A carbonaceous raw material fluidized bed pyrolysis product graded recovery system and recovery method thereof

A pyrolysis product, fluidized bed technology, which is applied in the direction of direct heating and dry distillation, the preparation of liquid hydrocarbon mixtures, and the petroleum industry, which can solve the problems of difficult processing, water consumption, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

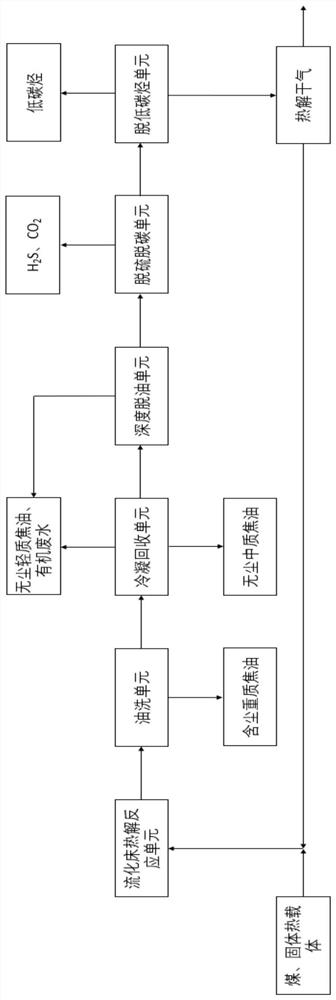

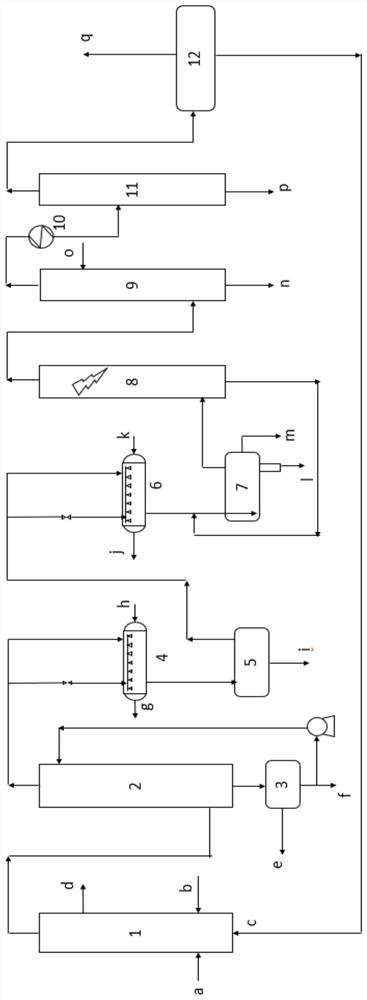

[0053] The schematic diagram of the process flow of the carbonaceous raw material fluidized bed pyrolysis product classification recovery method in this embodiment is as follows figure 2 shown. The raw material, solid heat carrier and fluidization gas enter the fluidized bed pyrolysis reactor 1 through raw material inlet a, solid heat carrier inlet b and fluidization gas inlet c respectively. The pyrolysis reaction is carried out in the fluidized bed pyrolysis reactor 1, and the pyrolysis reaction is operated under normal pressure. The pyrolysis semi-coke is discharged from the pyrolysis semi-coke outlet d located in the upper middle part of the fluidized bed pyrolysis reactor 1, and the pyrolysis oil gas is discharged from the top of the fluidized bed pyrolysis reactor 1 and enters through the gas inlet at the bottom of the oil washing tower 2 The oil scrubber 2, the oil scrubber 2 washes pyrolysis oil gas countercurrently with cold tar, recovers heavy tar and removes dust ...

Embodiment 2

[0059] Example 2 was completed in the process flow described in Example 1. The coal sample A used was dried and pulverized into a 40-80 mesh pulverized coal sample. The industrial analysis and elemental analysis of the sample are shown in Table 1.

[0060] Table 1 Industrial analysis and elemental analysis of coal samples

[0061] Coal sample A Coal sample B Industrial Analysis M ad

0.65 5.83 A d

11.03 11.47 V daf

33.45 38.40 FC daf

66.55 61.60 Elemental analysis / daf C 79.86 71.47 H 4.47 4.29 N 1.07 1.10 S 1.33 1.39 O 13.27 21.75

[0062] The pyrolysis temperature of the fluidized bed pyrolysis reactor is 600°C, and the selected fluidization velocity is 0.8m / s. The feeding amount of pulverized coal raw material A is 100t / h.

[0063] The oil washing tower recovers 4.7t / h of dusty heavy tar.

[0064] The first-stage heat exchanger recovers 3.6t / h of dust-free medium tar; the...

Embodiment 3

[0068] The coal sample B used in Example 3 was dried and pulverized into a 40-80 mesh pulverized coal sample. The industrial analysis and elemental analysis of the sample are shown in Table 1.

[0069] The pyrolysis temperature of the fluidized bed pyrolysis reactor is 550° C., and the fluidization velocity is 0.8 m / s. The feeding amount of pulverized coal raw material B is 100t / h.

[0070] The oil washing tower recovers 6.2t / h of dusty heavy tar.

[0071] The first-stage heat exchanger recovers 5.3t / h of dust-free medium tar; the second-stage heat exchanger recovers 1.1t / h of dust-free light tar, and at the same time discharges 6.2t / h of organic wastewater.

[0072] Desulfurization and decarbonization unit recovers CO 2 and H 2 S is 2916Nm respectively 3 / h and 93Nm 3 / h.

[0073] The recovery of low-carbon hydrocarbons by the low-carbon hydrocarbon removal unit is 1.61t / h, and the pyrolysis dry gas is 7700Nm 3 / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com