Combustor reducing emission of nitrogen oxide, gas boiler and control method

A burner and combustion chamber technology, which is applied in the field of gas-fired boilers and control and burners for reducing nitrogen oxide emissions, can solve the problems of increased cost, complex structure and control system, limited nitrogen oxide potential, etc., to reduce the peak flame Temperature, simple structure, and the effect of reducing nitrogen oxide emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0047] In an exemplary embodiment of the present invention, a burner that reduces emissions of nitrogen oxides is provided. The burner is suitable for 1t / h gas boiler with natural gas as fuel.

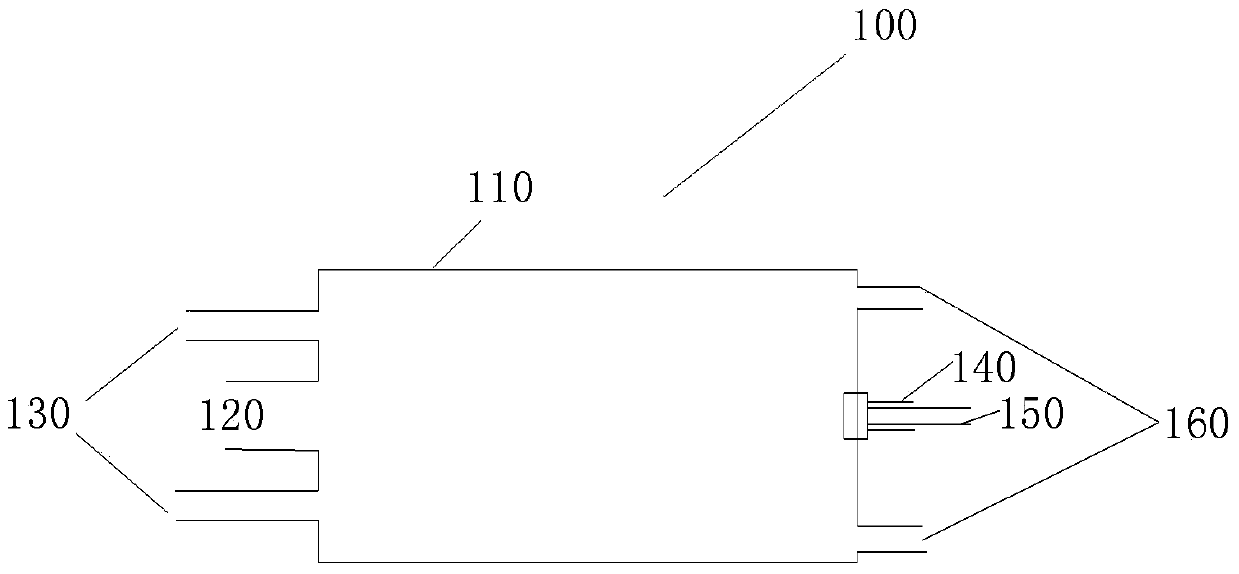

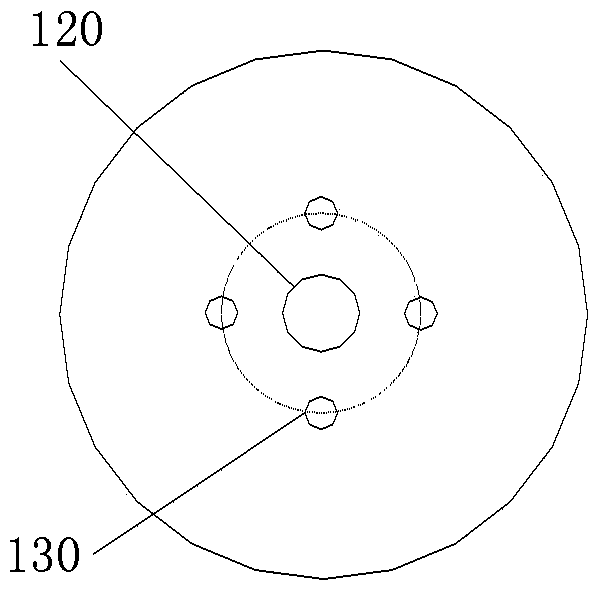

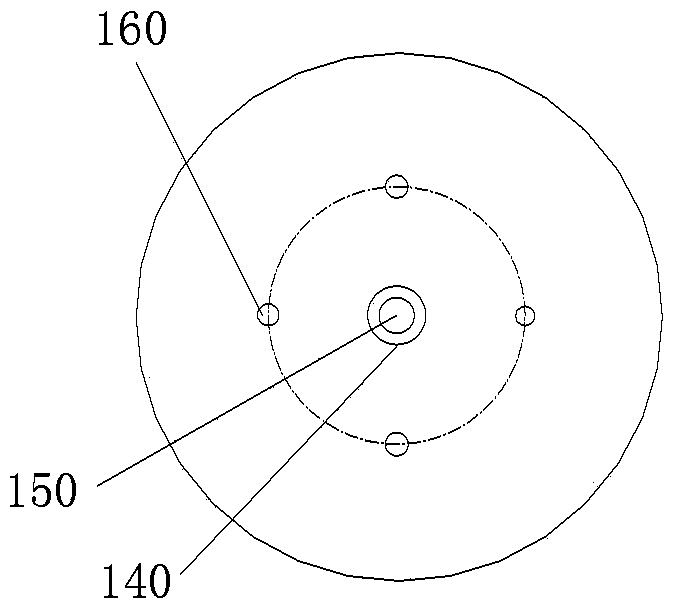

[0048] figure 1 It is a structural schematic diagram of a burner for reducing emissions of nitrogen oxides according to an embodiment of the present invention. Figure 2A and Figure 2B respectively figure 1 Left and right views of the burner shown. Such as figure 1 , Figure 2A and Figure 2B As shown, the burner 100 for reducing nitrogen oxide emissions in this embodiment includes:

[0049] The burner body 110 is a cylindrical combustion chamber surrounded by its front wall, cylindrical radiation wall and rear wall;

[0050] The flue gas outlet channel 120 is arranged at the center of the front wall of the burner body 110 and communicates with the combustion chamber;

[0051] Four main air nozzles 130 are arranged on the front wall of the burner body 110, and the radial peri...

no. 3 example

[0079] In yet another embodiment of the present invention, a method for controlling the above-mentioned burner is also provided.

[0080] In the burner provided by the first embodiment, the main air supply line, the main fuel supply line, the auxiliary air supply line and the auxiliary fuel supply line are all controlled by electric shut-off valves.

[0081] Figure 7 for figure 1 Flowchart of the control method for the shown burner. Such as Figure 7 As shown, the control method of the burner includes:

[0082] Step A: Open the electric cut-off valves of the auxiliary fuel supply pipeline and the auxiliary air supply pipeline, feed 50% of the total fuel into the auxiliary fuel nozzle 150, feed 60% of the total air into the auxiliary air nozzle 140, and ignite and burn , to preheat the combustion chamber;

[0083] In order to ensure stable and soft combustion in the burner, the auxiliary air nozzles 140 and auxiliary fuel nozzles 150 are required to preheat the cylindrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com