Continuous and forced combined asphalt mixing production method

A kind of asphalt mixing and combination technology, which is applied in the direction of mixer, pretreatment control, mixer accessories, etc., can solve the problems of polluting the environment, increasing the company's operating costs, wasting time and electric energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

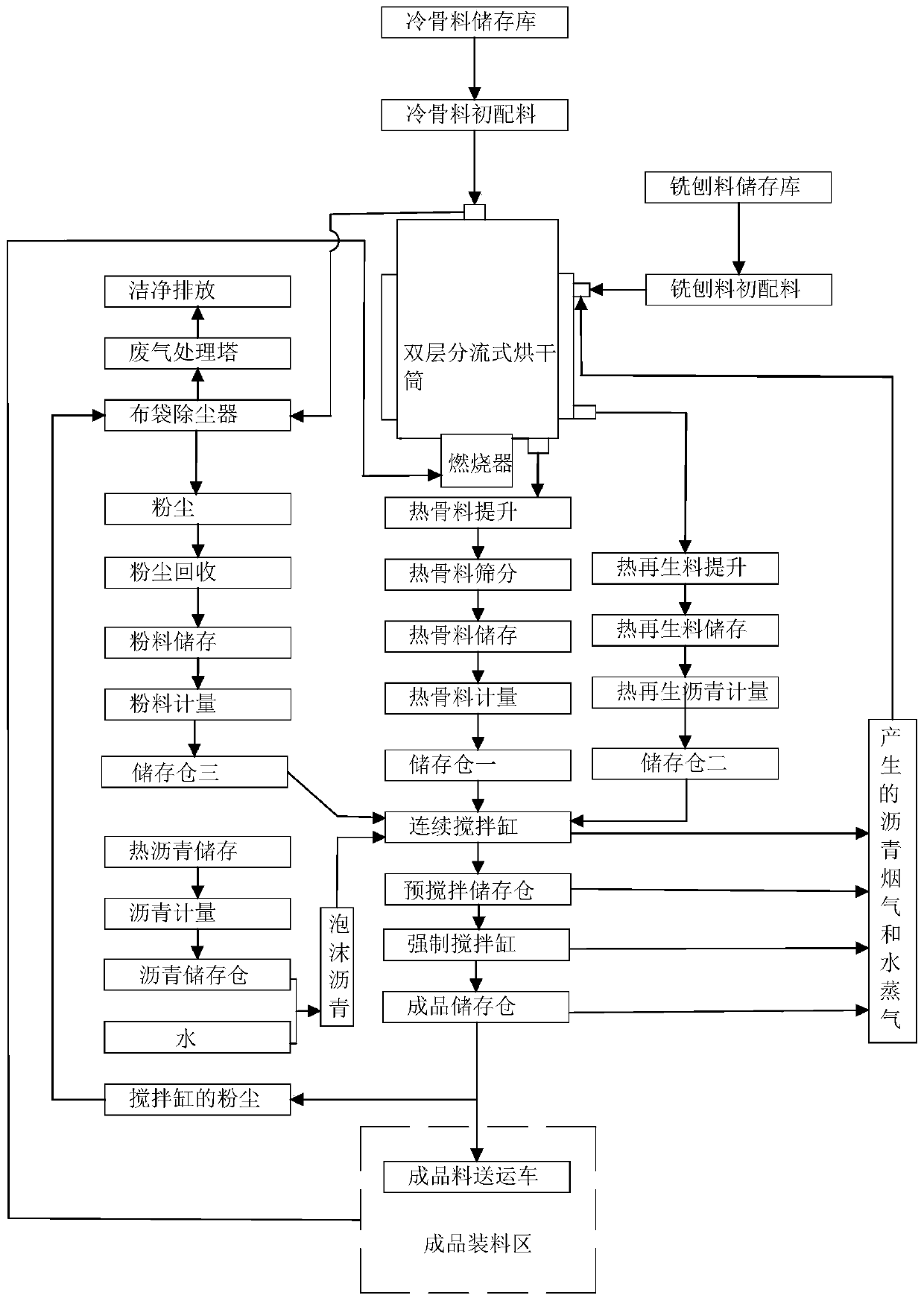

[0073] Embodiment 1-1: a kind of asphalt mixing production method combining continuous type and forced type, such as figure 1 shown, including the following steps:

[0074] In step one,

[0075] A1. According to the grading requirements, the new material is initially batched at room temperature to obtain cold aggregate, wherein the cold aggregate contains 18-31.5mm crushed stone, 10-20mm crushed stone and 5-10mm crushed stone, and The weight ratio of 18-31.5mm gravel, 10-20mm gravel and 5-10mm gravel is 21:18:18.

[0076] A2. The cold aggregate is discharged into the inner cylinder of the double-layer split-type drying drum for combustion. When the temperature of the double-layer split-type drying drum is raised to 100°C, the cold aggregate is first dried, and then the double-layer split-type drying drum is continuously raised. The temperature of the split drying cylinder is 200°C, and the cold aggregate is heated to 180°C to obtain hot aggregate.

[0077] A3. The hot aggre...

Embodiment 2-1

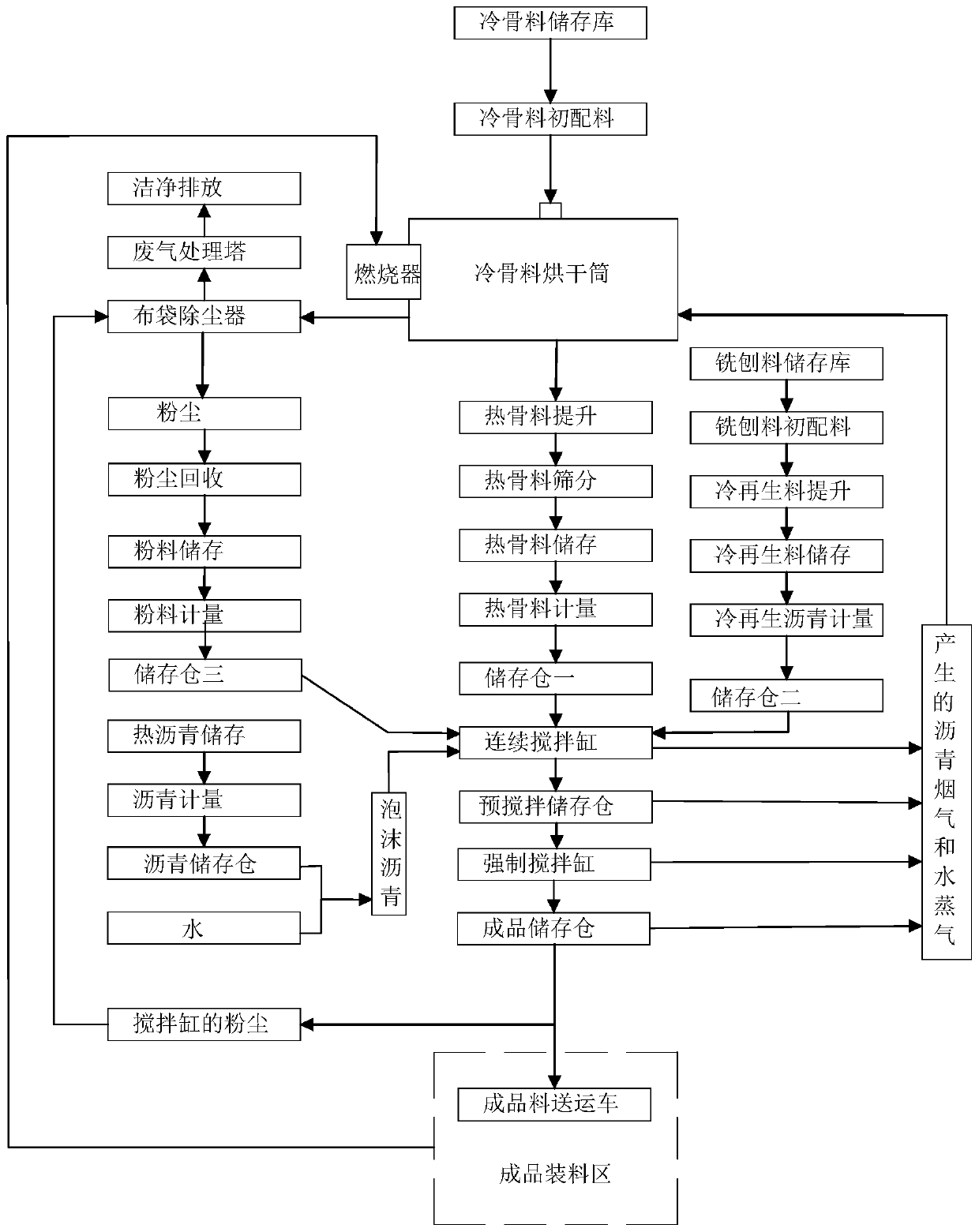

[0094] Embodiment 2-1: a kind of asphalt mixing production method combining continuous type and forced type, comprising the following steps:

[0095] In step one,

[0096] A1. According to the grading requirements, the new material is initially batched at room temperature to obtain cold aggregate, wherein the cold aggregate contains 18-31.5mm crushed stone, 10-20mm crushed stone and 5-10mm crushed stone, and The weight ratio of 18-31.5mm gravel, 10-20mm gravel and 5-10mm gravel is 22:20:19.

[0097] A2. The cold aggregate is discharged into the inner cylinder of the double-layer split-type drying drum for combustion. When the temperature of the double-layer split-type drying drum is raised to 110°C, the cold aggregate is first dried, and then the double-layer split-type drying drum is continuously raised. The temperature of the split-flow drying cylinder is 210°C, and the cold aggregate is heated to 190°C to obtain hot aggregate.

[0098] A3. The hot aggregate is temporarily...

Embodiment 3-1

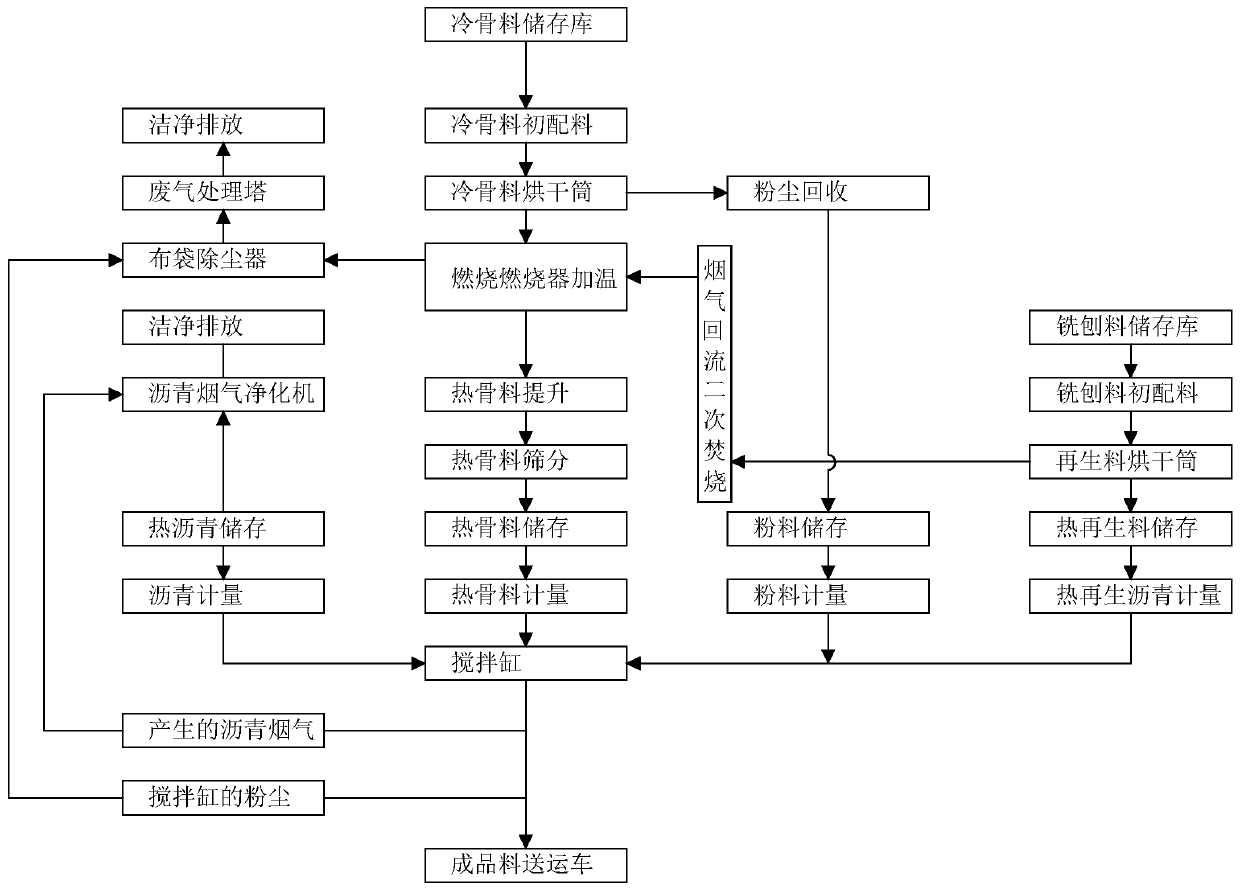

[0114] Embodiment 3-1: a kind of asphalt mixing production method combining continuous type and forced type, comprising the following steps:

[0115] In step one,

[0116] A1. According to the grading requirements, the new material is initially batched at room temperature to obtain cold aggregate, wherein the cold aggregate contains 18-31.5mm crushed stone, 10-20mm crushed stone and 5-10mm crushed stone, and The weight ratio of 18-31.5mm gravel, 10-20mm gravel and 5-10mm gravel is 23:25:20.

[0117] A2. The cold aggregate is discharged into the inner cylinder of the double-layer split-type drying drum for combustion. When the temperature of the double-layer split-type drying drum is raised to 120°C, the cold aggregate is first dried, and then the double-layer split-type drying drum is continuously raised. The temperature of the split-flow drying cylinder is 220°C, and the cold aggregate is heated to 200°C to obtain hot aggregate.

[0118] A3. The thermal aggregate is tempora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com