An integrated downdraft biomass gasification power generation system and method

A power generation system, biomass technology, applied in the gasification process, gasification device details, chemical industry, etc., can solve the problems of high tar content of combustible gas, low energy utilization rate, large and complex system, etc., to improve operating efficiency, Good production environment and high economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

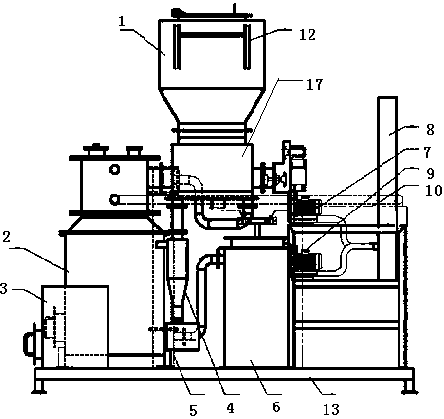

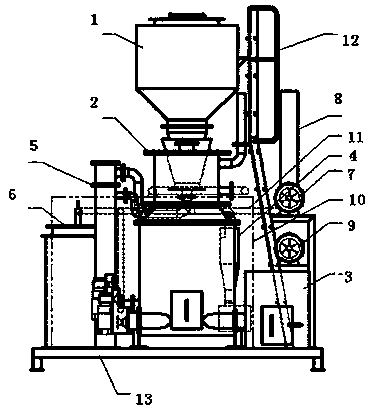

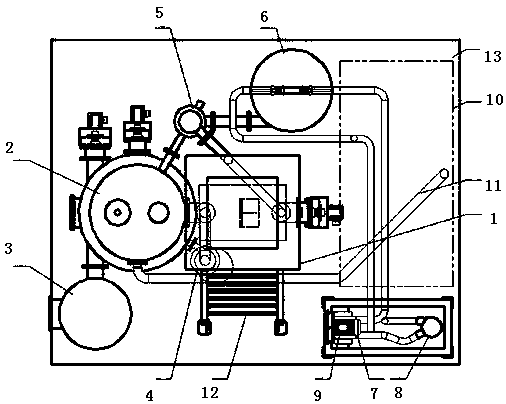

[0051] The specific embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0052] Such as figure 1 , 2 , 3 and 4, an integrated downdraft biomass gasification power generation system, including a hopper 1, a reactor 2, a dust removal device 4, an air preheater 5, an activated carbon adsorber 6, a gas The fan 7, the torch 8, the air fan 9, the gas generator set 10, and the base 13. The hopper 1 includes a drying chamber 17 and a conveying device 14. The wall of the drying chamber 17 is composed of two layers of shells. A jacketed cavity is formed between the bodies. The conveying device 14 conveys the materials in the drying chamber 17 to the reactor 2. The gas outlet of the reactor 2 is connected to the gas inlet of the dust removal device 4, and the dust removal device 4 The gas outlet of the air preheater 5 is connected to the gas inlet of the hopper drying chamber 17, the gas inlet of the air preheater 5 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com