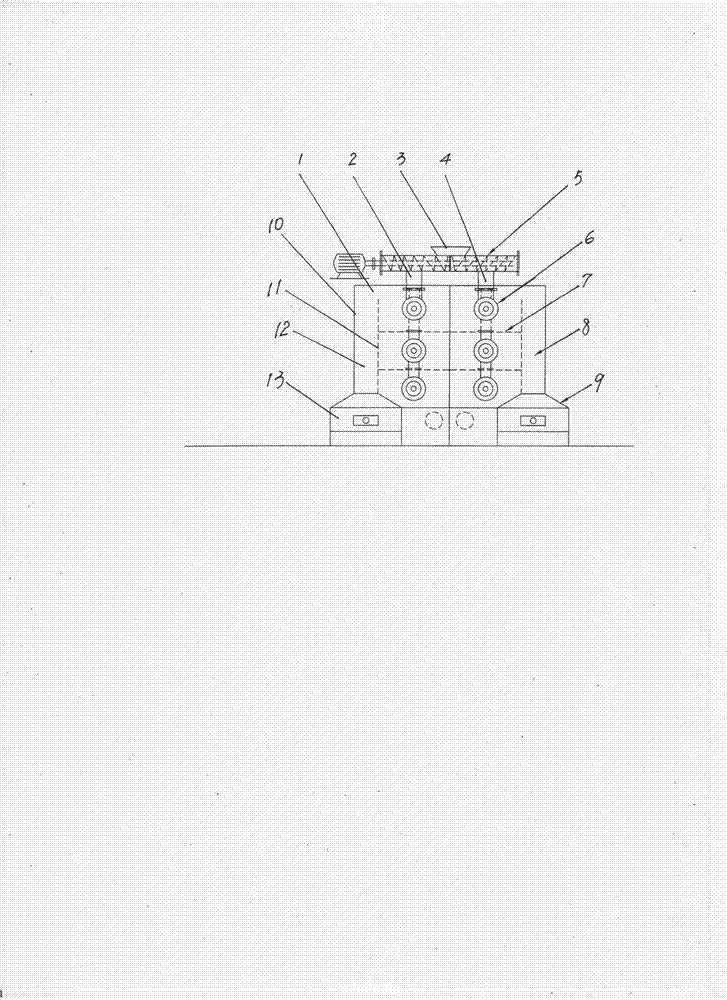

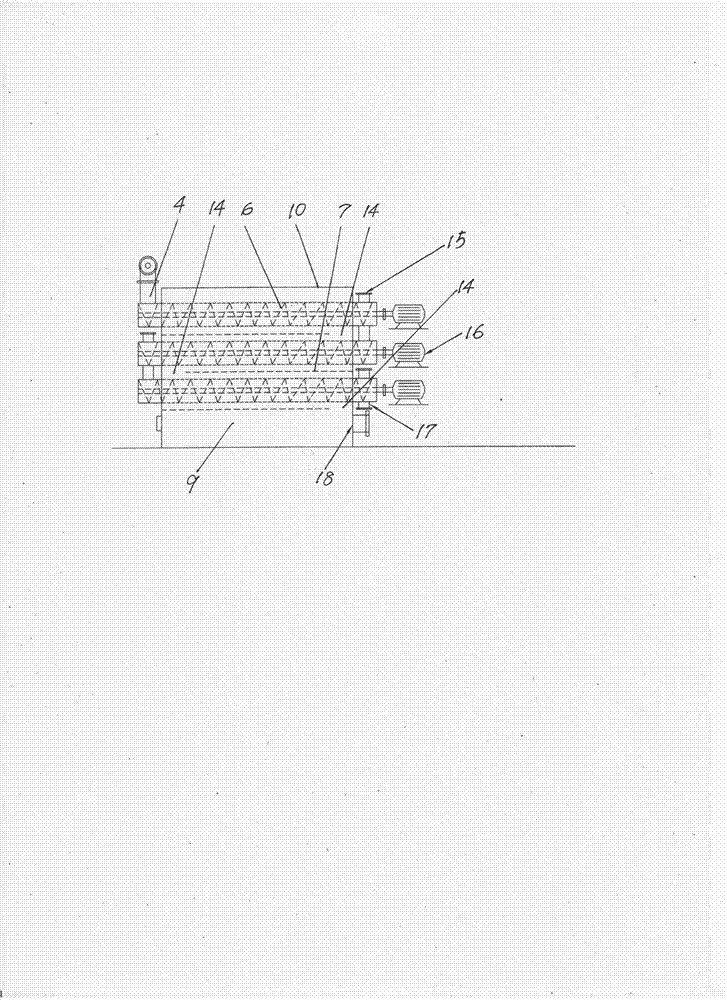

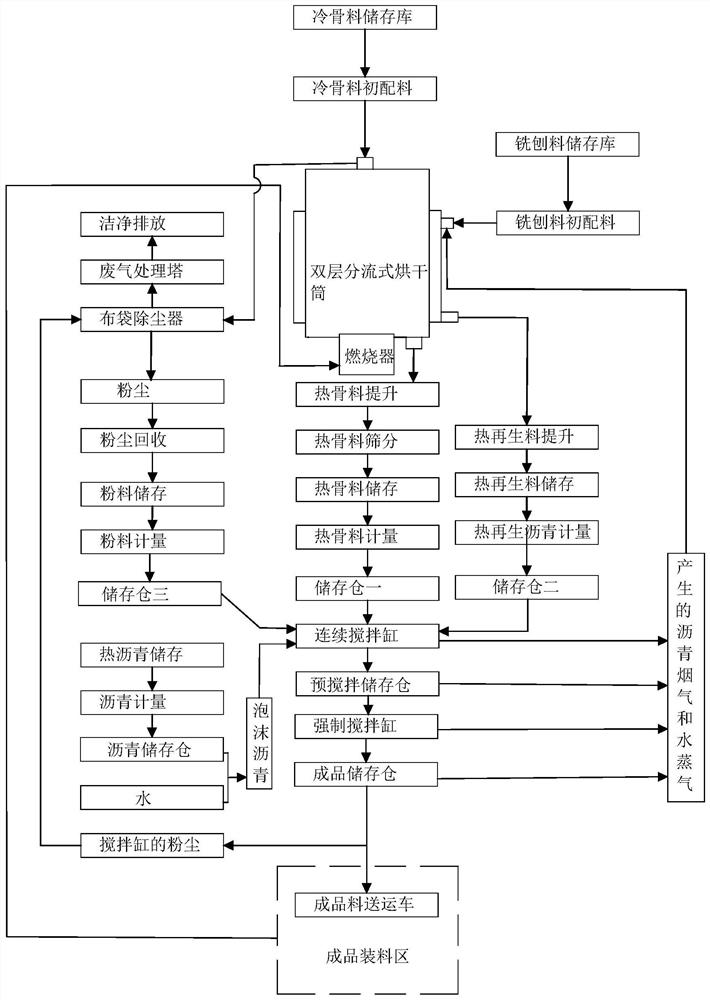

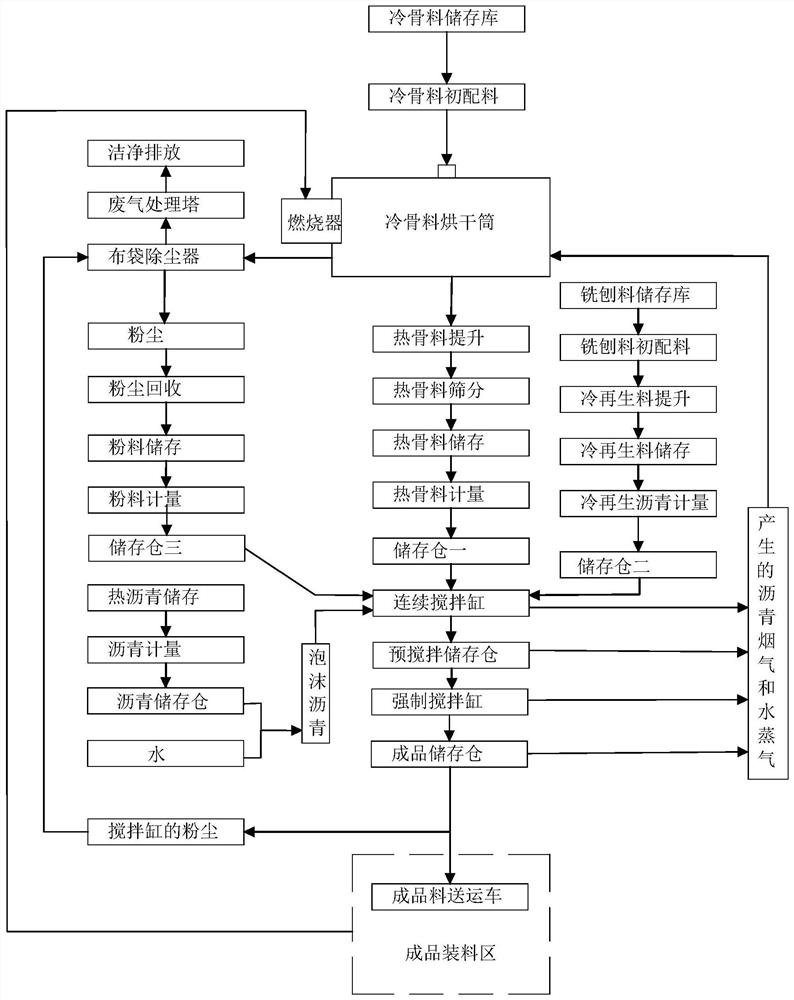

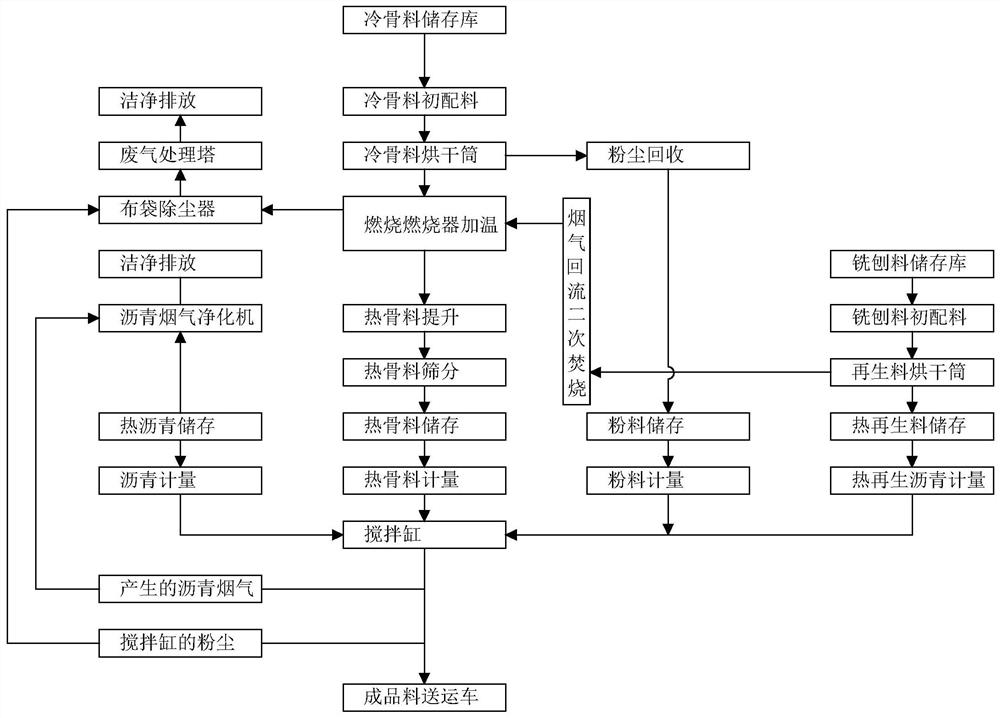

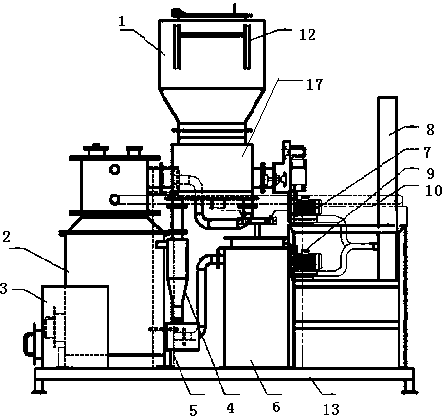

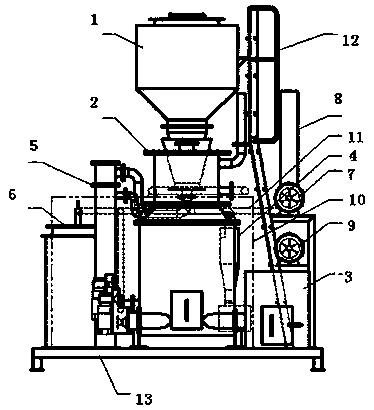

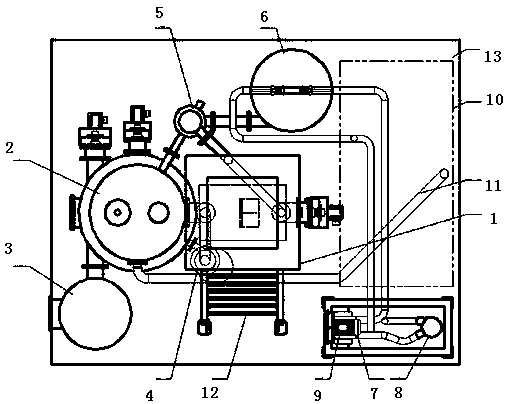

Continuous and forced combined asphalt mixing production method

ActiveCN111074714AAvoid direct burningPrevent leakageIn situ pavingsRotary stirring mixersHeat energyStorage tank

The invention discloses a continuous and forced combined asphalt mixing production method, and belongs to the technical field of concrete processing. The method comprises the following steps: heatingcold aggregate to obtain hot aggregate, and carrying out hot mixing and / or cold mixing on a milling material to obtain a recycled material; mixing the hot aggregate, the recycled material, a powder and asphalt to obtain a premix; temporarily storing the premix in a pre-stirring storage bin, then allowing the premix to enter a forced stirring cylinder and be stirred, and temporarily storing an obtained finished product material in a finished product storage bin; and unloading the finished product material to a storage tank of a finished product conveying vehicle in a finished product material loading area. Generated asphalt flue gas and water vapor are introduced into a drying cylinder and undergo secondary incineration; collected dust enters a tail gas absorption and purification device and is purified; and the collected flue gas and air are introduced to a combustor part, and are used as a combustion-supporting gas. Direct combustion of the milling material by open fire is avoided; and the hot aggregate is slowly premixed with the recycled material, the powder and the asphalt, so the mixing efficiency is high, asphalt smoke leakage can be avoided, heat energy is utilized, and energy conservation and environmental protection are achieved.

Owner:SHANGHAI SHISHEN IND & TRADE CO LTD

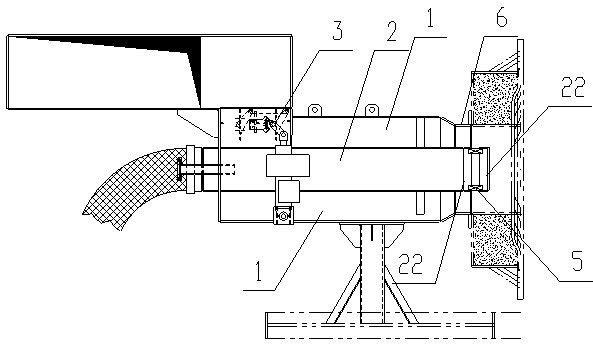

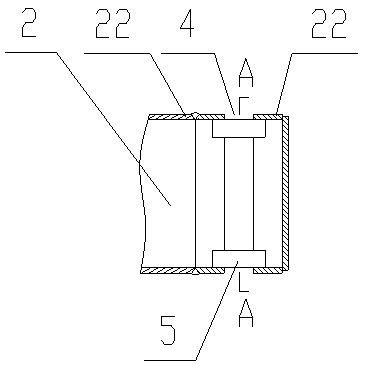

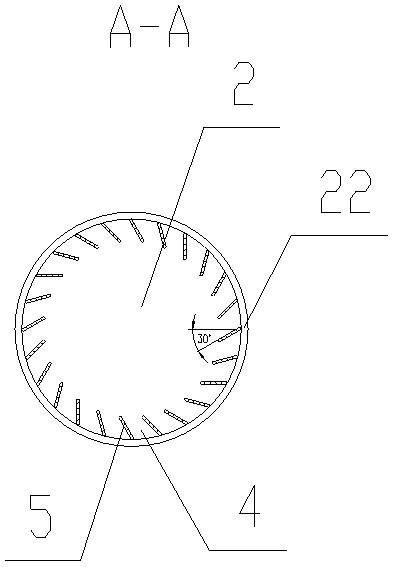

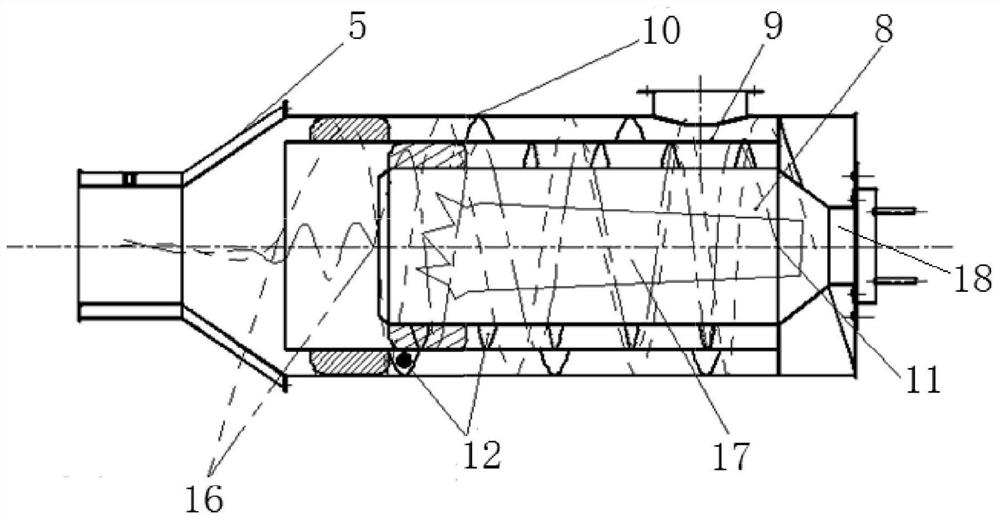

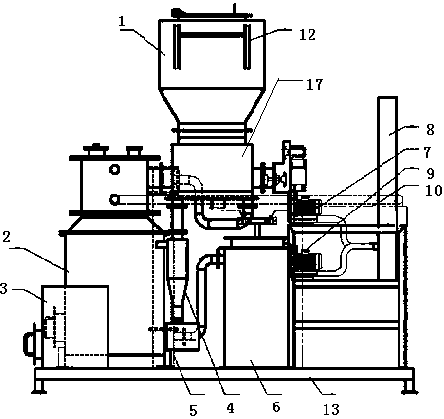

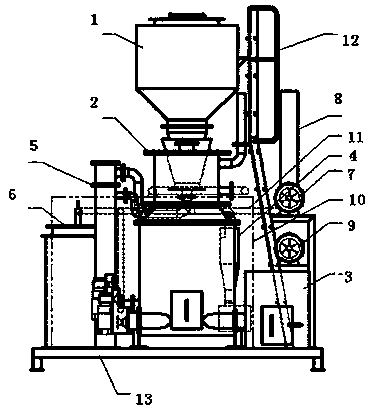

Reflective heated waste rubber and waste plastic thermal cracking device

InactiveCN102827626AHigh degree of automationIncrease productionPlastic recyclingLiquid hydrocarbon mixture productionRotary furnaceContinuous production

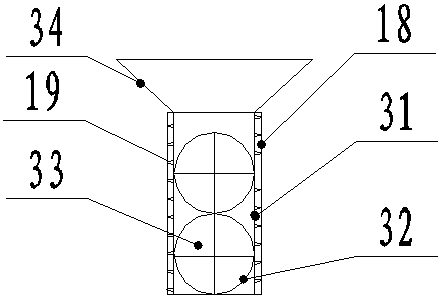

The invention relates to a reflective heated waste rubber and waste plastic thermal cracking device. The device comprises a feeder, a cracking chamber and two spiral cracking devices. The spiral cracking devices are vertically arranged. Two combustion furnaces are respectively arranged on both sides of the lower part of the cracking chamber. Separators are respectively arranged in a vertical direction outside the spiral cracking devices in the cracking chamber. The separators and inner walls on both sides of the cracking chamber form reflective hot air ducts, respectively. Hot air channels are reserved on the upper parts. Compared with conventional cracking devices, the reflective heated waste rubber and waste plastic thermal cracking device provided by the invention is high in degree of automation, large in production capacity and low in manufacturing cost which is half of that of conventional rotary furnaces, and the daily production capacity is twice as much as that of the conventional rotary furnaces. The spiral cracking device is prevented from being directly burned by flame, the upmost spiral cracking device is heated first to reach the higher temperature required by a feeding part. The reflective heated waste rubber and waste plastic thermal cracking device heats uniformly and has high thermal cracking efficiency. Retention time of hot air in the furnace is prolonged, so that the heat is adequately used, and the energy sources are saved. The reflective heated waste rubber and waste plastic thermal cracking device is in totally-enclosed continuous production and low in labor intensity, and no secondary pollution is generated.

Owner:SHANGQIU SIHAI MACHINERY EQUIP MFG

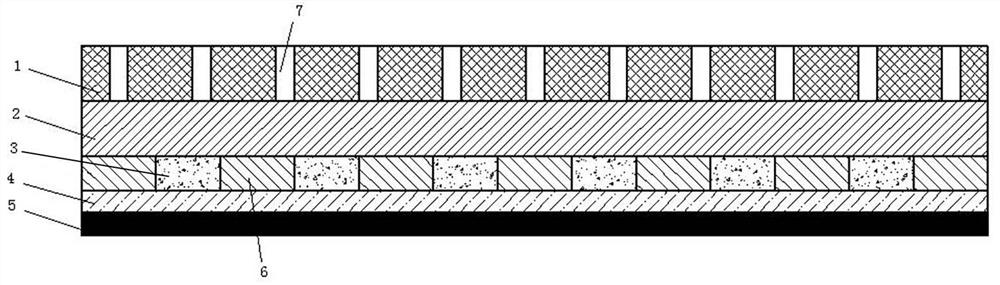

Continuous annealing furnace with shielding gas recovery function

ActiveCN104846159ATake advantage ofAvoid direct burningFurnace typesHeat treatment furnacesSocial benefitsMetallurgy

The invention relates to a continuous annealing furnace with a shielding gas recovery function. The continuous annealing furnace comprises a furnace body, and a shielding gas recycling device used for purifying the shielding gas discharged from the furnace body and feeding the shielding gas back into the furnace body for recycling, wherein the shielding gas inlet of the shielding gas recycling device is connected with the shielding gas outlet of the furnace body; and the shielding gas outlet of the shielding gas recycling device is connected with the shielding gas inlet of the furnace body. The shielding gas recycling device comprises an impurity filtering unit, an oxygen filtering unit, a water filtering unit and a control system, wherein the impurity filtering unit is used for filtering solid impurities in the shielding gas; the oxygen filtering unit is used for filtering oxygen in the shielding gas; the water filtering unit is used for filtering water in the shielding gas; and the control system is respectively in signal connection with the impurity filtering unit, the oxygen filtering unit and the water filtering unit. According to the continuous annealing furnace disclosed by the invention, the shielding gas can be fully utilized, the energy is saved, and the continuous annealing furnace adapts to the development direction of energy conservation and emission reduction and has obvious economic benefits and social benefits.

Owner:SUZHOU SUJING PROTECTIVE ATMOSPHERE

Mixed gas combustor

The invention discloses a mixed gas combustor, relating to a gas combustor. The mixed gas combustor comprises two channels which are embedded inside and outside, a combustion air channel is arranged on the periphery and a fuel channel is arranged in the center, a burner nozzle is formed on the front end of the combustion air channel, and the front end of the fuel channel is provided with a spraying orifice for enabling fuel in the fuel channel to be radially outwards spirally spayed. The invention aims at providing the novel gas combustor, which has better stable combustion while combusting low-heat-value gas fuel with large flow, can not cause nozzle burning and coking problems while combusting high-heat-value gas fuel with small flow, and can combust a mixed fuel of a low-heat-value gas fuel and a high-heat-value gas fuel.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Combustor reducing emission of nitrogen oxide, gas boiler and control method

InactiveCN104165361AEmission reductionImprove blending effectSteam boilersGaseous fuel burnerCombustorFlue gas

The invention provides a combustor reducing emission of nitrogen oxide, a gas boiler and a control method. According to the combustor, the distance L1 between each main fuel spray nozzle and the center axis of a combustion chamber is different from the distance L2 from each main air spray nozzle and the center axis of the combustion chamber, a backflow vortex structure is formed in the combustion chamber, high-temperature flue gas generated by high-speed air injection and combustion is made to flow back and mix with air, so that a high-temperature low-oxygen mixture is formed, then the mixture is quickly mixed with fuel to achieve soft combustion, the temperature of peak flame in the combustion process is effectively reduced, and accordingly the effect that emission of the nitrogen oxide is reduced by 50-80% than that in direction combustion is achieved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Coal slime drying treatment device

ActiveCN111998619ASimple structureIncrease productivityDrying solid materials without heatDrying gas arrangementsThermodynamicsFilter press

The invention discloses a coal slime drying treatment device, belongs to the field of coal slime drying. The problems of non-uniform heating of coal slime, overheating decomposition of an outer layerand insufficient drying of an inner layer in the prior art are solved. The device comprises a concentration unit, a filter pressing unit and a slivering drying unit which are sequentially connected, wherein the slivering drying unit comprises an extrusion assembly, a drying assembly located below the extrusion assembly and a slivering pore plate located between the extrusion assembly and the drying assembly, and the extrusion assembly comprises an extrusion cylinder and a piston located in the extrusion cylinder; the drying assembly comprises a drying cylinder and a gas supply unit used for providing drying gas for the interior of the drying cylinder; a space between a piston in the extrusion cylinder and the slivering pore plate is an extrusion cavity, the interior of the drying cylinderis a drying cavity, the extrusion cavity communicates with a feeding pipe, and the drying cylinder is communicated with a discharging pipe. The device disclosed by the invention can be used for concentration, filter pressing, slivering and drying of coal slime.

Owner:CHINA UNIV OF MINING & TECH

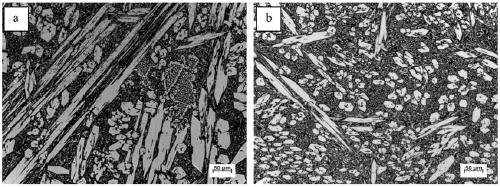

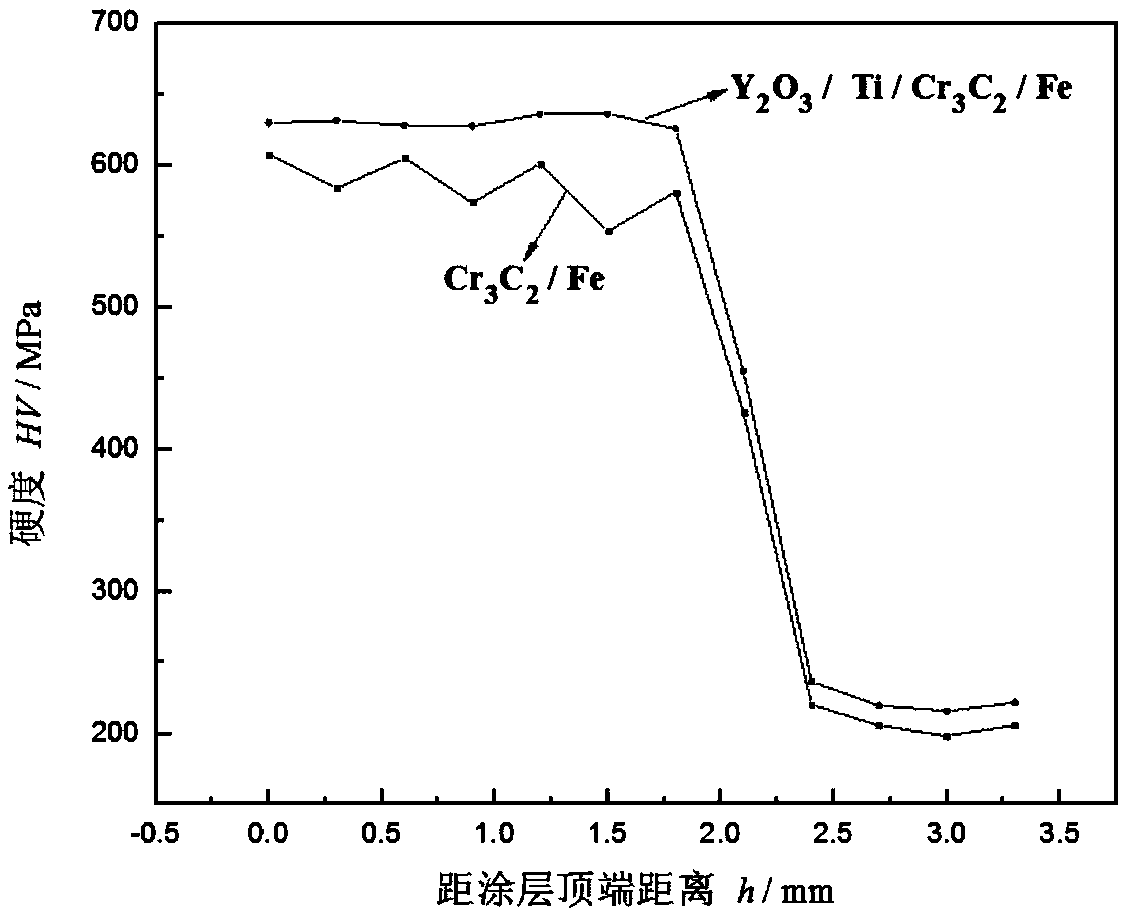

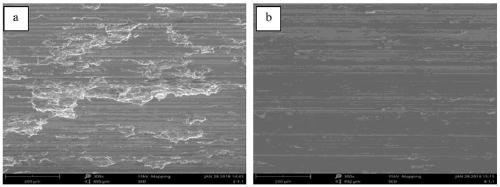

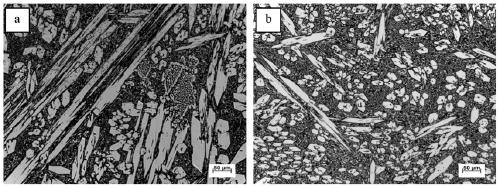

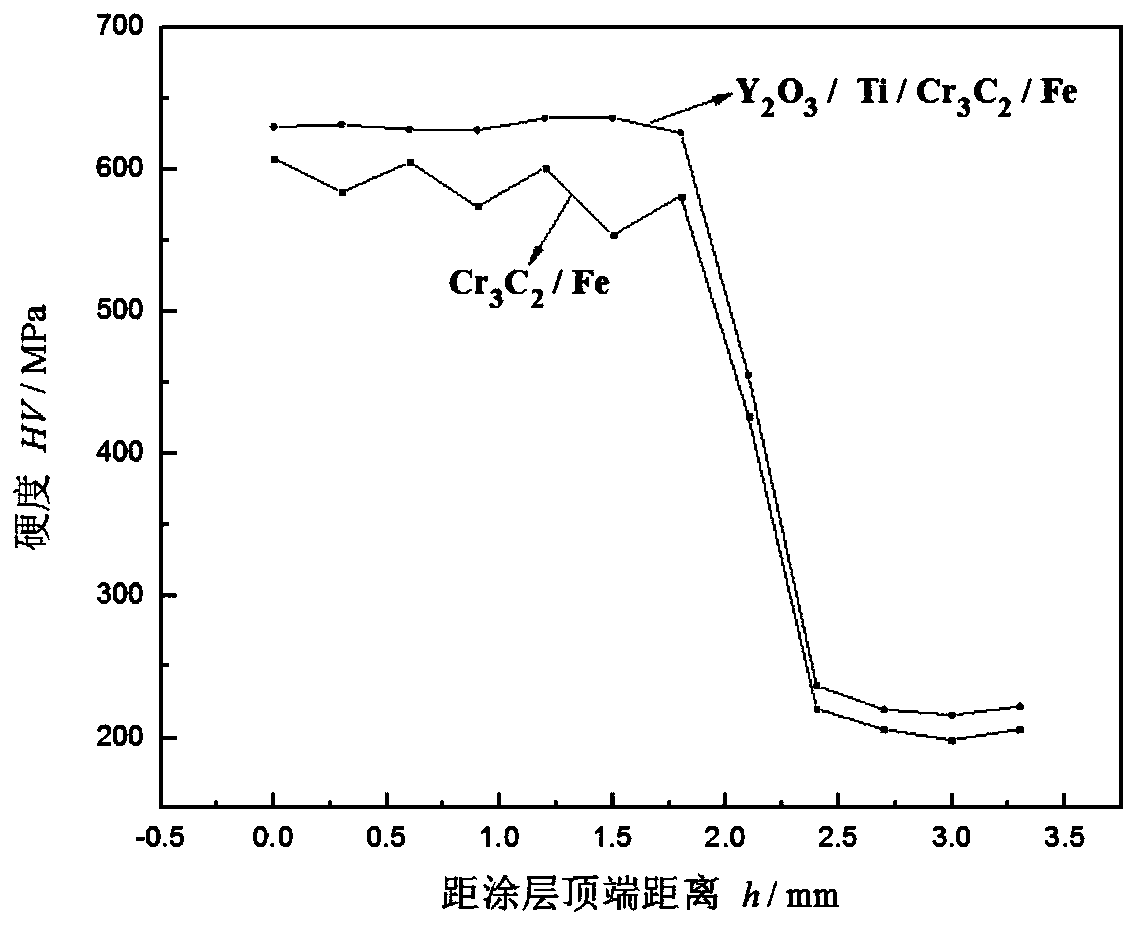

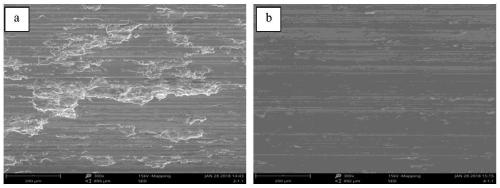

Multi-scale particle reinforced plasma surfacing iron-based hypereutectic wear-resistant coating and preparation method thereof

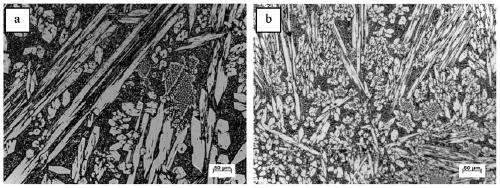

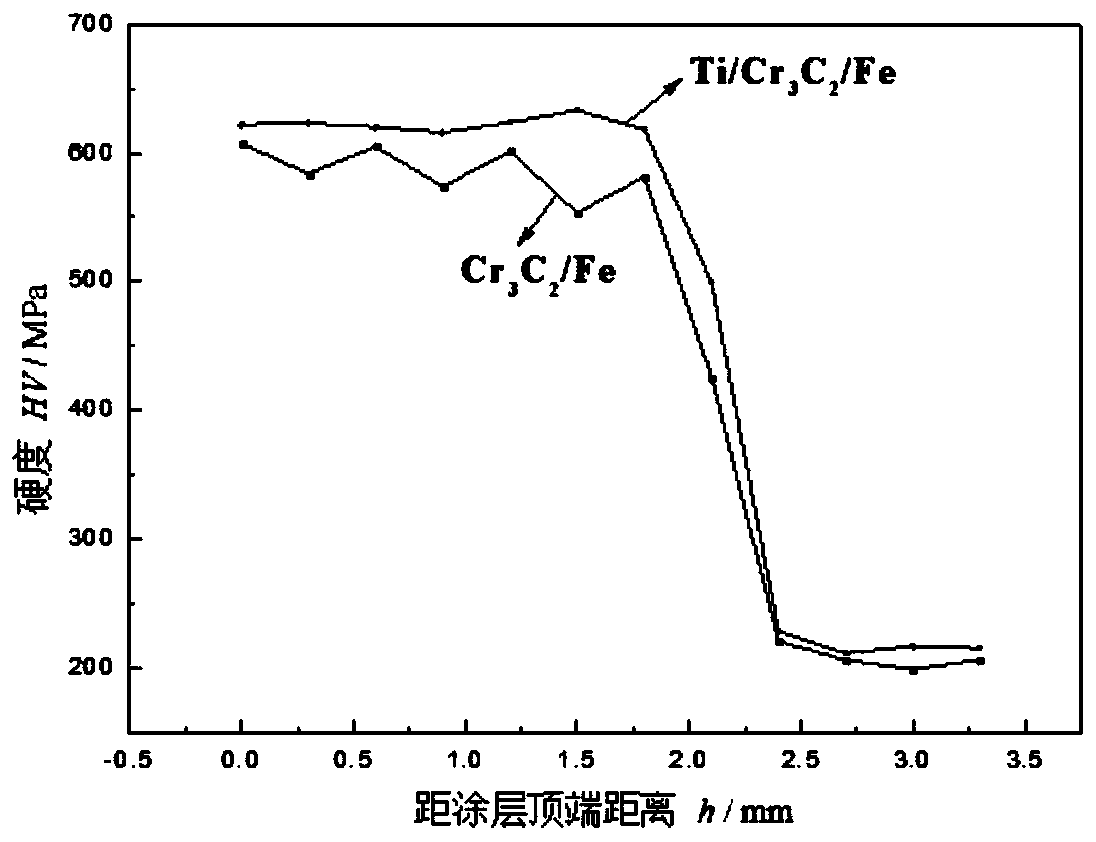

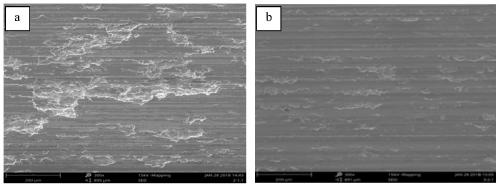

ActiveCN109023355AImprove liquidityInhibit growthMetallic material coating processesCrazingWear resistance

The invention discloses a multi-scale particle reinforced plasma surfacing iron-based hypereutectic wear-resistant coating and a preparation method thereof, and belongs to the technical field of surface wear-resistant coatings. The plasma surfacing iron-based hypereutectic wear-resistant coating is prepared from the following components in a plasma surfacing mode, and wherein the components comprise, by mass, 48-69% of iron-based self-fluxing alloy powder, 30-50% of micron Cr3C2 powder, 0.5-1% of micron Ti powder, and 0.5-1% of nano Y2O3 powder. The preparation method of the plasma surfacing iron-based hypereutectic wear-resistant coating comprises the following steps of substrate pretreatment, preparation and drying of composite powder, preparation of the coating and post-heat treatment.By using the technical scheme, on the basis that hardness and wear resistance of the multi-scale particle reinforced plasma surfacing iron-based hypereutectic wear-resistant coating can be further improved, the process performance of the coating can be improved obviously, and cracks of the coating are effectively prevented.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

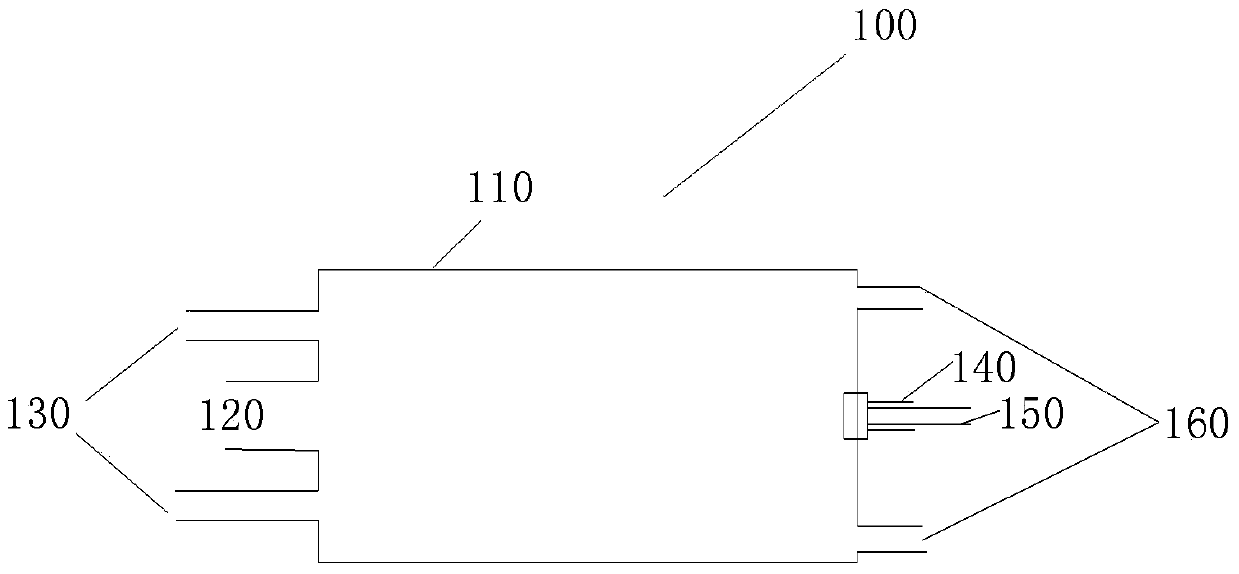

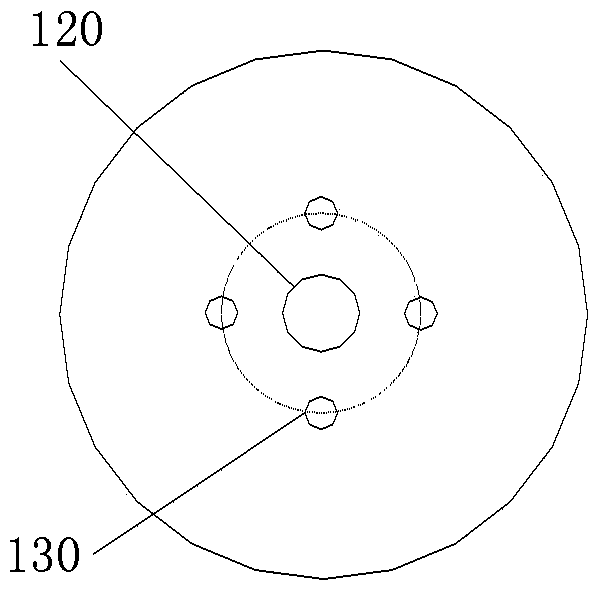

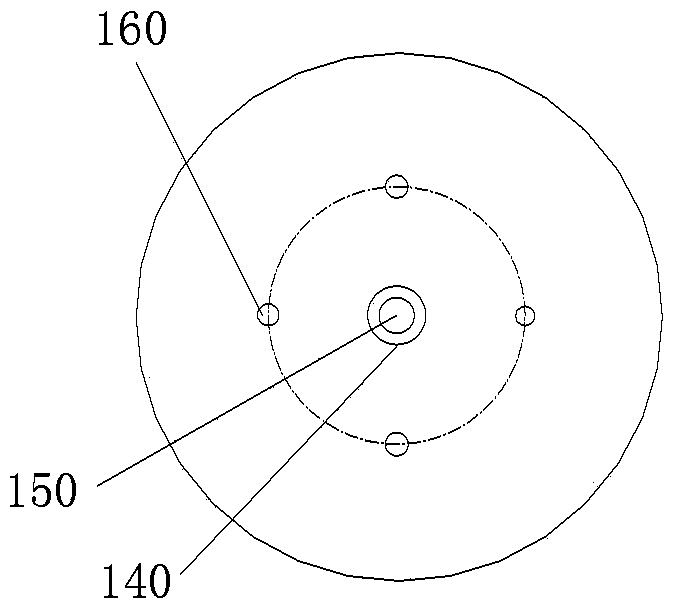

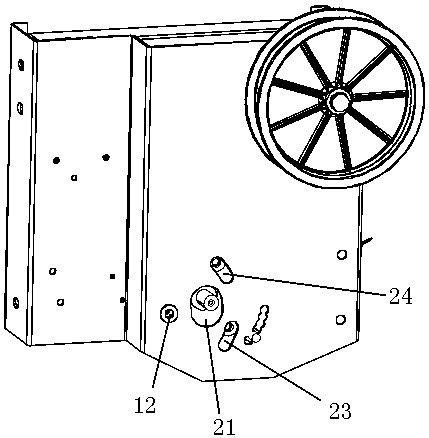

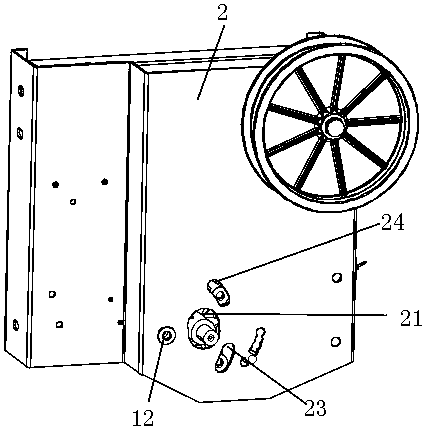

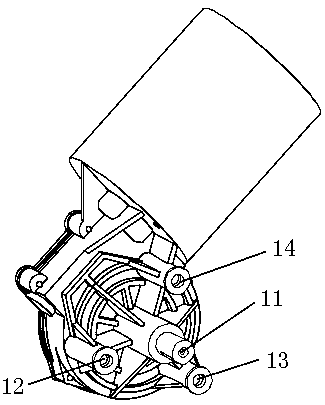

A motor protection device and a hanging ascending and descending system

ActiveCN109510387AAvoid direct burningReduce economic lossConveyorsEmergency protective circuit arrangementsElectricityDrive shaft

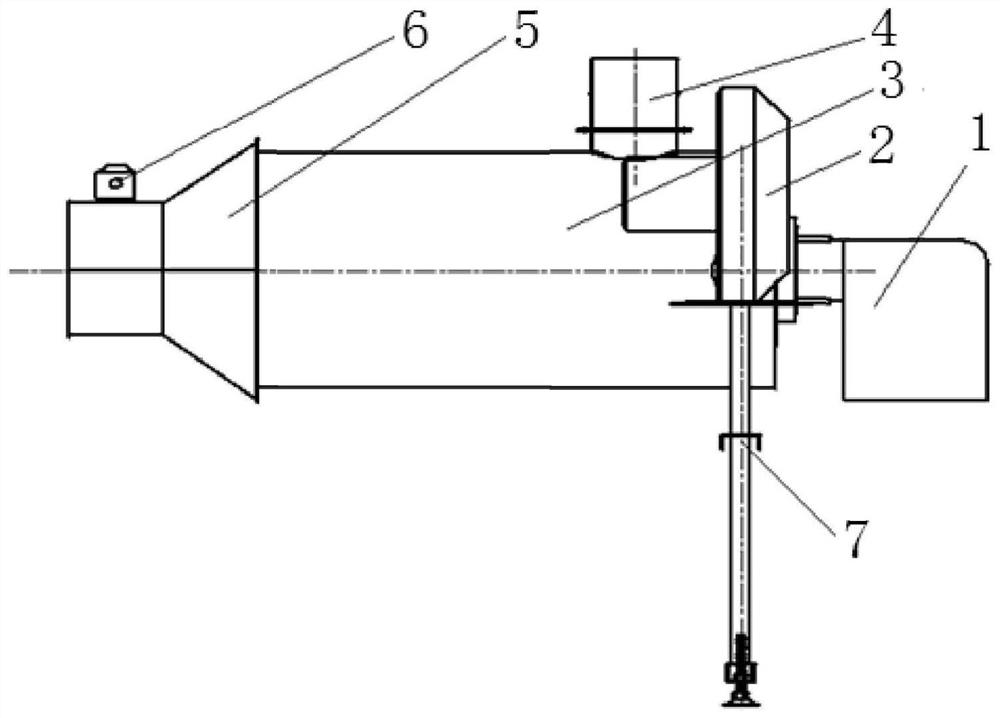

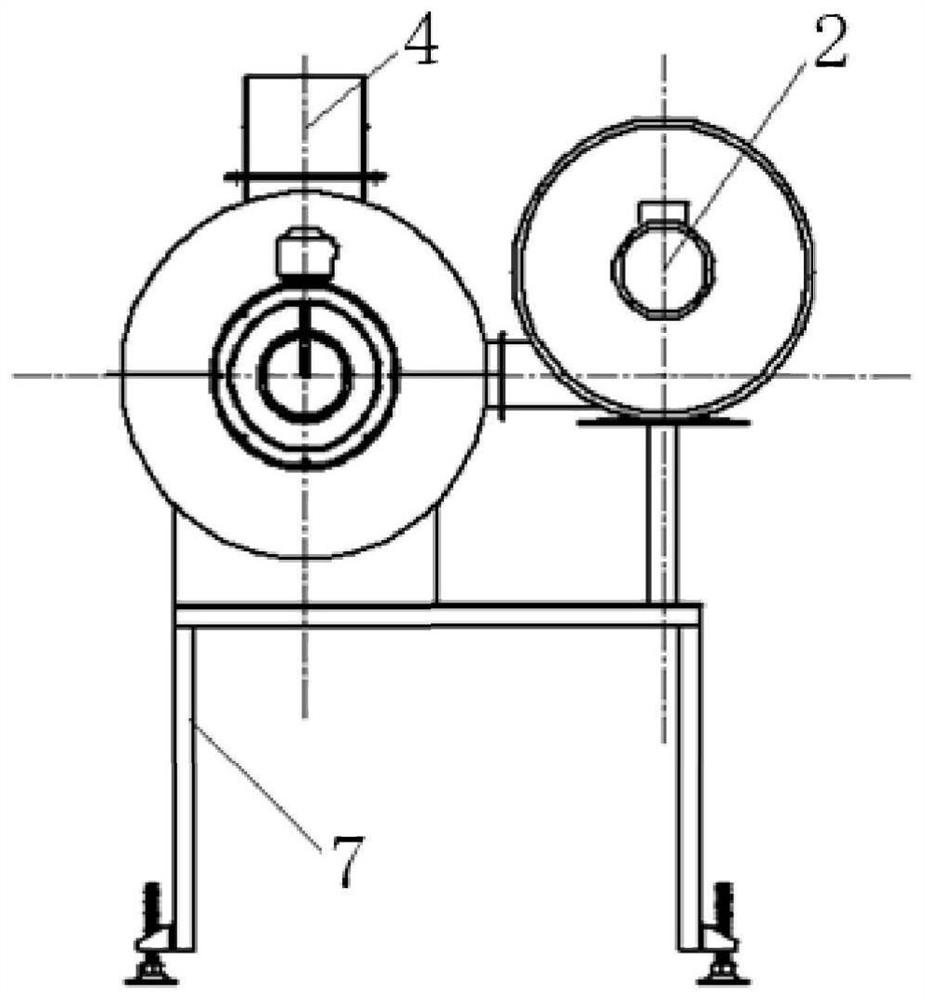

The invention relates to the technical field of motor control protection. The invention relates to a motor protection device and a hanging ascending and descending system. The motor protection devicecomprises a motor body, a motor mounting shell and a power supply switch in contact connection with the motor body; one end of the motor body is provided with a driving shaft, and a fixed-point connecting shaft and a guide limiting shaft which are arranged around the driving shaft; the motor mounting shell is movably connected with the fixed-point connecting shaft and is provided with arc-shaped notches which are in movable butt joint with the driving shaft and the guide limiting shaft, and the other end of the motor body is connected with the motor mounting shell through a spring. According to the invention, under the condition that the motor is jammed, the motor body can rotate by a certain angle along the fixed-point connecting shaft and the motor body can be separated from the power supply switch, so that the motor can stop running because of power loss for a short time, the motor is prevented from being directly burnt out due to the fact that the motor is always in a jammed state,and economic loss is reduced.

Owner:浙江特盛智能科技有限公司

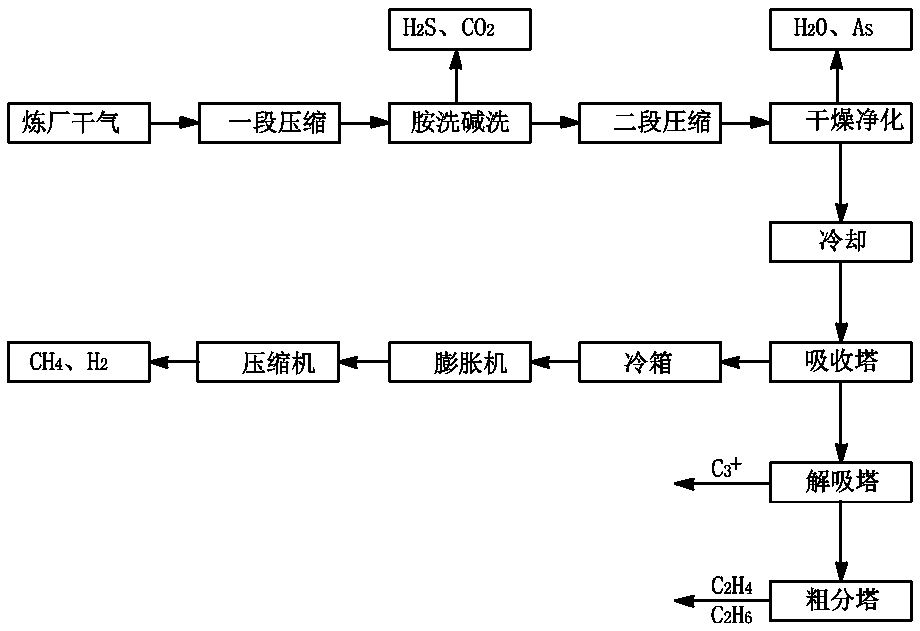

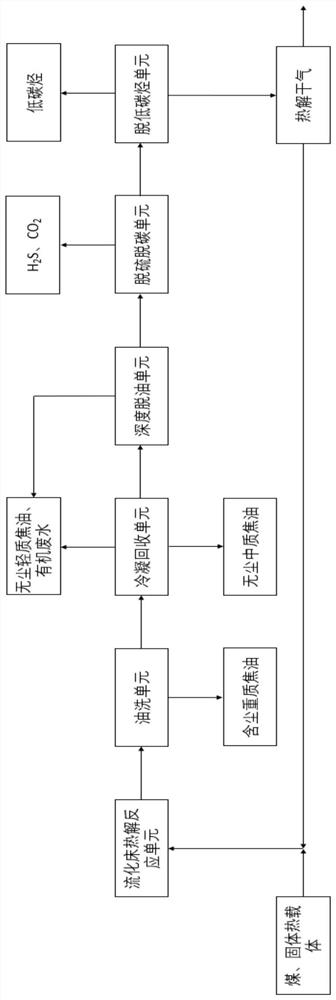

Refinery dry gas treatment method

The invention discloses a refinery dry gas treatment method, and belongs to the field of refinery dry gas treatment. The refinery dry gas treatment method comprises that (1) refinery dry gas is subjected to amine washing and alkali washing to separate H2S and CO2; (2) the washed gas is subjected to drying purification to separate H2O and AS; (3) the gas obtained in the step (2) is conveyed into anabsorption tower, and is treated; (4) the treated gas is conveyed into a desorption tower to separate C3+; and (5) the gas separated by the desorption tower is conveyed into a coarse separation towerto separate C2H4 and C2H6, wherein the refinery dry gas is subjected to amine washing and alkali washing after compression. According to the pre sent invention, the refinery dry gas is sequentially subjected to amine washing and alkali washing and drying purification, the purified gas is conveyed into the absorption tower, and the obtained material is sequentially conveyed into the desorption tower and the coarse separation tower to separate C2H4 and C2H6, such that ethylene can be obtained, and the waste of resources due to the direct combustion of the refinery dry gas can be avoided; and the method can be used in the treatment of refinery dry gas.

Owner:刘洋

A multi-scale particle-reinforced plasma surfacing iron-based hypereutectic wear-resistant coating and its preparation method

The invention discloses a multi-scale particle reinforced plasma surfacing iron-based hypereutectic wear-resistant coating and a preparation method thereof, and belongs to the technical field of surface wear-resistant coatings. The plasma surfacing iron-based hypereutectic wear-resistant coating is prepared from the following components in a plasma surfacing mode, and wherein the components comprise, by mass, 48-69% of iron-based self-fluxing alloy powder, 30-50% of micron Cr3C2 powder, 0.5-1% of micron Ti powder, and 0.5-1% of nano Y2O3 powder. The preparation method of the plasma surfacing iron-based hypereutectic wear-resistant coating comprises the following steps of substrate pretreatment, preparation and drying of composite powder, preparation of the coating and post-heat treatment.By using the technical scheme, on the basis that hardness and wear resistance of the multi-scale particle reinforced plasma surfacing iron-based hypereutectic wear-resistant coating can be further improved, the process performance of the coating can be improved obviously, and cracks of the coating are effectively prevented.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A Continuous and Forced Asphalt Mixing Production Method

ActiveCN111074714BAvoid direct burningPrevent leakageIn situ pavingsRotary stirring mixersDelivery vehicleWater vapor

The invention discloses a continuous and forced asphalt mixing production method, which belongs to the technical field of concrete processing, and comprises the following steps: heating cold aggregates to obtain hot aggregates; Recycled material is obtained after mixing; hot aggregate, recycled material, powder and asphalt are mixed to obtain premix; the premix is temporarily stored in the pre-mixing storage bin and then mixed in the forced mixing tank, and the obtained finished material enters the finished product Temporary storage in the storage warehouse; in the finished material loading area, the material is unloaded into the storage tank of the finished material delivery vehicle. Pass the generated bitumen flue gas and water vapor into the drying cylinder for secondary incineration; the collected dust enters the exhaust gas absorption and purification device for exhaust gas purification treatment; at the same time, the collected flue gas and air are passed to the burner for use as combustion-supporting gas . The invention avoids the direct burning of the milling and planing material by an open flame; at the same time, the hot aggregate is slowly premixed with the recycled material, the powder material and the asphalt, the mixing efficiency is high, and at the same time, the leakage of the asphalt smoke can be avoided and the heat energy can be utilized, which is energy-saving and environment-friendly.

Owner:SHANGHAI SHISHEN IND & TRADE CO LTD

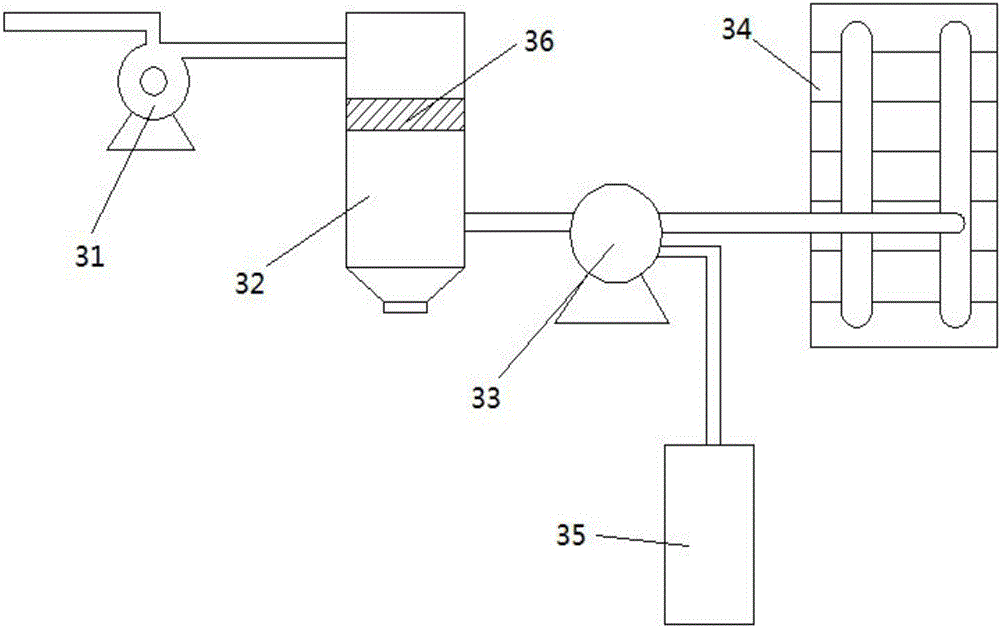

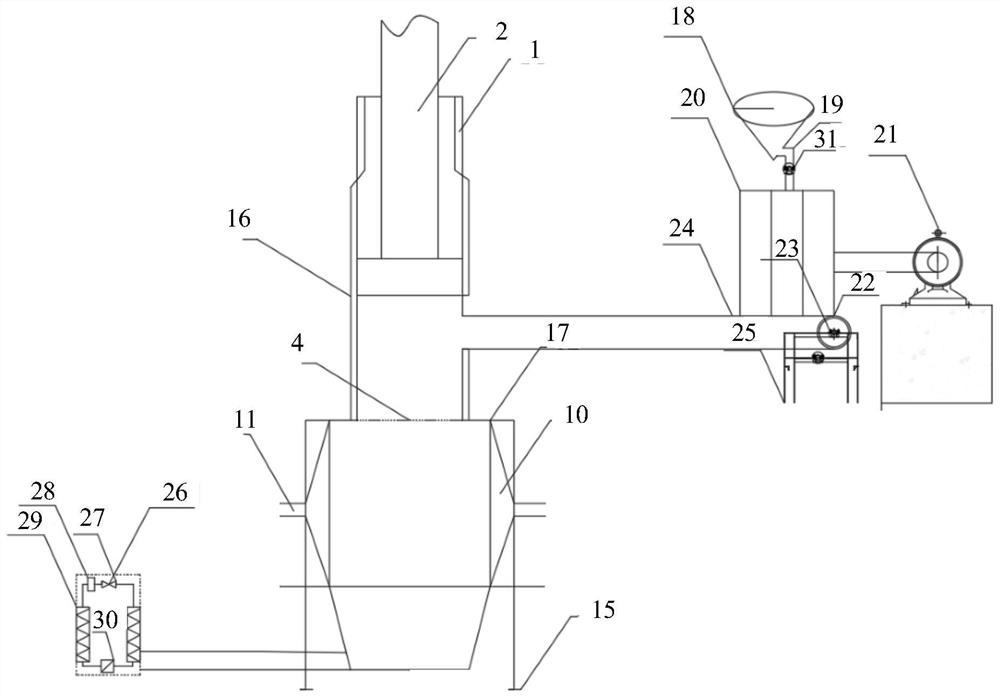

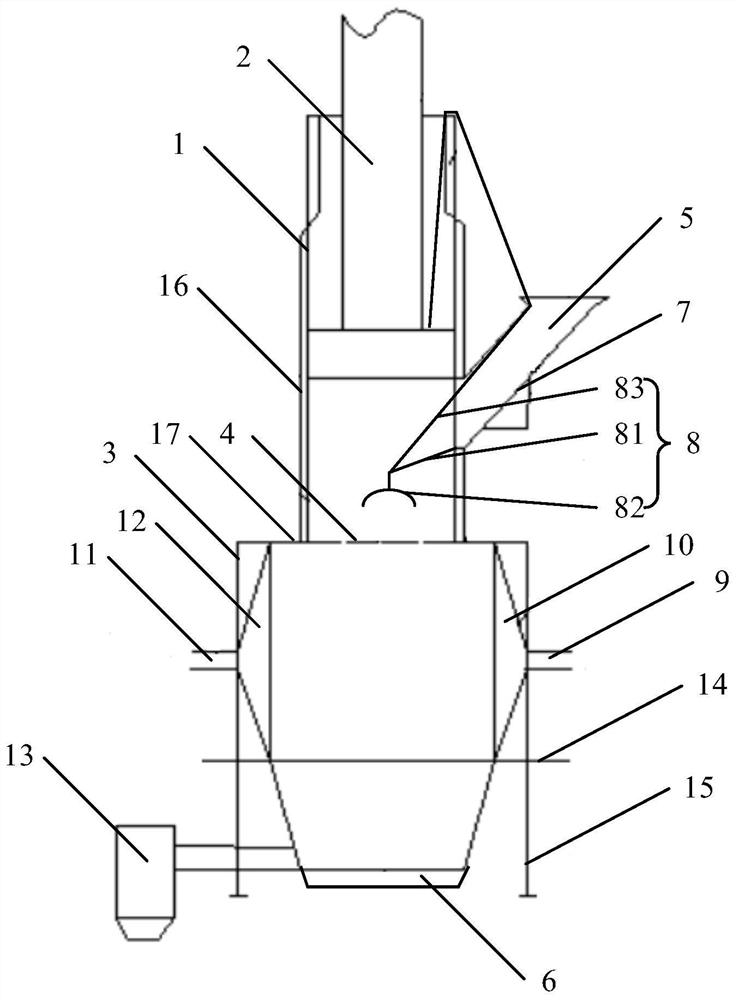

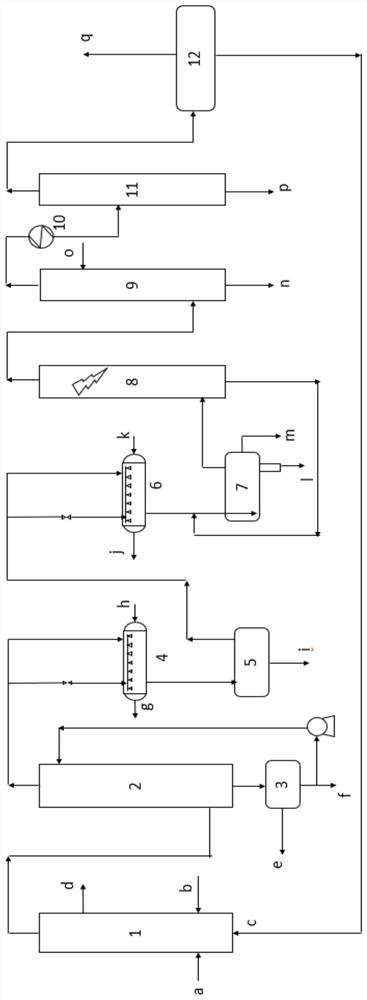

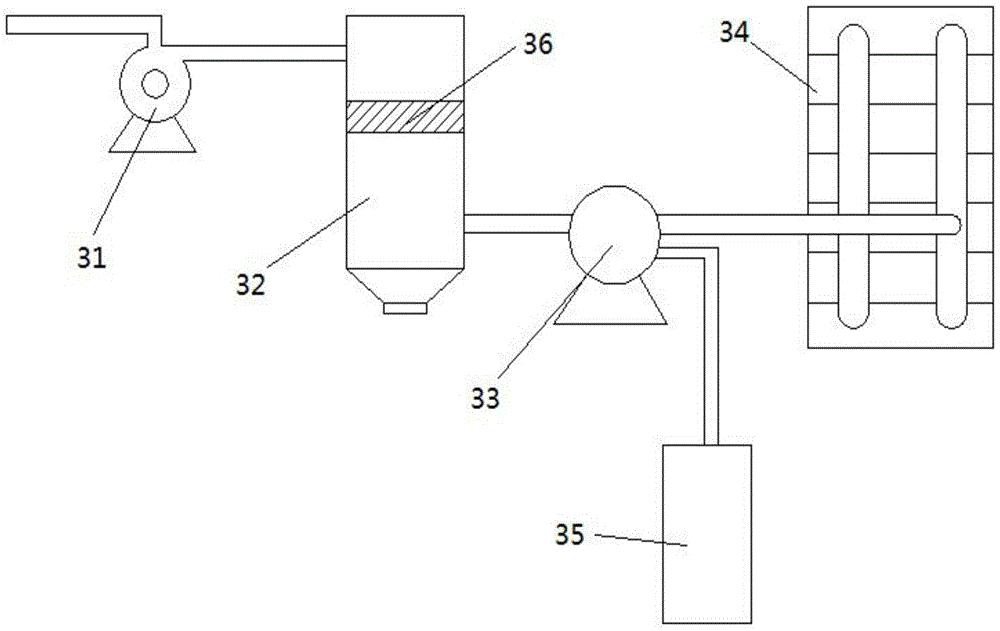

Integrated downdraft biomass gasification power generation system and method

ActiveCN110295065AImprove efficiencyIncrease profitEnergy inputGasification processes detailsActivated carbonGas generator

The invention discloses an integrated downdraft biomass gasification power generation system, belongs to the technical field of biomass gasification power generation, and particularly relates to an integrated downdraft biomass gasification power generation system and method. The system comprises a hopper, a reactor, a slag barrel, a cyclone dust remover, an air preheater, an activated carbon adsorber, a gas fan, a torch, an air fan, a gas generator set, a pipeline, a ladder and a base, and is characterized in that the hopper, the air preheater, the cyclone dust remover, the slag barrel and thereactor are coupled into a compact whole, so that the heat efficiency of the whole system is greatly improved. The system is suitable for gasifying straw particles, wood chips, crushed coconut shellsand other carbonaceous biomass materials to generate combustible gas, and the combustible gas is conveyed into a gas engine to be combusted to push the engine to drive a generator to generate electric energy. The system is compact in structure, high in universality, high in energy utilization rate, reliable, convenient to use and easy to operate.

Owner:青岛德瑞汇丰环保科技股份有限公司

A kind of plasma surfacing iron-based cr with micron ti added 3 c 2 Hypereutectic wear-resistant coating and preparation method thereof

ActiveCN109234727BSpeed up meltingImprove cladding qualityMetallic material coating processesCrazingAlloy

The invention discloses a plasma-surfacing iron-based Cr3C2 hypereutectic wear-resistant coating layer added with micrometer Ti and a preparation method thereof and belongs to the technical field of wear-resistant coating layers on the surfaces. The plasma-surfacing iron-based Cr3C2 hypereutectic wear-resistant coating layer is prepared from the following components in percent by mass after plasmasurfacing: 49%-69.5% of iron-based self-fluxed alloy powder, 30%-50% of micrometer Cr3C2 powder and 0.5%-1% of micrometer Ti powder. The plasma-surfacing iron-based Cr3C2 hypereutectic wear-resistantcoating layer is prepared by the following steps: pretreatment of base materials, preparation and drying of composite powder, preparation of the coating layer and post heat treatment. By use of the technical scheme disclosed by the invention, on the basis of improving the hardness and wear resistance of the plasma-surfacing iron-based hypereutectic wear-resistant coating layer enhanced by multiscale particles, the process characteristics of the coating layer can be obviously improved, and the generation of cracks of the coating layer can be effectively prevented.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Biomass gasifier with preheating recovery function

PendingCN110747011AGuaranteed precipitation effectReduce the temperatureProductsGasifier feeding meansCombustorSlag

The invention discloses a biomass gasifier with a preheating recovery function. The biomass gasifier comprises a pyrolyzing furnace, wherein a grate is arranged in the pyrolyzing furnace, a feeding port is arranged at the position, above the grate, of the pyrolyzing furnace, a sealed feeder is arranged at the feeding port in a matched mode, a discharging port is arranged at the position, below thegrate, of the pyrolyzing furnace, and a sealed discharger is arranged at the position of the discharging port in a matched mode; the biomass gasifier further comprises an oxygen-free medium-temperature gas source mechanism which is arranged outside the pyrolyzing furnace and supplies smoke to the pyrolyzing furnace; a combustible gas collector is further arranged in the pyrolyzing furnace; and apreheating sleeve is arranged outside the sealed feeder in a sleeving mode, a preheating pipe set is arranged at the position of the preheating sleeve, a cooling sleeve is arranged outside the sealeddischarger in a sleeving mode, a cooling pipe set is arranged at the position of the cooling sleeve, a water inlet / outlet of the preheating pipe set is connected with a heating path of a heat exchanger, and a water inlet / outlet of the cooling pipe set is connected with a cooling path of the heat exchanger. According to the biomass gasifier, a combustor provides an oxygen-free medium-temperature heat source for the pyrolyzing furnace, preheating recovery of carbon slag can be realized, and resourceful and integrated utilization is realized.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Combustion cylinder and fuel gas boiler

Owner:ZOOMLION HEAVY MASCH CO LTD

Corrugated metal sheath inorganic mineral insulation cable and method for producing the same

InactiveCN101430947BBurn out preventionGuaranteed uptimeInsulated cablesInorganic insulatorsCopper wireWeld seam

The invention discloses a corrugated metallic sheath inorganic mineral insulated cable and a manufacturing method thereof. The cable consists of an inner cable core, an insulating layer winding the outside of the cable core, and an outermost metallic sheath; the cable core is formed by twisting a bundle of copper wires, the insulating layer is an inorganic mineral insulated tape, the metallic sheath is a copper corrugated tube, corrugation of the copper corrugated tube has upper peaks and lower valleys, the cable core, the insulating layer and the copper corrugated tube have the same length, and the surface of the copper corrugated tube is provided with a welding seam with the same length of the copper corrugated tub along the axial direction. As the cable takes a corrugated shape, the cable is easy to be bent and mounted in a laying field, which lowers the construction cost, can prevent a cable conductor and the insulating layer from being directly burnt by flame, prevents a phase and phase conductor from short circuit, and prevents elevators and fire fighting devices from being incapable of operating without power supply, thus obtaining precious time to facilitate persons to escape in time, and reduce property loss.

Owner:张荣生

A carbonaceous raw material fluidized bed pyrolysis product graded recovery system and recovery method thereof

ActiveCN111100656BReduce dosageAchieving Cascade RecyclingDirect heating destructive distillationLiquid hydrocarbon mixture productionFluidized bedTar

The invention discloses a carbonaceous raw material fluidized bed pyrolysis product graded recovery system and a recovery method thereof. The recovery system comprises a fluidized bed pyrolysis reaction unit, an oil washing unit, a condensation recovery unit, a deep deoiling unit, a desulfurization and decarbonization unit and a low-carbon hydrocarbon removal unit. According to the system and themethod provided by the invention, high-temperature pyrolysis oil gas is sequentially subjected to the processes of oil washing, heat exchange condensation, deep deoiling, desulfurization and decarburization, low-carbon hydrocarbon removal and the like to respectively obtain heavy tar, medium tar, light tar, low-carbon hydrocarbon and pyrolysis dry gas products, so that the step-by-step recovery and purification of pyrolysis products are realized. And compared with the prior art, the use amount of water and the discharge amount of organic wastewater are greatly reduced, and the wastewater treatment cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

An integrated downdraft biomass gasification power generation system and method

ActiveCN110295065BReduce moisture contentIncrease temperatureEnergy inputGasification processes detailsAir preheaterCyclonic spray scrubber

The invention discloses an integrated downdraft biomass gasification power generation system, belongs to the technical field of biomass gasification power generation, and particularly relates to an integrated downdraft biomass gasification power generation system and method. The system comprises a hopper, a reactor, a slag barrel, a cyclone dust remover, an air preheater, an activated carbon adsorber, a gas fan, a torch, an air fan, a gas generator set, a pipeline, a ladder and a base, and is characterized in that the hopper, the air preheater, the cyclone dust remover, the slag barrel and thereactor are coupled into a compact whole, so that the heat efficiency of the whole system is greatly improved. The system is suitable for gasifying straw particles, wood chips, crushed coconut shellsand other carbonaceous biomass materials to generate combustible gas, and the combustible gas is conveyed into a gas engine to be combusted to push the engine to drive a generator to generate electric energy. The system is compact in structure, high in universality, high in energy utilization rate, reliable, convenient to use and easy to operate.

Owner:青岛德瑞汇丰环保科技股份有限公司

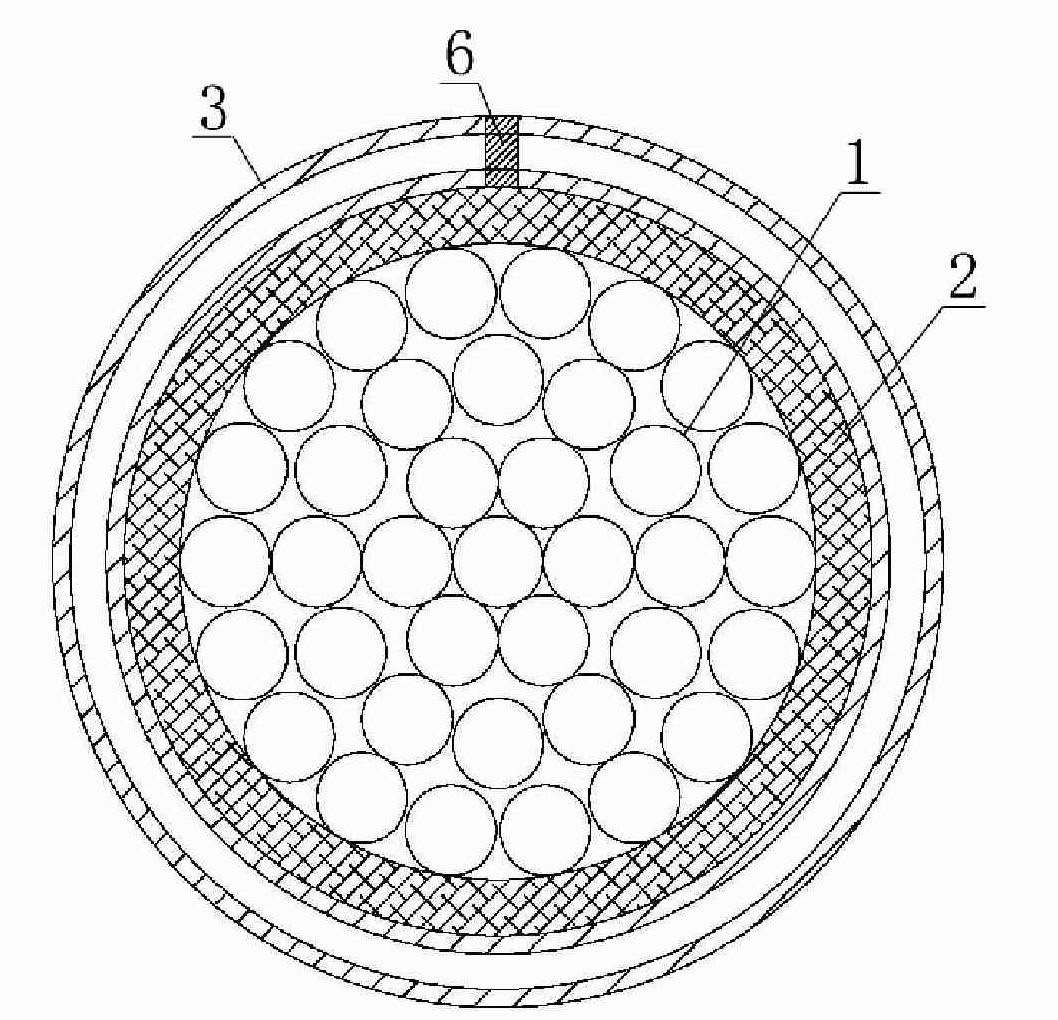

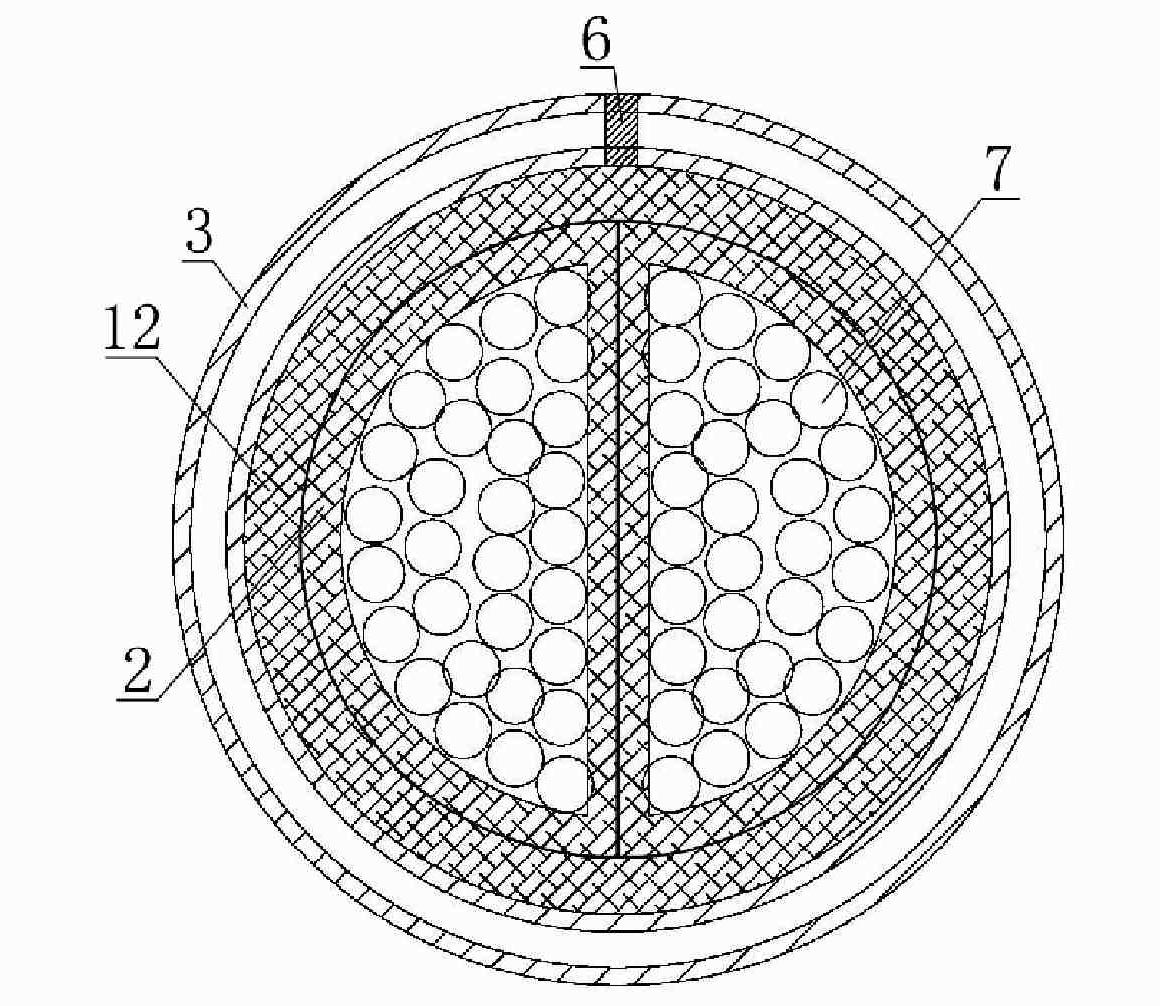

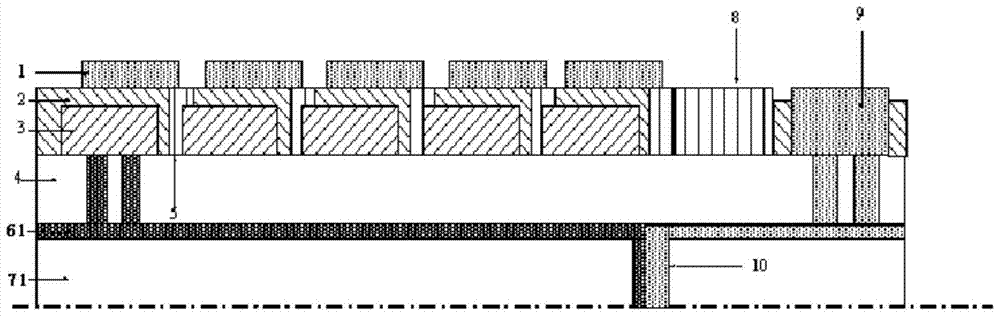

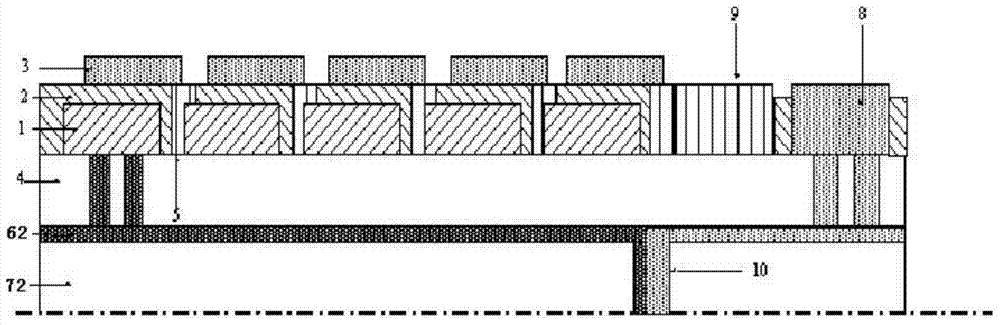

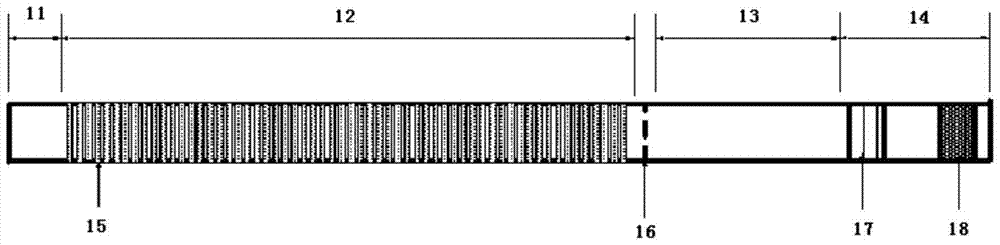

Porous inert support tubular solid oxide fuel cell with open ends, stack and preparation method thereof

ActiveCN104979575BHigh strengthImprove reliabilityFinal product manufactureSolid electrolyte fuel cellsFuel cellsElectrical connection

The invention relates to a porous inert support tubular solid oxide fuel cell with open ends, an electric stack and a preparation method thereof. The battery includes a porous inert support tube with openings at both ends and a porous inert support tube that is electronically connected but airtightly separated. The outer wall is coated with different functional sections: inlet gas isolation section, series battery section, thermal isolation section, and battery connection terminal. The gas isolation section is used to isolate air and fuel. A series battery section is a battery connected in series. The thermal isolation section places the external conductive connection of the battery outside the high temperature area. The battery connection terminal provides an external electrical connection terminal of the battery. The battery of the present invention forms a battery row through the battery connection terminals, and the battery row further forms a battery stack by connecting in series or in parallel. The invention can greatly reduce the cost of the solid oxide fuel cell, avoid the influence of thermal expansion on the battery and the battery stack, reduce the influence of high temperature on the conductive connection, facilitate the series and parallel connection of different batteries, and facilitate the assembly of the battery stack.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

An exhaust gas recovery, purification and recycling device and process for an annealing furnace system

InactiveCN104110972BAvoid direct burningAvoid pollutionIncreasing energy efficiencyWaste heat treatmentProcess engineeringEngineering

The invention discloses a tail gas recovery purification recycling device of an annealing furnace system. The tail gas recovery purification recycling device of the annealing furnace system is characterized by comprising components of an adsorption purification device, a circulation power device, a catalysis purification device or a deoxidizing device, a first cooling device, an air and water separator, and an adsorption drying device, and further comprising a pipeline connected among all the components, wherein all the components are sequentially connected through the pipeline, an air inlet of the adsorption purification device is connected with a tail gas outlet of an annealing furnace, an air outlet of the adsorption drying device is connected with an air inlet of the annealing furnace through the pipeline, and a first pressure adjustment device is arranged on the pipeline. The tail gas recovery purification recycling technology of the annealing furnace system is characterized in that tail gas sequentially passes through the adsorption purification device, the circulation power device, the catalysis purification device, the first cooling device, the air and water separator and the adsorption drying device from the tail gas outlet of the annealing furnace, and finally enters the air inlet of the annealing furnace through the first pressure adjustment device. The tail gas recovery purification recycling device and the tail gas recovery purification recycling technology of the annealing furnace system achieve purification treatment of the tail gas of the annealing furnace, and the tail gas after the purification treatment can be recycled, and therefore energy consumption is effectively reduced.

Owner:苏州为众气体设备有限公司

A heat-dissipating flame-retardant tape

ActiveCN110041844BImprove cooling efficiencyAvoid direct burningFilm/foil adhesivesEngineeringSilicone tape

Owner:HUNAN PROVINCE PURUIDA INTERIOR MATERIAL CO LTD

A high-efficiency treatment device for medical waste and its manufacturing method

InactiveCN104534484BTo avoidAvoid direct burningSolid waste disposalTransportation and packagingCombustion chamberSlag

The invention discloses a high-efficiency treatment device for medical waste, which includes a reaction chamber, a combustion chamber, a blower, a waste residue chamber and an oxygen-enriched air supply system. There is a filter screen between the waste chamber and the waste chamber, and a piston feeding device is installed on the upper side of the reaction chamber. In the reaction chamber, the medical waste is pyrolyzed under anoxic conditions to produce flammable gases and harmless residues, which are treated in the combustion chamber. The combustible gas is combusted, and the harmless residue is collected and processed to avoid direct combustion to produce harmful gas. The oxygen-enriched gas is delivered to the combustion chamber through the oxygen-enriched air supply system, and the oxygen content in the combustion chamber is adjusted to ensure that different combustible gases are fully charged. Combustion, the exhaust gas after full combustion is filtered by the exhaust gas treatment device and then discharged into clean air, which is harmless to the environment.

Owner:寇卫国 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com