A Continuous and Forced Asphalt Mixing Production Method

一种沥青拌合、相结合的技术,应用在混合机、预处理控制、搅拌机配件等方向,能够解决增加公司经营成本、损耗时间和电能、污染环境等问题,达到避免沥青烟气外泄、提高使用寿命、提高安全性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

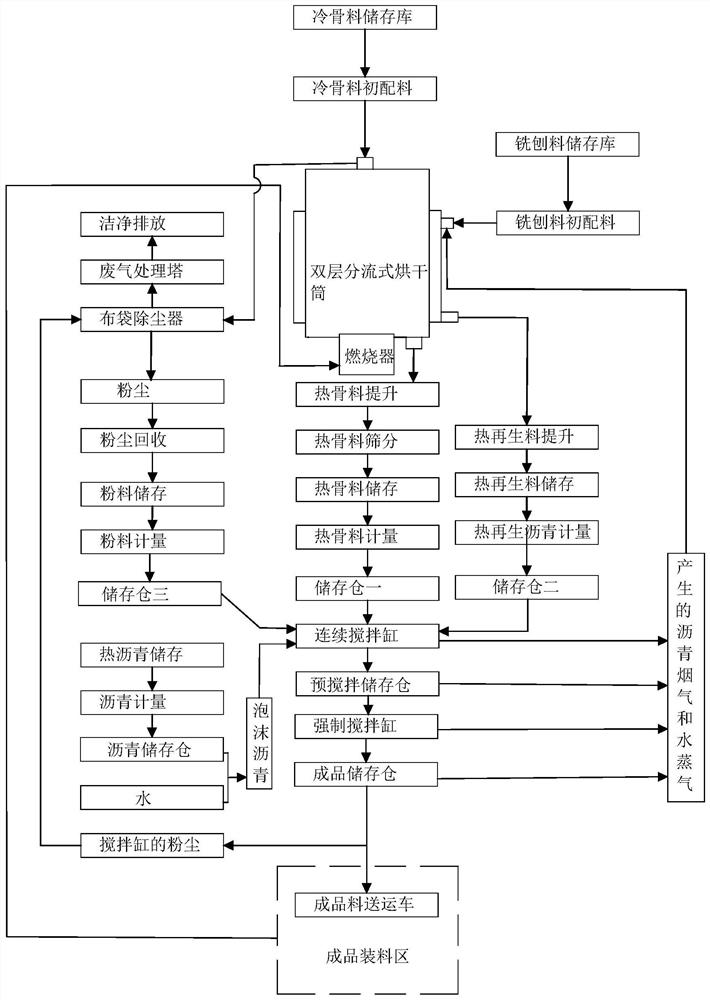

[0073] Embodiment 1-1: a kind of asphalt mixing production method combining continuous type and forced type, such as figure 1 shown, including the following steps:

[0074] In step one,

[0075] A1. According to the grading requirements, the new material is initially batched at room temperature to obtain cold aggregate, wherein the cold aggregate contains 18-31.5mm crushed stone, 10-20mm crushed stone and 5-10mm crushed stone, and The weight ratio of 18-31.5mm gravel, 10-20mm gravel and 5-10mm gravel is 21:18:18.

[0076] A2. The cold aggregate is discharged into the inner cylinder of the double-layer split-type drying drum for combustion. When the temperature of the double-layer split-type drying drum is raised to 100°C, the cold aggregate is first dried, and then the double-layer split-type drying drum is continuously raised. The temperature of the split drying cylinder is 200°C, and the cold aggregate is heated to 180°C to obtain hot aggregate.

[0077] A3. The hot aggre...

Embodiment 2-1

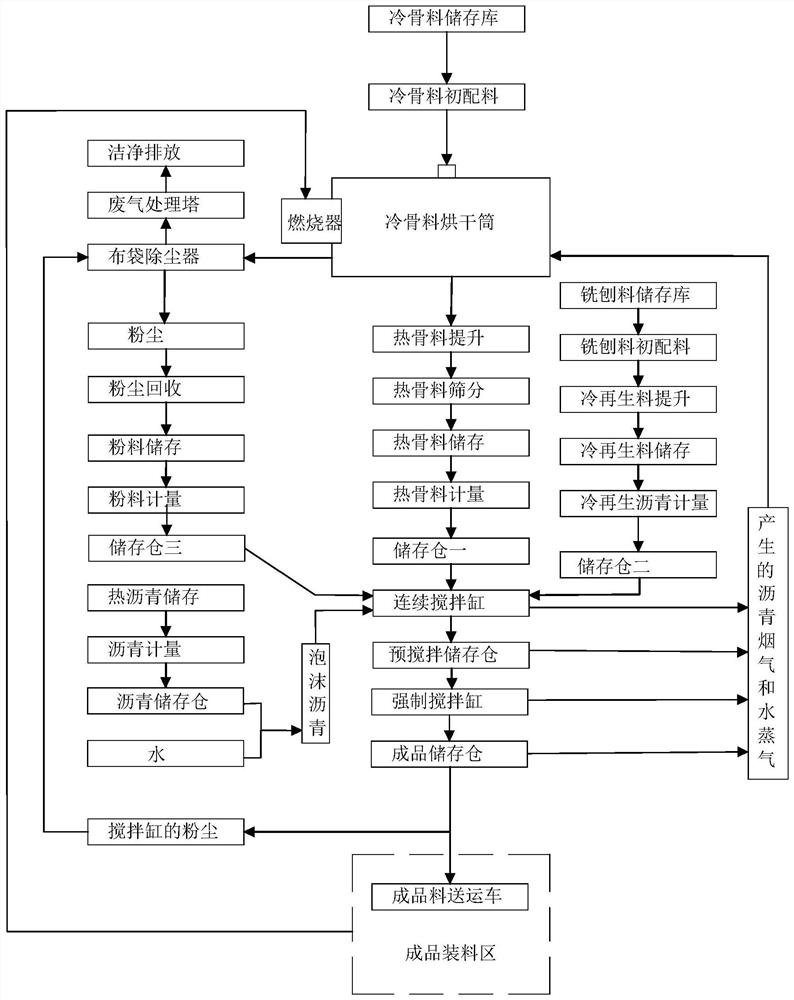

[0094] Embodiment 2-1: a kind of asphalt mixing production method combining continuous type and forced type, comprising the following steps:

[0095] In step one,

[0096] A1. According to the grading requirements, the new material is initially batched at room temperature to obtain cold aggregate, wherein the cold aggregate contains 18-31.5mm crushed stone, 10-20mm crushed stone and 5-10mm crushed stone, and The weight ratio of 18-31.5mm gravel, 10-20mm gravel and 5-10mm gravel is 22:20:19.

[0097] A2. The cold aggregate is discharged into the inner cylinder of the double-layer split-type drying drum for combustion. When the temperature of the double-layer split-type drying drum is raised to 110°C, the cold aggregate is first dried, and then the double-layer split-type drying drum is continuously raised. The temperature of the split-flow drying cylinder is 210°C, and the cold aggregate is heated to 190°C to obtain hot aggregate.

[0098] A3. The hot aggregate is temporarily...

Embodiment 3-1

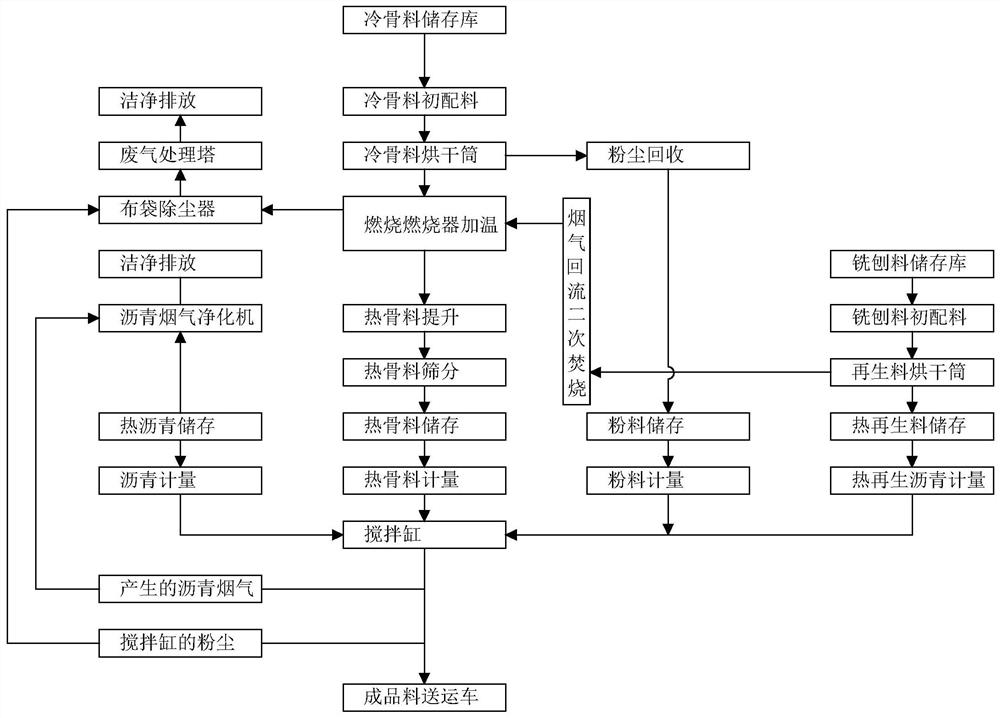

[0114] Embodiment 3-1: a kind of asphalt mixing production method combining continuous type and forced type, comprising the following steps:

[0115] In step one,

[0116] A1. According to the grading requirements, the new material is initially batched at room temperature to obtain cold aggregate, wherein the cold aggregate contains 18-31.5mm crushed stone, 10-20mm crushed stone and 5-10mm crushed stone, and The weight ratio of 18-31.5mm gravel, 10-20mm gravel and 5-10mm gravel is 23:25:20.

[0117] A2. The cold aggregate is discharged into the inner cylinder of the double-layer split-type drying drum for combustion. When the temperature of the double-layer split-type drying drum is raised to 120°C, the cold aggregate is first dried, and then the double-layer split-type drying drum is continuously raised. The temperature of the split-flow drying cylinder is 220°C, and the cold aggregate is heated to 200°C to obtain hot aggregate.

[0118] A3. The thermal aggregate is tempora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com