Mixed gas combustor

A technology for mixing gas and burners, applied in the directions of gas fuel burners, burners, combustion methods, etc., can solve the problems that the type of gas burners cannot be adapted, the combustion characteristics of gas fuels are very different, and save equipment costs and The effect of running costs, large pipe size, and low gas pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

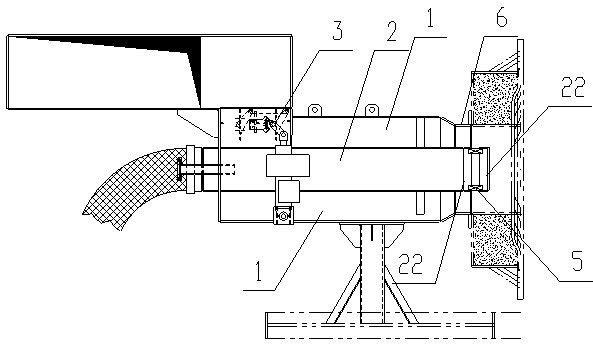

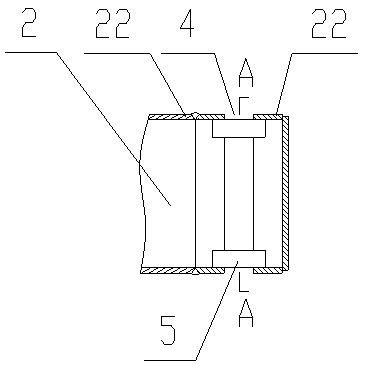

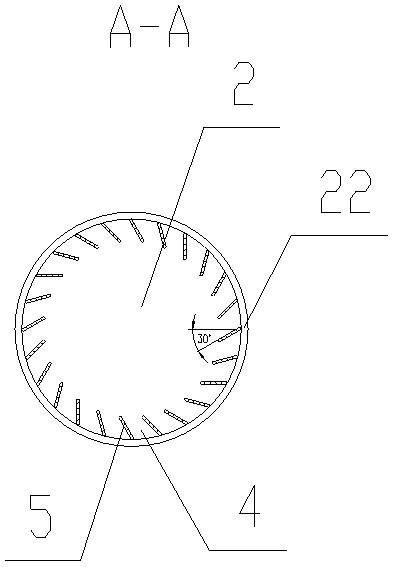

[0028] like Figures 1 to 3 As shown, the new mixed gas burner is a circular burner. Each burner is composed of two channels nested inside and outside. The air inlet is provided with a damper baffle 3 for adjusting the air intake. A single large-sized air gun tube (gas channel 2) is arranged in the center of the burner, and the nozzle hole 4 at the front end of the air gun (gas channel 2) is formed by dividing 5 segments with 22 built-in tangential blades. The area of the nozzle hole 4 is large, and the gas ejection speed relatively low. The vanes are preferably inclined by 30° relative to the radial direction of the gas channel. The burner nozzle 6 adopts a constricted type, which can strengthen the mixing of fuel and air, and make the mixed gas fuel have an appropriate flow velocity. The nozzle hole 4 of the air gun (gas channel 2) is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com