Patents

Literature

31results about How to "Reduce ejection speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

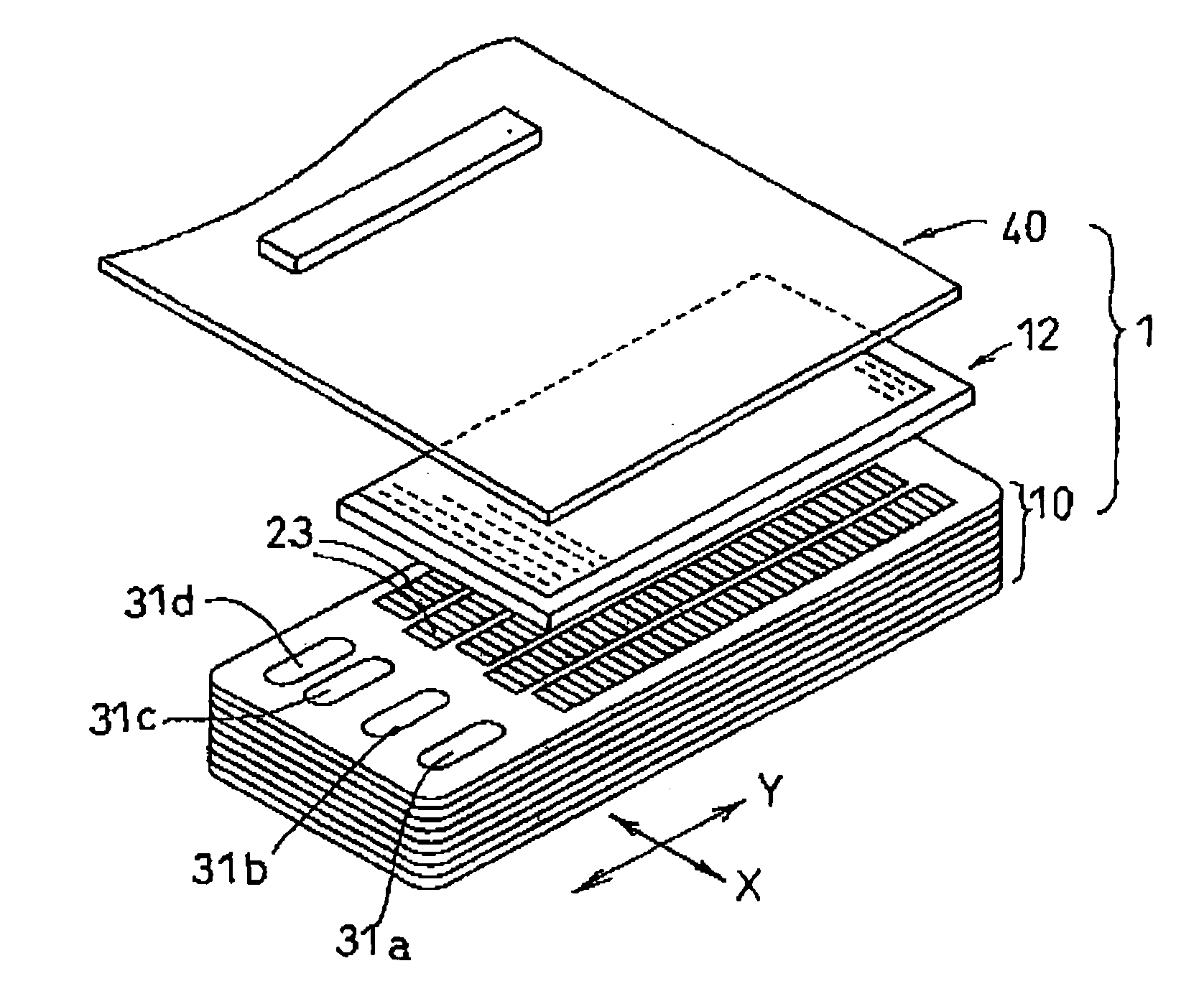

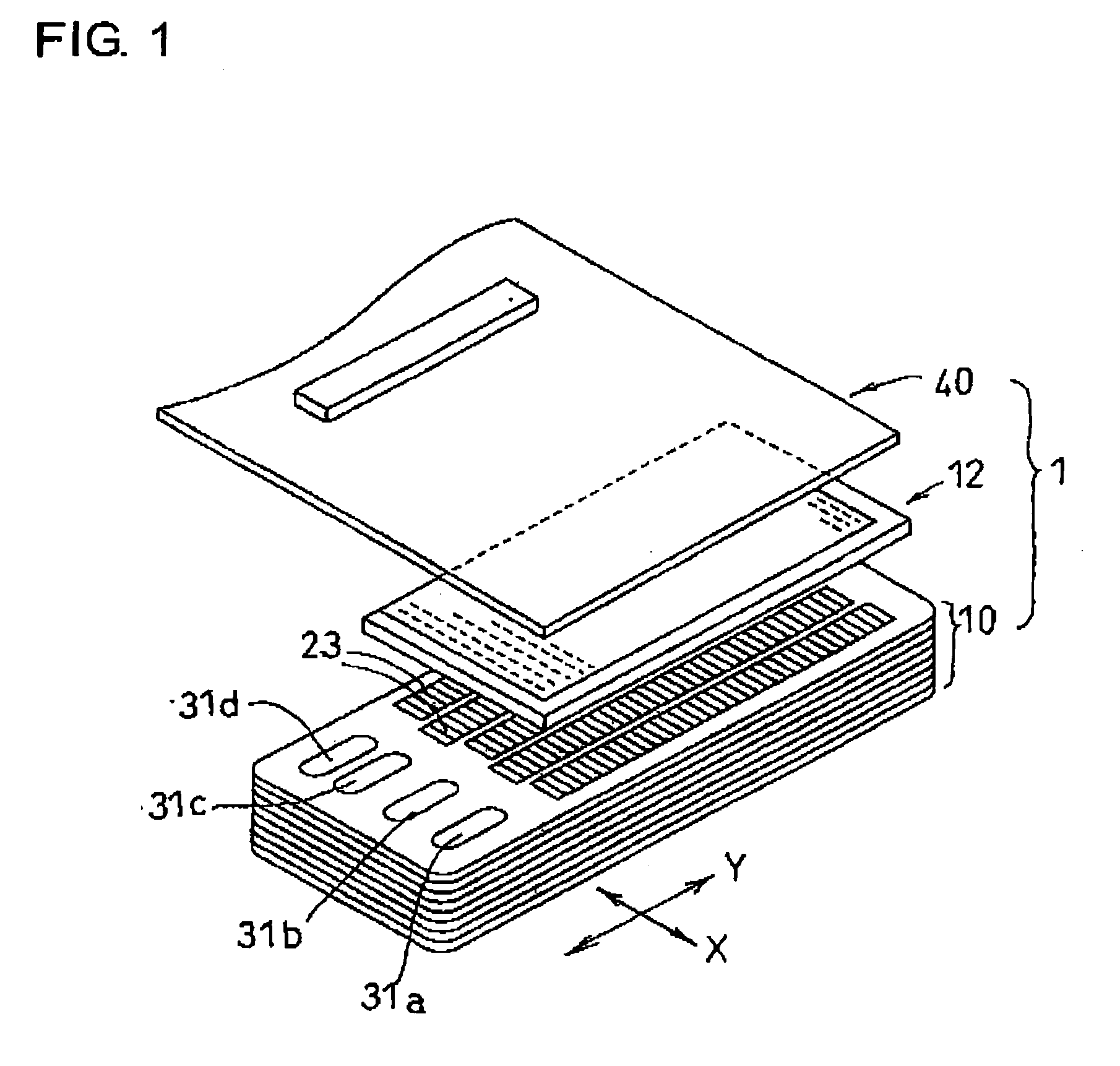

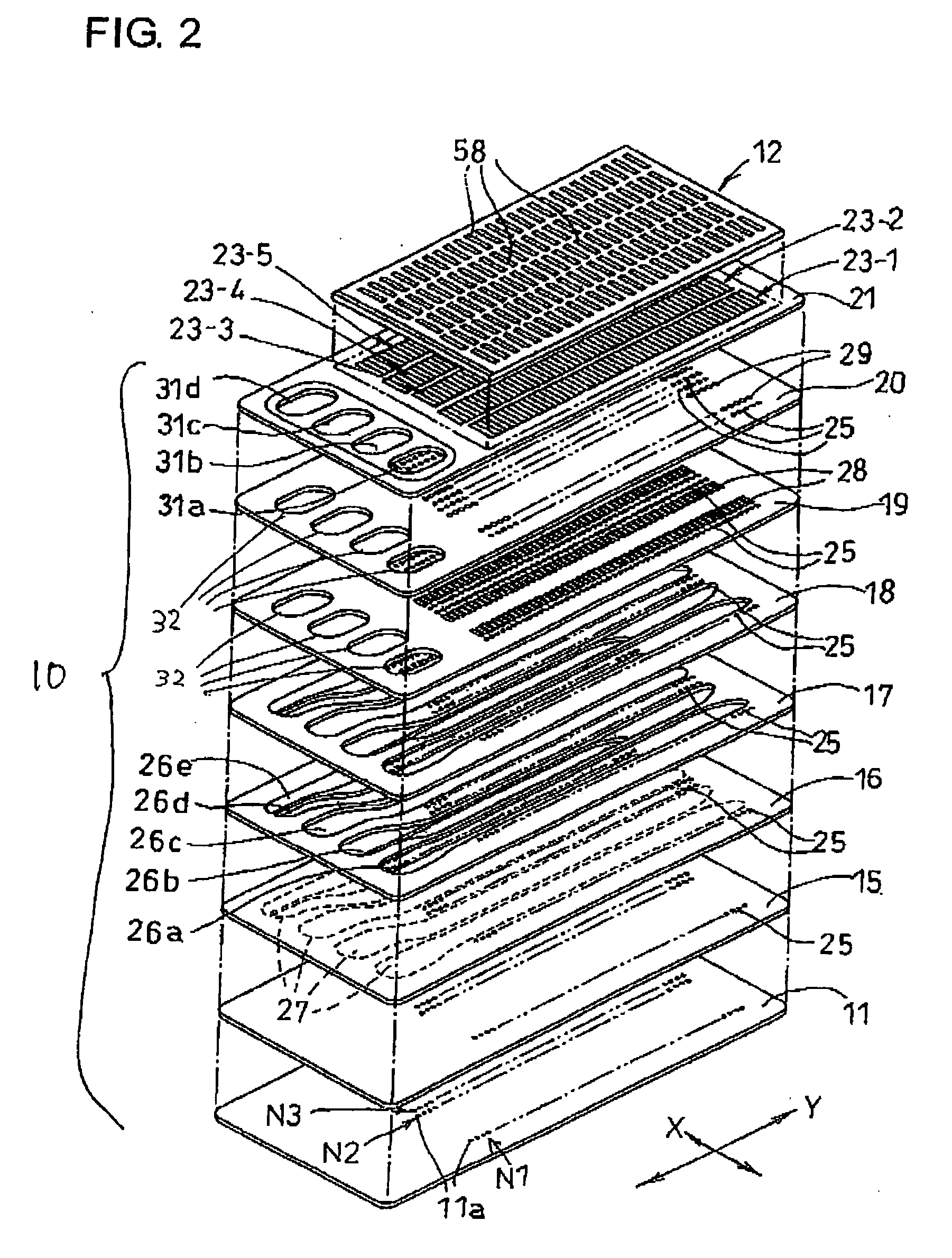

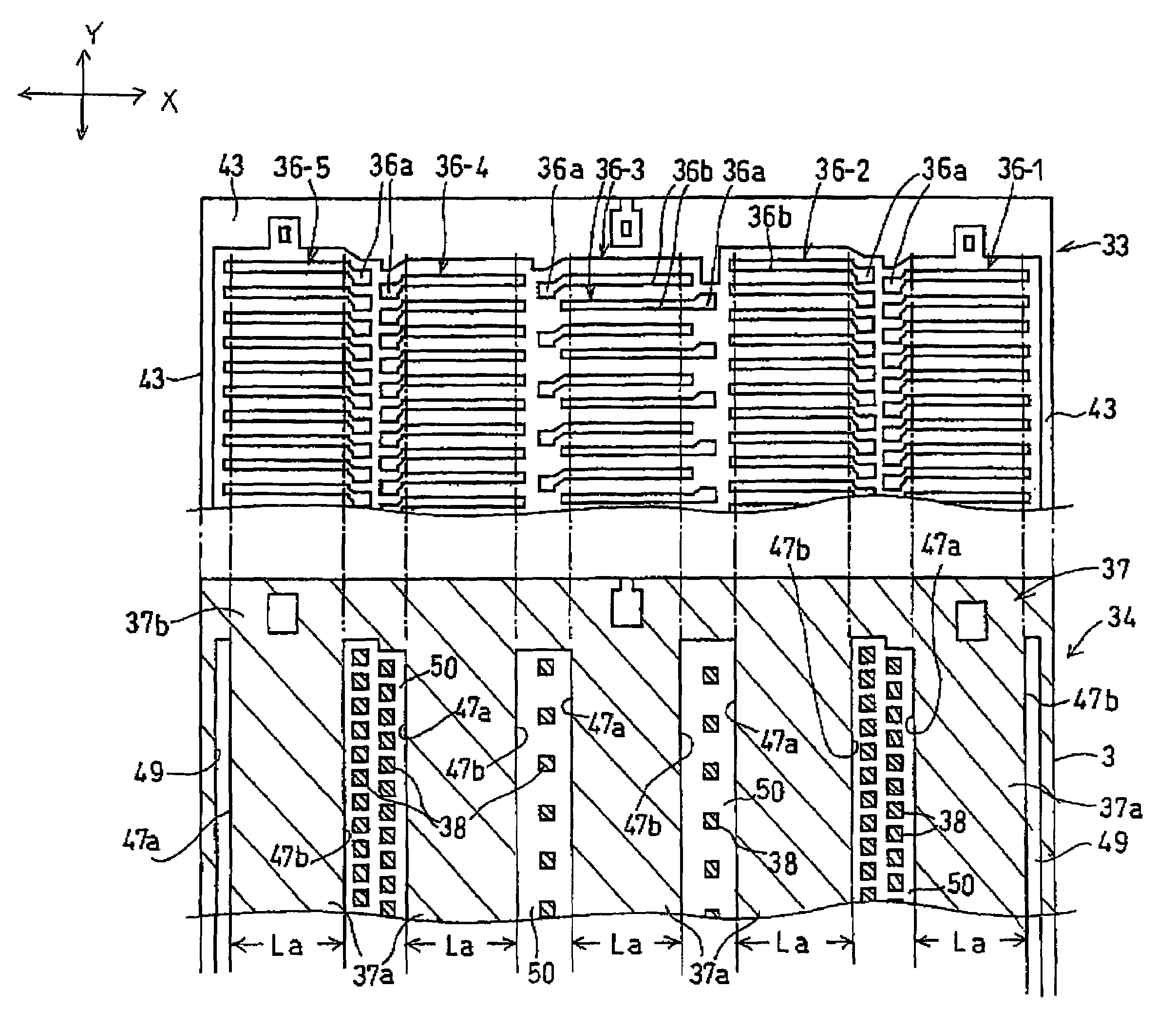

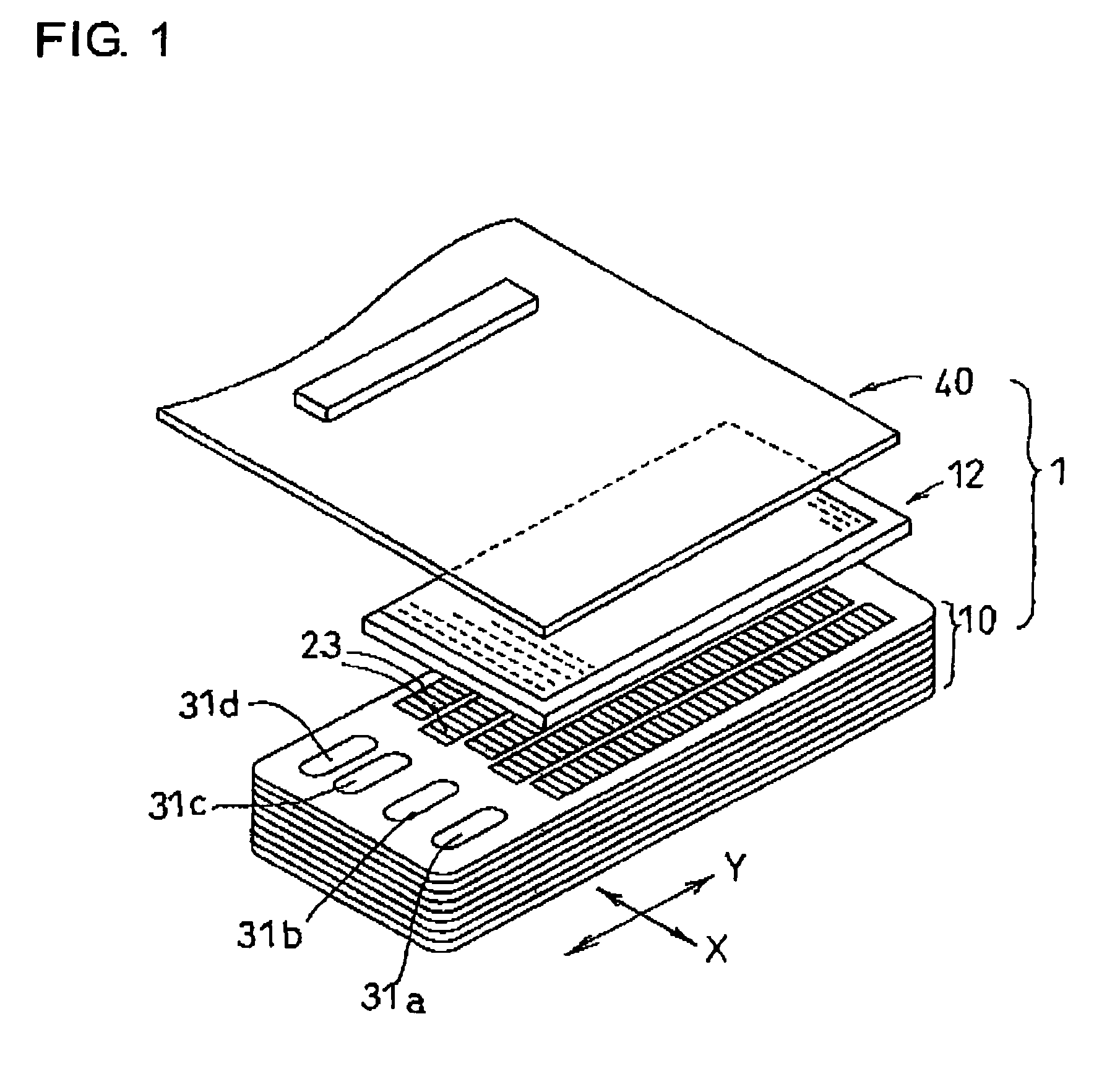

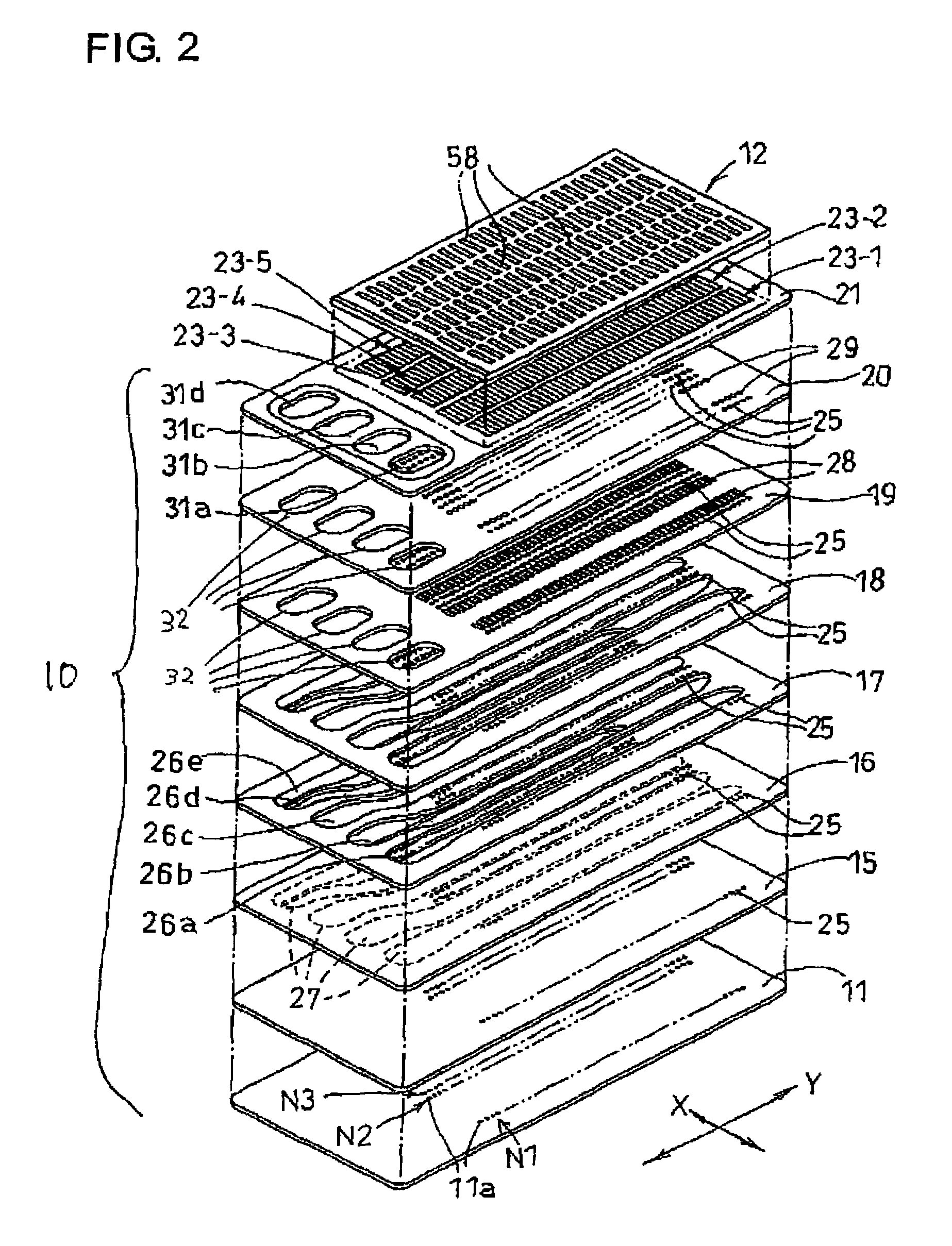

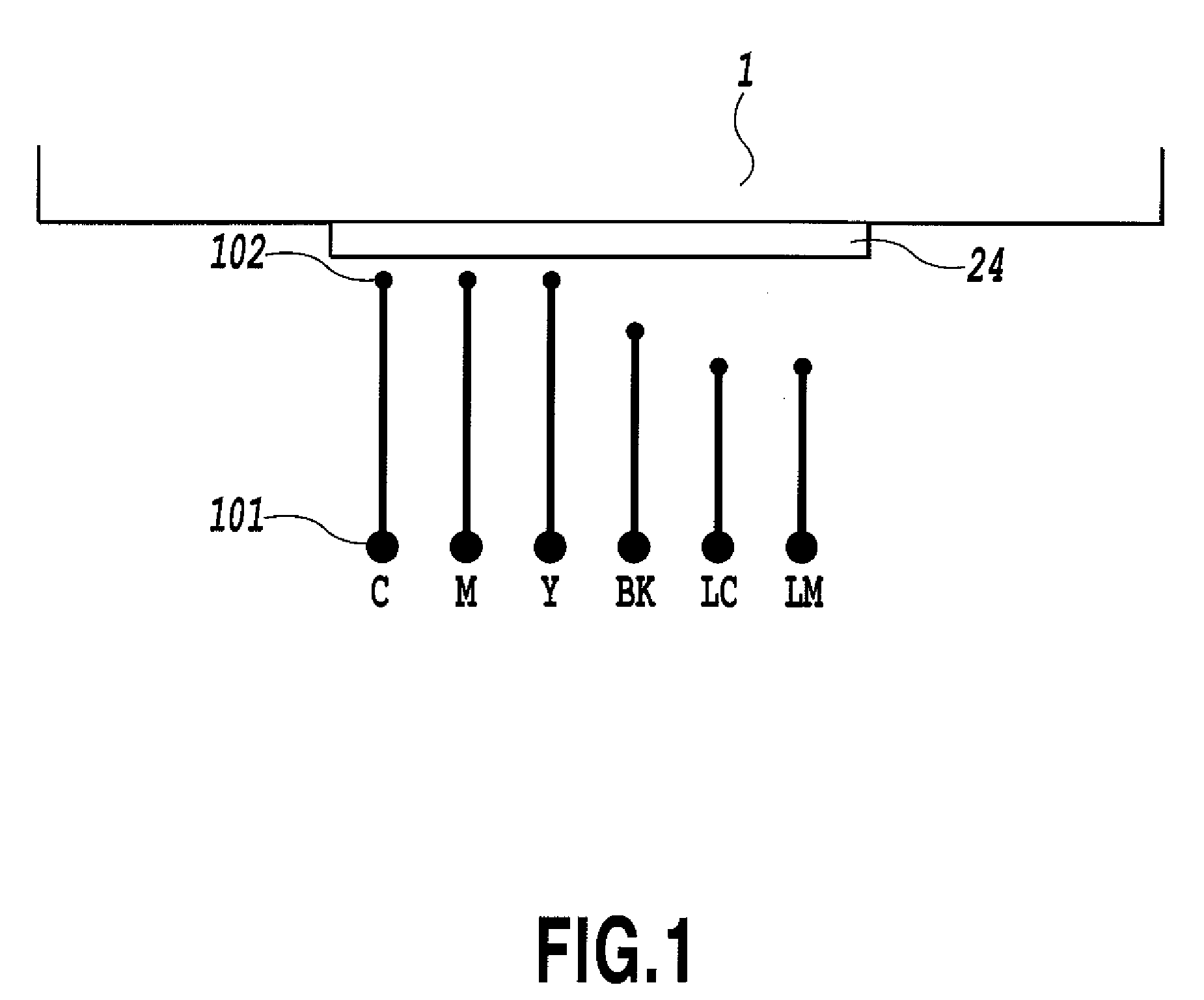

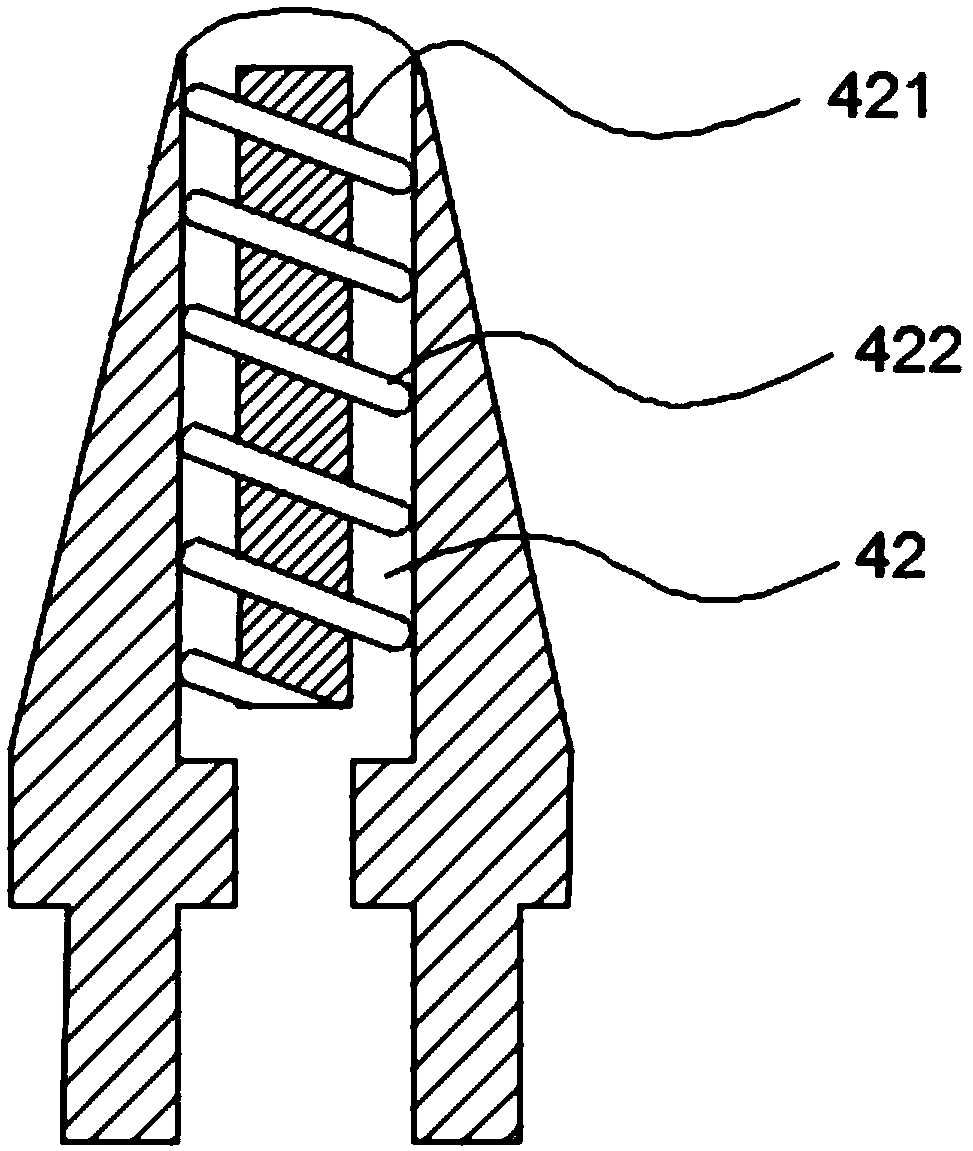

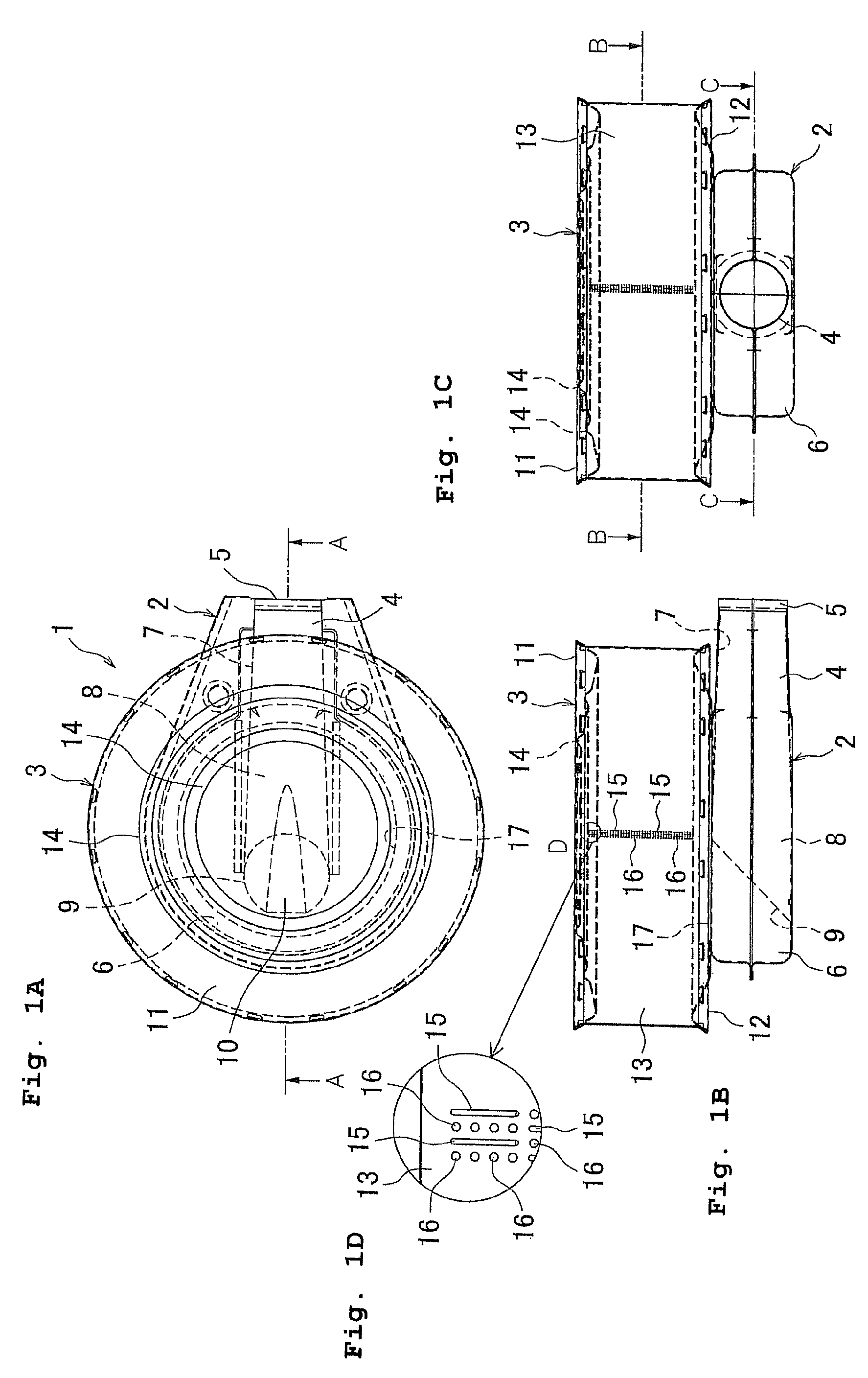

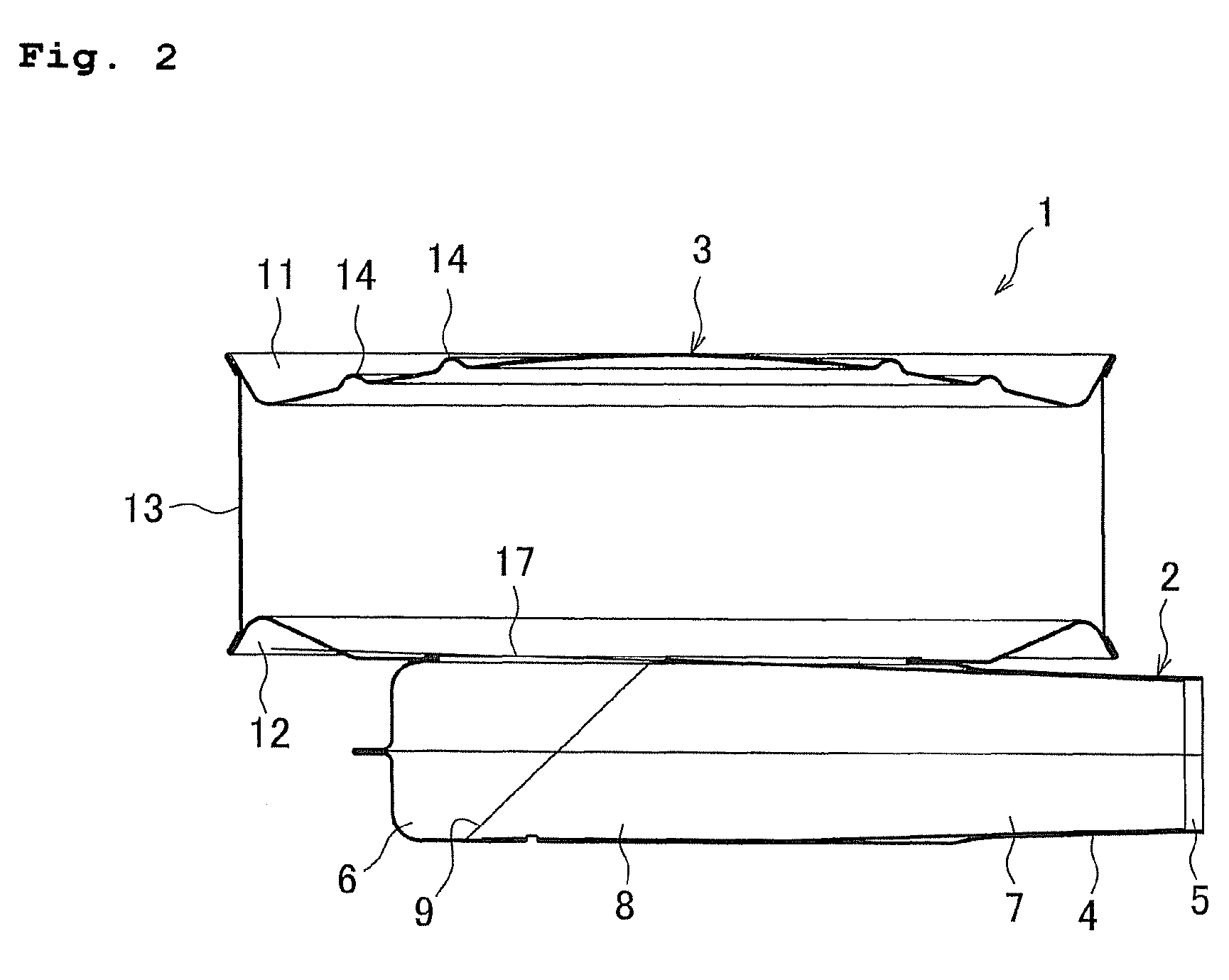

Laminated-type piezoelectric element and inkjet recording head having the same

ActiveUS20050253488A1Improve recording qualityReduce ejection speedPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesBand shapeBiomedical engineering

A laminated-type piezoelectric element includes first electrode layers defining individual electrodes, second electrode layers defining common electrodes, and piezoelectric sheets sandwiched between the first and second electrode layers. The first and second electrode layers are laminated alternately. Each individual electrode has a substantially rectangle shape extending in a first direction. The individual electrodes defined in each first electrode layer are arranged at predetermined intervals in a second direction perpendicular to the first direction, to form a row. The common electrode includes a first portion having a band shape. The first portion overlaps the row when viewed in a plan view. The first portion has a pair of edges extending to be perpendicular to a long side of the rectangle shape of each individual electrode. Both ends of each individual electrode in the first direction protrude to outer positions than the edges, when viewed in the plan view.

Owner:BROTHER KOGYO KK

Laminated-type piezoelectric element and inkjet recording head having the same

ActiveUS7294952B2Simple structureQuality improvementPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesBand shapeBiomedical engineering

A laminated-type piezoelectric element includes first electrode layers defining individual electrodes, second electrode layers defining common electrodes, and piezoelectric sheets sandwiched between the first and second electrode layers. The first and second electrode layers are laminated alternately. Each individual electrode has a substantially rectangle shape extending in a first direction. The individual electrodes defined in each first electrode layer are arranged at predetermined intervals in a second direction perpendicular to the first direction, to form a row. The common electrode includes a first portion having a band shape. The first portion overlaps the row when viewed in a plan view. The first portion has a pair of edges extending to be perpendicular to a long side of the rectangle shape of each individual electrode. Both ends of each individual electrode in the first direction protrude to outer positions than the edges, when viewed in the plan view.

Owner:BROTHER KOGYO KK

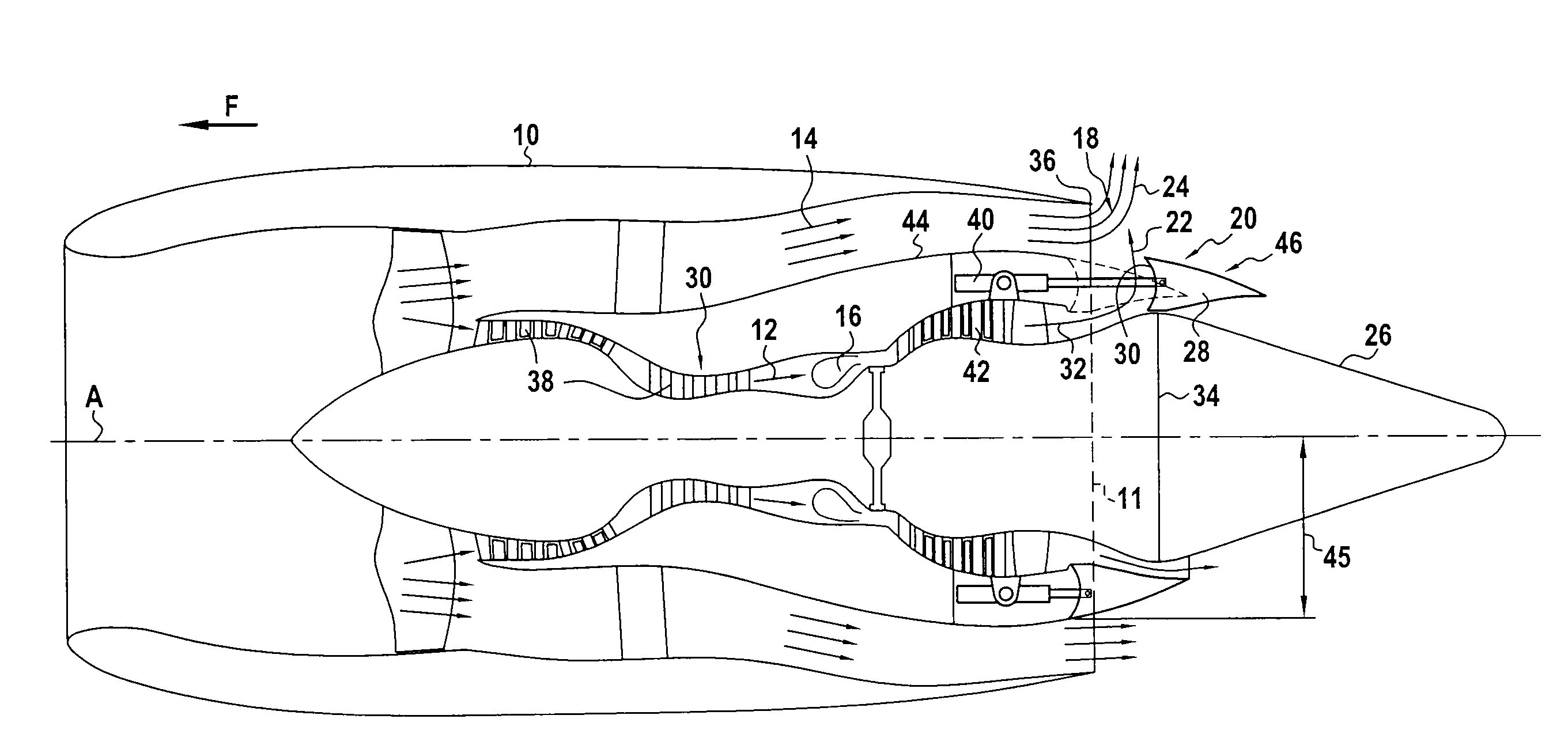

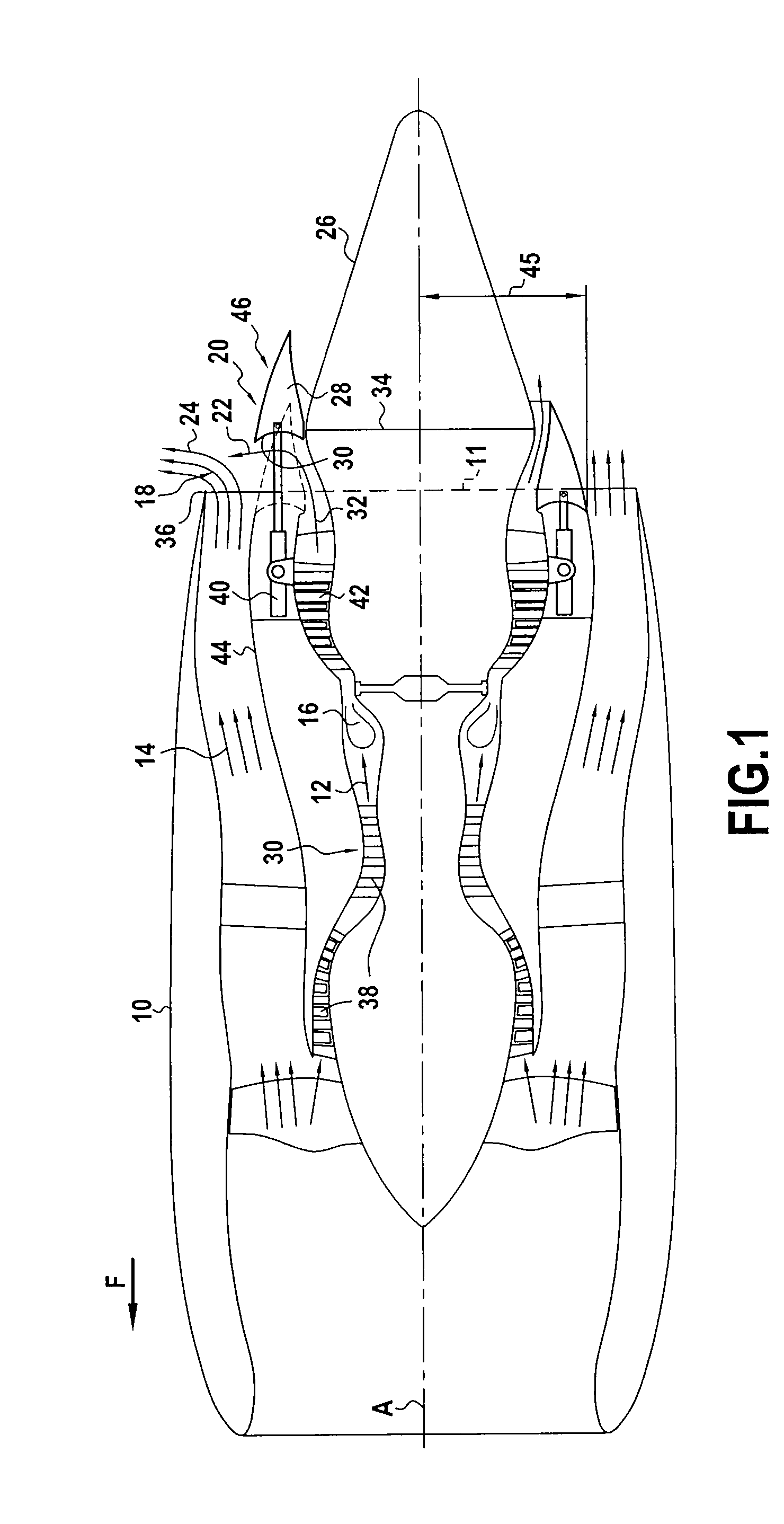

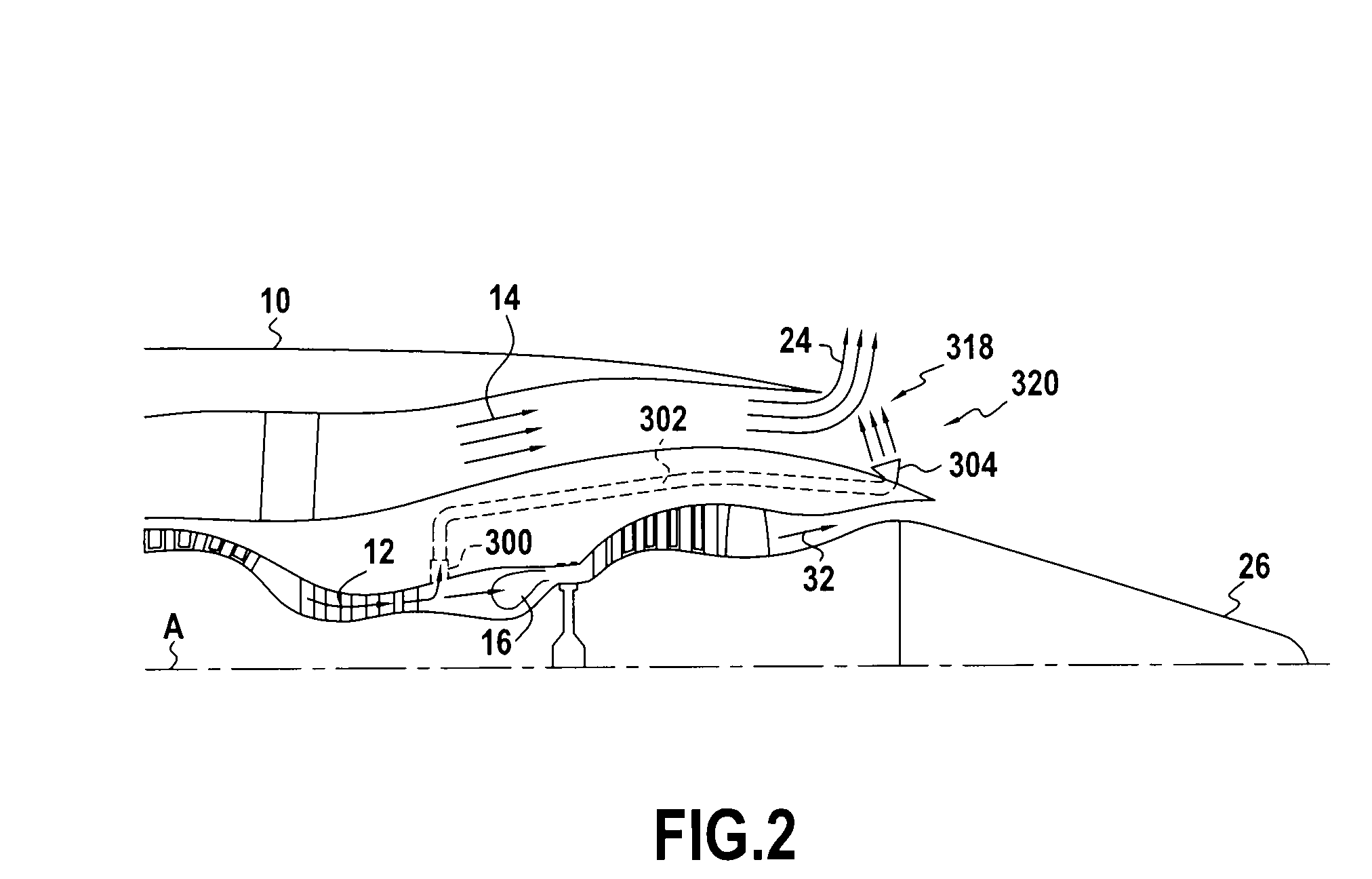

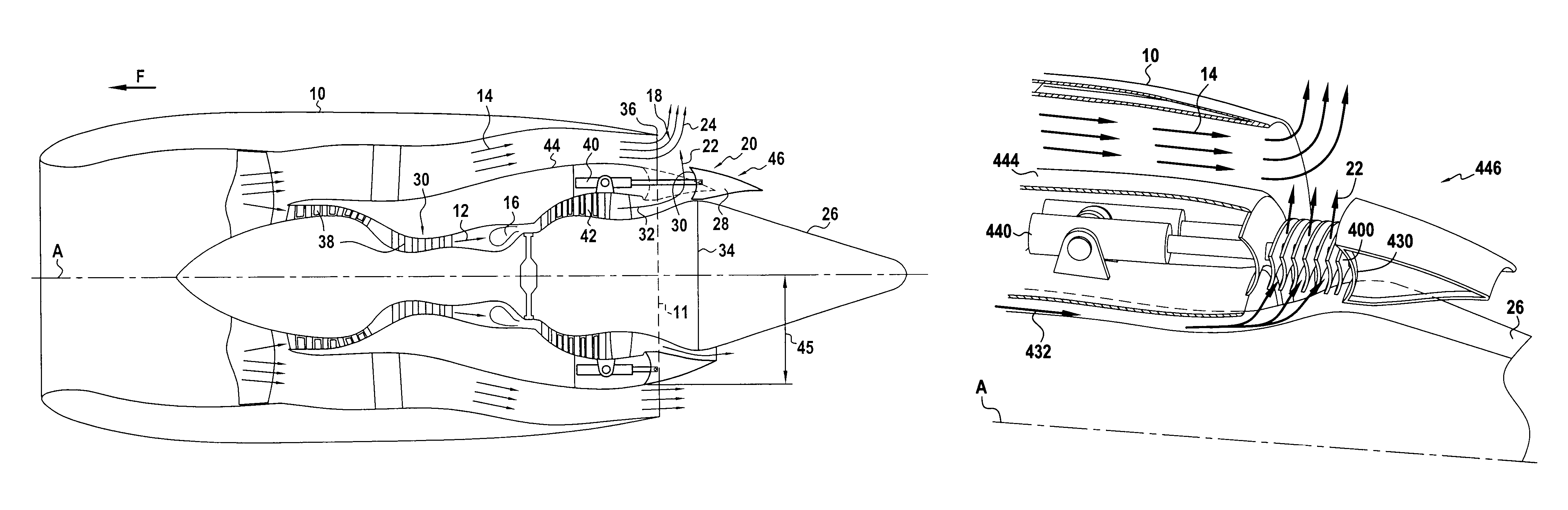

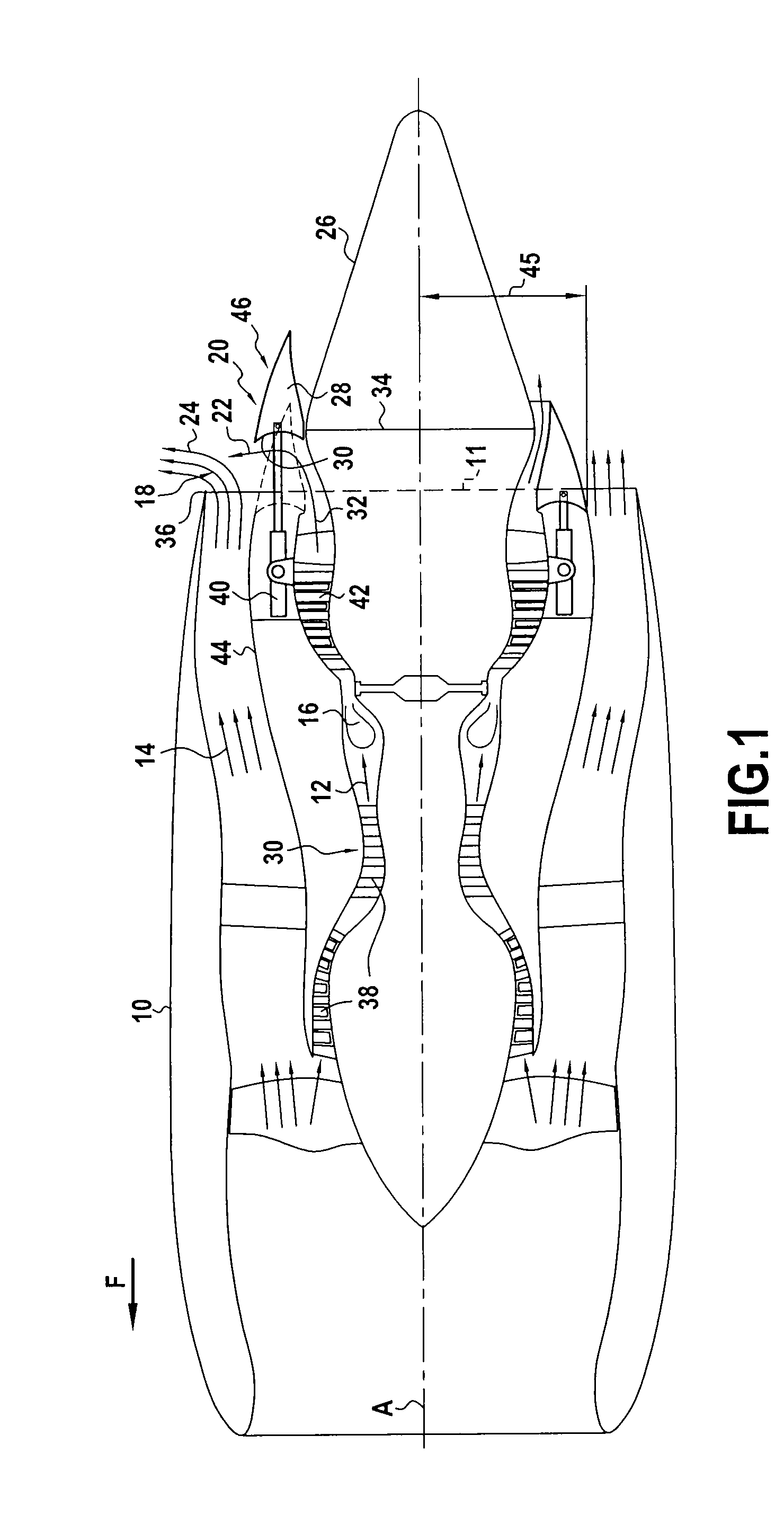

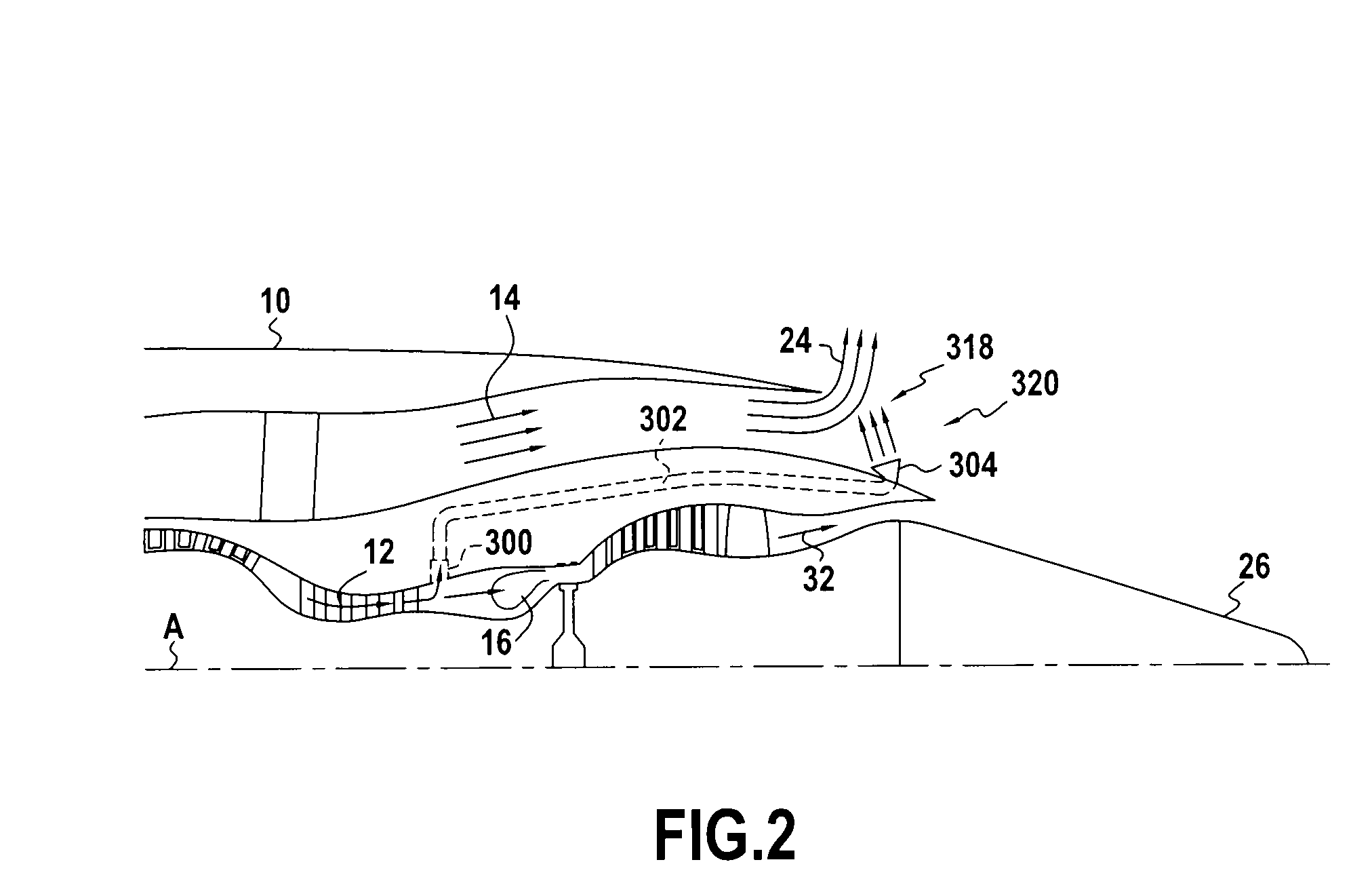

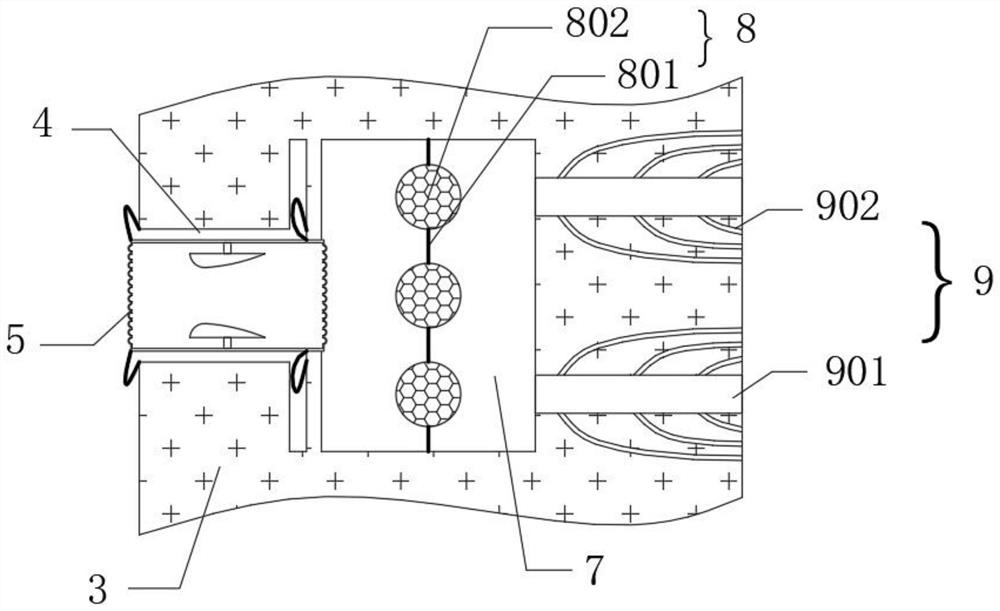

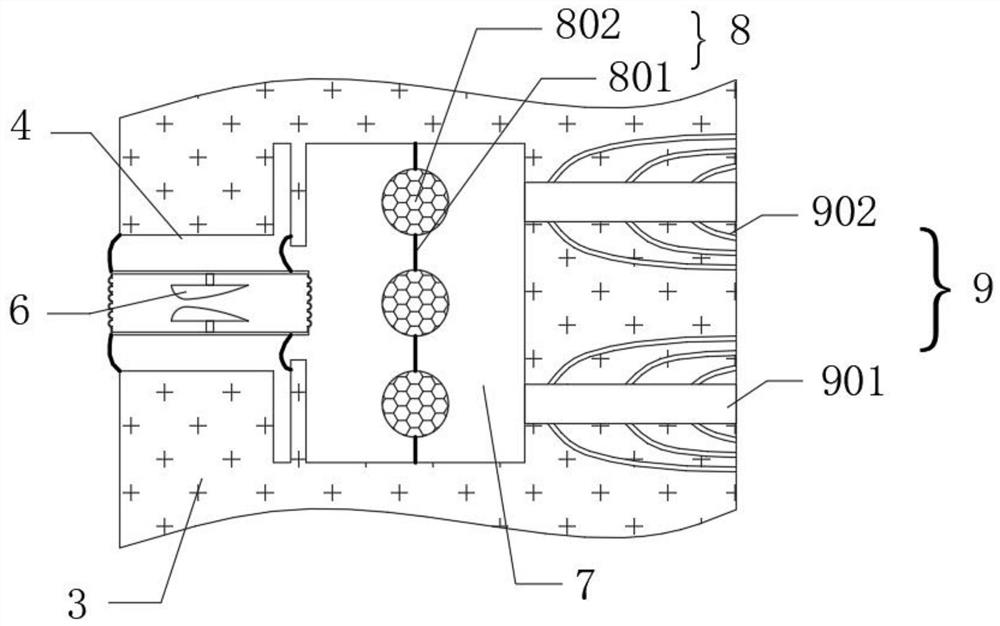

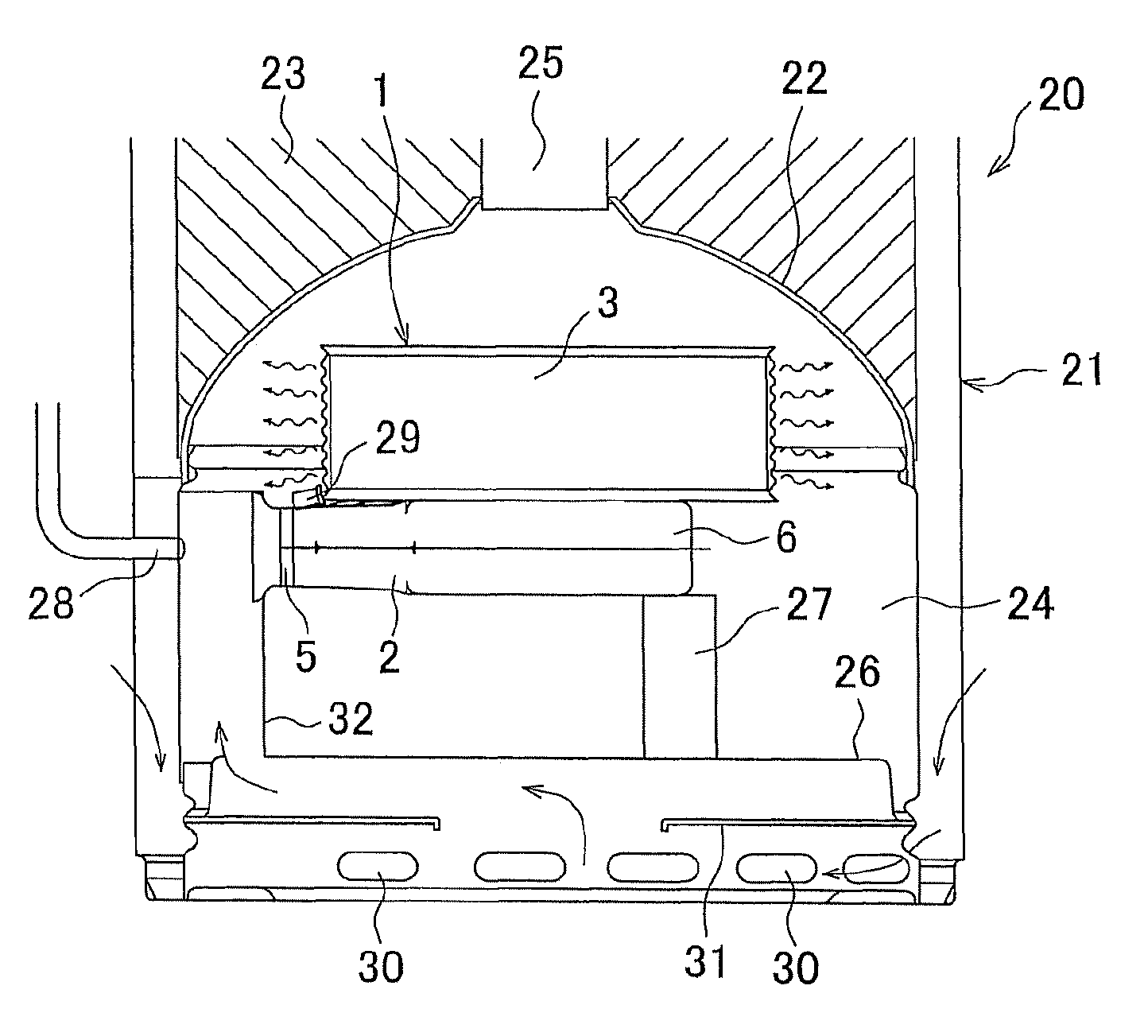

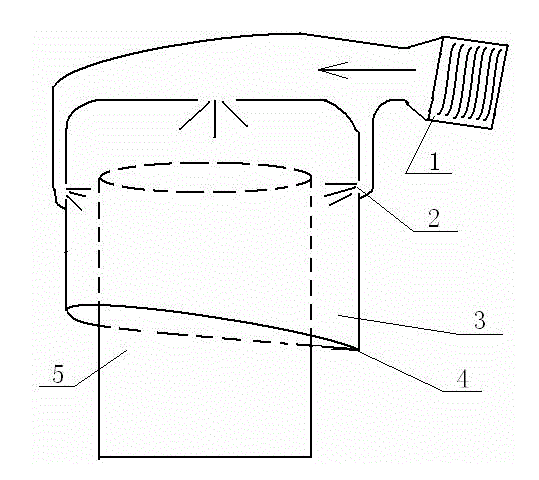

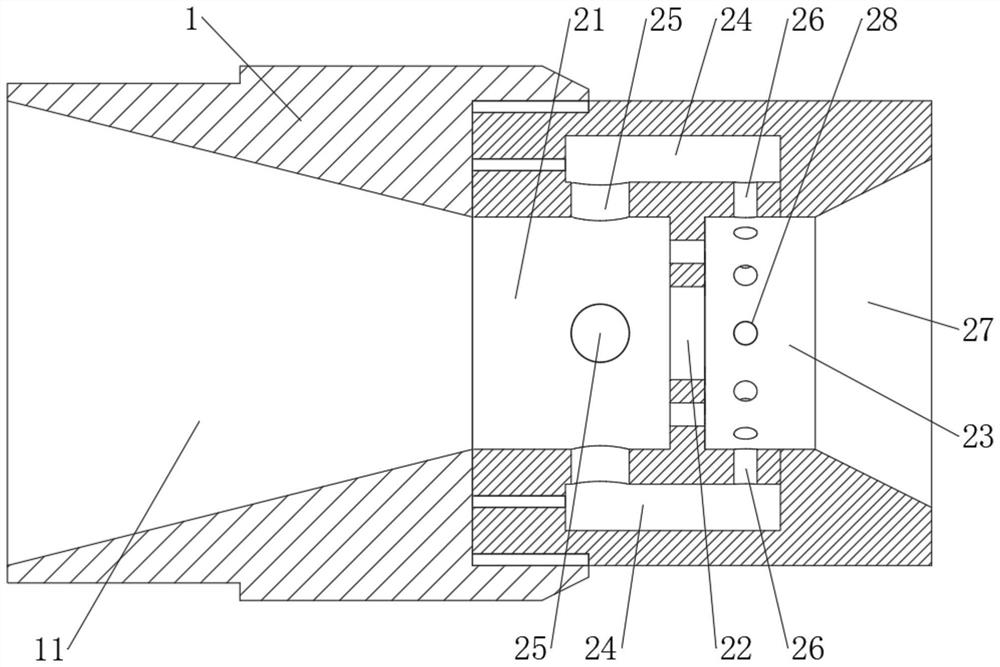

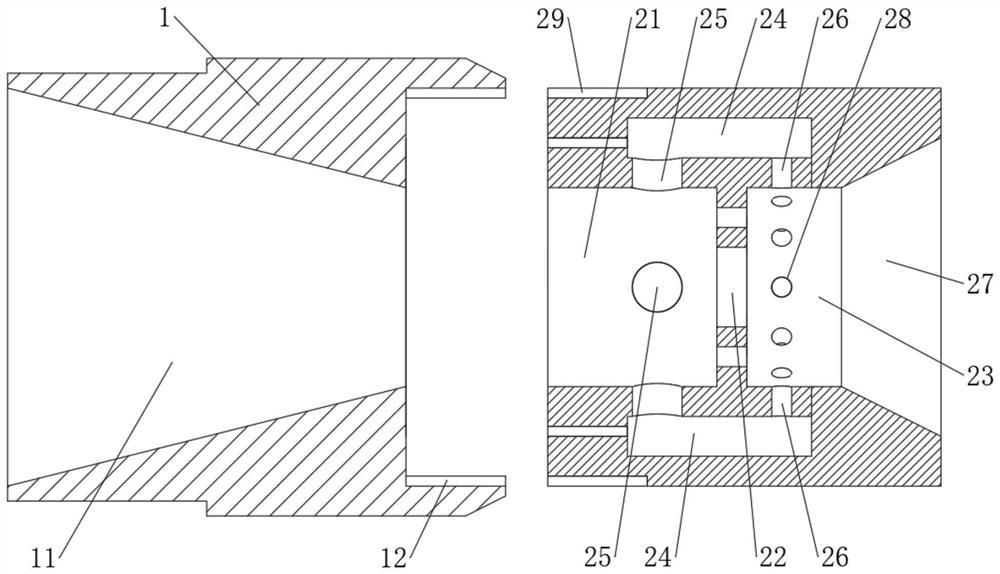

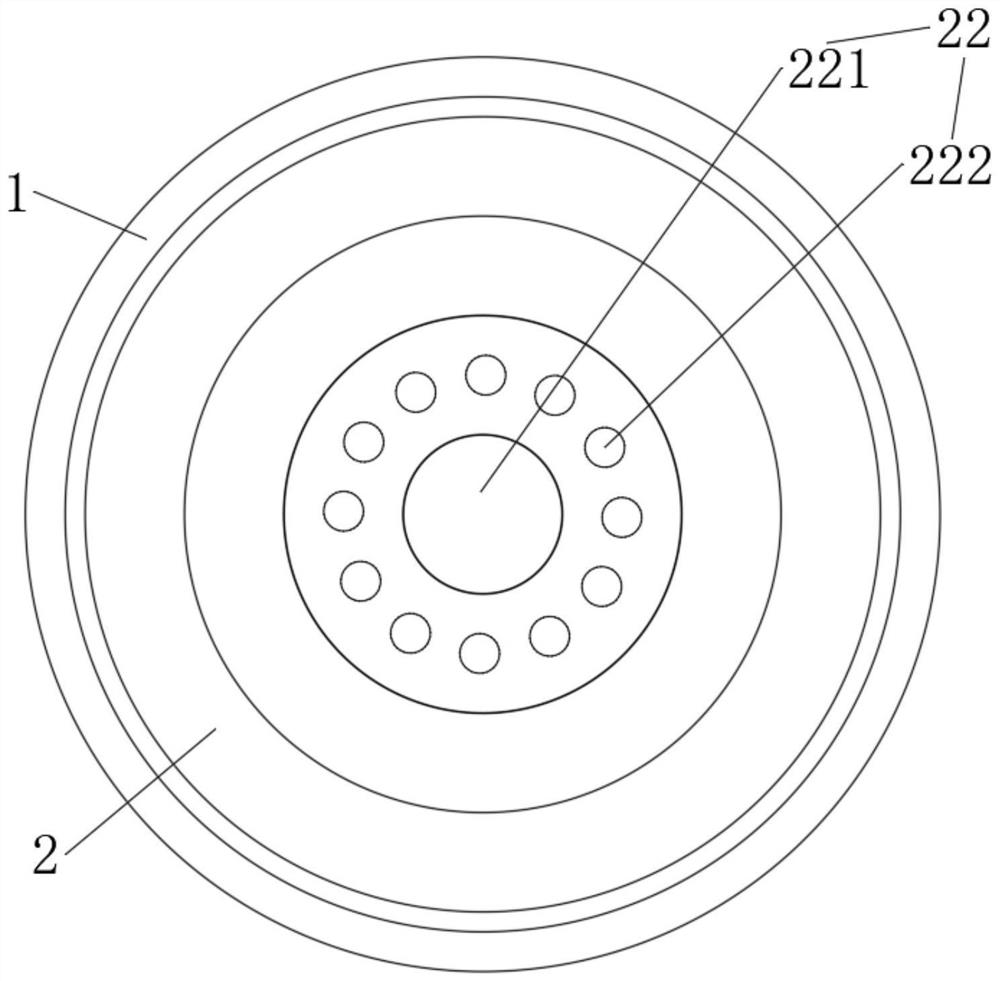

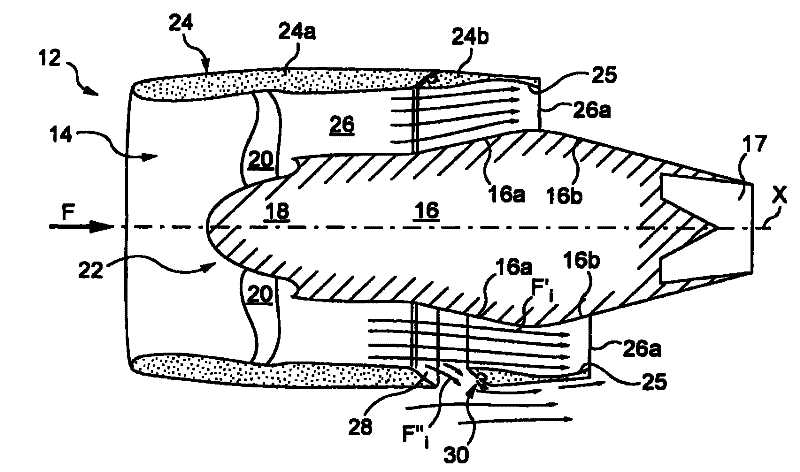

By-pass turbojet including a thrust reverser

ActiveUS20080250770A1Compact structureWeight controlSpraying apparatusGas turbine plantsNacelleMoving parts

A by-pass turbojet including a thrust reverser. The thrust reverse comprises deflector means for deflecting all or part of the primary stream gas in such a manner that the deflected primary stream gas encounters the secondary stream, thereby reducing the injection speed of the secondary stream in an aft direction, and thus generating the thrust-reversal effect. The secondary stream escapes from the aft end of the nacelle. In the thrust-reversal position, the deflector means are inscribed radially substantially within the section of the primary nozzle cowl at the aft end of the nacelle. Such a thrust reverser is particularly simple in design, inexpensive, and makes it possible to avoid having moving parts present on the outside portion of the nacelle, thus simplifying the design of the turbojet.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

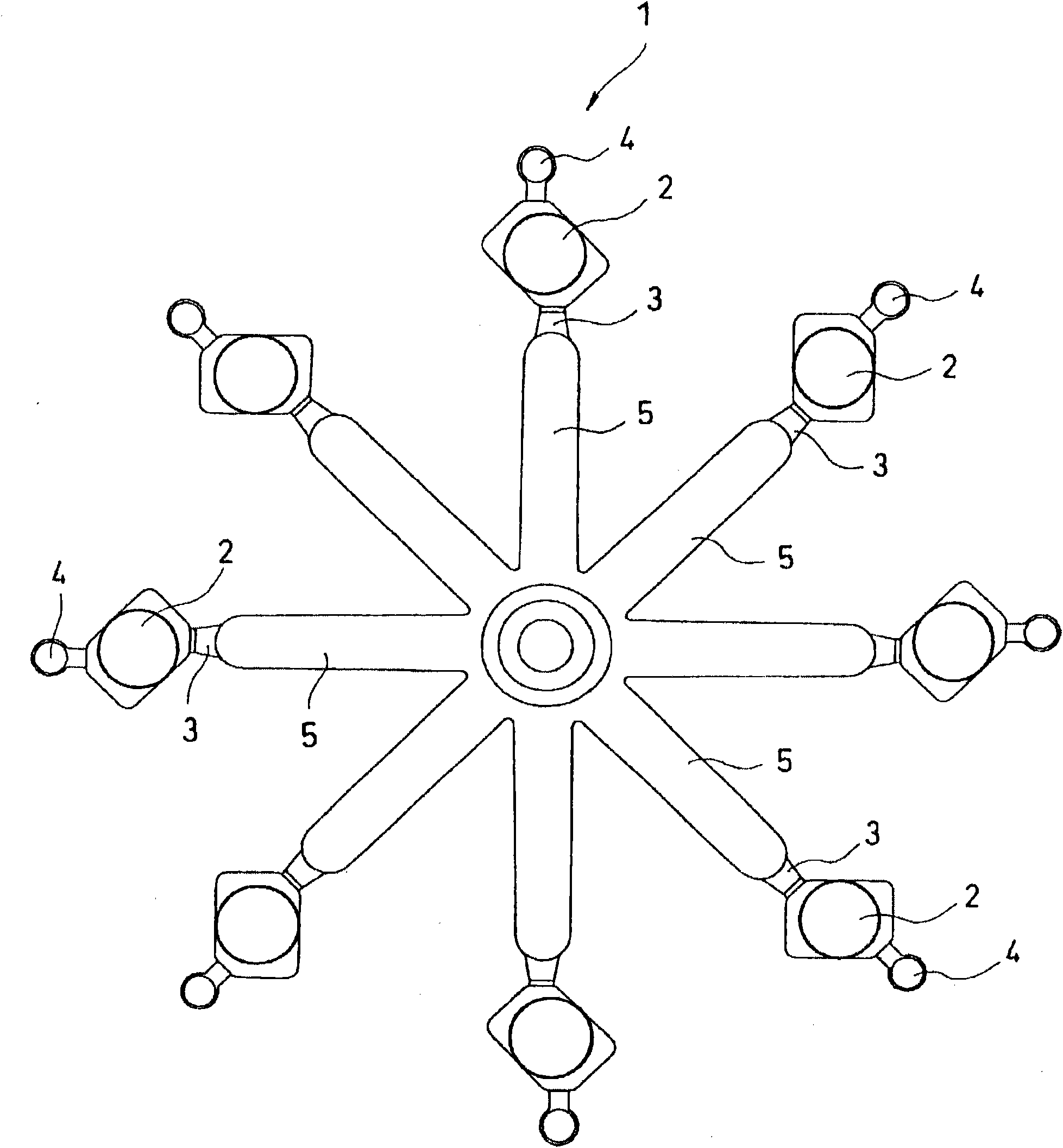

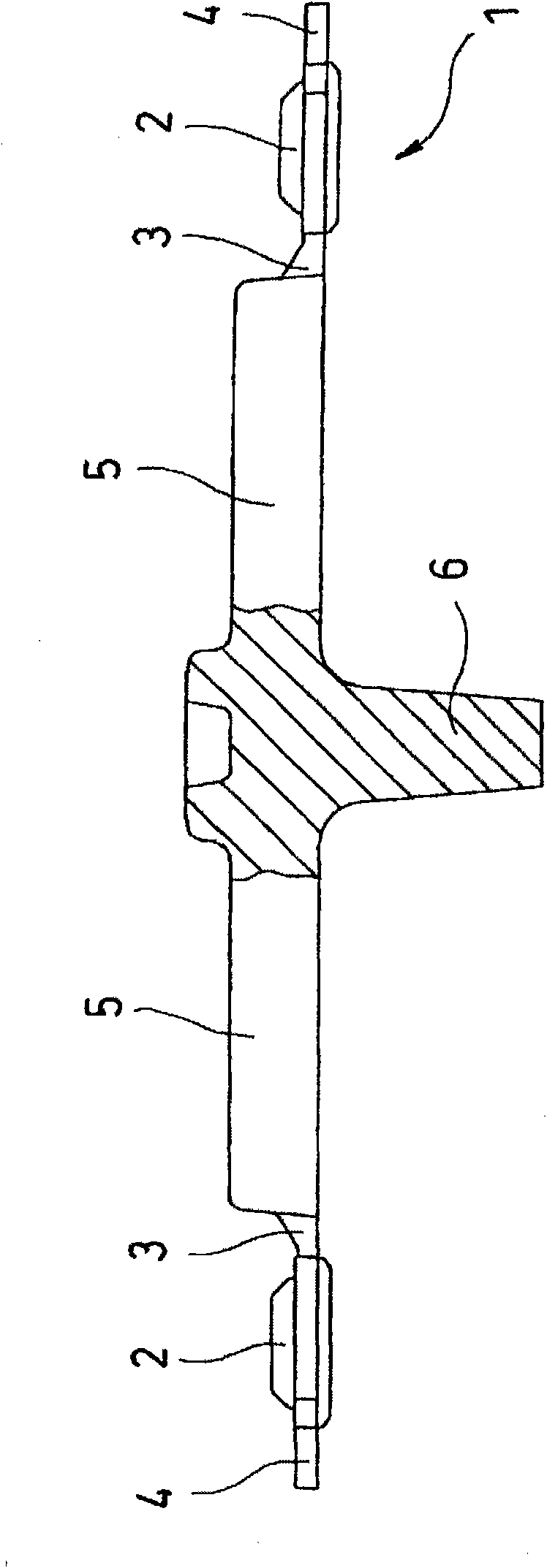

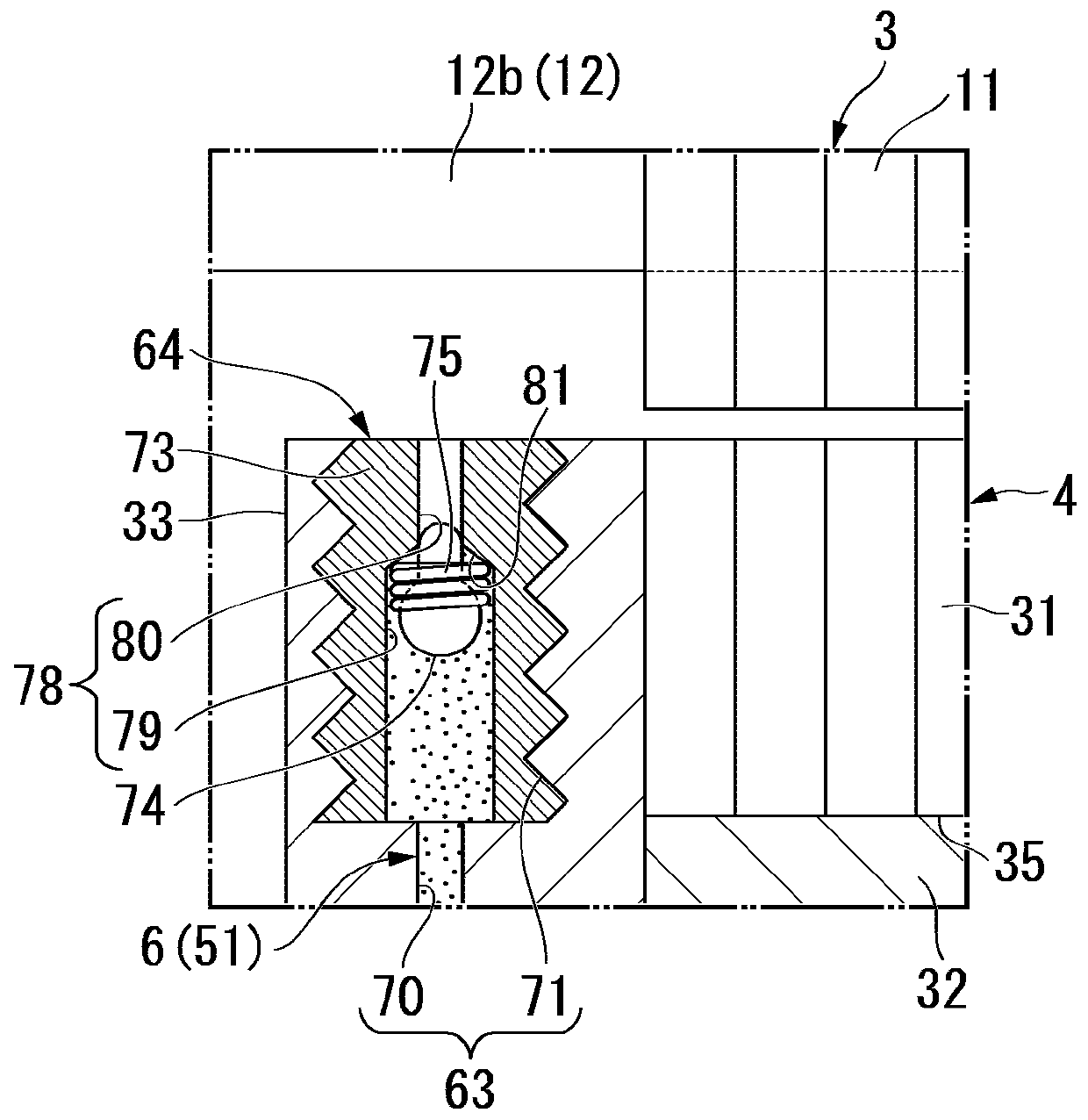

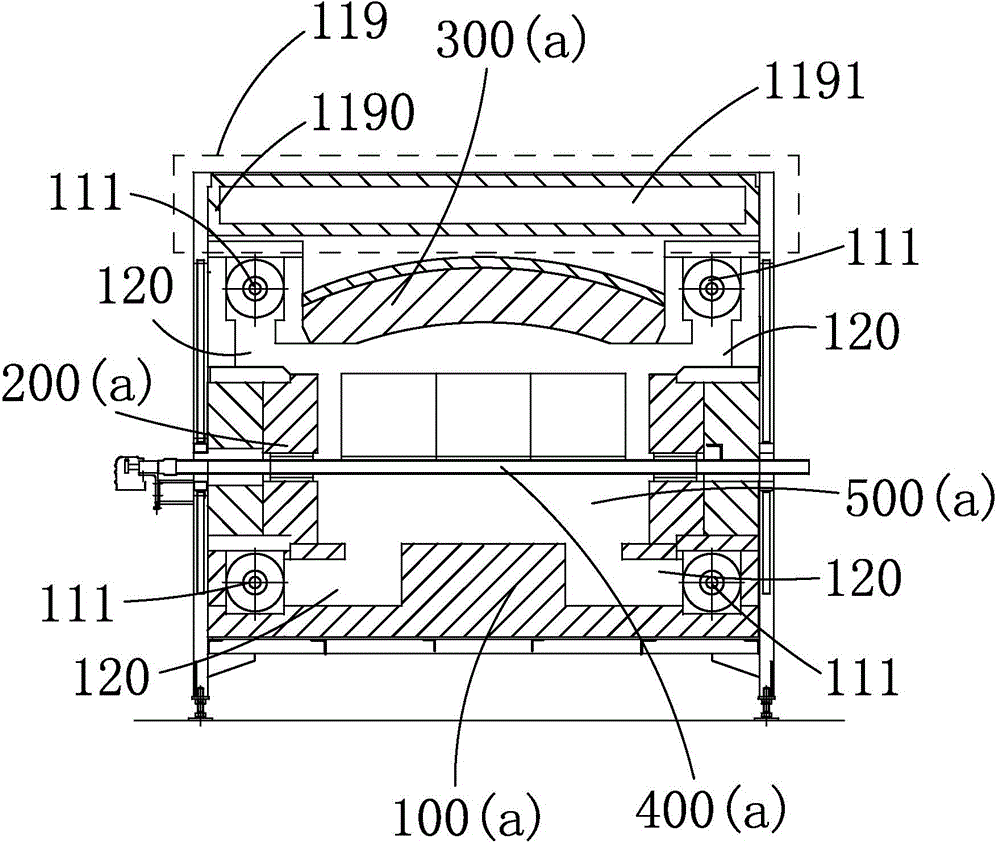

Process for producing molded item of thermosetting resin and injection molding machine therefor

InactiveCN101557916AImprove cooling effectEasy to demouldOptical articlesInjection molding machineLiquid resin

A process for producing a molded item of thermosetting resin, and injection molding machine therefor, capable of preventing burring and bubble inclusion at molding operation. There is provided a process for producing a molded item of thermosetting resin with the use of a mold having a cavity for forming a product part, a gate forming a gate part, a runner forming a runner part and an overflow catcher communicating with the cavity and forming an overflow part, which process comprises the injection step of injecting a liquid resin until filling the region from the runner through the gate to the cavity and further the region from the cavity to the overflow catcher; the hardening step of heating the liquid resin within the mold so as to effect hardening; the demolding step of detaching a resin molded item having the runner part, gate part, product part and overflow part from the mold; and the cutting step of cutting the gate part and overflow part off the product part of the demolded resin molded item.

Owner:TOSHIN SEIKO CO LTD +1

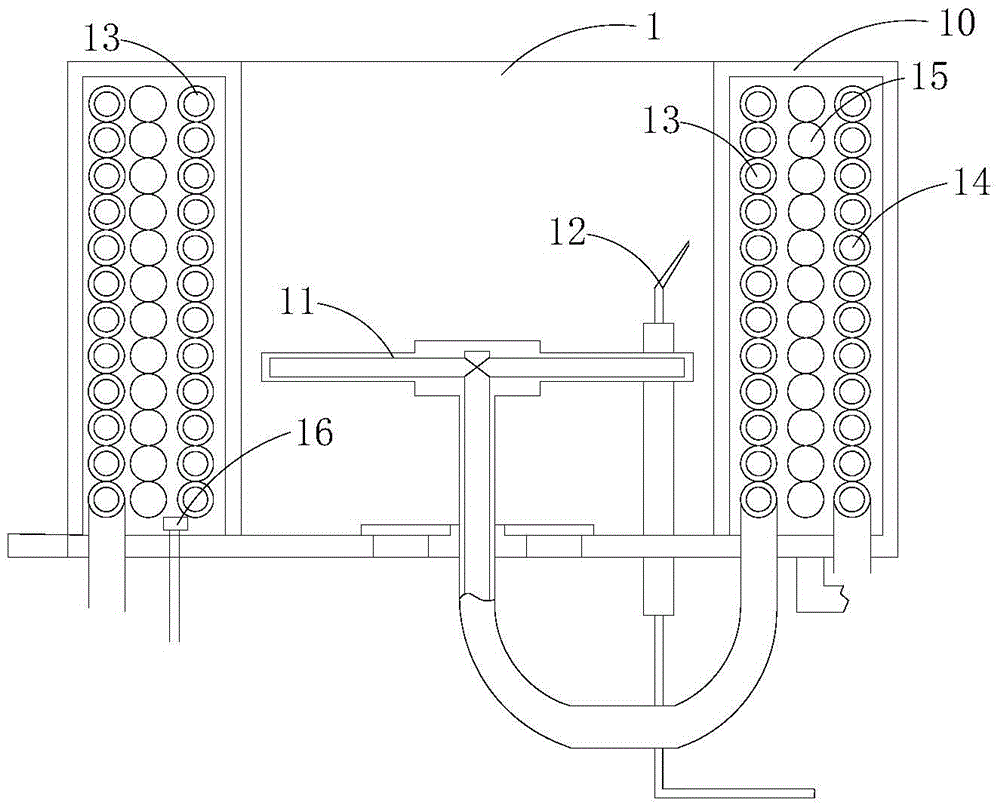

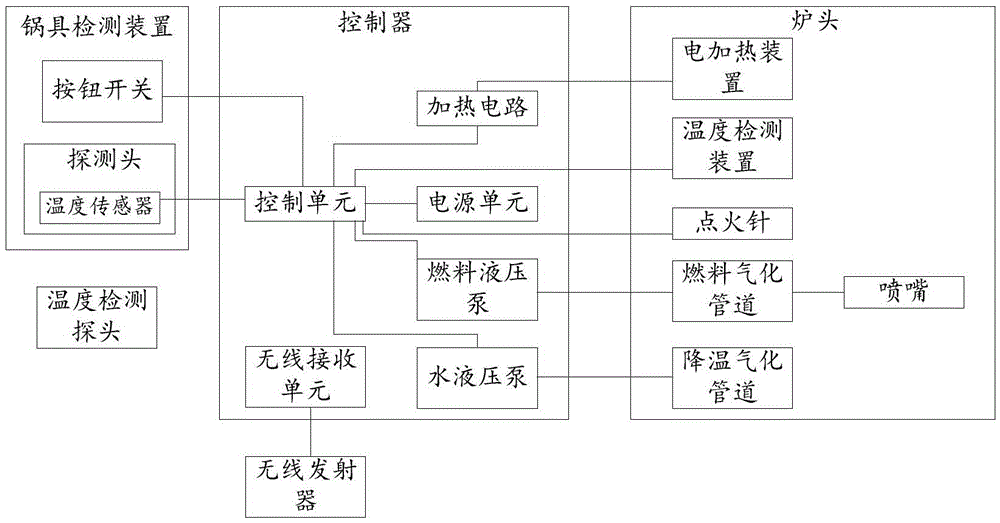

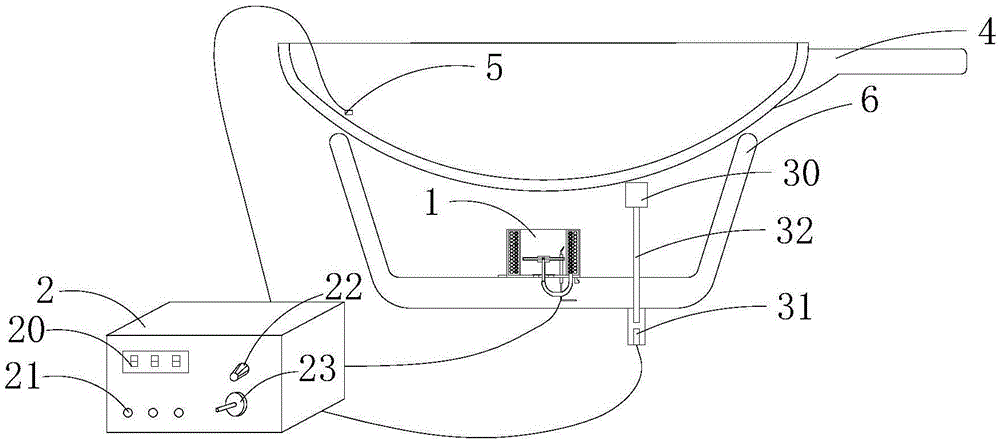

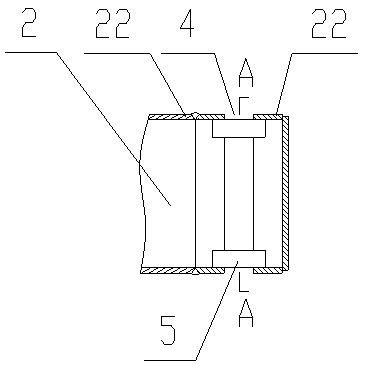

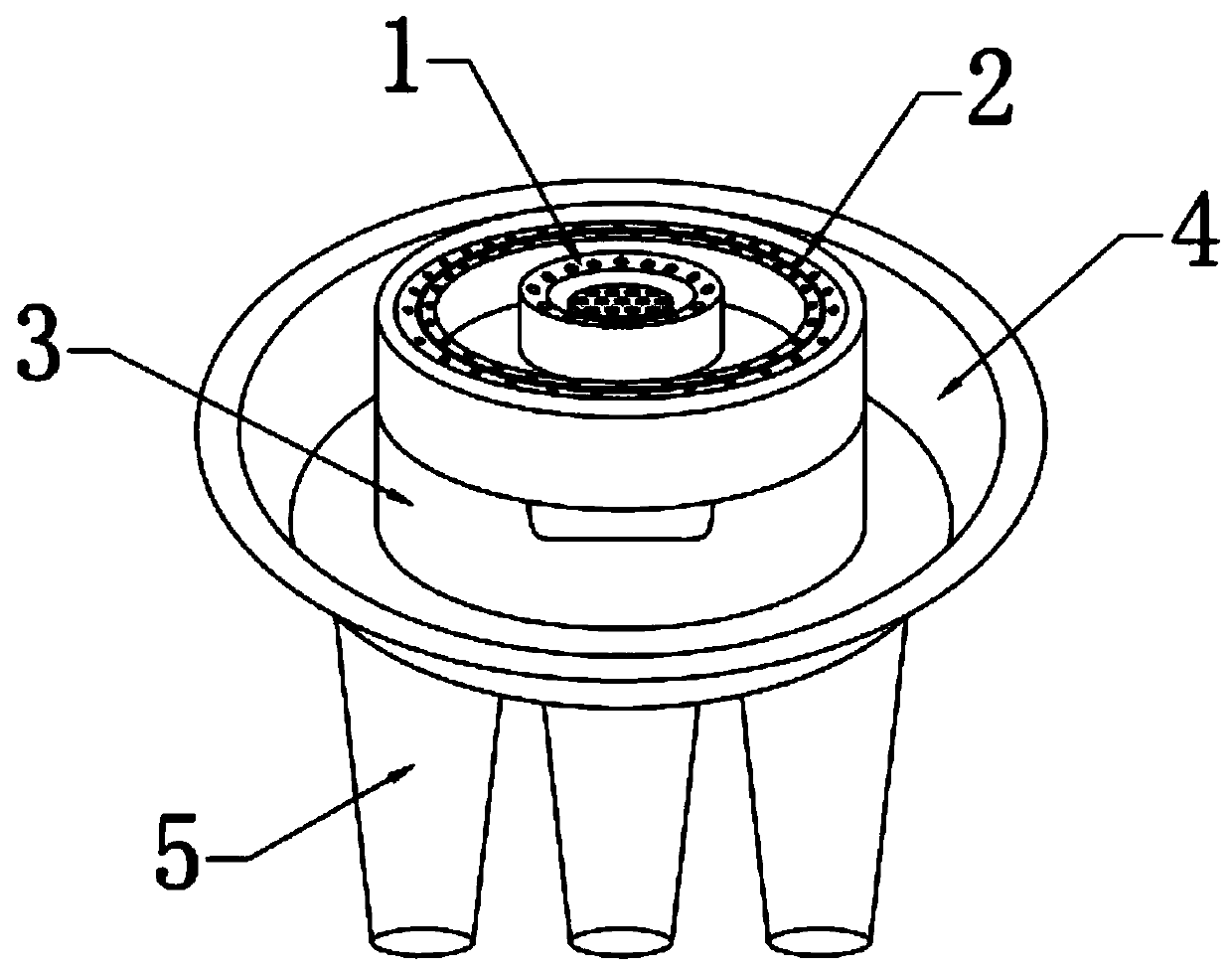

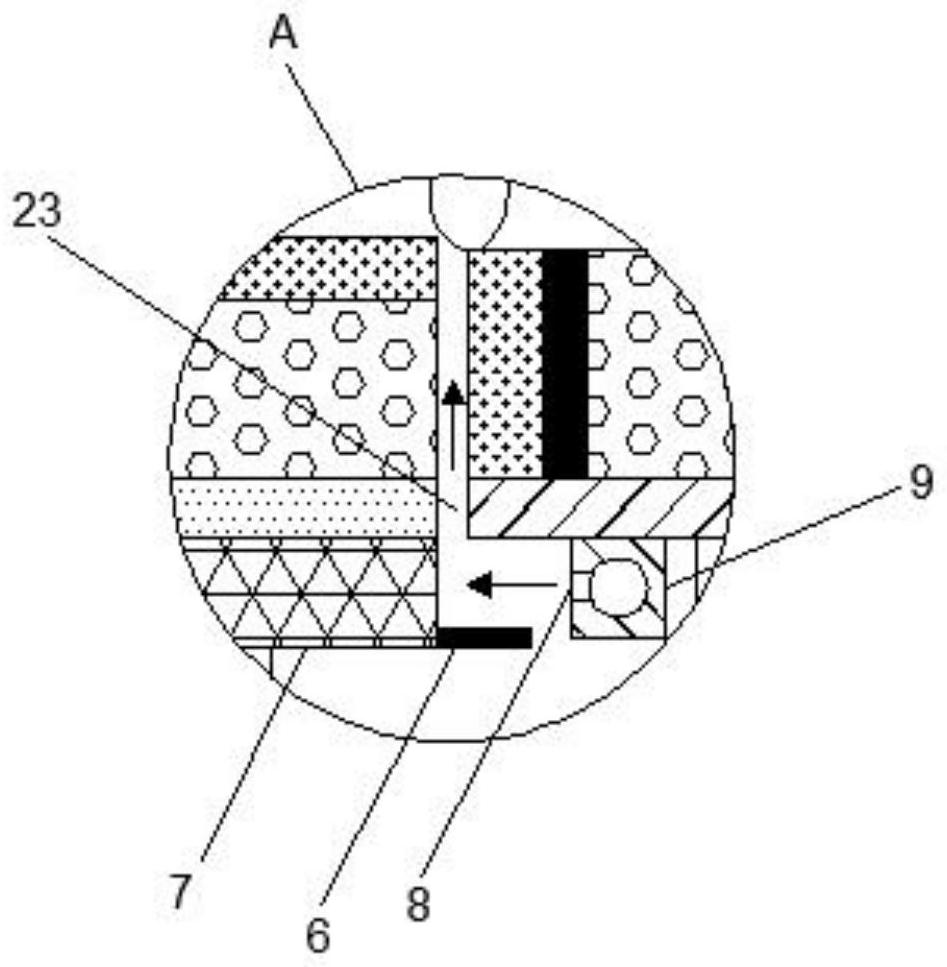

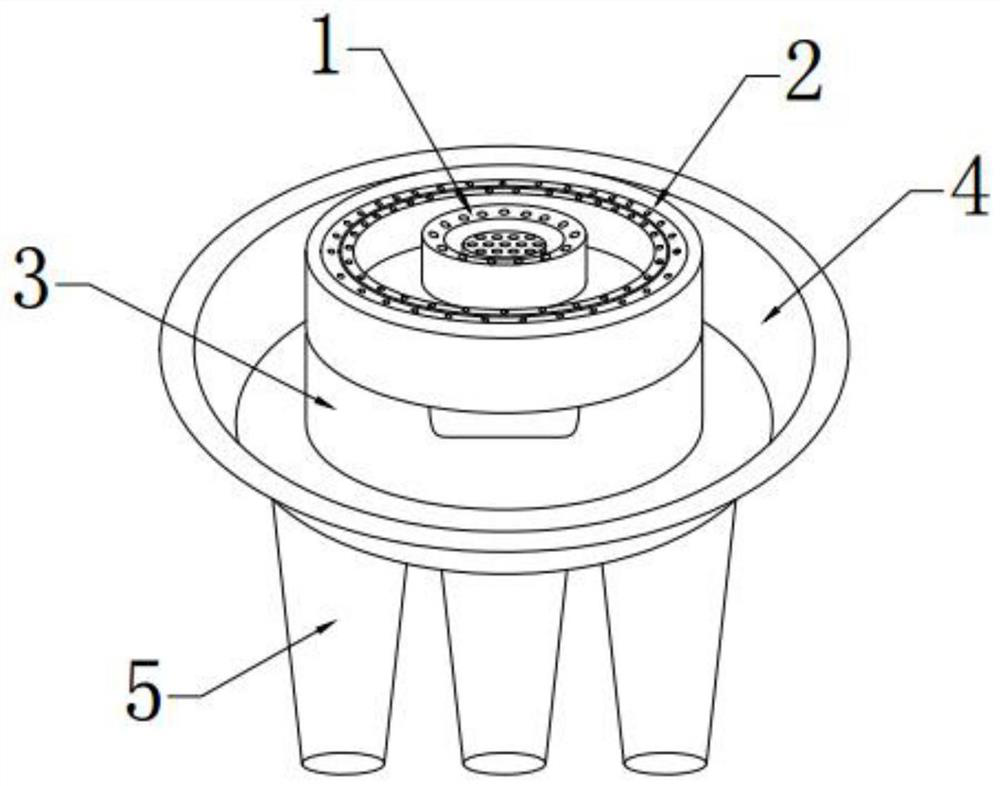

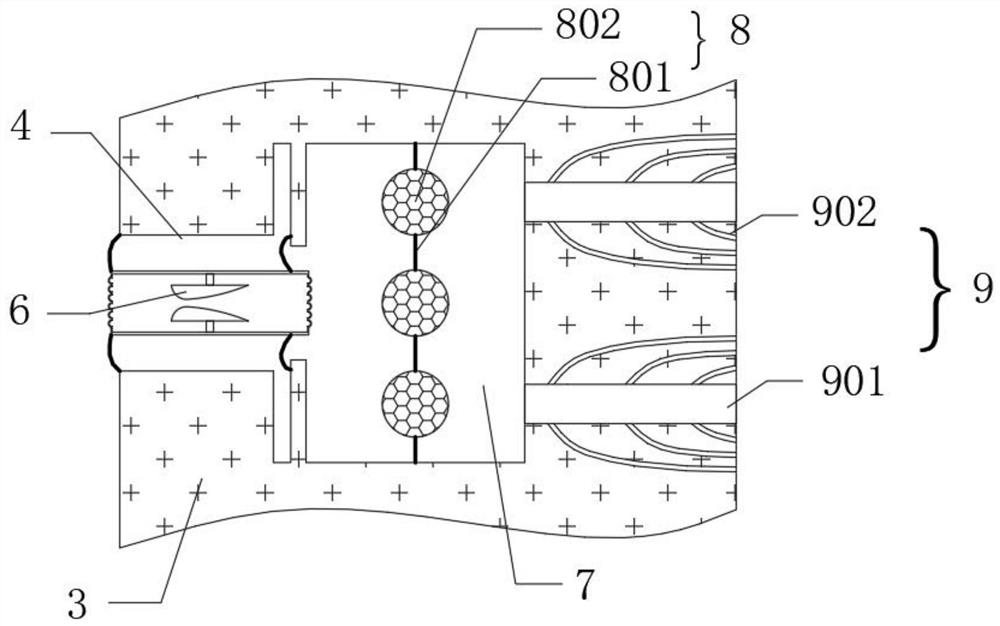

Alcohol-based fuel combustion furnace end and combustor

InactiveCN105546530AReduce the temperatureReduce gasification rateLiquid fuel burnerElectricityCombustor

The invention provides an alcohol-based fuel combustion furnace end and a combustor. The furnace end comprises a hood body, a nozzle, an ignition needle, fuel gasifying pipelines, temperature reduction gasifying pipelines, electric heating devices and a temperature measurement device, wherein the hood body is arranged at the periphery of the ignition needle and the periphery of the nozzle in a sleeving manner; the ignition needle is arranged on one side of the nozzle; the fuel gasifying pipelines, the temperature reduction gasifying pipelines, the electric heating devices and the temperature measurement device are arranged in the hood body; output terminals of the fuel gasifying pipelines are connected with the nozzle, and input terminals of the fuel gasifying pipelines are connected with a fuel supplying device. According to the alcohol-based fuel combustion furnace end and the combustor disclosed by the invention, through the temperature reduction gasifying pipelines, the temperature of the furnace end can be reduced, so that the gasifying speed of alcohol-based fuel is reduced, the speed in spraying gas out of the nozzle is reduced, and the situation that thermal power is reduced due to too fast dissipation of the gas is avoided.

Owner:魏伟

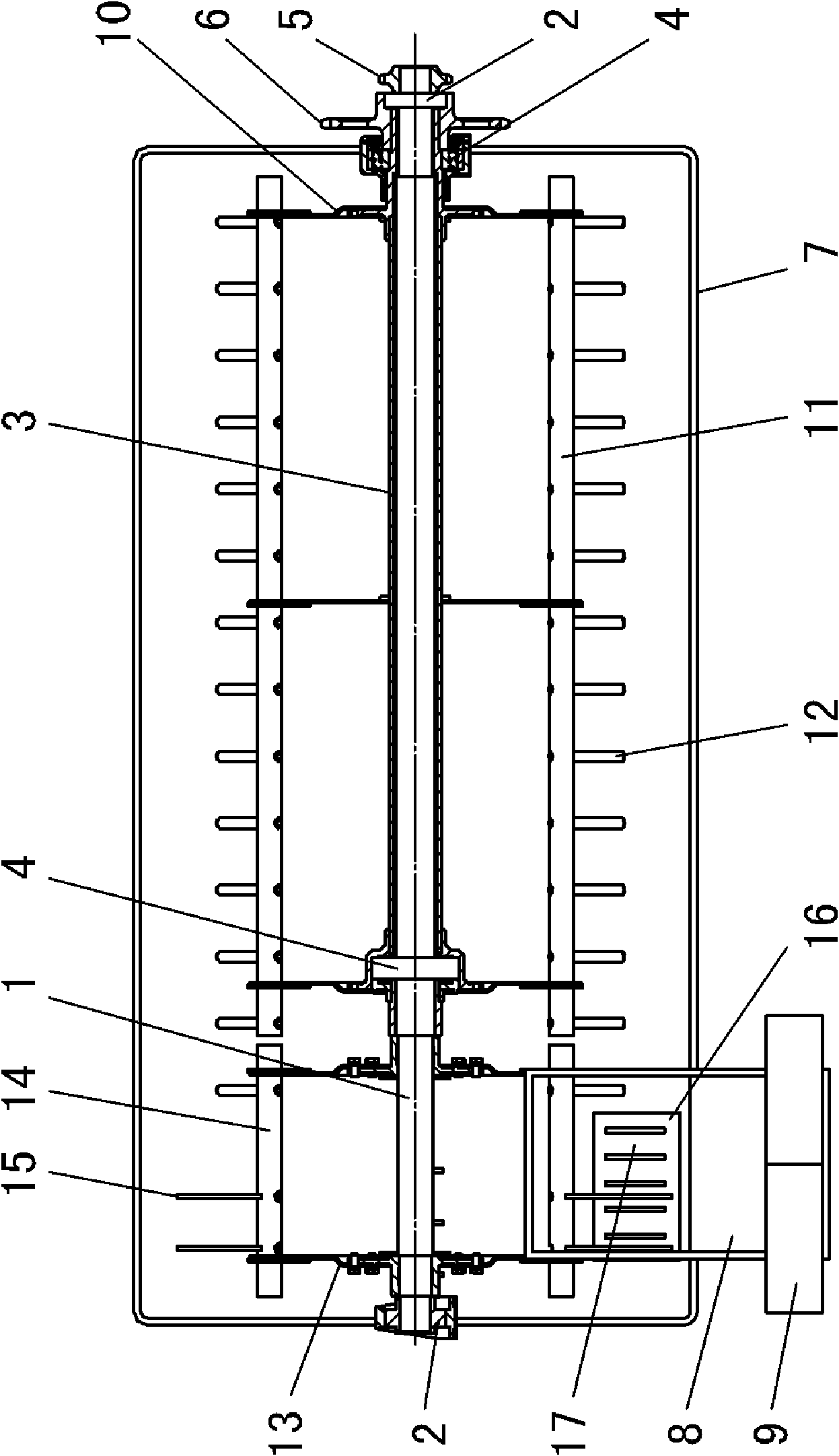

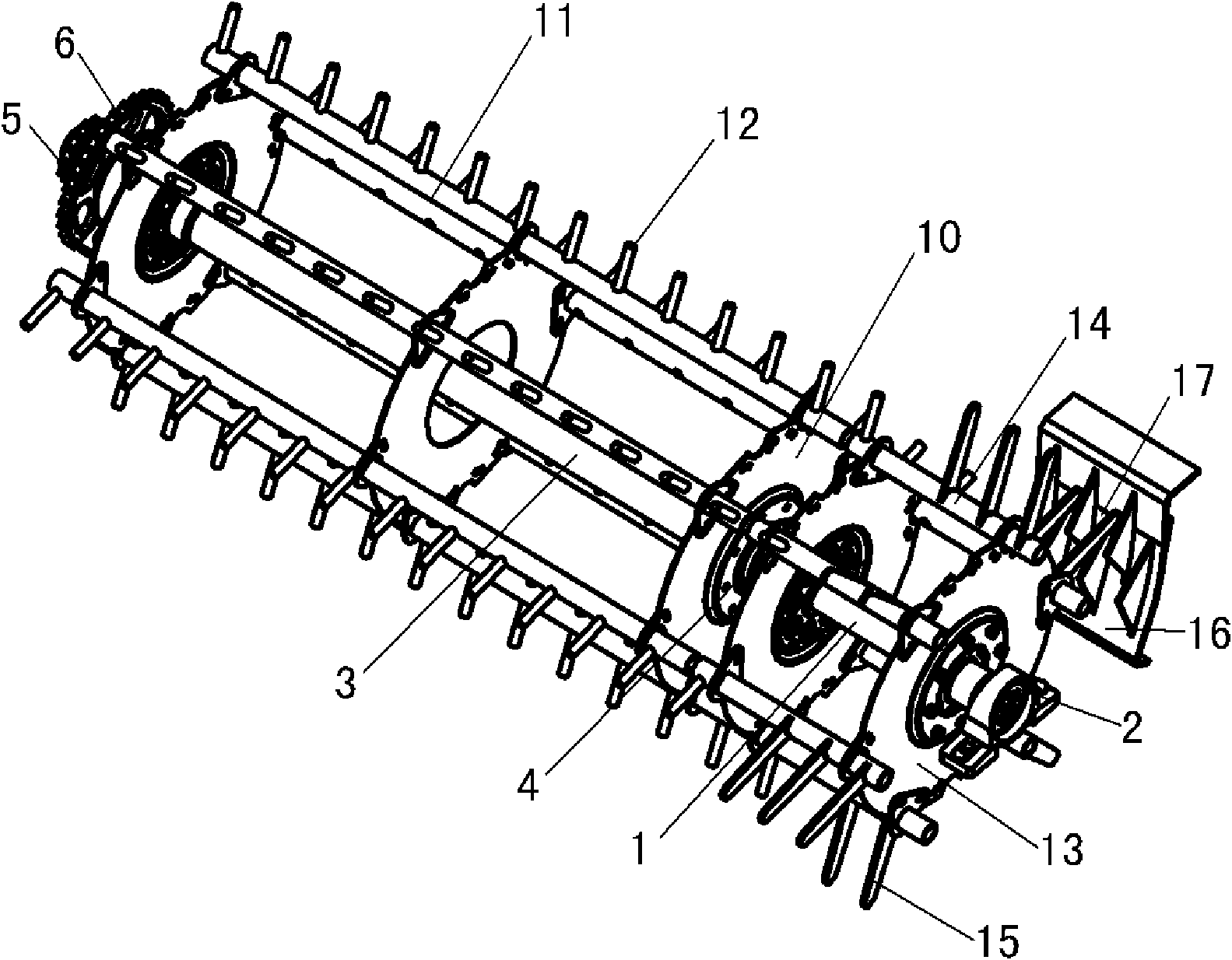

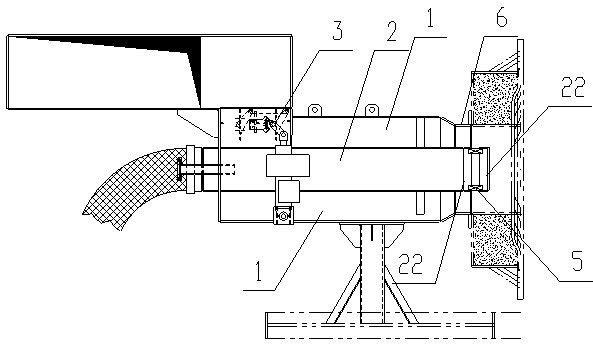

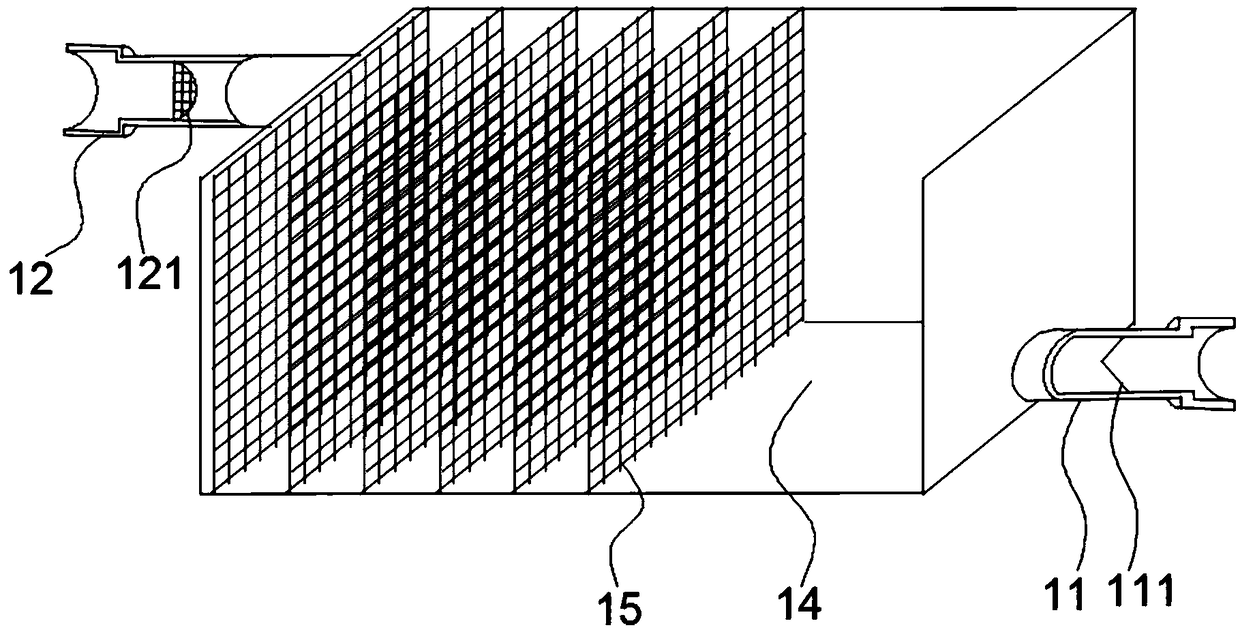

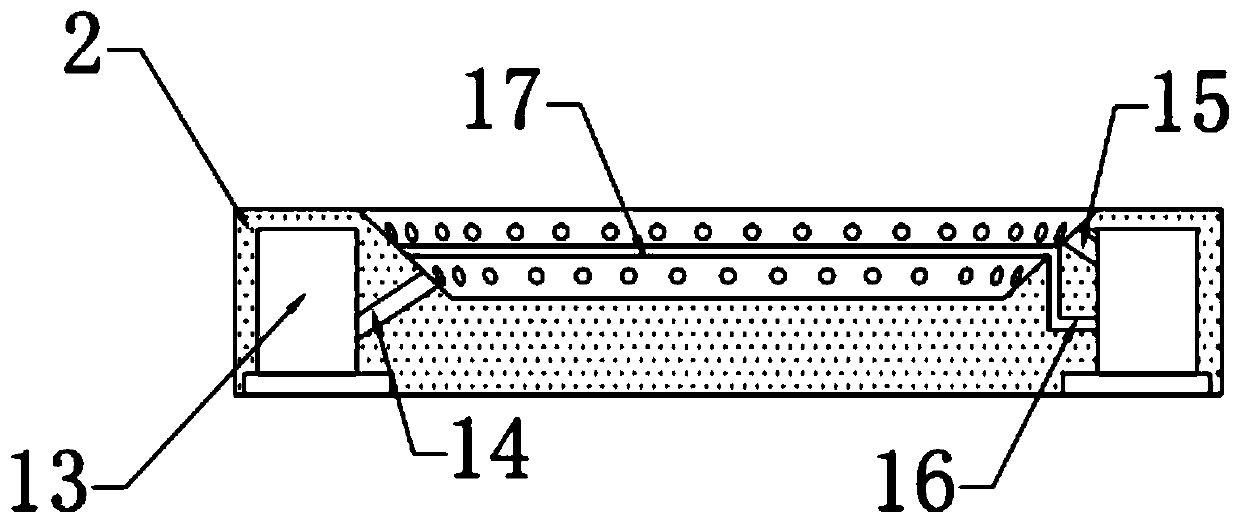

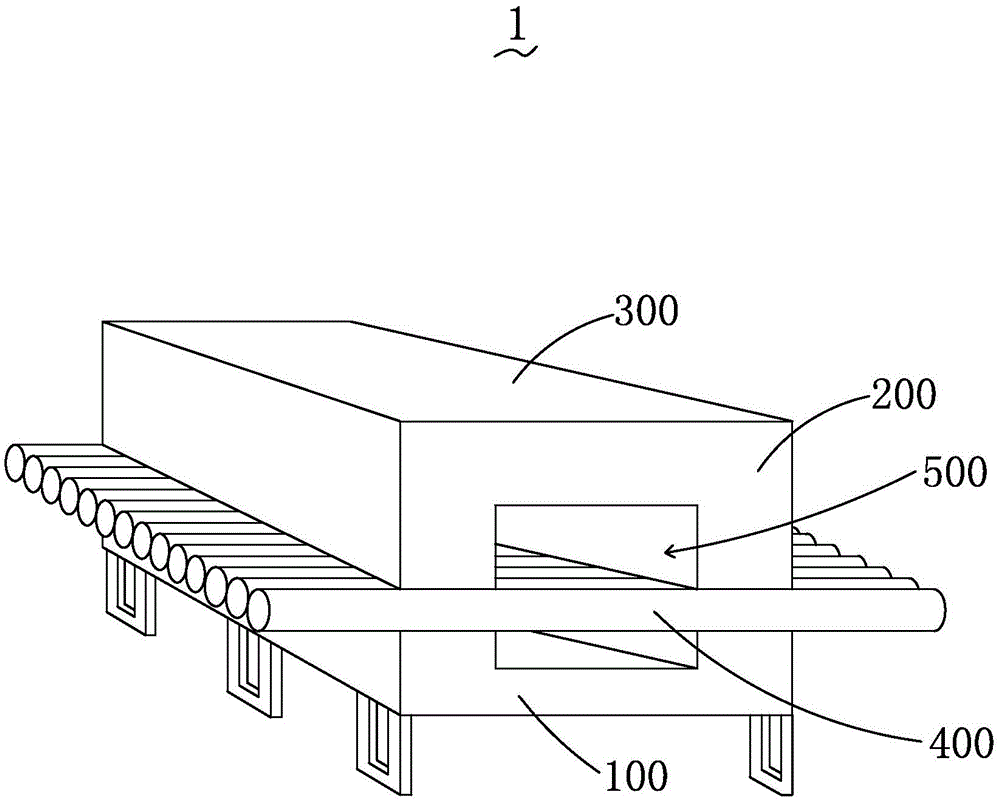

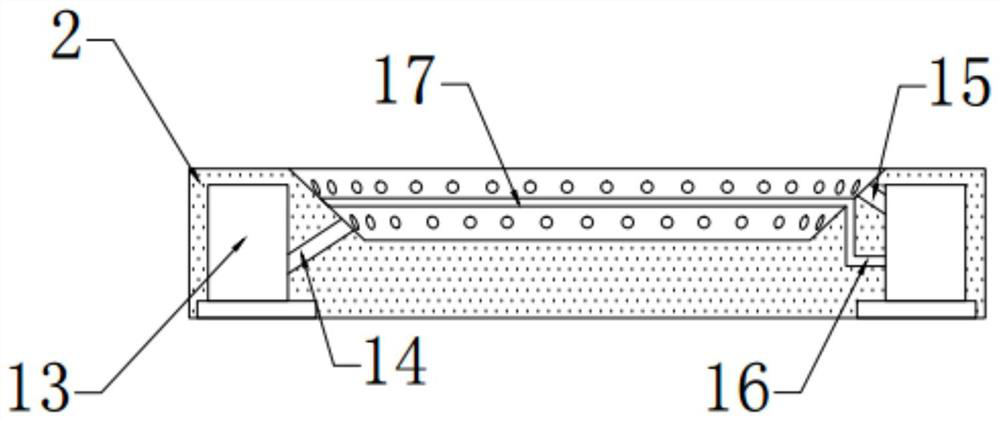

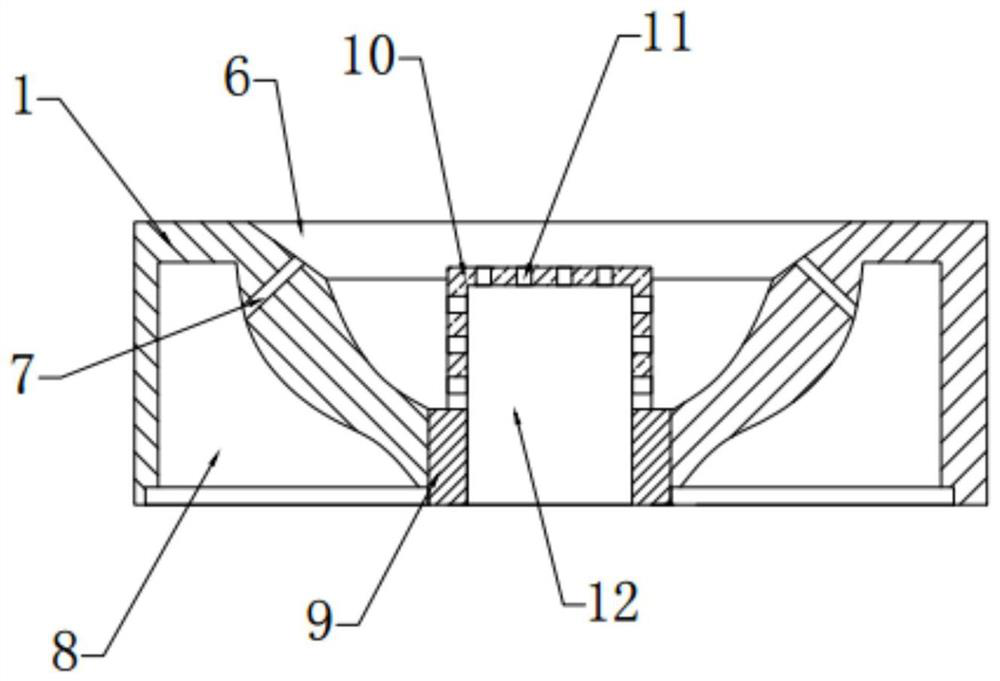

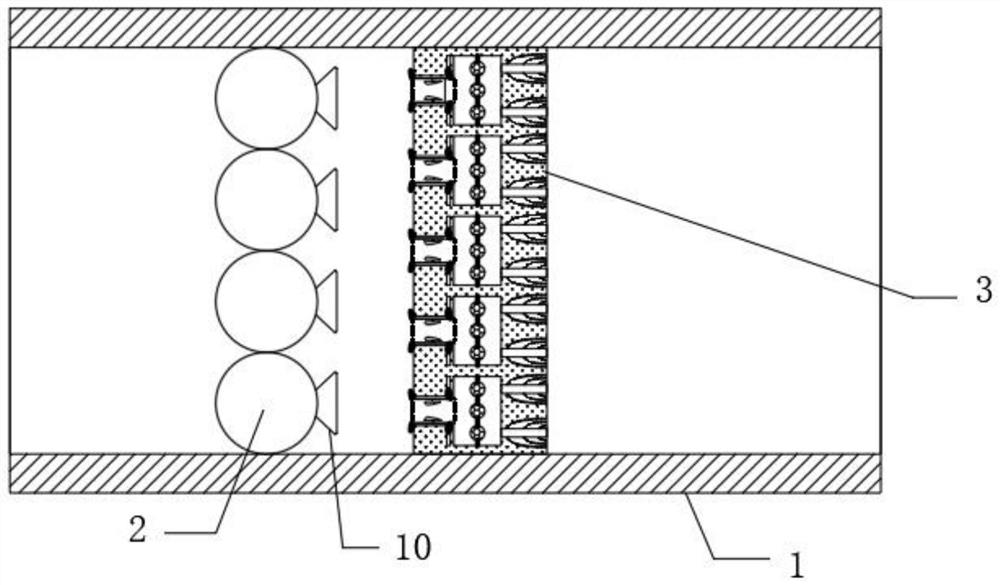

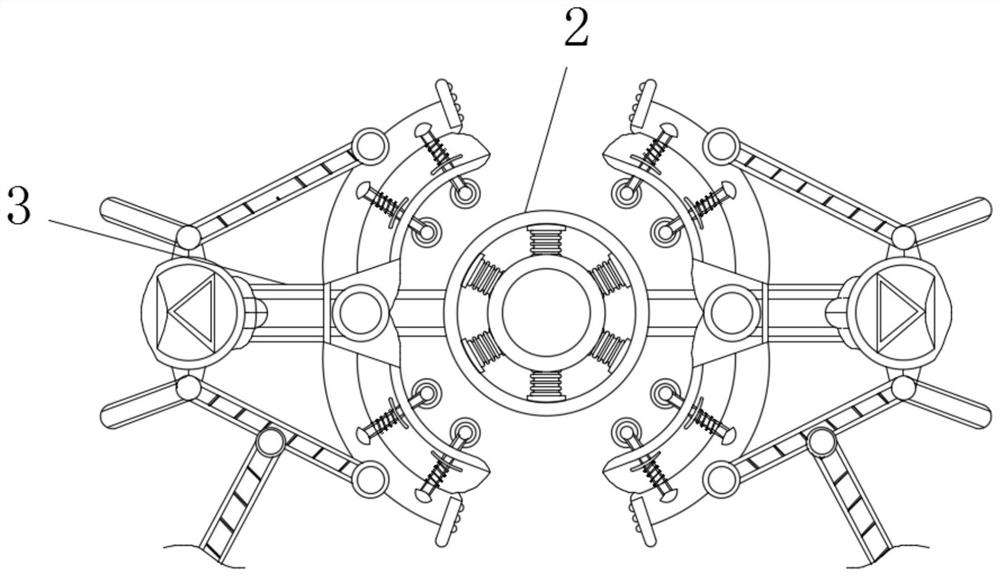

Straw crushing and throwing method and device of full-feeding combine harvester

InactiveCN101663937AReduce power consumptionReduce noiseCrop conditionersMowersAgricultural engineeringLow speed

The invention discloses a straw crushing and throwing method and a device of a full-feeding combine harvester. The method adopts a coaxial different-speed transmission mode, uses a low-speed shaft todrive the threshing teeth to do threshing, and uses a high-speed shaft to drive the crushing teeth and a crushing cutter which corresponds to the crushing teeth to crush the straw. The device is characterized in that a crushing auxiliary board (13) is connected on a solid shaft (1); a crushing teeth rod (14) is installed on the crushing auxiliary board (13); crushing teeth (15) are arranged on thecrushing teeth rod (14); a hollow shaft (3) is sheathed outside the solid shaft (1); a threshing auxiliary board (10) is connected on the hollow shaft (3); threshing teeth rod (11) is installed on the threshing auxiliary board (10); and the threshing teeth (12) are arranged on the threshing teeth rod (11). The straw crushing and throwing method and the device of the full-feeding combine harvestercan crush the straw and then evenly throw the straw into the earth when in harvest, can reduce the spray speed of the crushed straw so as to avoid the crushed straw from injuring people, thus improving the security.

Owner:XINGGUANG AGRI MACHINERY

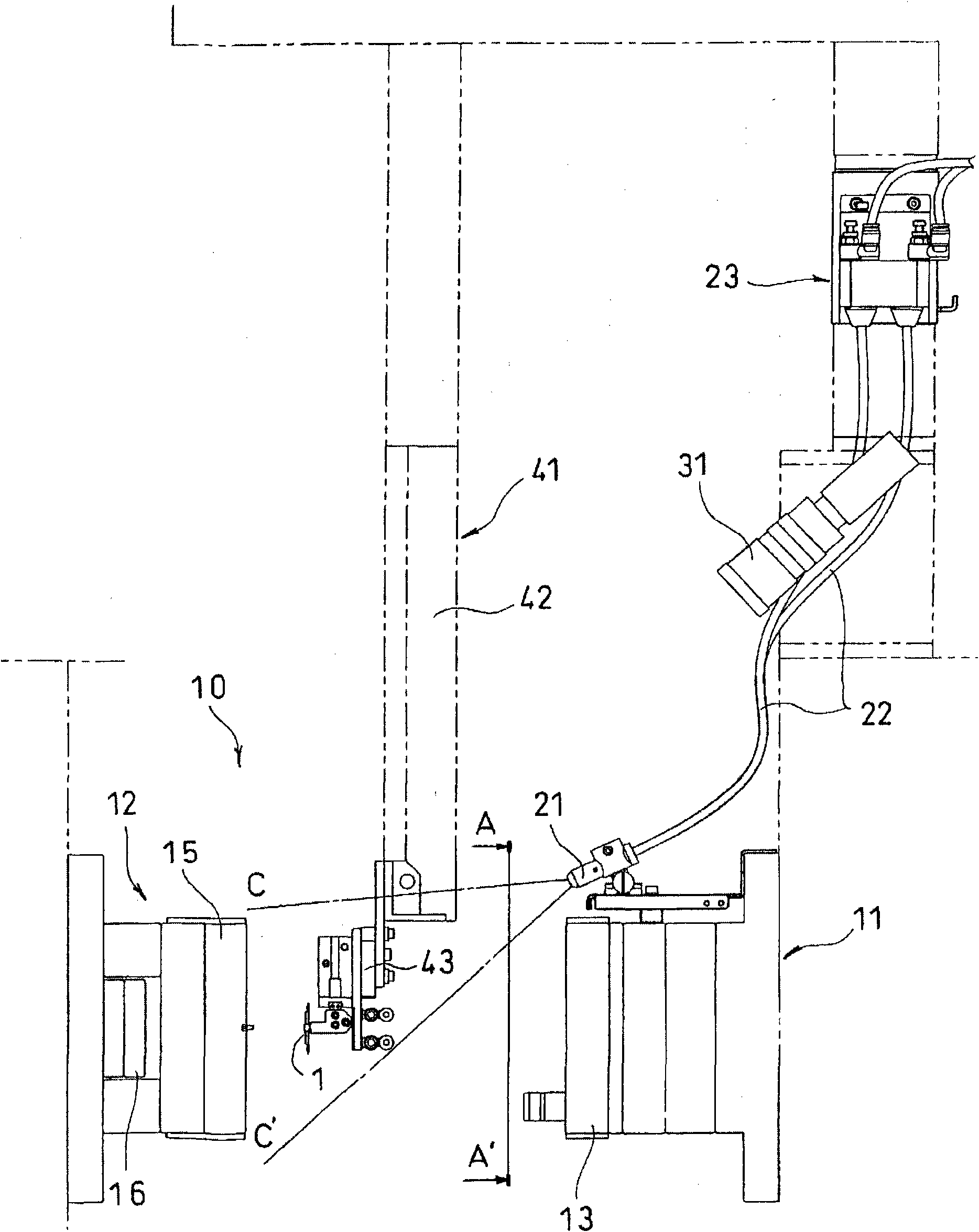

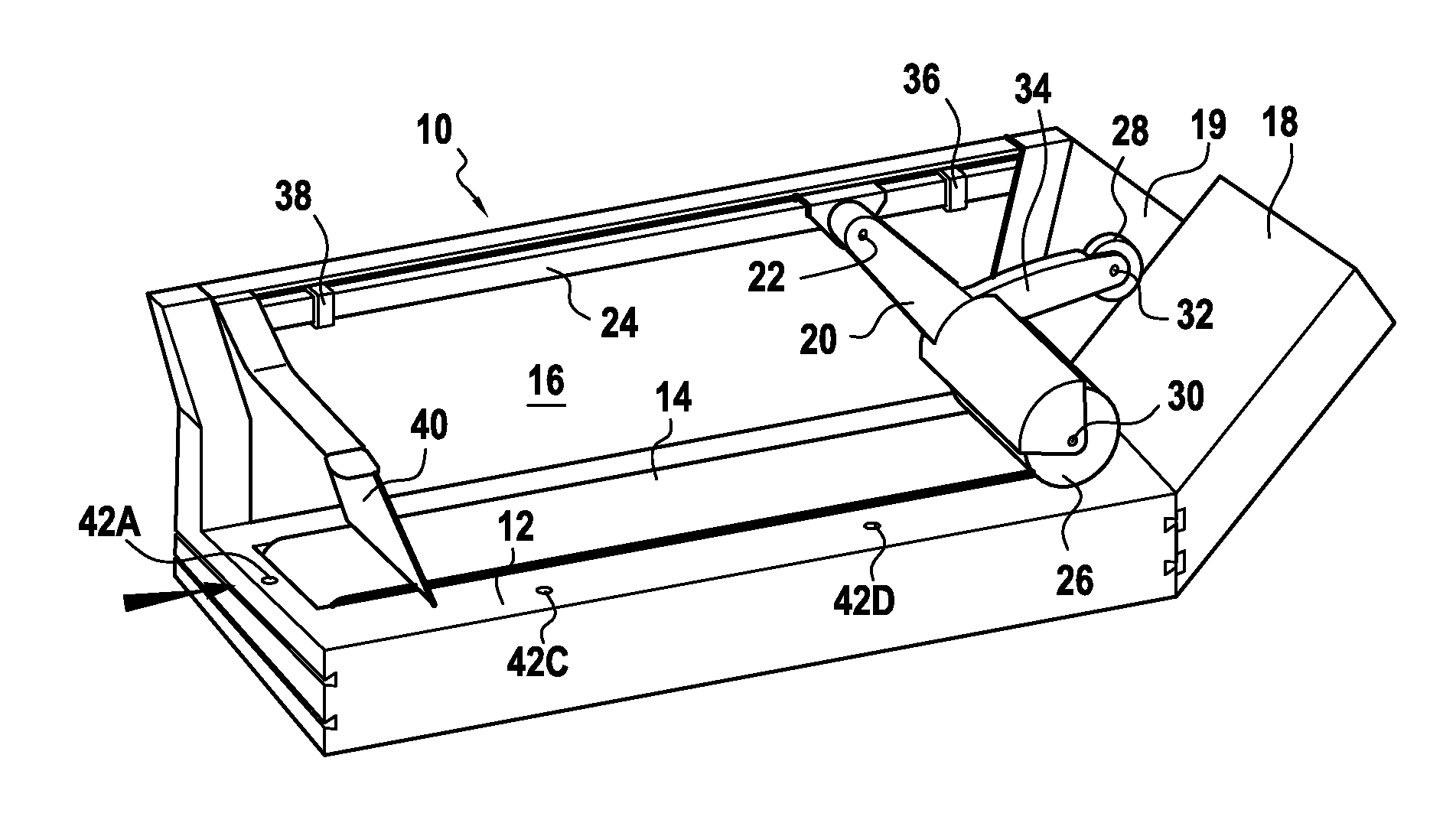

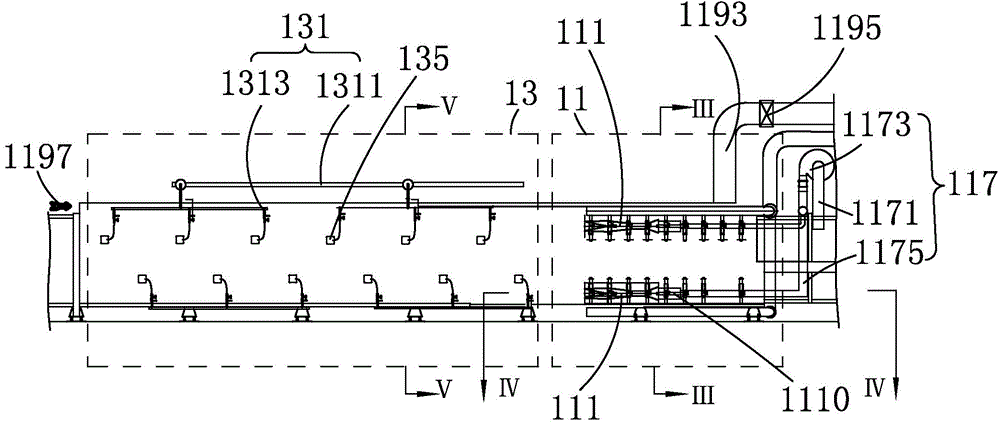

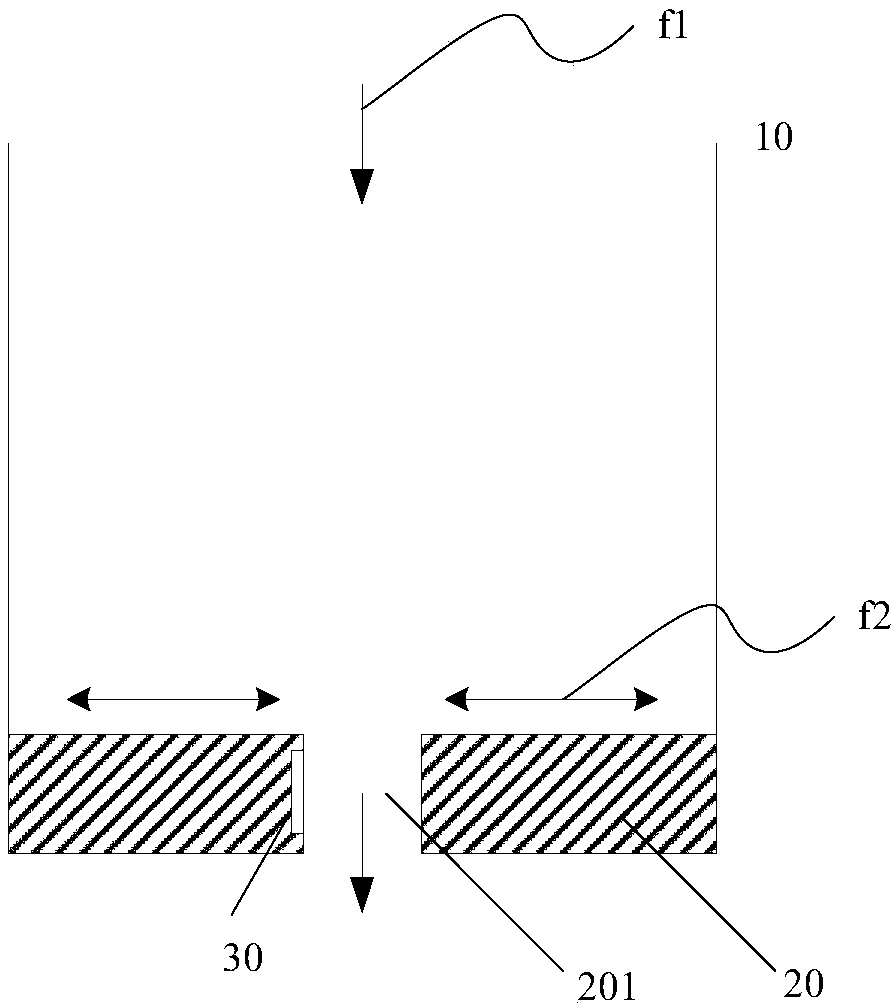

High-capacity device for receiving mailpieces

ActiveUS8256765B2Increase the number ofReduce ejection speedPile receiversStacking articlesEngineeringConveyor belt

A storage device for a mail-handling machine, said storage device comprising a mailpiece-receiving deck along a longitudinal edge of which a referencing wall extends, and through which a conveyor belt passes for the purpose of conveying mailpieces along said referencing wall from an inlet of the device towards a sloping surface against which said mailpieces accumulate, said storage device further comprising a pivot arm that is mounted to move both vertically about hinge pin and horizontally along a slide rail, on which arm firstly a friction roller is mounted for pressing said mailpieces against the conveyor belt, and secondly a holding roller is mounted for pressing said mailpieces against the sloping surface.

Owner:NEOPOST TECH SA

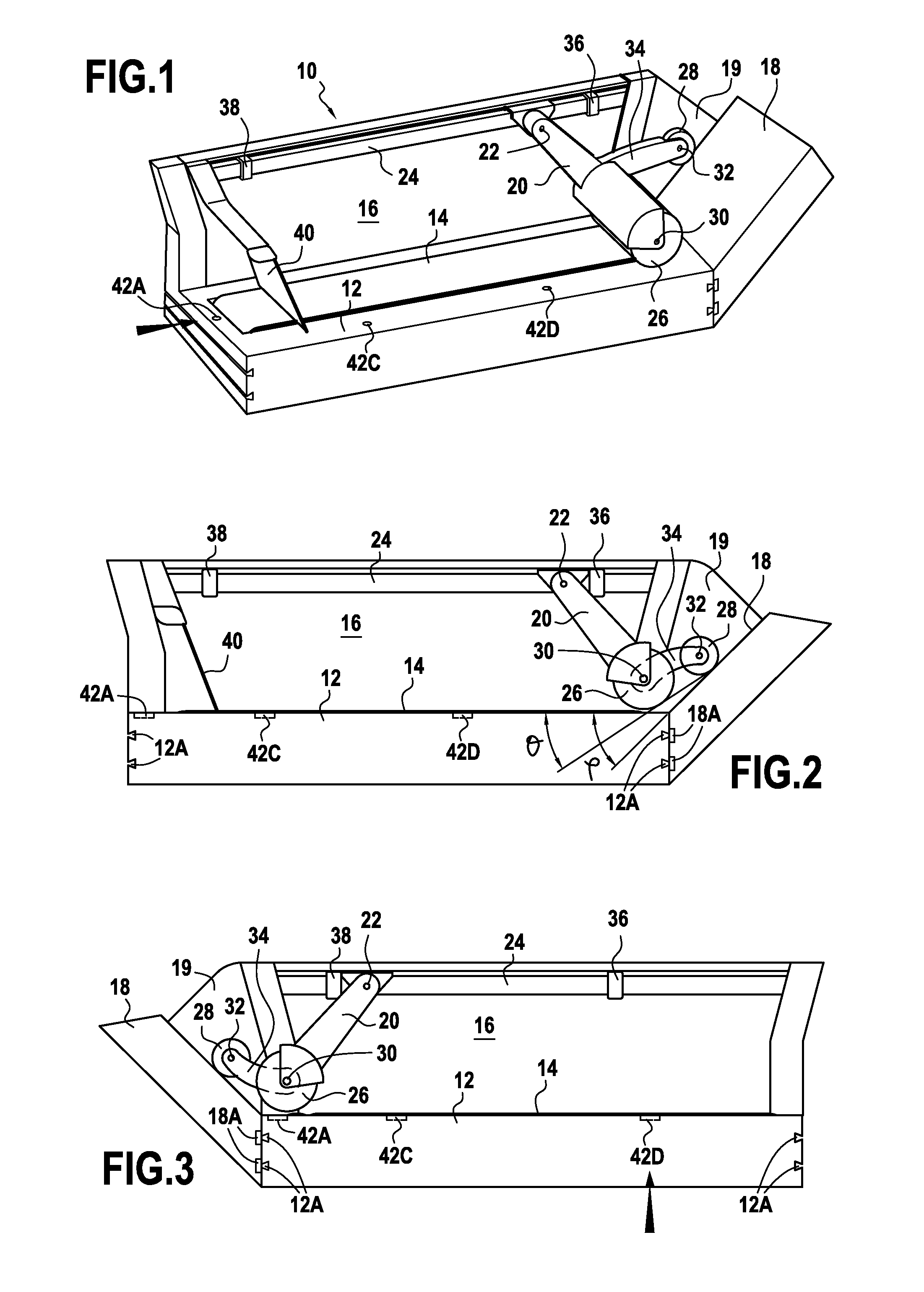

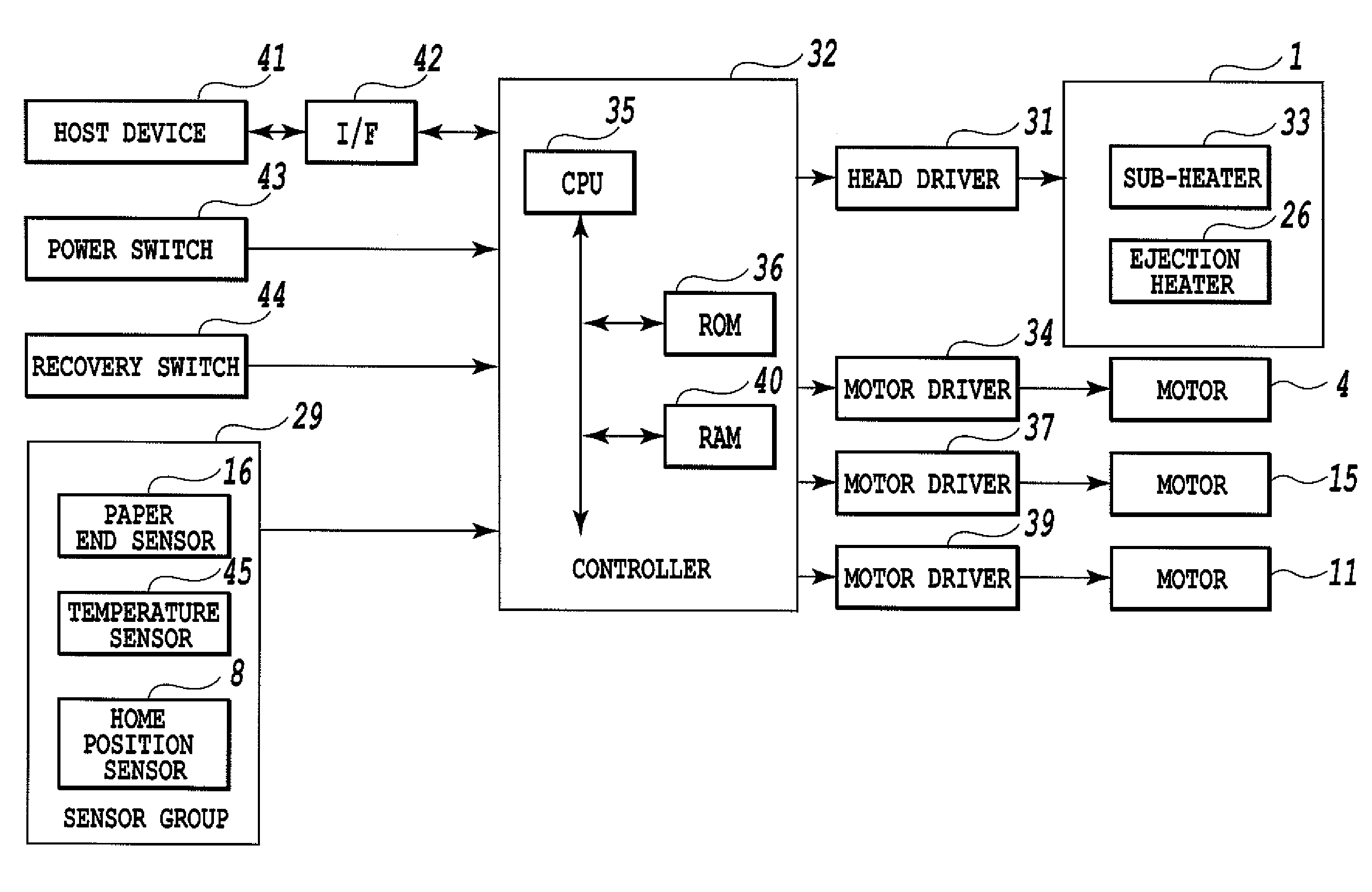

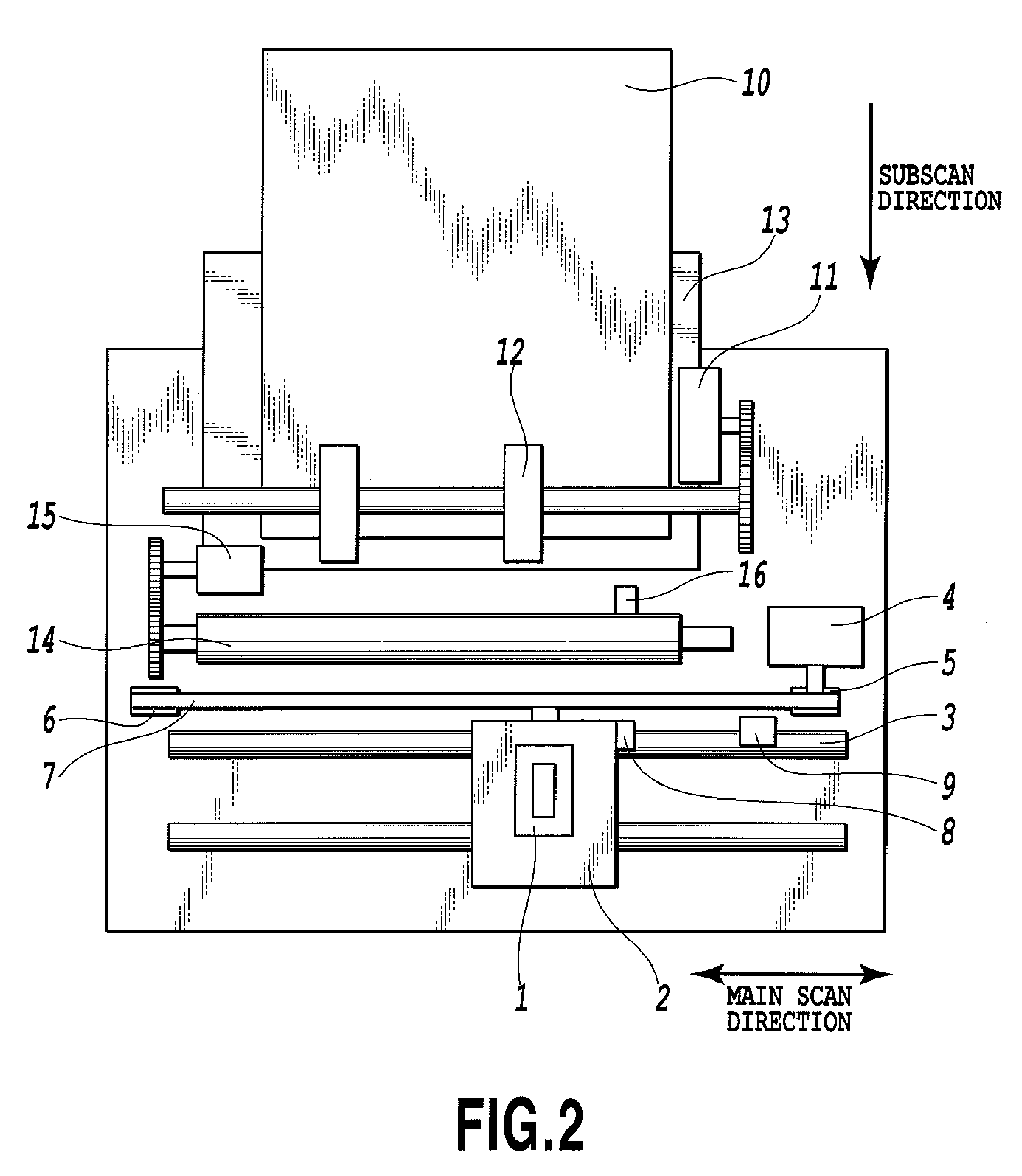

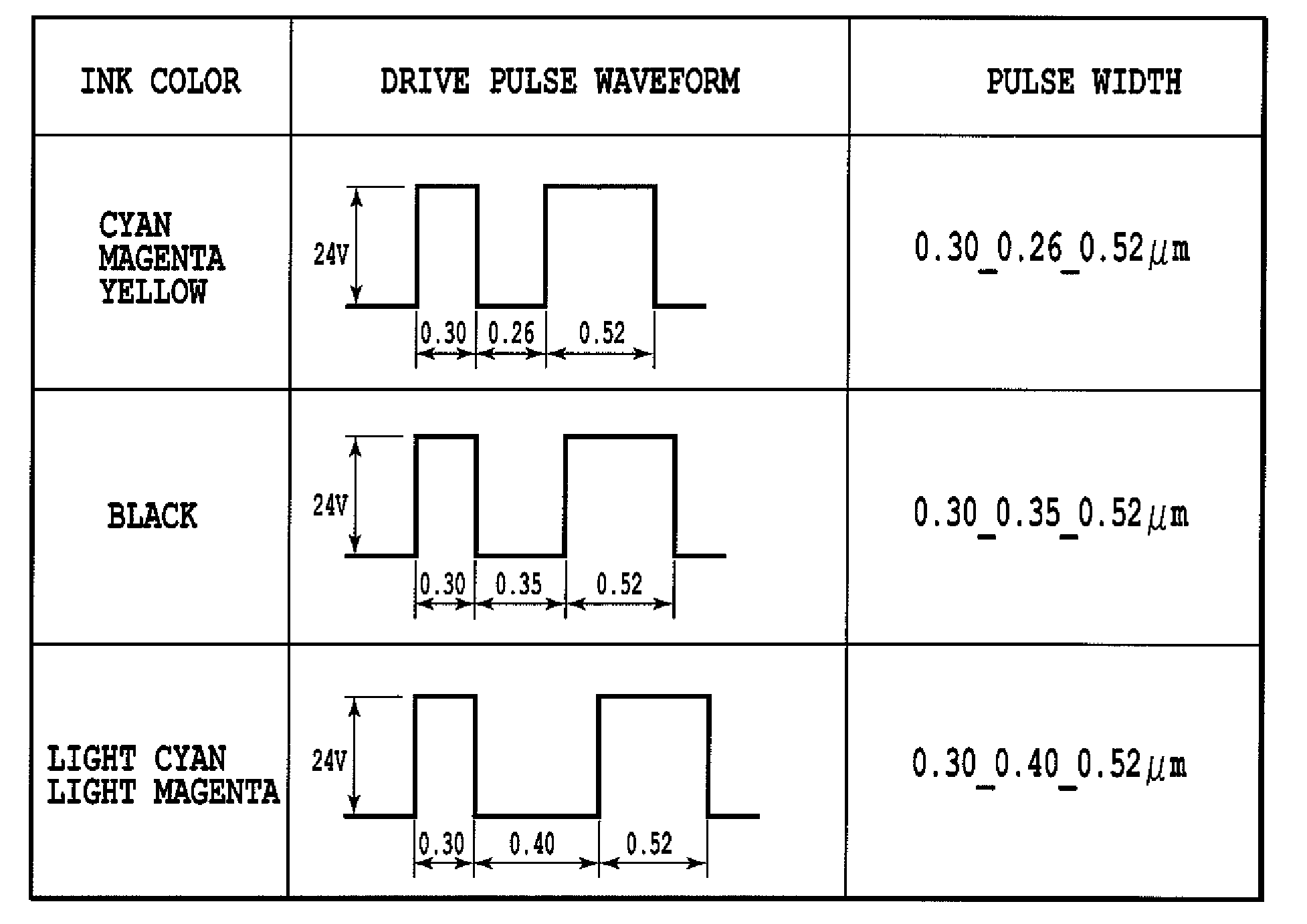

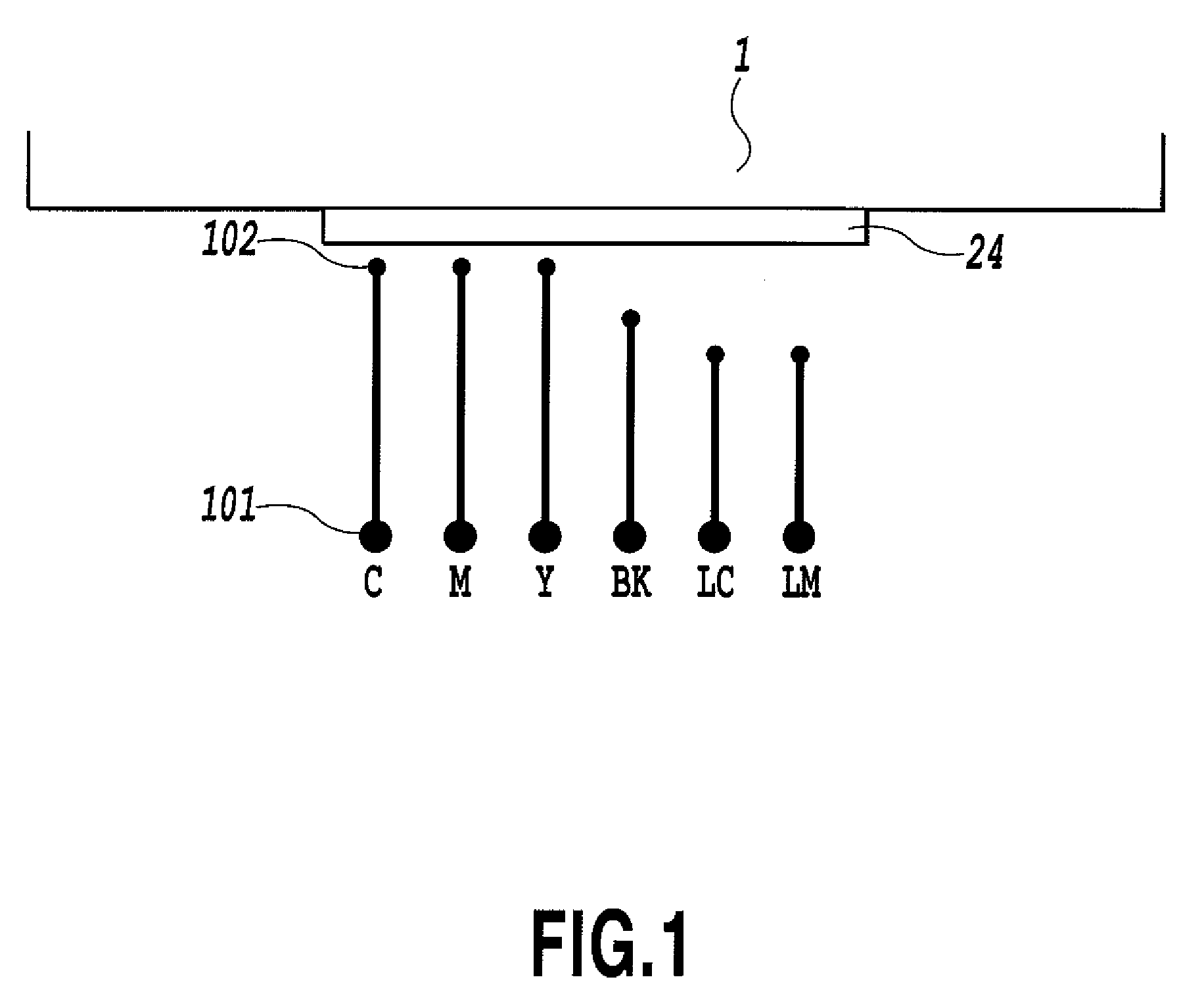

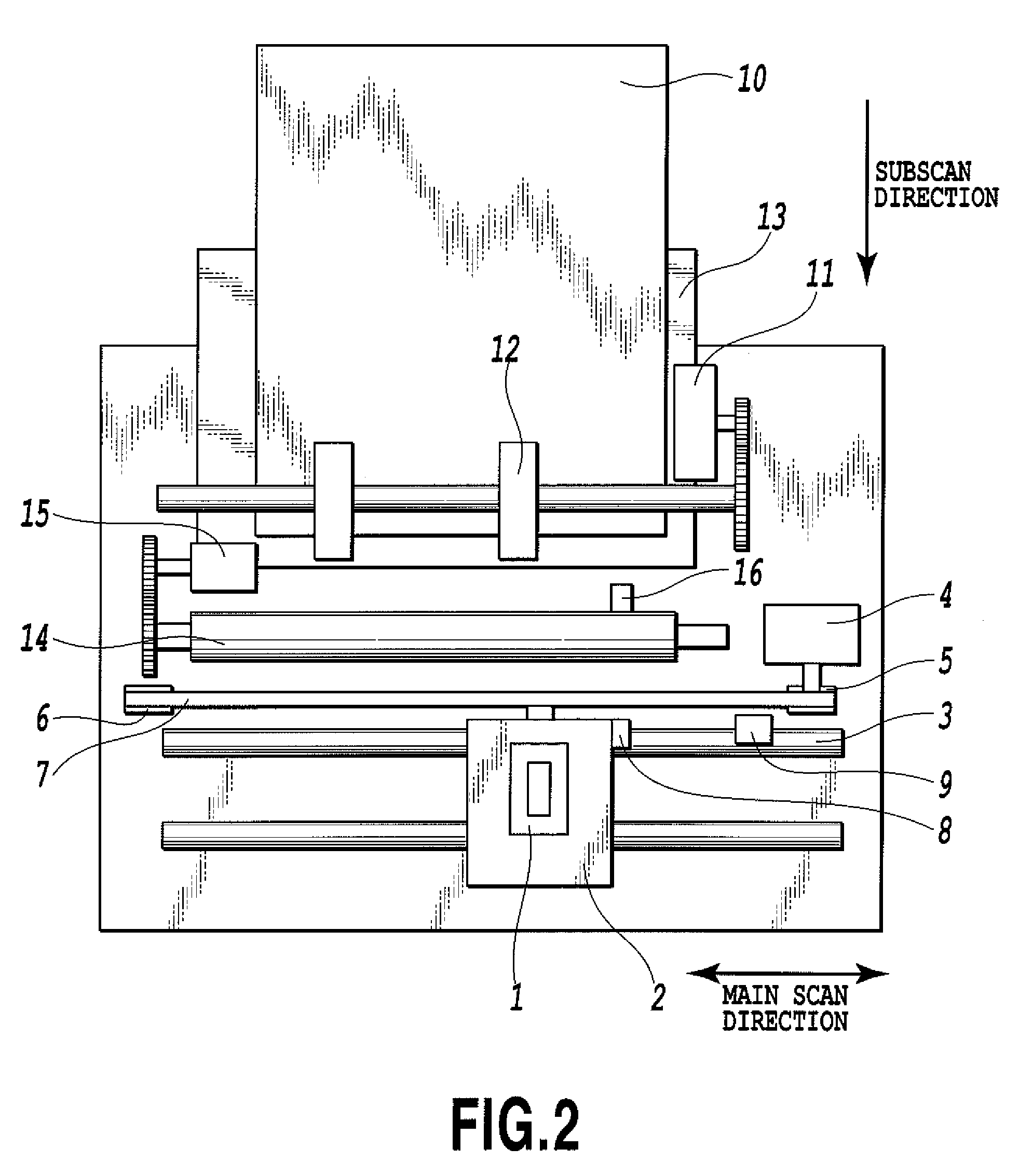

Ink jet printing apparatus and ink jet printing method

InactiveUS20080084442A1Reduce ejection speedViscosity of ink increaseOther printing apparatusSmall dropletImage density

In an ink jet printing apparatus that ejects a plurality of kinds of pigment inks in small droplets, the drive pulse waveform to be applied to each of the heaters is adjusted according to the viscosity of the ink in a way that assures that the lengths of liquid columns ejected are approximately equal among different colors. This enables the dot areas formed on a print medium to be constant among different colors, realizing an image output with excellent color reproducibility, free from variations in image density and tonality.

Owner:CANON KK

By-pass turbojet including a thrust reverser

ActiveUS8468796B2Compact structureWeight controlSpraying apparatusEfficient propulsion technologiesNacelleJet engine

A by-pass turbojet including a thrust reverser is disclosed. The thrust reverse includes a deflector device which deflects all or part of the primary stream gas in such a manner that the deflected primary stream gas encounters the secondary stream, thereby reducing the injection speed of the secondary stream in an aft direction, and thus generating the thrust-reversal effect. The secondary stream escapes from the aft end of the nacelle. In the thrust-reversal position, the deflector device is inscribed radially substantially within the section of the primary nozzle cowl at the aft end of the nacelle. Such a thrust reverser is particularly simple in design, inexpensive, and makes it possible to avoid having moving parts present on the outside portion of the nacelle, thus simplifying the design of the turbojet.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Ink jet printing apparatus and ink jet printing method

InactiveUS7753467B2Reduce ejection speedHigh viscosityOther printing apparatusSmall dropletImage density

In an ink jet printing apparatus that ejects a plurality of kinds of pigment inks in small droplets, the drive pulse waveform to be applied to each of the heaters is adjusted according to the viscosity of the ink in a way that assures that the lengths of liquid columns ejected are approximately equal among different colors. This enables the dot areas formed on a print medium to be constant among different colors, realizing an image output with excellent color reproducibility, free from variations in image density and tonality.

Owner:CANON KK

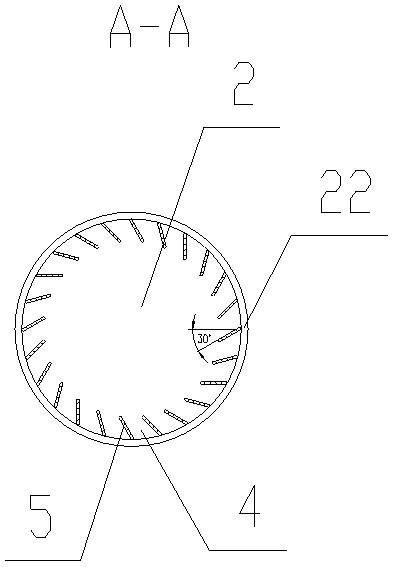

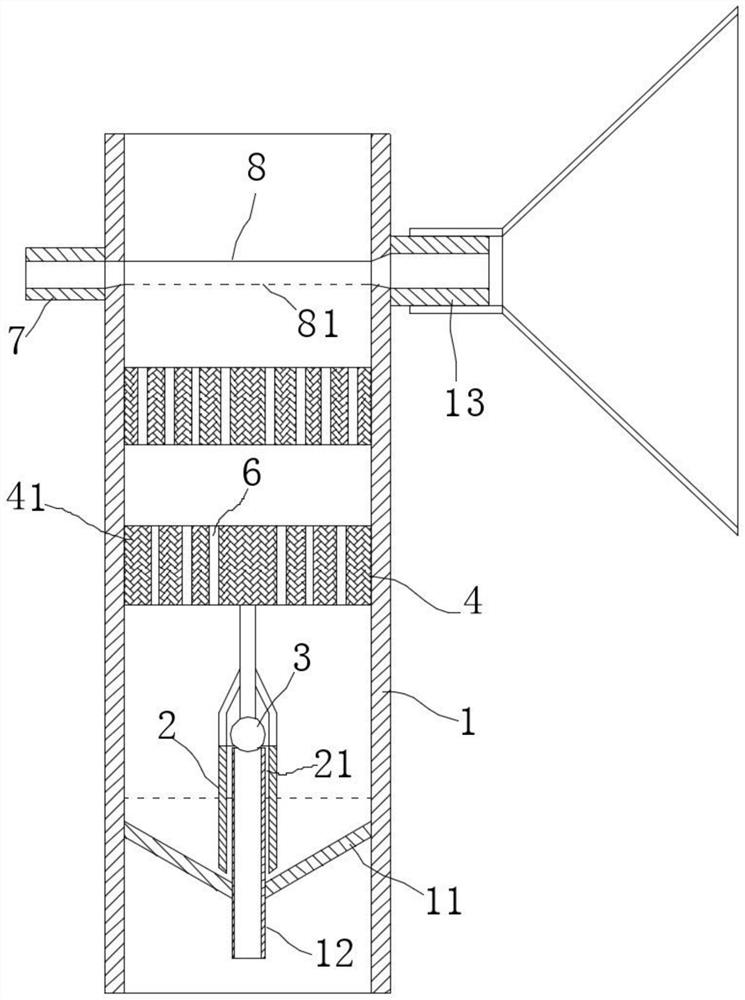

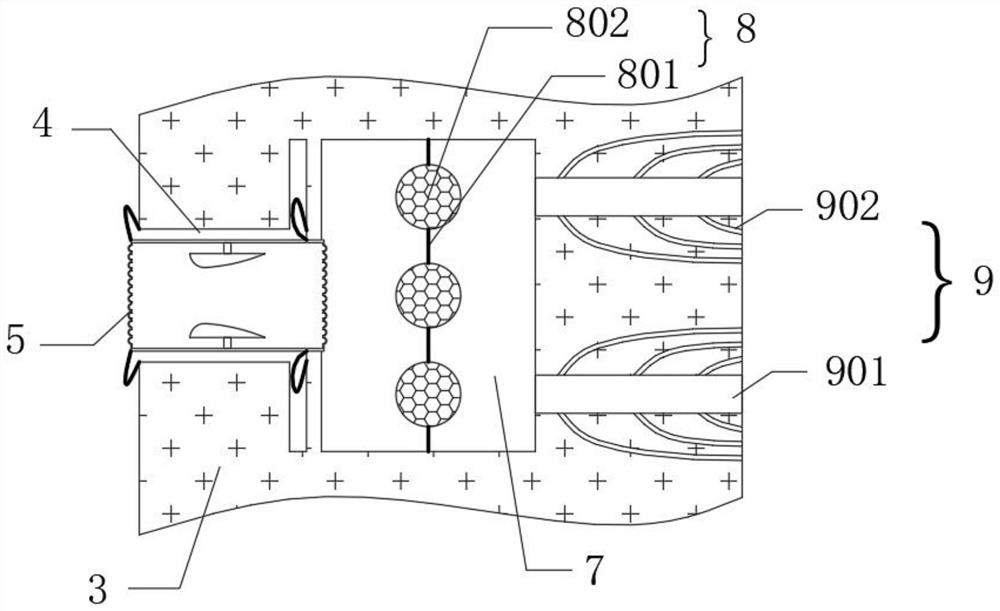

Mixed gas combustor

The invention discloses a mixed gas combustor, relating to a gas combustor. The mixed gas combustor comprises two channels which are embedded inside and outside, a combustion air channel is arranged on the periphery and a fuel channel is arranged in the center, a burner nozzle is formed on the front end of the combustion air channel, and the front end of the fuel channel is provided with a spraying orifice for enabling fuel in the fuel channel to be radially outwards spirally spayed. The invention aims at providing the novel gas combustor, which has better stable combustion while combusting low-heat-value gas fuel with large flow, can not cause nozzle burning and coking problems while combusting high-heat-value gas fuel with small flow, and can combust a mixed fuel of a low-heat-value gas fuel and a high-heat-value gas fuel.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

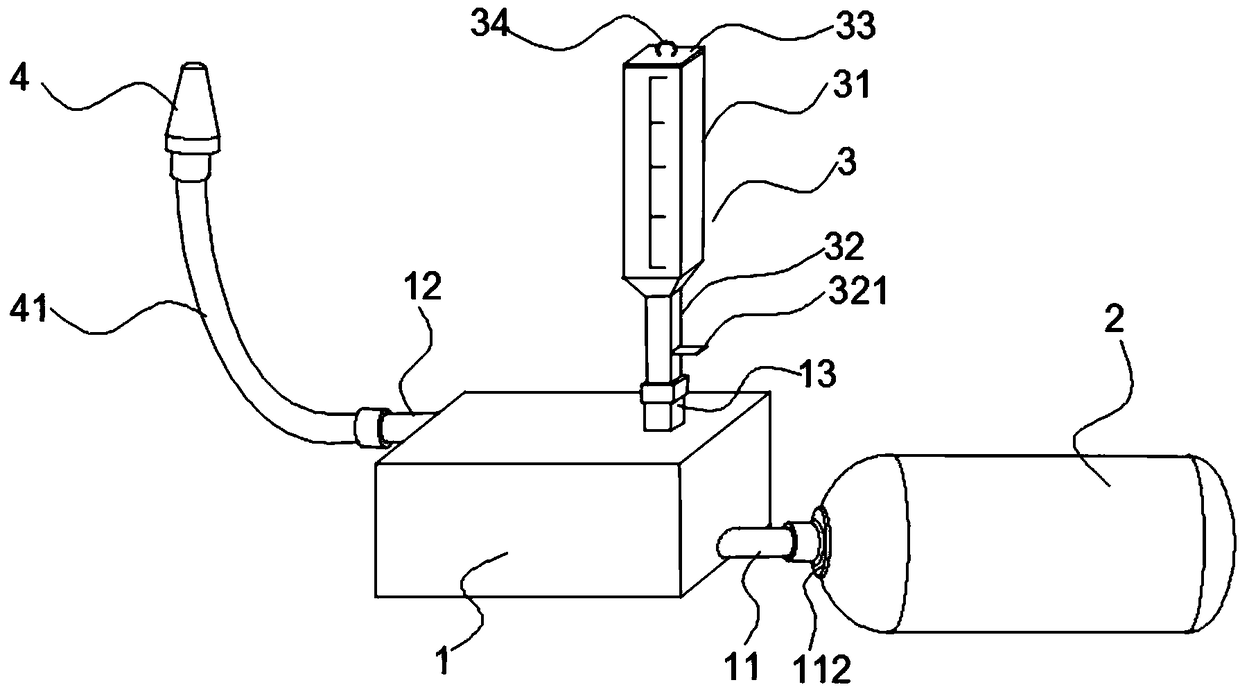

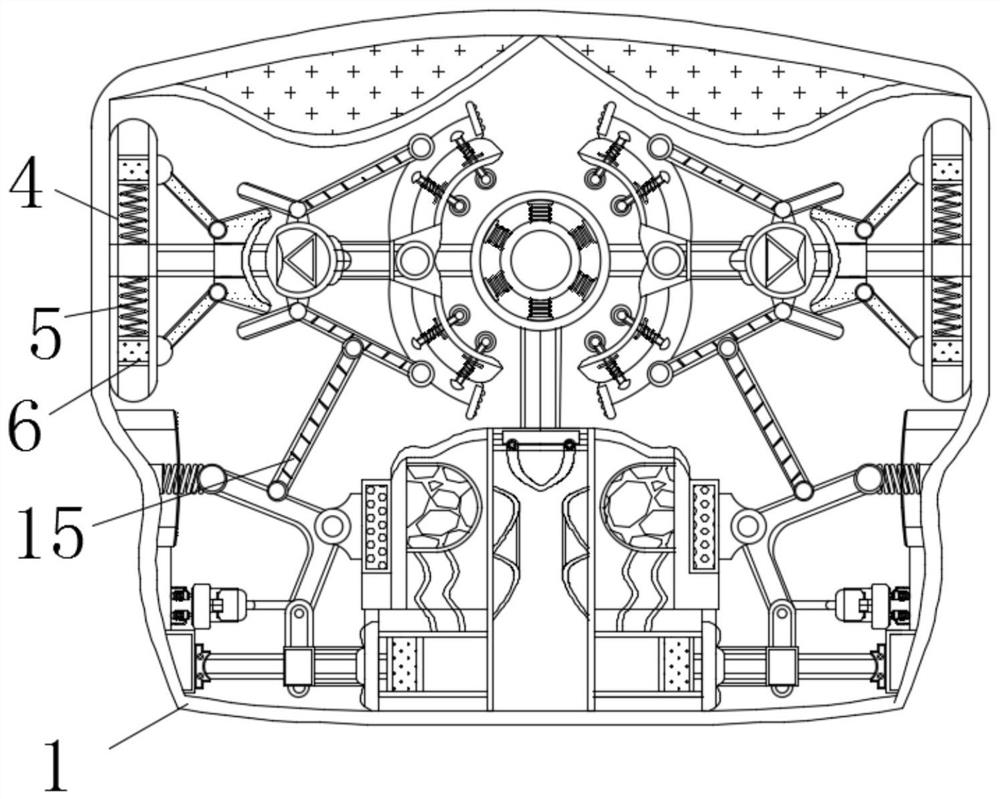

Portable dry powder nasal cavity inhalation and drug delivery device

The invention discloses a portable dry powder nasal inhalation and drug delivery device, which comprises a connecting base, an air bag, a feeding device and a spray head. An air bag connector and a spray head connector are arranged on the opposite side surfaces of the connecting base. A feeding port is formed in the top surface of the connecting base. A dust raising chamber communicated with the air bag connector, the nozzle connector and the feeding port is arranged in the feeding port. One end, closer to the spray head connector and inside the dust raising chamber, is provided with a plurality of net-shaped partition layers perpendicular to the bottom surface of the dust raising chamber. The feeding device comprises a transparent material storage chamber. Scales are arranged on the transparent material storage chamber. A discharging port is formed in the lower end of the transparent material storage chamber. The discharging port is connected with the feeding port of the connecting base, and the spray head is connected with the spray head connector through a guide pipe. A buffer device capable of relieving the delivery speed of the drug entering the nasal cavity is arranged in thespray head. The dry powder nasal cavity inhalation and drug delivery device can control the suction amount of drug dry powders. The speed of drug ejection can be effectively reduced, and the discomfort caused by the medication of a patient can be effectively improved.

Owner:CHENGDU YITIAN TECH CO LTD

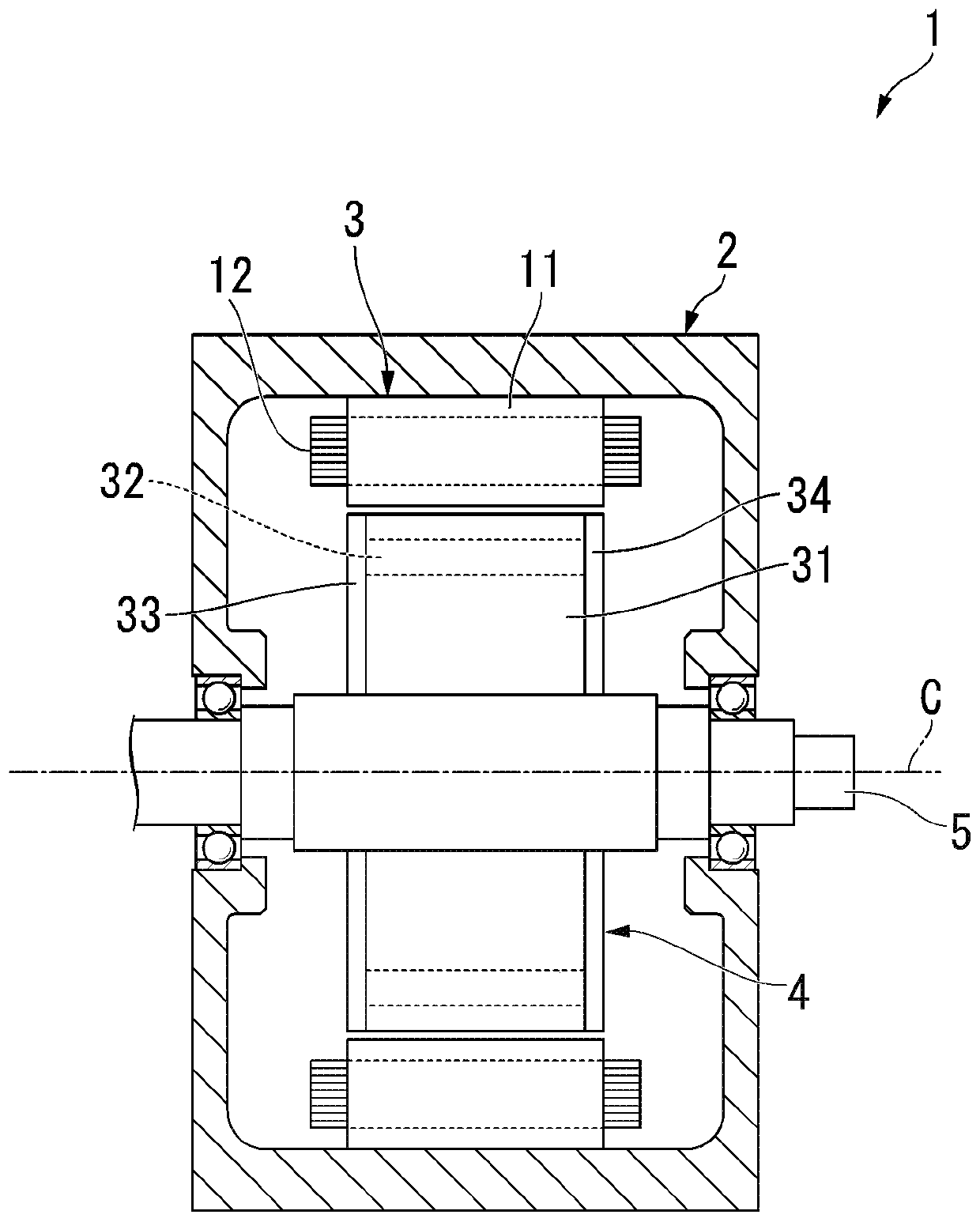

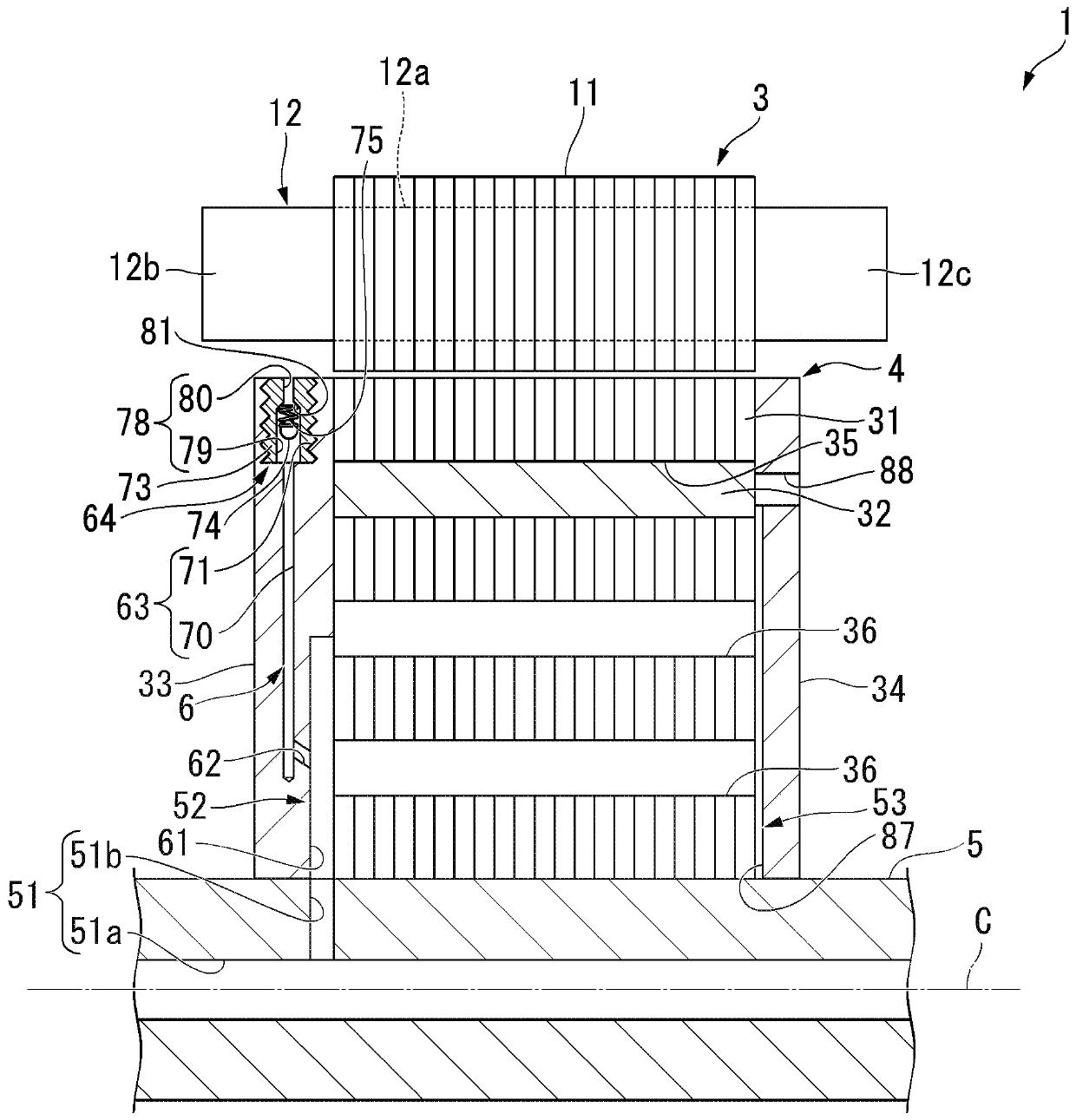

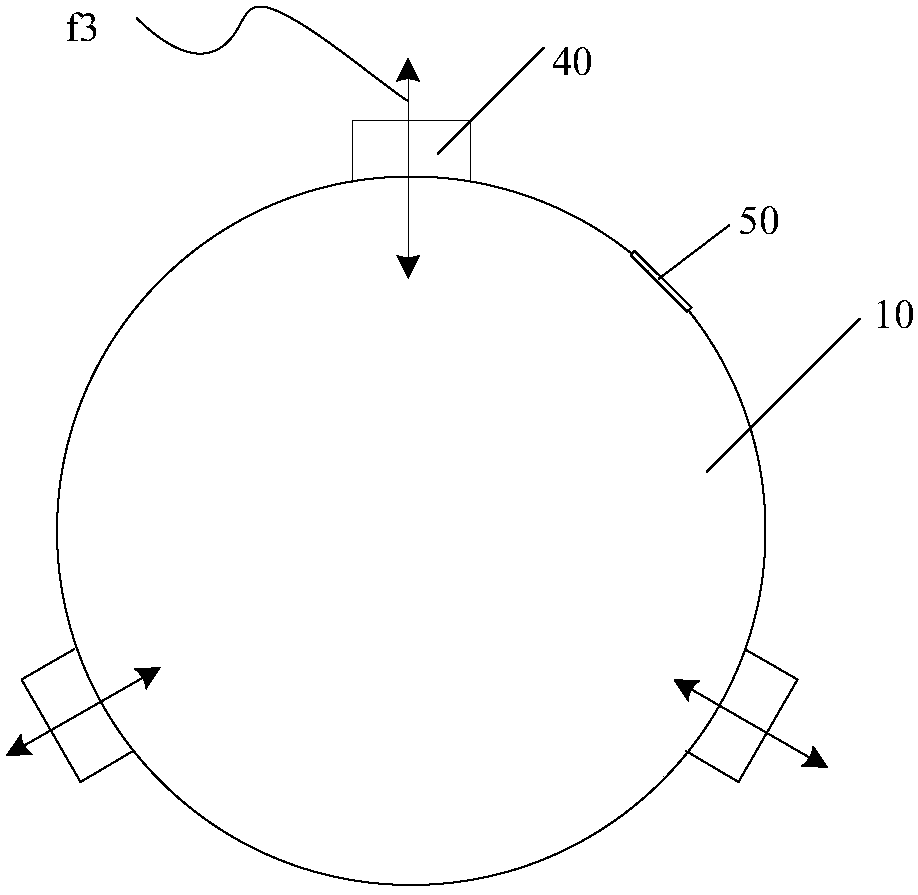

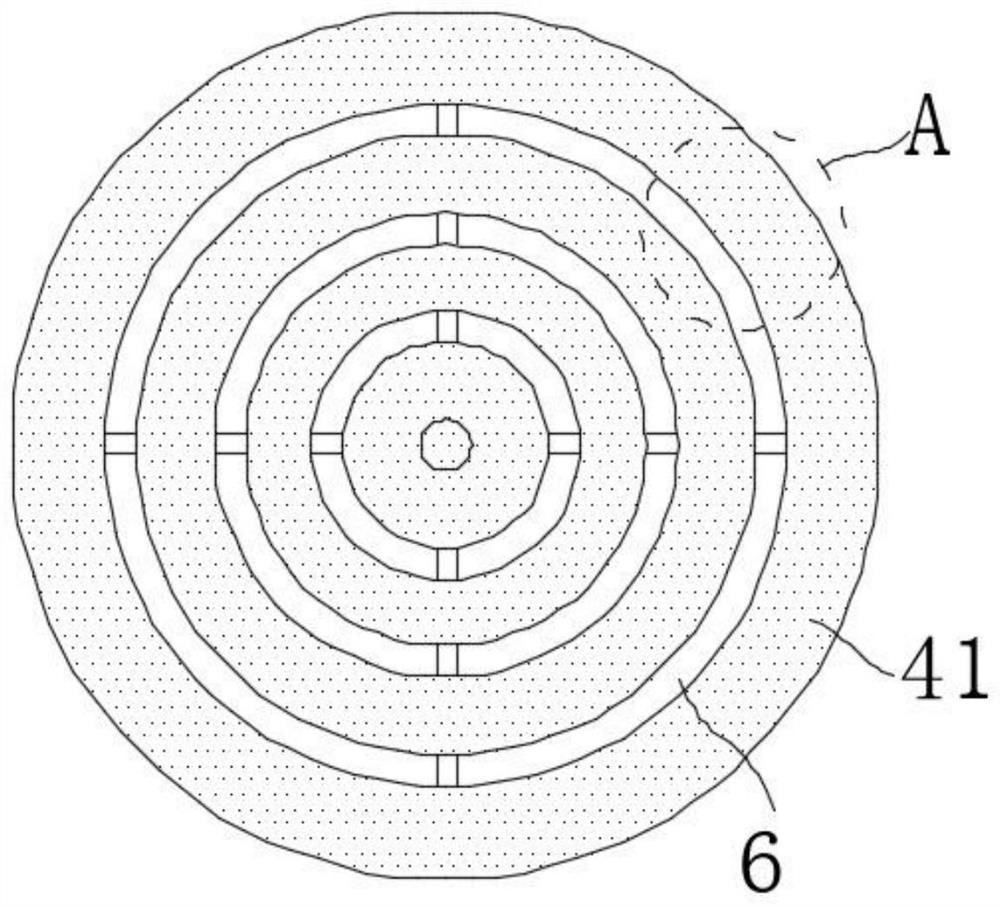

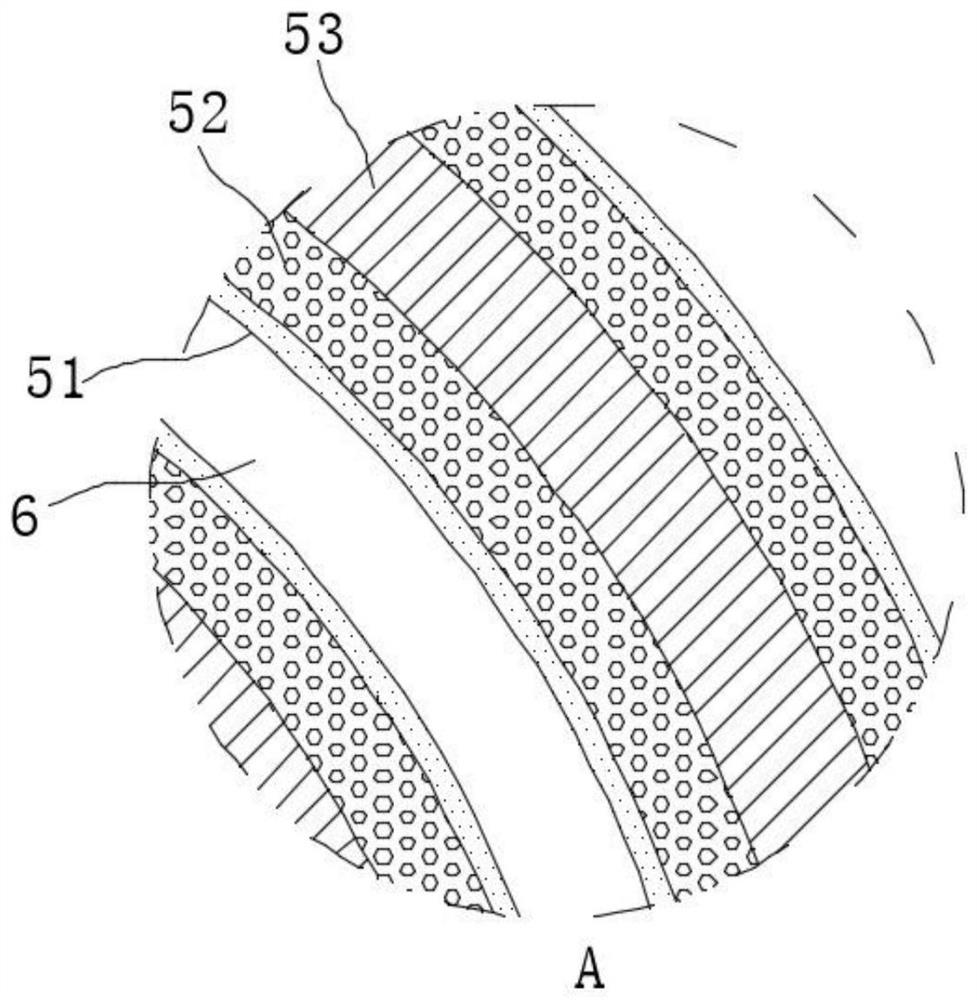

Rotating electrical machine

InactiveCN110098680AReduce openingImprove cooling effectMagnetic circuit rotating partsCooling/ventillation arrangementElectric machineMachine

A rotating electrical machine includes a tubular stator on which a coil is mounted, a rotor which is configured to be rotatable on an inner side in a radial direction with respect to the stator and has a rotor inner flow path through which a refrigerant can flow, and a refrigerant supply flow path which is provided in the rotor and through which a refrigerant flows from an inner side to an outer side in the radial direction as the rotor rotates. The refrigerant supply flow path includes a first flow path which communicates with the rotor inner flow path, and a second flow path which extends from the first flow path to an outer side in the radial direction and has a discharge port opening at an end portion in an axial direction of the rotor. A refrigerant adjustment section which adjusts adischarge amount of the refrigerant discharged from the discharge port by reducing an opening degree of the discharge port as a rotation speed of the rotor increases is provided in the second flow path.

Owner:HONDA MOTOR CO LTD

Three-ring fire burner and gas stove

ActiveCN110186042AStrong firepowerIncrease the areaDomestic stoves or rangesGaseous fuel burnerHeat lossesEngineering

The invention relates to the technical field of household gas stoves, in particular to a three-ring fire burner and a gas stove. The three-ring fire burner comprises a gas dividing base, wherein an outer-ring fire cover and an inner-ring fire cover are sequentially arranged on the top of the gas dividing base from outside to inside; a plurality of fire holes are formed in the the inner side of theouter-ring fire cover; a fire groove is formed among the fire holes; the gas outgoing directions of the fire holes and the fire groove point to a central area of the burner; a water receiving tray isarranged at the bottom of the gas dividing base; and an injection tube is arranged at the bottom of the water receiving tray. According to the three-ring fire burner and the gas stove disclosed by the invention, through arrangement of the fire holes and the fire groove pointing to the central area of the burner, heat-gathering burning can be carried out, so that the heating efficiency is improved, and the heat loss is reduced; through arrangement of a second fire outlet hole and a third fire outlet hole, the area of fire outlet holes can be increased; and through arrangement of partitioning plates, a structure of the inner-ring fire cover is more compact, and the size of the top part of the burner can be reduced, so that the heat exchanging time between a pot bottom and flame is extended,the heat exchanging area is increased, the heat efficiency of the gas stove is improved, and the cost of the burner is reduced.

Owner:深圳市唐家厨房设备有限公司

Dyeing device

InactiveCN112921562AThe ejection speed slows downLess dyes and auxiliaries brought outTextile treatment dyeing devicesPhysicsDyeing

The invention discloses a dyeing device. The dyeing device comprises a cup body, a cup cover and an abutting block and a spring; the cup cover is detachably connected with the cup body; the cup cover is provided with a through first cylinder part in the vertical direction; the periphery of the first cylinder part is provided with a second cylinder part; the second cylinder part extends downwards from the bottom of the cup cover, and a plurality of open holes are formed in the side wall of the second cylinder part; the abutting block and the spring are sequentially arranged in the second cylinder part; the abutting block is sleeved with a first sealing ring; the first sealing ring abuts against an opening in the bottom of the first cylinder part; the abutting position is lower than the opening position in the side wall of the second cylinder part; and a containing space is formed between the abutting position and the opening position. The steam is sprayed from the containing space at the upper part to the abutting position at the lower part, the spraying speed is reduced, less dye and assistant are brought out, and the dyeing effect is improved.

Owner:广州市鸿通机械有限公司

Roller kiln and working method thereof

InactiveCN104807324AMeet delivery requirementsIncrease temperatureCombustion processFurnace typesCombustorEngineering

The invention provides a roller kiln and a working method thereof. The roller kiln comprises an injection mixer, a high temperature waste heat air duct, an injection burner and a waste heat air system; the roller kiln is divided into a preheating section, a firing section and a cooling section along the direction of movement of products; the injection mixer is arranged on the cooling section; the injection burner is arranged on the firing section; the high temperature waste heat air duct is communicated with the cooling section and the firing section; the waste heat air system is arranged at the top of the firing section and the top of the cooling section; the injection mixer is of a concealed venturi tube structure and the injection burner is of a concealed venturi tube structure. According to the roller kiln and the working method thereof, the injection mixer which is of a venturi tube structure is added into the roller kiln so as to directly suck the high temperature waste heat air of a cooling zone of the roller kiln to be pressurized and conveyed to the injection burner of a firing zone and accordingly the high temperature waste heat is well utilized, the sufficient burning is ensured, the energy is saved, and the production workshop environment is improved.

Owner:HUNAN OTLAN IND EQUIP

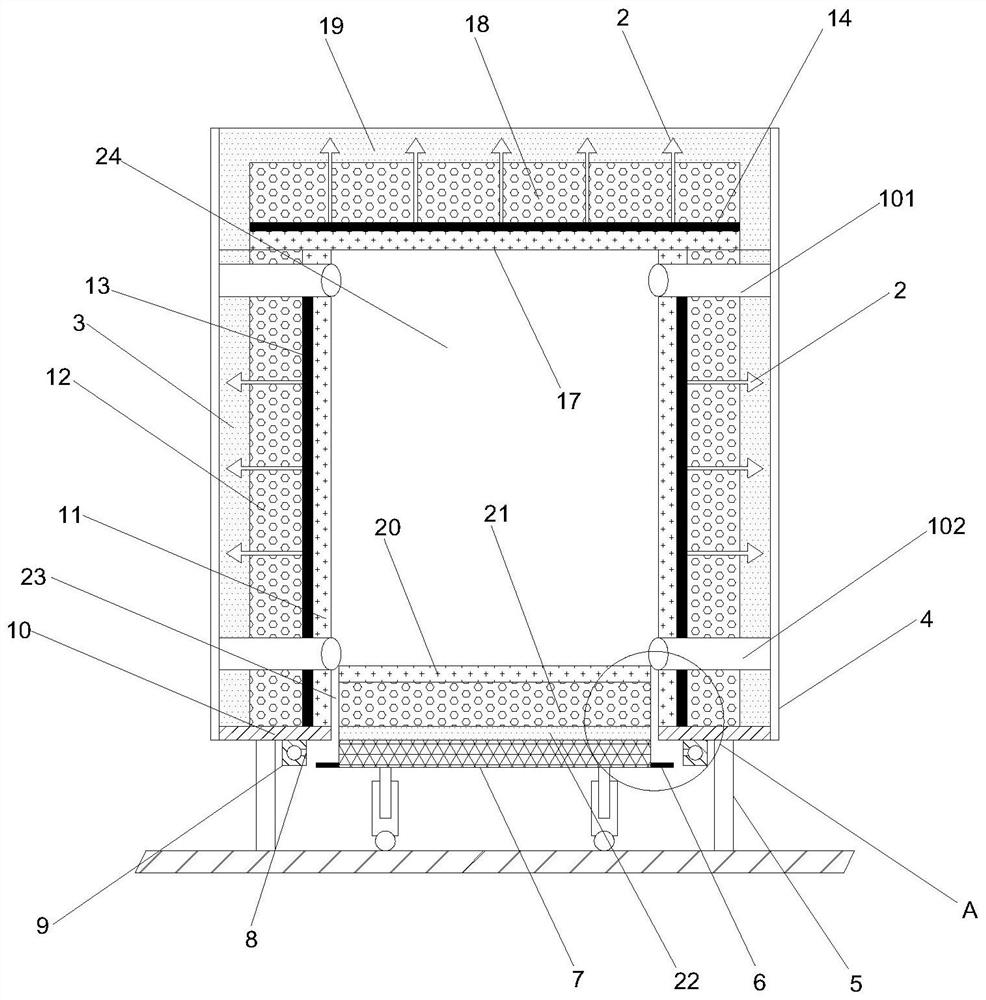

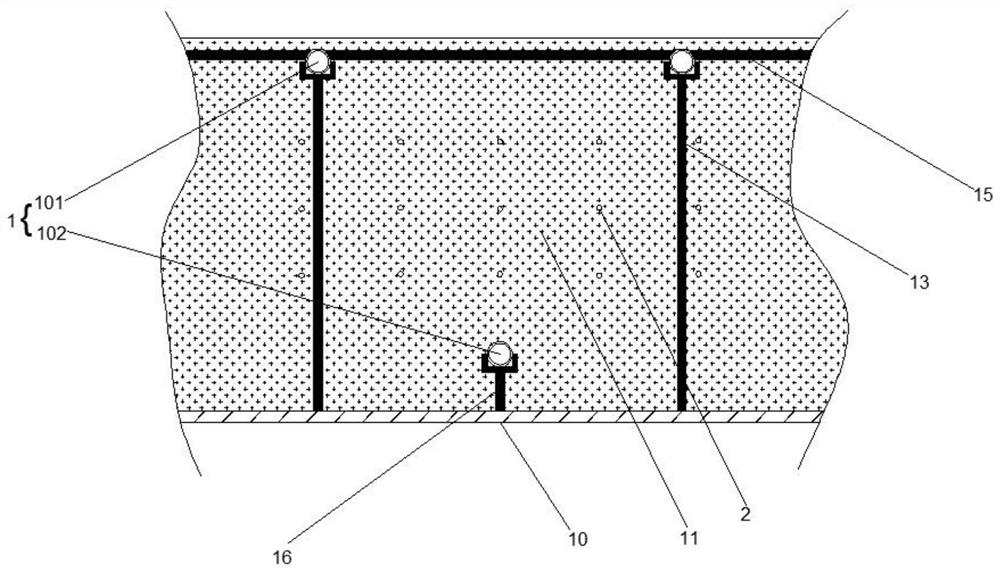

Novel energy-saving kiln

Owner:汤勇

A three-ring fire burner and gas stove

ActiveCN110186042BStrong firepowerIncrease the areaDomestic stoves or rangesGaseous fuel burnerEngineeringHeat losses

Owner:深圳市唐家厨房设备有限公司

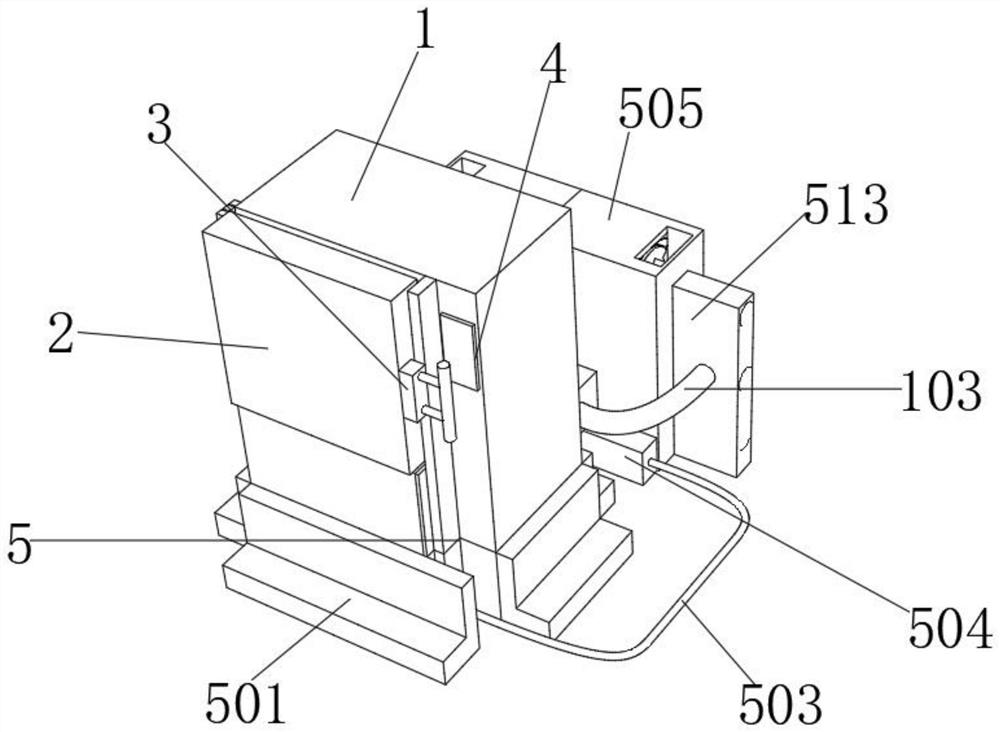

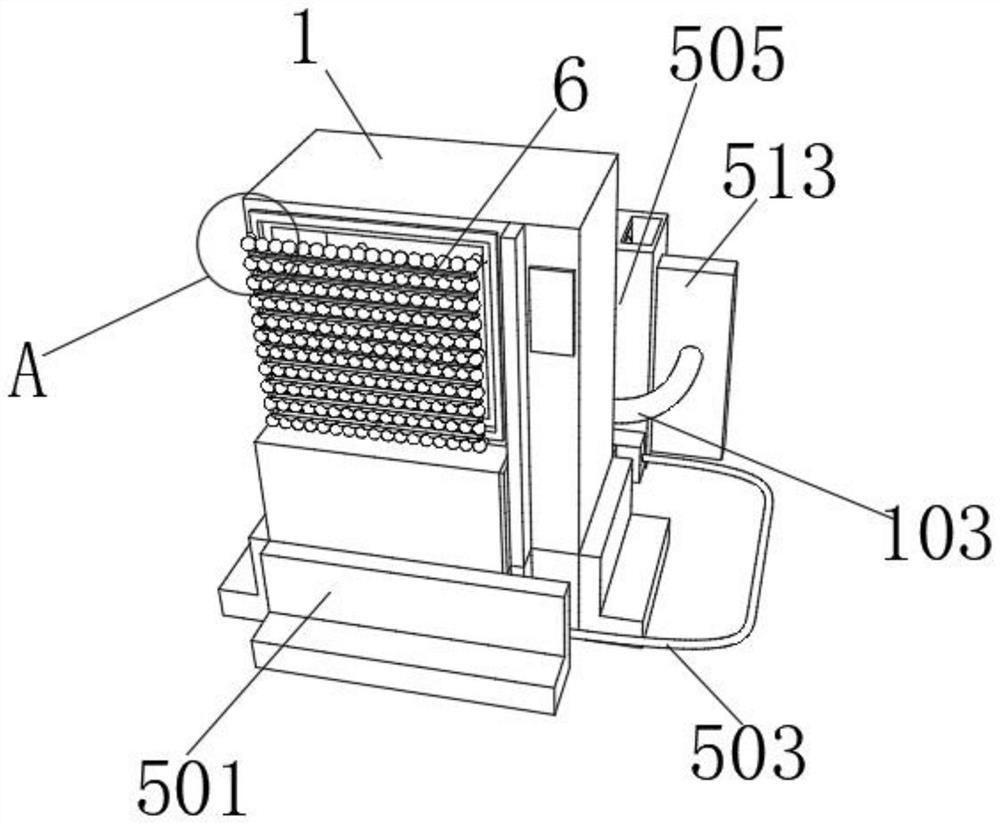

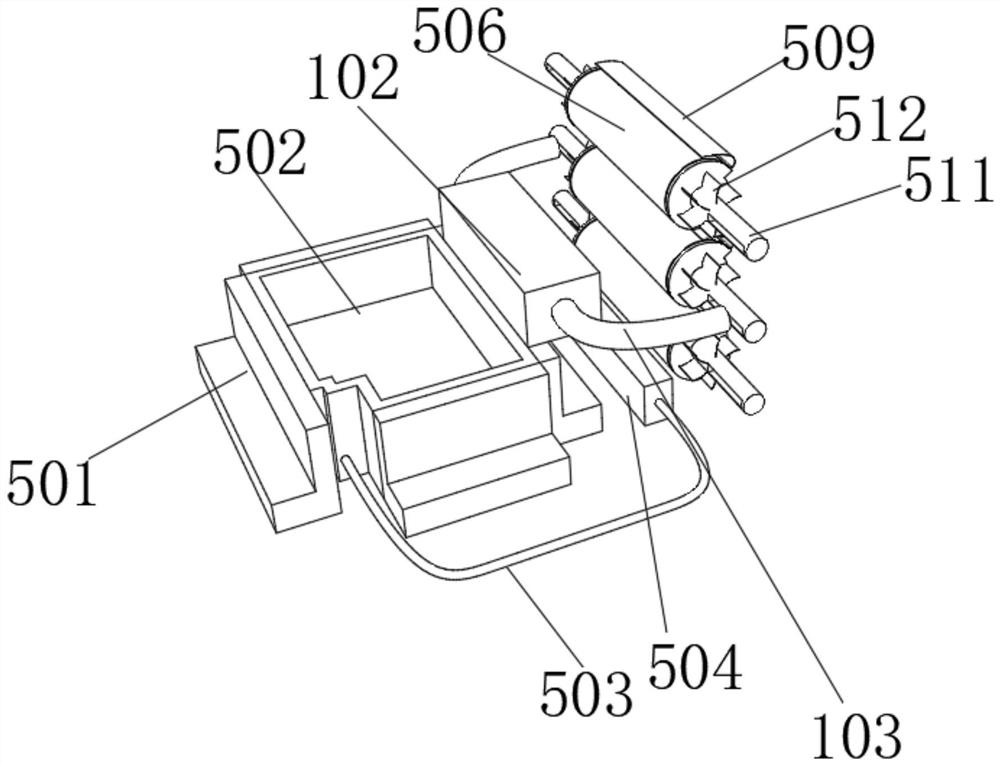

A small air compressor for environmental protection construction and its use method

ActiveCN111810383BImprove noise reductionRealize dynamic changesPositive displacement pump componentsPositive-displacement liquid enginesStructural engineeringEnvironmental engineering

The invention discloses a small-sized air compressor for environmental protection construction and its use method, which belongs to the field of air compressors. It uses the principle of aerodynamics to make two pneumatic parts approach each other under the action of air flow, so that the front and rear sections There is a large mutation in the area to improve the noise reduction effect, and the greater the airflow intensity, the greater the change in the cross-sectional area of the aerodynamically deformable shell, and the better the noise reduction effect. The annular cavity inside the aerodynamic weakening part is used to weaken the airflow The flow rate, and two air inlet holes and one air outlet hole can allow the airflow to form convection, which has a certain noise reduction effect. The porous airflow disturbance ball is used to further weaken the airflow velocity, and finally the airflow passes through the airflow distribution pipes with different inner diameters. Ejection, once again uses the sudden change of the cross-sectional area to reduce noise, and further improves the noise reduction effect. Compared with the existing technology, it realizes the dynamic change of the cross-sectional area, and strengthens the effect of using the sudden change of the cross-sectional area to reduce noise.

Owner:汉尼米克(山东)智能科技有限公司

Cover type multi-point sprinkler head

The invention discloses a cover type multi-point sprinkle head which can relieve the liquid medicine spraying velocity and prevent liquid medicine from splashing to the outside. The cover type multi-point sprinkle head is characterized in that one end of the sprinkle head is connected with an anti-splashing cover (3) which reduces the outside splashing liquid medicine, and the other end of the sprinkle head is provided with a screwed joint (1) which is connected with a spray rod of a sprayer; and the lower end of the anti-splashing cover (3) is opened, and spray ports (2) are respectively formed on the top of an inner cavity and side part which is connected with the sprinkle head and are communicated with a medicine box through the spray rod of the sprayer. The spray ports for top spraying and multi-point side spraying are formed in the sprinkle head, so that the number of liquid medicine outlets is increased, uniform spraying can be realized, the liquid medicine spraying speed of each spray port is relieved, the liquid medicine splashing is reduced, and the liquid medicine is sprayed to a smoke rod in the whole anti-splashing cover at low velocity in a short time.

Owner:云南省烟草公司保山市公司昌宁分公司

High and low temperature test box capable of simulating atmospheric temperature change for instrument detection

PendingCN114177953AReduce gapAffect normal operationCombination devicesHeating or cooling apparatusAtmospheric temperatureEngineering

The invention provides a high and low temperature test box capable of simulating atmospheric temperature change for instrument detection, and relates to the technical field of instrument detection. The instrument detection high and low temperature test box capable of simulating the atmospheric temperature change comprises a test box, a sealing door, a handle, a control center, a filtering mechanism and a buffer mechanism, the sealing door is rotatably connected to the front side of the test box close to the top end, the handle is fixedly connected to the right side of the sealing door, and the control center is fixedly connected to the front side of the test box on the right side of the handle; the bottom end of the test box is fixedly connected with a filter mechanism, a buffer mechanism is arranged in the part between the test box and the sealing door, and the buffer mechanism prevents internal hot air from being sprayed out to scald workers when the sealing door is opened. The problem that the instrument detection result of the high and low temperature test box is affected by high air humidity and excessive dust in the air is solved.

Owner:JIANGSU JACK INSTR

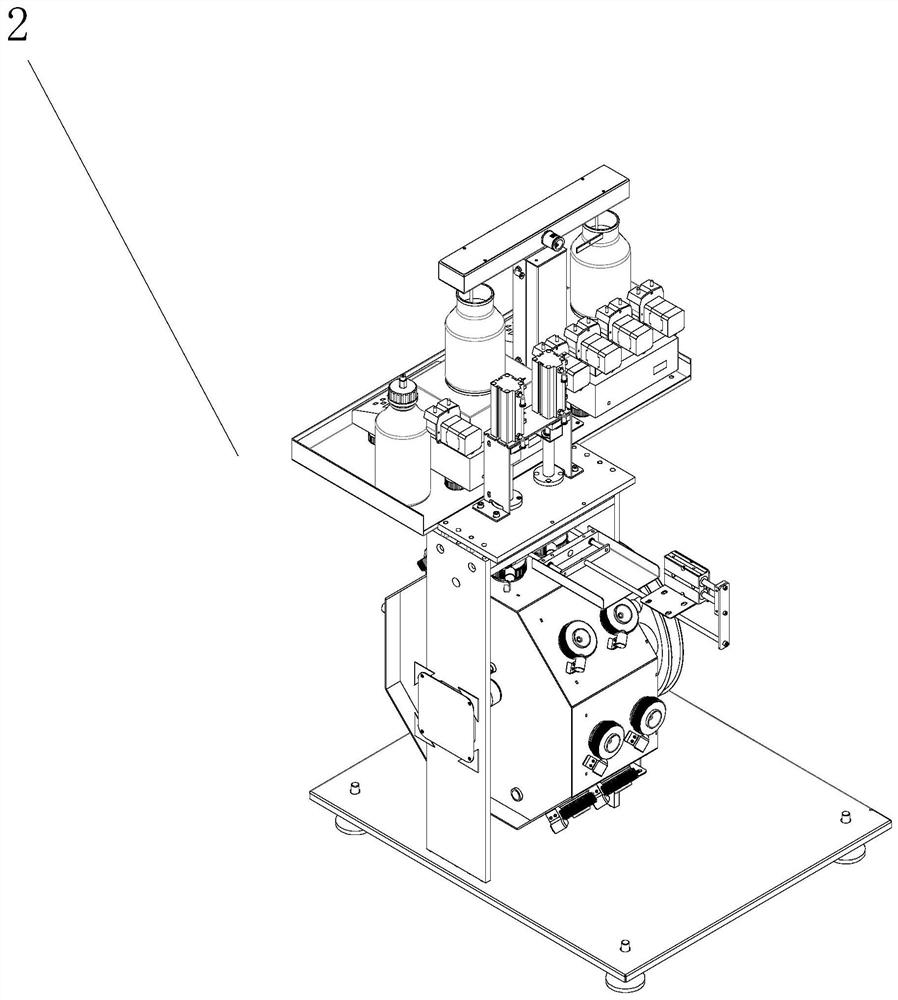

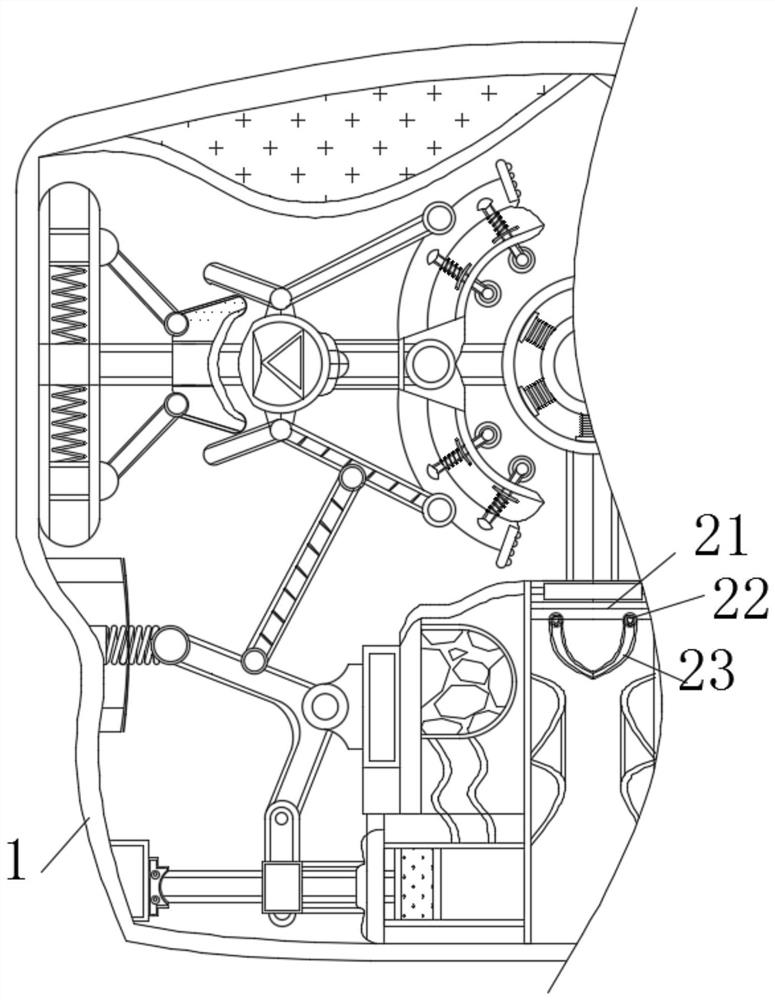

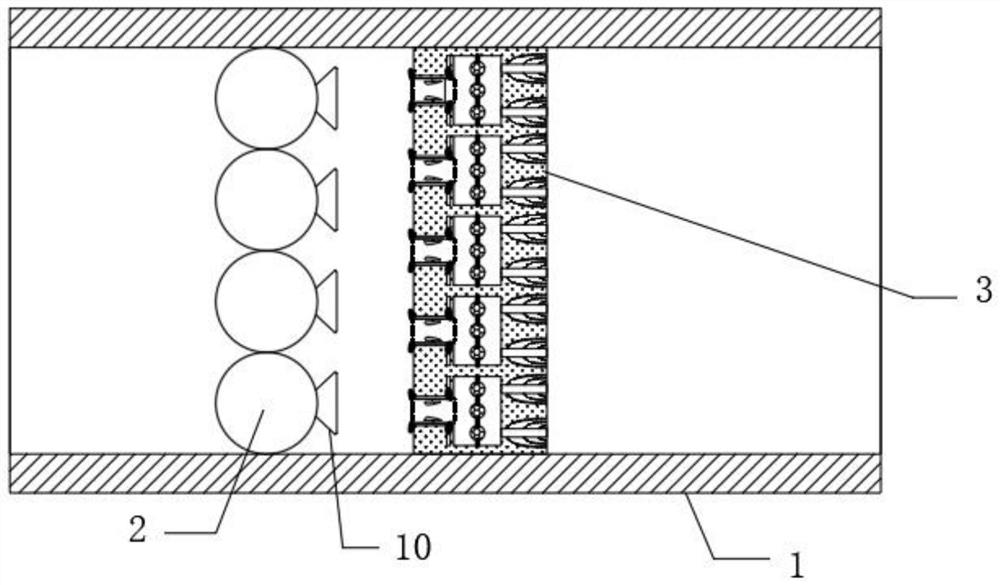

Inkjet equipment capable of slowly reducing machine operation inertia through rolling

InactiveCN112477429AIncrease frictionReduce ejection speedOther printing apparatusDrive shaftEngineering

The invention relates to the technical field of computer inkjet, and provides inkjet equipment capable of slowly reducing machine operation inertia through rolling. The inkjet equipment comprises a shell, the inner wall of the shell is movably connected with a driving shaft, the outer wall of the driving shaft is movably connected with a rotating shaft, and the outer wall of the rotating shaft isfixedly connected with a turntable. According to the inkjet equipment capable of slowly reducing the machine operation inertia through rolling, when inkjet is finished, a driving shaft still rotates due to inertia, centrifugal force borne by a sliding block is reduced, the sliding block moves towards the circle center of a rotary disc, the sliding block enables a fixing frame to extrude a first turning rod through a linkage rod, and the first turning rod changes the opening and closing degree of an arc-shaped plate. The arc-shaped plate enables a pulley to make contact with the outer wall of the driving shaft, the pulley gives rolling friction force to the driving shaft, and the rolling friction force is continuously increased, so that the ink spraying speed is decreased, and the speed ofa rotating wheel is decreased. A valve draws back to block an outlet, the pulley gives slow speed to the driving shaft to reduce the spraying speed, and the rolling friction force deceleration givingclosing time is increased.

Owner:广州市美色喷画设计有限公司

Burner

The object is to provide a burner capable of taking in sufficient primary air even though the size thereof is compact, and capable of being used as an all-primary air burner. A burner includes a mixing pipe to which a fuel gas and combustion air are supplied, a burner main body having a mixing chamber at a top end on a downstream side of the mixing pipe, and a burner head which is provided at an upper part of the burner main body while communicating with the mixing chamber and has first and second burner ports for ejecting mixed gas of the fuel gas and air for combustion mixed in the mixing chamber. The burner further includes an extension pipe in the burner main body protruding inside the mixing chamber being formed by extending the mixing pipe.

Owner:PALOMA

Cover type multi-point sprinkle head

The invention discloses a cover type multi-point sprinkle head which can relieve the liquid medicine spraying velocity and prevent liquid medicine from splashing to the outside. The cover type multi-point sprinkle head is characterized in that one end of the sprinkle head is connected with an anti-splashing cover (3) which reduces the outside splashing liquid medicine, and the other end of the sprinkle head is provided with a screwed joint (1) which is connected with a spray rod of a sprayer; and the lower end of the anti-splashing cover (3) is opened, and spray ports (2) are respectively formed on the top of an inner cavity and side part which is connected with the sprinkle head and are communicated with a medicine box through the spray rod of the sprayer. The spray ports for top spraying and multi-point side spraying are formed in the sprinkle head, so that the number of liquid medicine outlets is increased, uniform spraying can be realized, the liquid medicine spraying speed of each spray port is relieved, the liquid medicine splashing is reduced, and the liquid medicine is sprayed to a smoke rod in the whole anti-splashing cover at low velocity in a short time.

Owner:云南省烟草公司保山市公司昌宁分公司

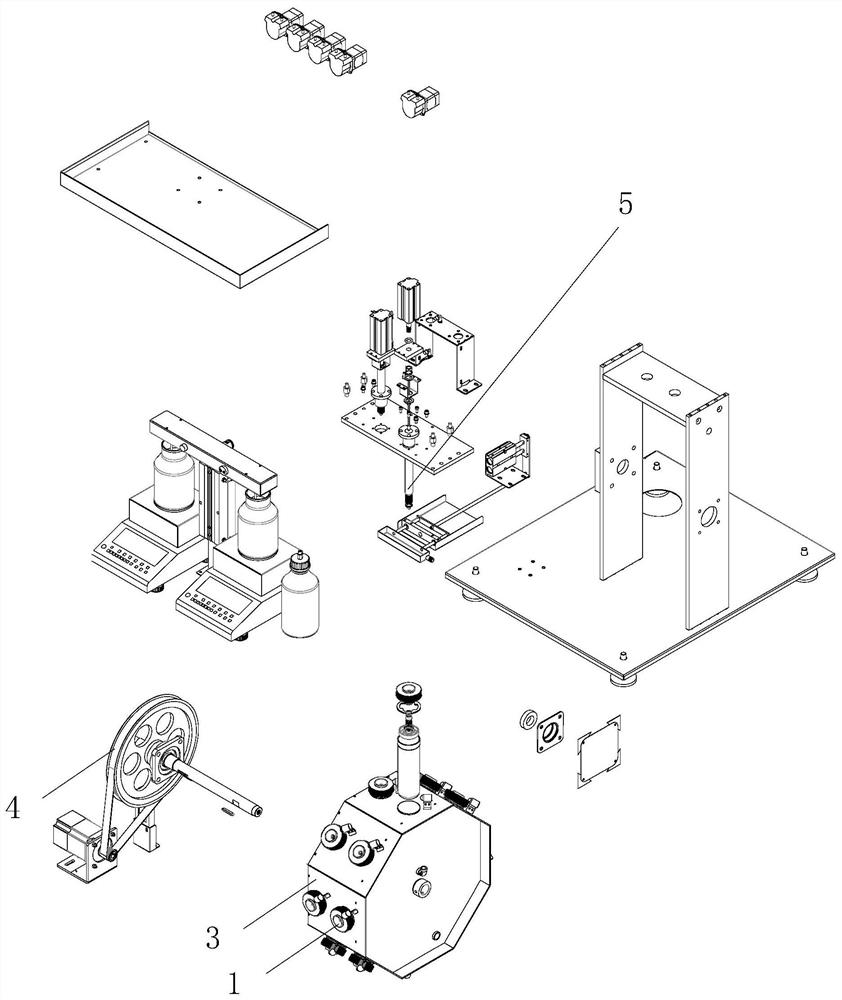

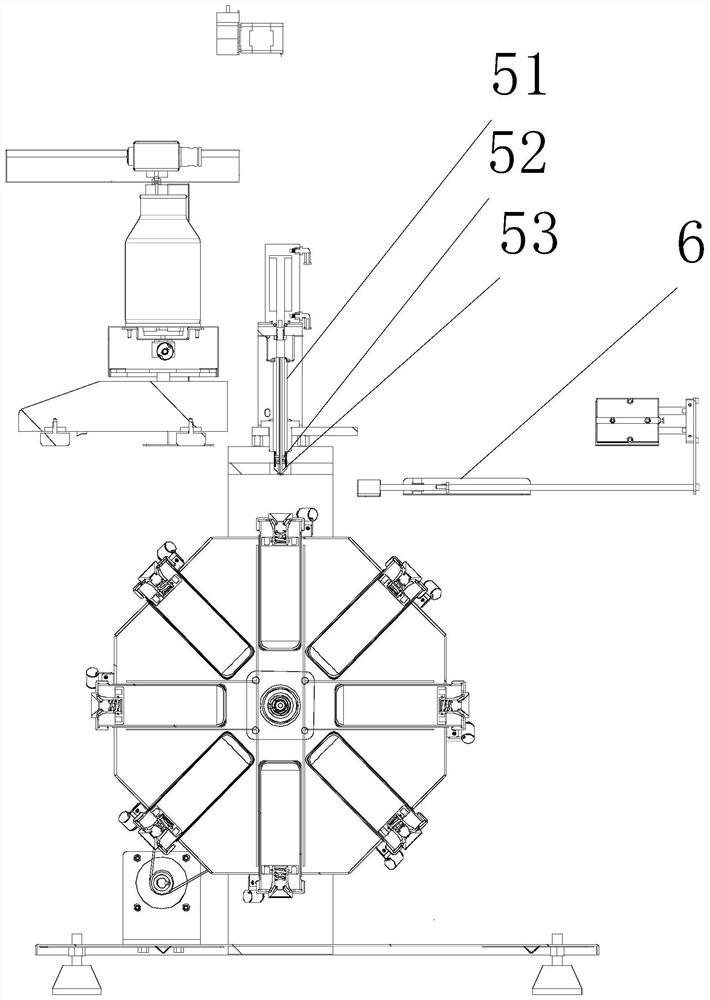

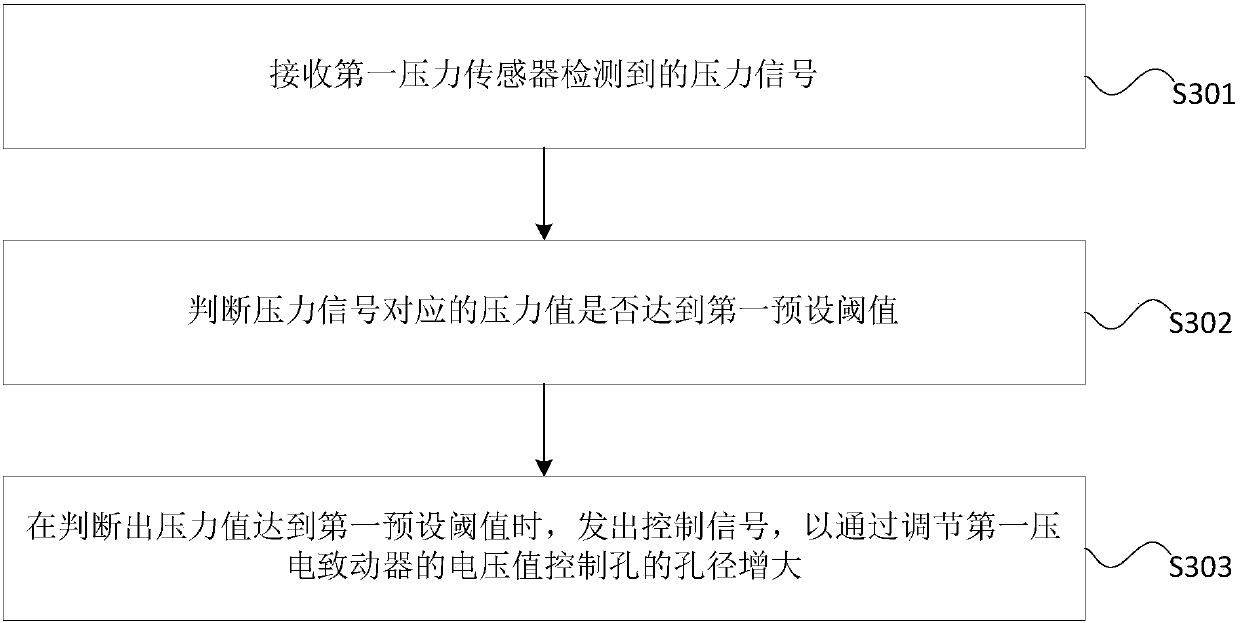

A nucleic acid extractor, its injection device, and its control method

ActiveCN105820949BTechnical Issues Affecting the Extraction ProcessAvoid Splash SituationsBioreactor/fermenter combinationsBiological substance pretreatmentsControl signalPiezoelectric actuators

Owner:SUZHOU BAIYUAN GENT CO LTD

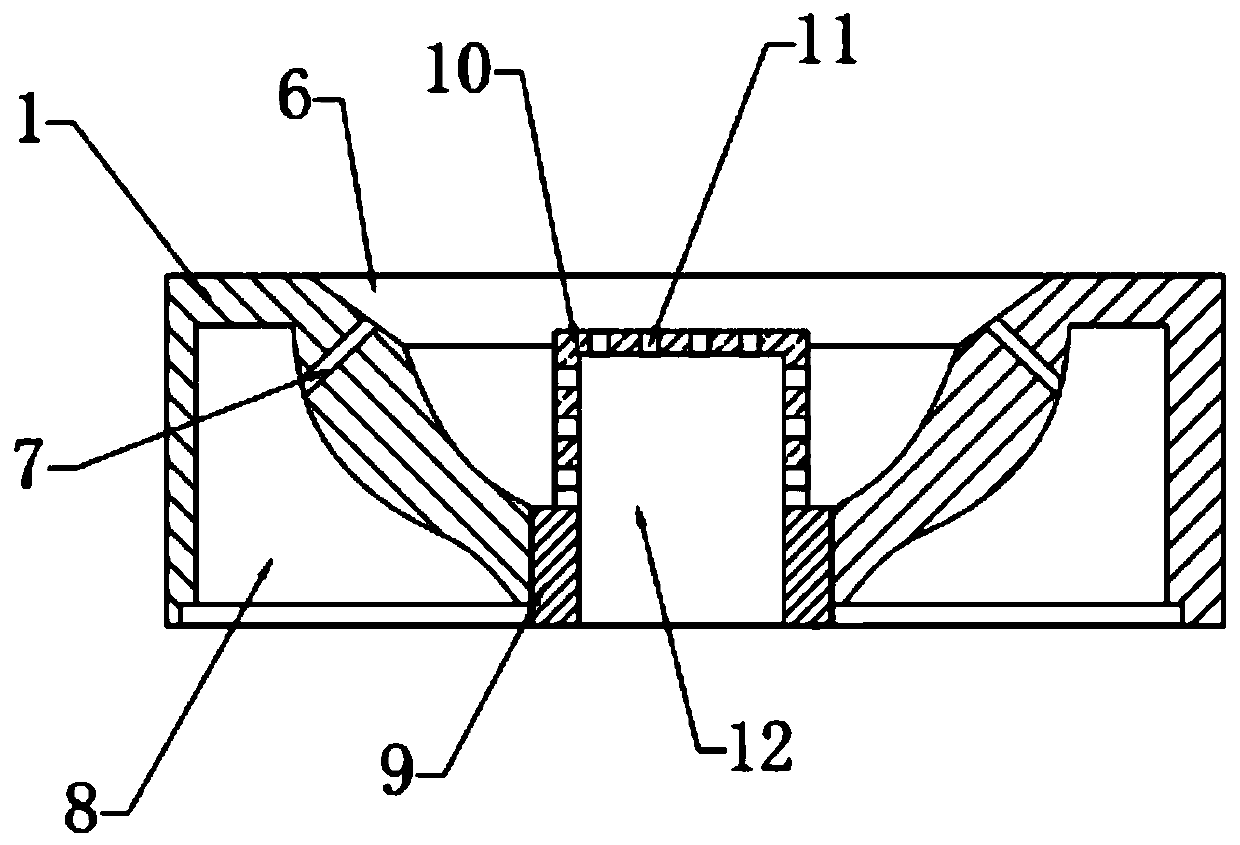

Droplet ejecting apparatus

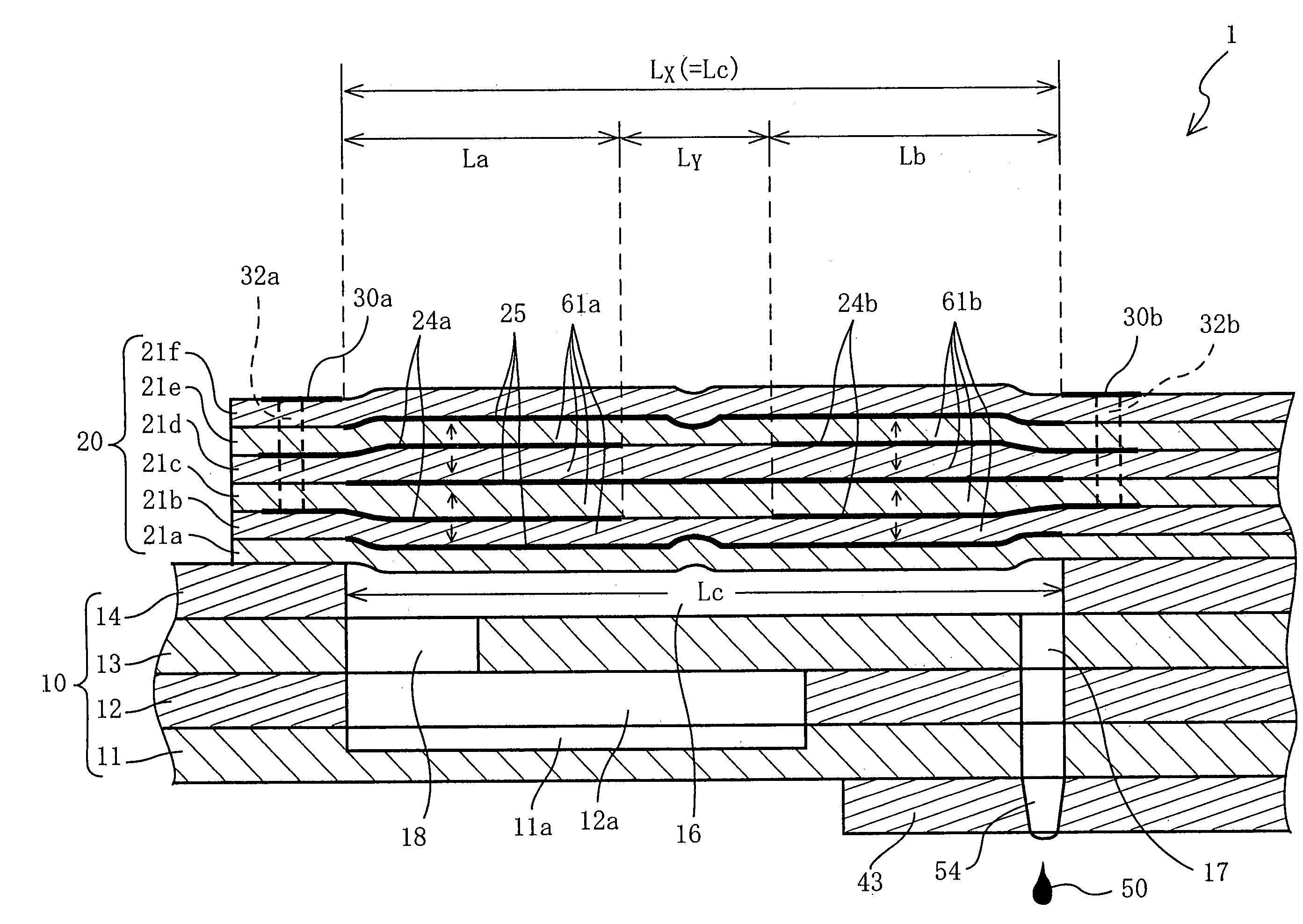

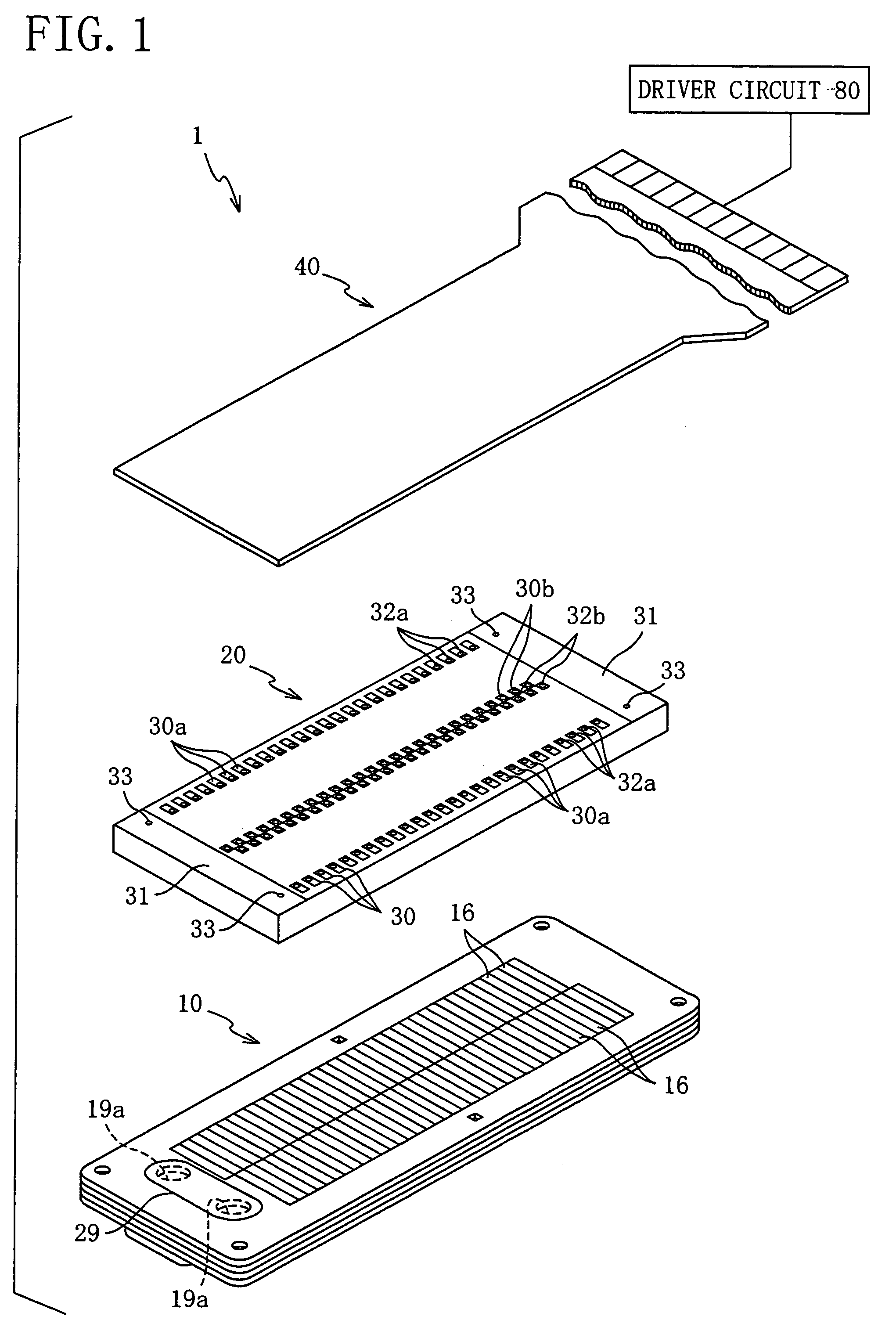

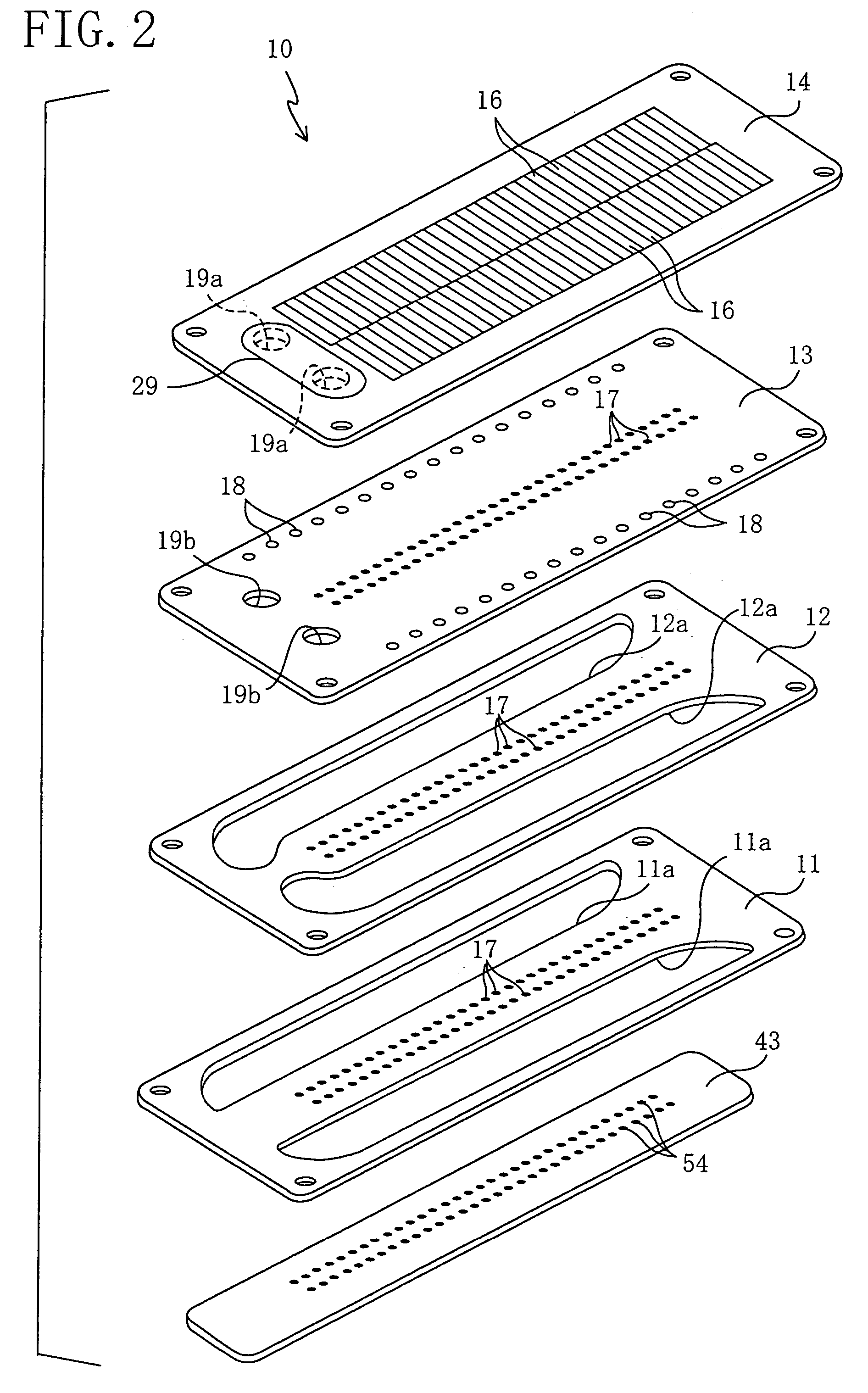

An ink jet printer head includes a channel unit and an actuator unit that are bonded to each other. The channel unit has pressure chambers located between a manifold and nozzles. The actuator unit includes piezoelectric sheets, and individual electrodes and common electrodes that are sandwiched by the piezoelectric sheets. Two individual electrodes are paired, and are provided in an area corresponding to each one of the pressure chambers, and cooperate with the common electrodes and the piezoelectric sheets to provide two active portions. When the actuator unit is driven or operated, the two active portions, and respective portions of the piezoelectric sheets that are located between the two active portions are elongated in the direction of thickness of the actuator unit, so that the volume of the each pressure chamber as a whole is decreased. Consequently a droplet of ink is ejected from the nozzle corresponding to the each pressure chamber.

Owner:BROTHER KOGYO KK

Flame gun nozzle

PendingCN114526482AAvoid going outReduce ejection speedFurnace componentsGaseous fuel burnerEngineeringCombustion

The flame gun nozzle comprises a connecting end and a nozzle end which are connected, the connecting end is provided with an air inlet channel, an air inlet cavity, an air outlet hole, an air outlet cavity, an air storage cavity, a first connecting channel and a second connecting channel are formed in the nozzle end, one end of the air inlet cavity is communicated with the air inlet channel, and the other end of the air inlet cavity is communicated with one end of the air outlet hole; the other end of the air outlet hole communicates with the air outlet cavity, the air storage cavity communicates with the air inlet cavity through a first connecting channel, and the air storage cavity communicates with the air outlet cavity through a second connecting channel. When the flame gun nozzle carries out flame spraying work, combustible mixed gas enters the nozzle end from the connecting end and then is sprayed out for combustion, and meanwhile the combustible mixed gas enters the gas storage cavity through the first connecting channel and then is output to the gas outlet cavity in the radial direction through the second connecting channel. The pressure of the radially output gas can slow down the speed of the mixed gas sprayed out of the gas outlet, so that the flame is prevented from being too far away from the gun nozzle to be extinguished, and the effect of stabilizing the flame is achieved.

Owner:FOSHAN NANHAI RES THERMAL EQUIP

Noise reduction type medical atomizer

InactiveCN111760138AReduce intimidationReduce distractionsMedical devicesMedical atomisersPharmacy medicineEngineering

The invention relates to a noise reduction type medical atomizer. The noise reduction type medical atomizer comprises a cylinder body, a facial mask, a liquid adding opening, a liquid collecting bowl,a gas guide pipe and a liquid outlet pipe, wherein a plurality of noise reduction units are arranged in the cylinder body; each noise reduction unit comprises a conducting layer, a noise reduction layer and a supporting layer; an atomization channel is arranged on each noise reduction unit; a guide pipe is also arranged on the cylinder body; the gas inlet end of the guide pipe communicates with aguide gas source; the gas pressure of the guide gas source can be independently adjusted; the exhaust end of the guide pipe communicates with the liquid outlet pipe through a guide unit; the gas distribution area is reduced when gas flows into the guide unit from the guide pipe; the guide unit comprises a guide cavity; a guide hole is arranged on the guide cavity; and the cylinder space and the guide cavity are in communication through the guide hole. According to the invention, sound interference during atomization treatment is reduced through the unique noise reduction design; medicine application can be adjusted according to the state of a patient; and medicine waste is reduced.

Owner:蔺淑娟

Small-sized air compressor for environmental protection construction and using method thereof

ActiveCN111810383AImprove noise reductionRealize dynamic changesPositive displacement pump componentsPositive-displacement liquid enginesEnvironmental engineeringAir compressor

The invention discloses a small-sized air compressor for environmental protection construction and a using method of the small-sized air compressor, belongs to the field of air compressors. Accordingto the small-sized air compressor for environmental protection construction, the aerodynamic principle is utilized, two pneumatic parts get close to each other under the action of air flow, so that the front section area and the rear section area are greatly changed suddenly, the noise reduction effect is improved, and the larger the air flow strength is, the larger the section area of a pneumaticdeformation shell is changed, and the better the noise reduction effect is; an annular cavity in the inner part of a pneumatic weakening part is used for weakening the air flow velocity, and two airinlets and one air outlet can enable the air flow to form convection, so that a certain noise reduction effect is achieved; a porous air flow disturbance ball is used for further weakening the air flow velocity, finally, the air flow is sprayed out through air flow dispersing pipelines with different inner diameters, and noise reduction is carried out again through sudden change of the cross section area, so that the noise reduction effect is further improved; and compared with the prior art, dynamic change of the cross section area is achieved, and the noise reduction effect through sudden change of the cross section area is enhanced.

Owner:汉尼米克(山东)智能科技有限公司

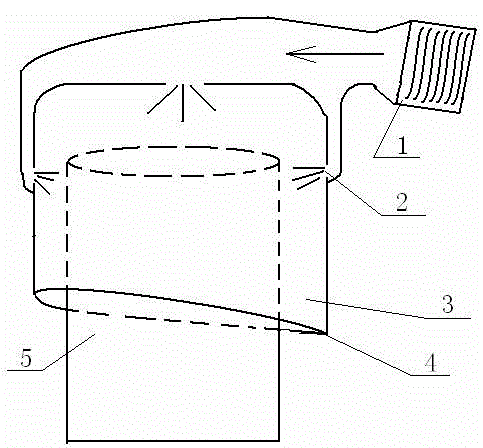

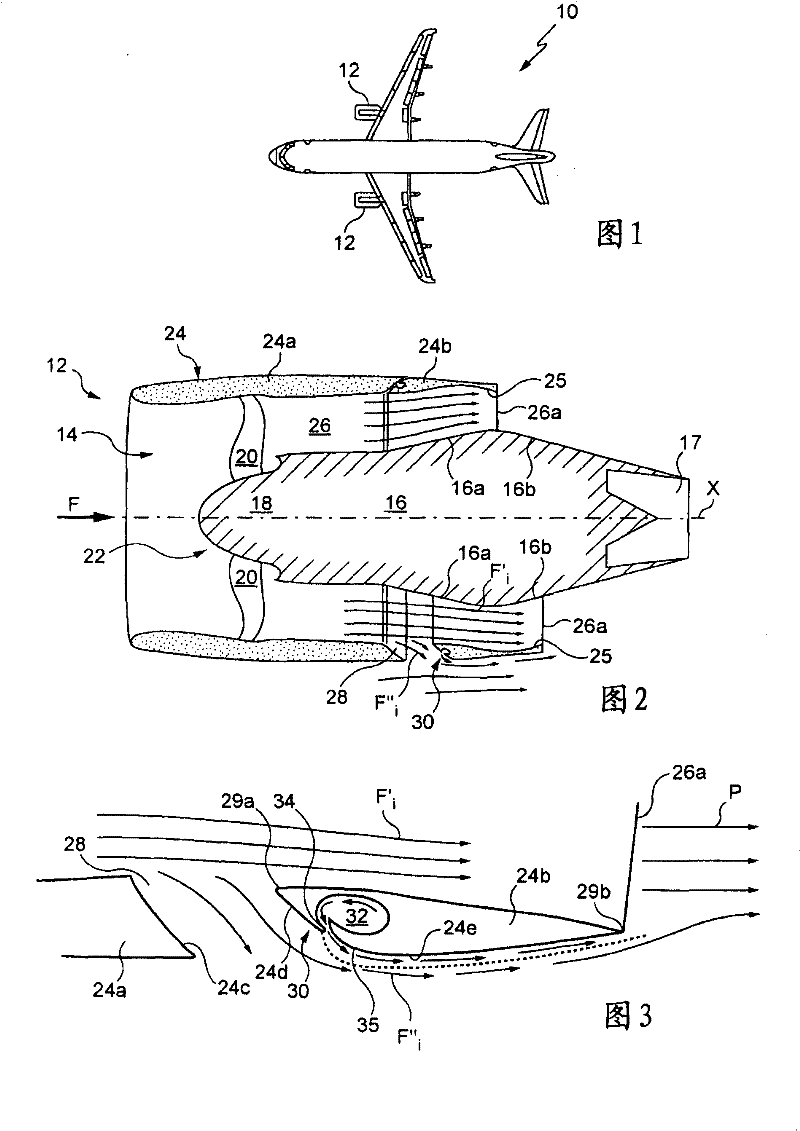

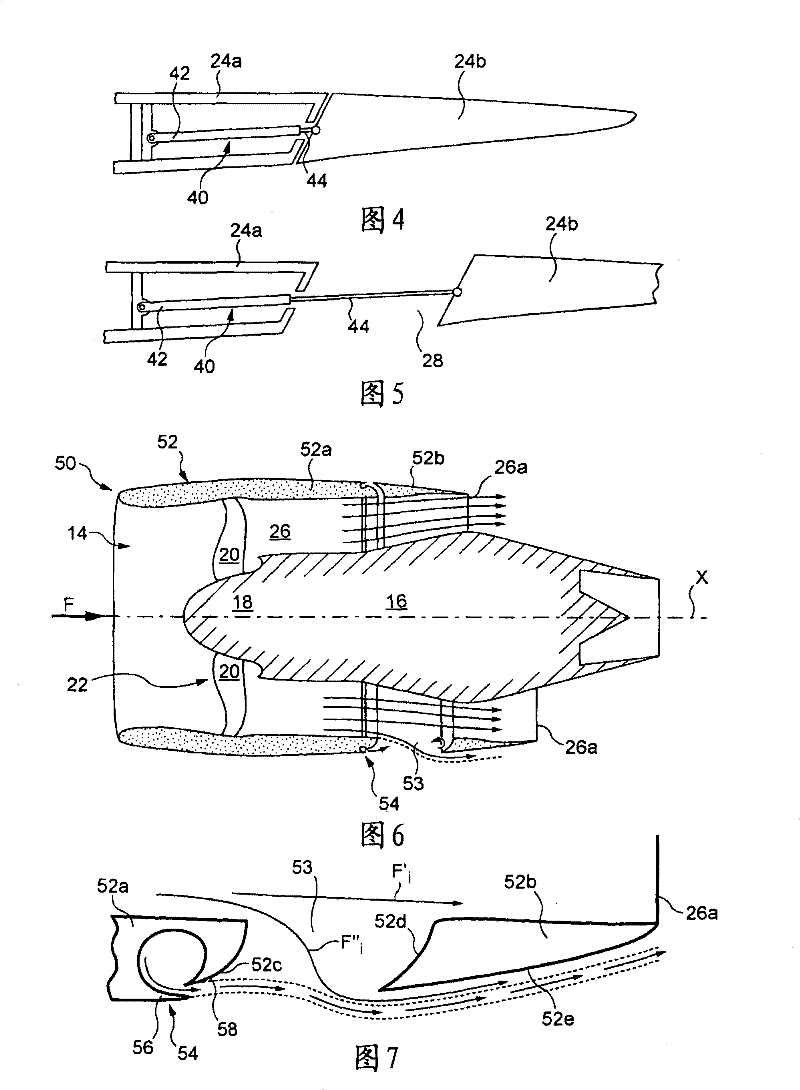

Jet engine nacelle for an aircraft and aircraft comprising such a nacelle

InactiveCN101523041BThrust helpsImprove efficiencyEfficient propulsion technologiesJet propulsion plantsNacelleJet engine

The invention relates to a nacelle (12) for an aircraft high-bypass jet engine, in which a jet engine having a longitudinal axis (X) is mounted, the nacelle including a wall (24) concentrically and atThe invention relates to a nacelle (12) for an aircraft high-bypass jet engine, in which a jet engine having a longitudinal axis (X) is mounted, the nacelle including a wall (24) concentrically and atleast partially surrounding the jet engine and defining with the latter an annular duct (26) for the fluid inner flow, comprising at the downstream end (26a) of said nacelle wall a passage section of least partially surrounding the jet engine and defining with the latter an annular duct (26) for the fluid inner flow, comprising at the downstream end (26a) of said nacelle wall a passage section of the flow outlet, characterised in that the nacelle includes displacement means (42) for displacing on request a portion (24b) of the nacelle wall in order to modify the passage section of the flow outhe flow outlet, characterised in that the nacelle includes displacement means (42) for displacing on request a portion (24b) of the nacelle wall in order to modify the passage section of the flow outlet through which a major portion of the flow (Fi') escapes, said displacement forming in the nacelle wall at least one opening (28; 53) through which a small portion of the flow, called the leak flotlet through which a major portion of the flow (Fi') escapes, said displacement forming in the nacelle wall at least one opening (28; 53) through which a small portion of the flow, called the leak flow (Fi '), naturally escapes, the nacelle further comprising a fluid device (30; ; 54) that uses a fluid for compelling the leak flow to flow along the outer face (24e) of the portion of the nacelle waw (Fi '), naturally escapes, the nacelle further comprising a fluid device (30; ; 54) that uses a fluid for compelling the leak flow to flow along the outer face (24e) of the portion of the nacelle wall located downstream relative to said at least one opening.ll located downstream relative to said at least one opening.

Owner:AIRBUS OPERATIONS (SAS)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com