An exhaust gas recovery, purification and recycling device and process for an annealing furnace system

A tail gas recovery and purification cycle technology, which is applied to the improvement of process efficiency, furnaces, furnace components, etc., can solve the problems that impurities cannot be effectively processed, increase equipment production costs, and increase processing problems, so as to ensure smooth flow and reduce maintenance rate , the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

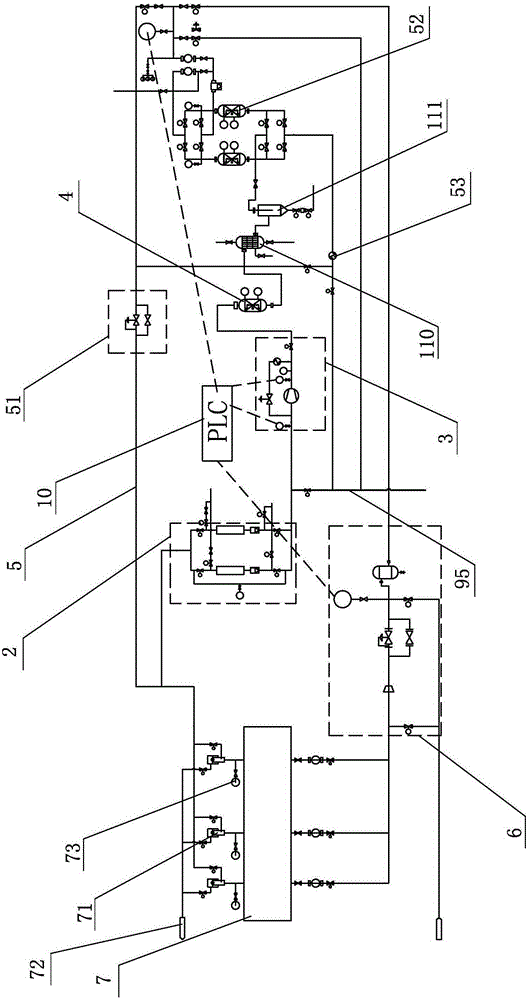

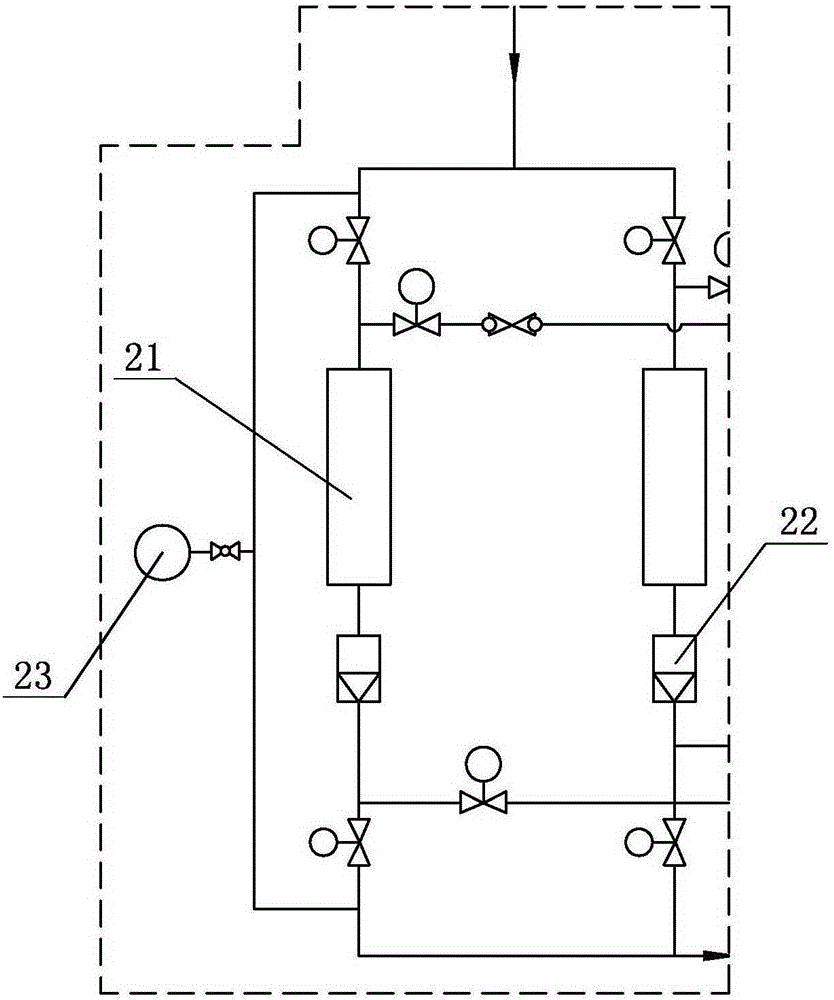

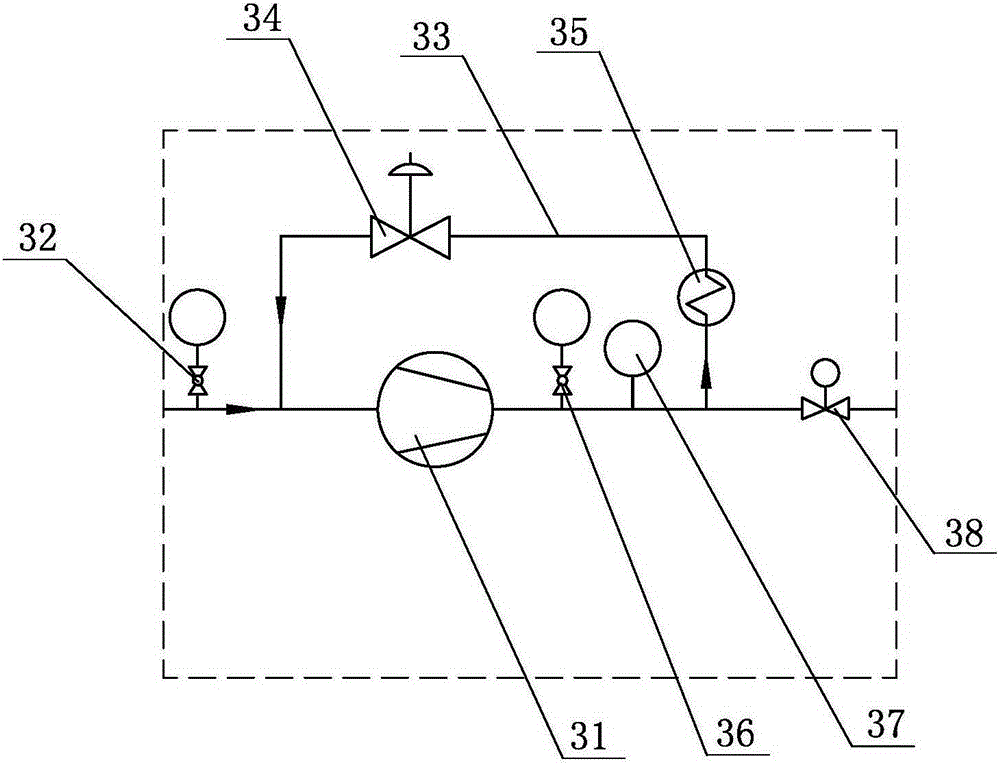

[0045] Example one: such as Figure 1~4 As shown, an exhaust gas recovery and purification recycling device of an annealing furnace system includes an adsorption purification device 2, a circulating power device 3, a catalytic purification device 4, a first cooler 110, a gas-water separator 111, an adsorption drying device, and connection In the pipeline between the parts, the air inlet of the adsorption purification device 2 is connected to the exhaust outlet of the annealing furnace 7, and the air outlet of the adsorption purification device 2 is connected to the circulating power device 3. The air outlet is connected to the first cooler 110, the gas-water separator 111 and the adsorption drying device in sequence after the catalytic purification device 4, and the air outlet of the adsorption drying device is connected to the air inlet of the annealing furnace 7 through the pipeline, so A first pressure regulating device 6 is provided on the pipeline.

[0046] A constant press...

Embodiment 2

[0062] Embodiment 2: A tail gas recovery and purification recycling device of an annealing furnace system, including an adsorption purification device, a circulating power device, a deaerator, a first cooler, a gas-water separator, an adsorption drying device, and a connection between each part Pipeline, the air inlet of the adsorption purification device is connected to the exhaust outlet of the annealing furnace, the air outlet of the adsorption purification device is connected to the circulating power device, and the air outlet of the circulating power device is sequentially connected after the deaerator Connected to the first cooler, the gas-water separator and the adsorption drying device, the air outlet of the adsorption drying device is connected to the air inlet of the annealing furnace through a pipeline, and the pipeline is provided with a first pressure regulating device.

[0063] In this embodiment, its structure is basically similar to that of the first embodiment. Th...

Embodiment 3

[0064] Example three: such as Figure 5 , 6 As shown, a tail gas recovery and purification recycling device of an annealing furnace system. In this embodiment, its structure is basically similar to that of the first embodiment. The difference lies in: the annealing furnace tail gas discharge port and the adsorption purification device 2 There is also a dust-removing and oil-collecting device 1 on the pipeline between them. The dust-removing and oil-collecting device 1 includes a front and a rear two-stage oil collector, a first-stage oil collector 11 and a second-stage oil collector 12, respectively. A cleaning port is provided, a cooling jacket is also provided on the outer wall of the oil collector, and bypass valves 13 are respectively provided on the inlet and outlet of the two-stage oil collector, such as Image 6 Shown. When working, the exhaust gas is blown into the oil collector in a direction tangential to the oil collector, and rotates along the inner wall of the oil c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com