Dicyclopentadiene-cyclopentene copolymer and preparation method thereof

A technology of cyclopentene copolymer and dicyclopentadiene, which is applied in the field of dicyclopentadiene-cyclopentadiene copolymer and its preparation, can solve the problems of high preparation cost, low production efficiency, long reaction time, etc., and achieve anti- Improved impact strength and bending performance, improved impact strength, and good material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

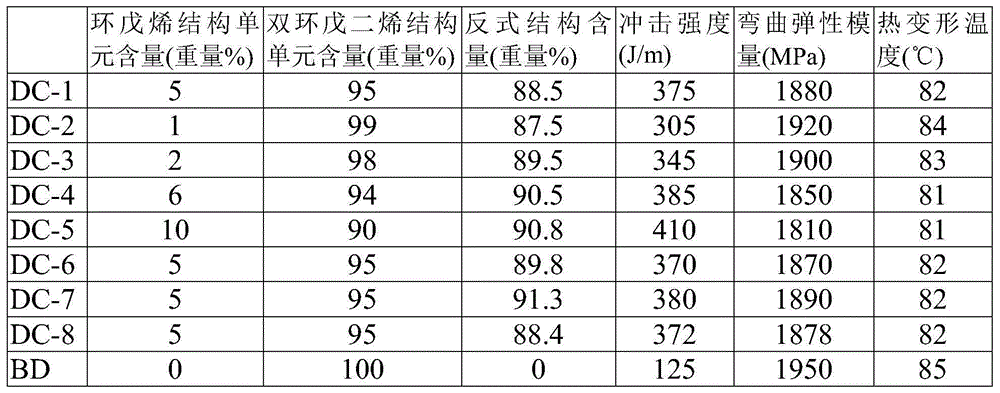

[0023] The present invention also provides a preparation method of dicyclopentadiene-cyclopentene copolymer, the method comprising: injecting solution A and solution B into a mold for reaction injection molding to obtain dicyclopentadiene-cyclopentene copolymer wherein, solution A contains a catalyst and a stabilizer, solution B contains an activator and a polymerization reaction time regulator, and at least one of solution A and solution B contains dicyclopentadiene, and at least one of solution A and solution B also contains Containing cyclopentene, the weight ratio of dicyclopentadiene to cyclopentene is 99-90:1-10; preferably, the weight ratio of dicyclopentadiene to cyclopentene is 98-94:2-6.

[0024] Reaction Injection Molding (RIM) is a method of injecting liquid monomers or low-viscosity copolymers directly into a mold for rapid polymerization. Short cycle, low energy consumption, low cost and good product quality.

[0025] In the presence of a catalyst, dicyclopentad...

Embodiment 1

[0046] This example is used to illustrate the preparation method of the dicyclopentadiene-cyclopentene copolymer provided by the present invention.

[0047] (1) Prepare solution A

[0048] Add catalyst bis(2,6 di-tert-butylphenoxy)tungsten tetrachloride 15g, dicyclopentadiene (dicyclopentadiene Purity>97%) 2750g, cyclopentene (cyclopentene purity greater than 99%) 250g and benzyl acetonitrile 0.075g, of which two (2,6 di-tert-butylphenoxy) tungsten tetrachloride: (dicyclopentadiene + cyclopentene): benzyl acetonitrile (weight ratio) = 1:200:0.005.

[0049] (2) Prepare Solution B

[0050] Add 18g of diethylaluminum chloride, 2g of diethylzinc, and 2000g of dicyclopentadiene (purity of dicyclopentadiene >97%) into tank B of the reaction injection molding machine at a temperature of 40±5°C and nitrogen protection and diethylene glycol dimethyl ether 300g. Wherein (diethylaluminum chloride+diethylzinc): dicyclopentadiene: diethylene glycol dimethyl ether (weight ratio) = 1:100...

Embodiment 2

[0058] This example is used to illustrate the preparation method of the dicyclopentadiene-cyclopentene copolymer provided by the present invention.

[0059] (1) Prepare solution A

[0060] Add catalyst bis(p-methylphenoxy)tungsten tetrachloride 15g, dicyclopentadiene (purity of dicyclopentadiene>97% ) 2950g, cyclopentene (cyclopentene purity greater than 99%) 50g and benzonitrile 0.15g; wherein two (p-methylphenoxy) tungsten tetrachloride: (dicyclopentadiene + cyclopentene): benzyl Formaldehyde (weight ratio)=1:200:0.01.

[0061] (2) Prepare Solution B

[0062] Add 9 g of diethyl aluminum chloride, 1 g of diethyl zinc, and 2000 g of dicyclopentadiene (purity of dicyclopentadiene >97%) into tank B of the reaction injection molding machine at a temperature of 40±5°C and nitrogen protection And diethylene glycol dibutyl ether 200g. Wherein (diethylaluminum chloride+diethylzinc): dicyclopentadiene: diethylene glycol dibutyl ether (weight ratio) = 1:200:20.

[0063] Where (dic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com