A high-efficiency treatment device for medical waste and its manufacturing method

A technology for medical waste and treatment devices, applied in combustion methods, chemical instruments and methods, transportation and packaging, etc., can solve problems such as instability, environmental and public health safety hazards, and large fluctuations in combustion conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

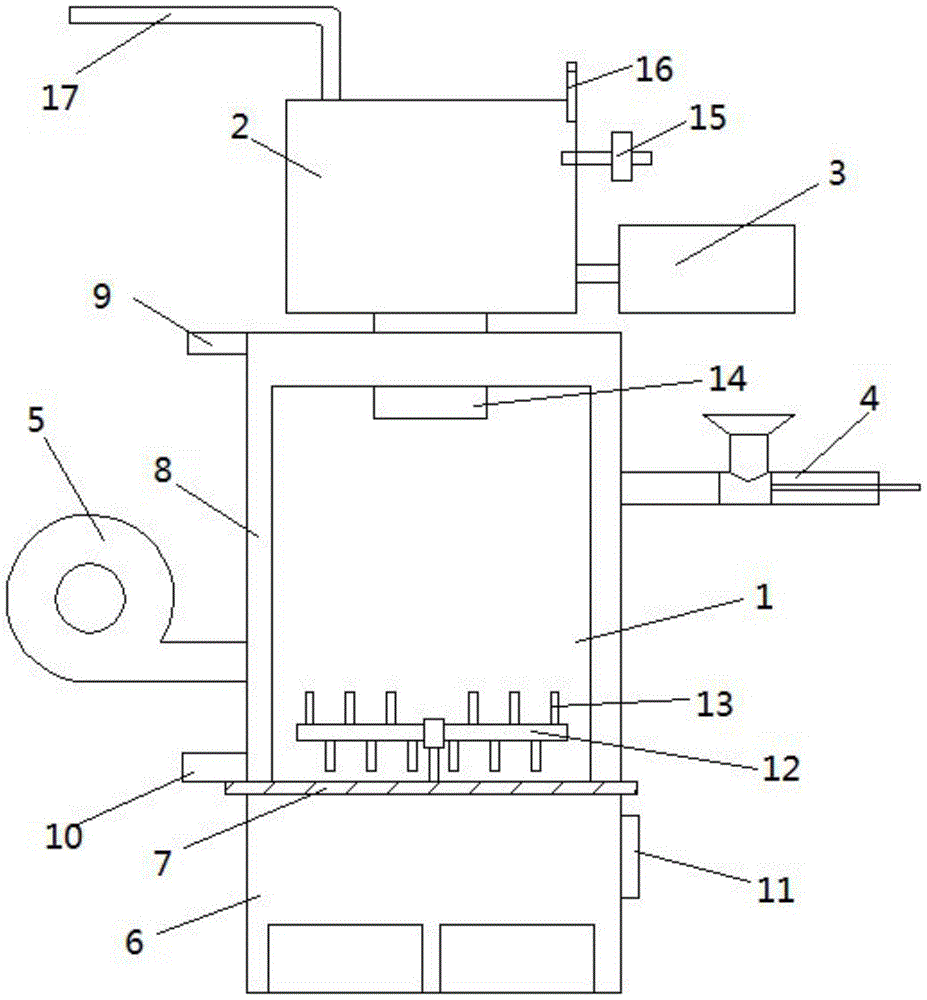

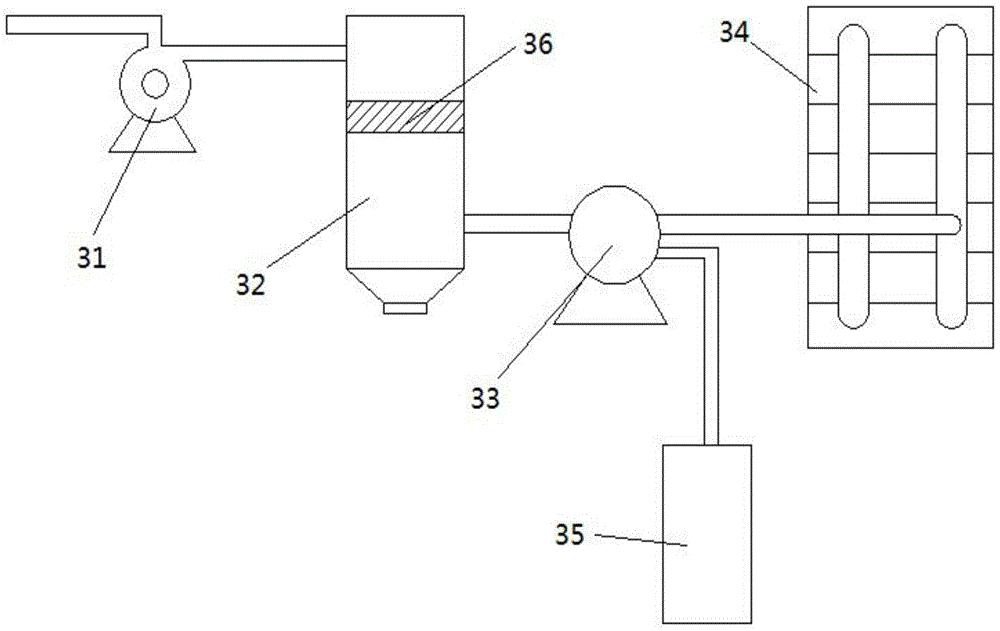

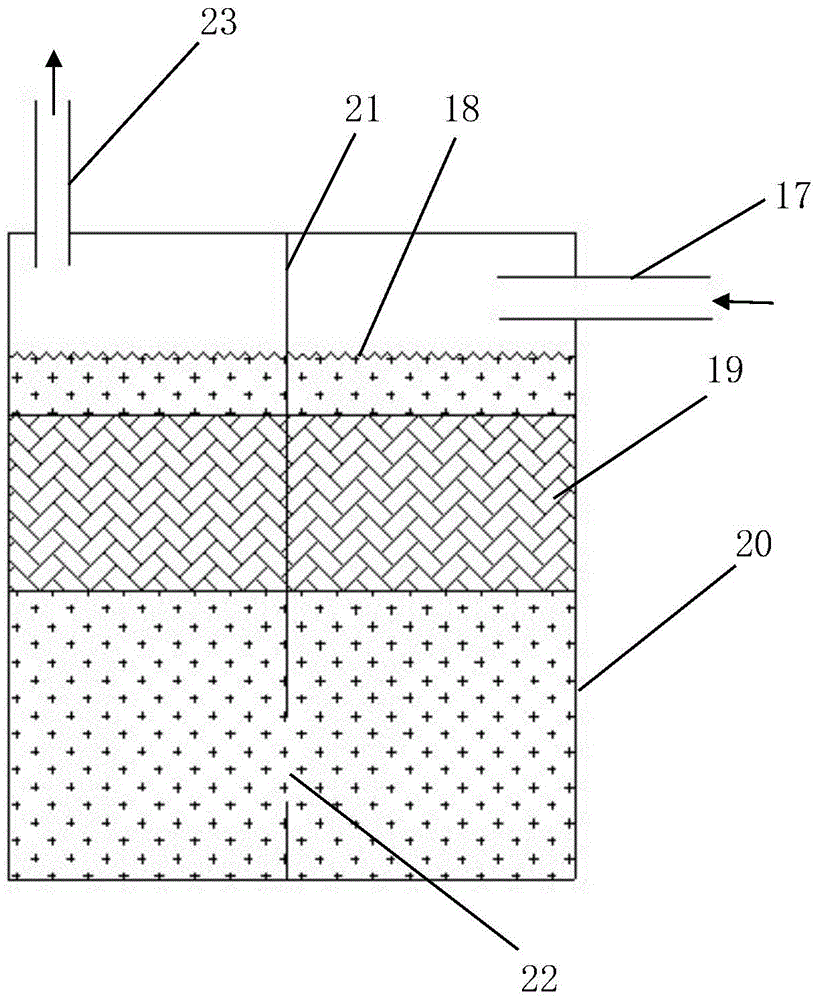

[0026] Example 1: See Figure 1~2 , a high-efficiency treatment device for medical waste, comprising a reaction chamber 1, a combustion chamber 2, a blower 5, a waste residue chamber 6 and an oxygen-enriched air supply system 3, the reaction chamber 1 is arranged above the waste residue chamber 6, the reaction chamber 1 and the waste residue chamber 6 constitute the tower body of the device, a filter residue screen 7 is provided between the reaction chamber 1 and the waste residue chamber 6, and a piston feeding device 4 extending to the inside of the reaction chamber 1 is provided on the side of the upper end of the reaction chamber 1, and the piston feeding method is used to ensure the reaction. The sealing effect in the chamber 1, a blower 5 is provided on the side of the reaction chamber 1 opposite to the piston feeding device 4, and the reaction chamber 1 is provided with a rotating row 12, and several rows of teeth 13 are arranged crosswise on the rotating row 12, and med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com