Straw crushing and throwing method and device of full-feeding combine harvester

A technology of combine harvester and throwing device, applied in harvesters, cutters, crop processors, etc., can solve the problems of high energy consumption and noise, personal injury, large size, etc., and achieve low power consumption, simple appearance, and noise. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

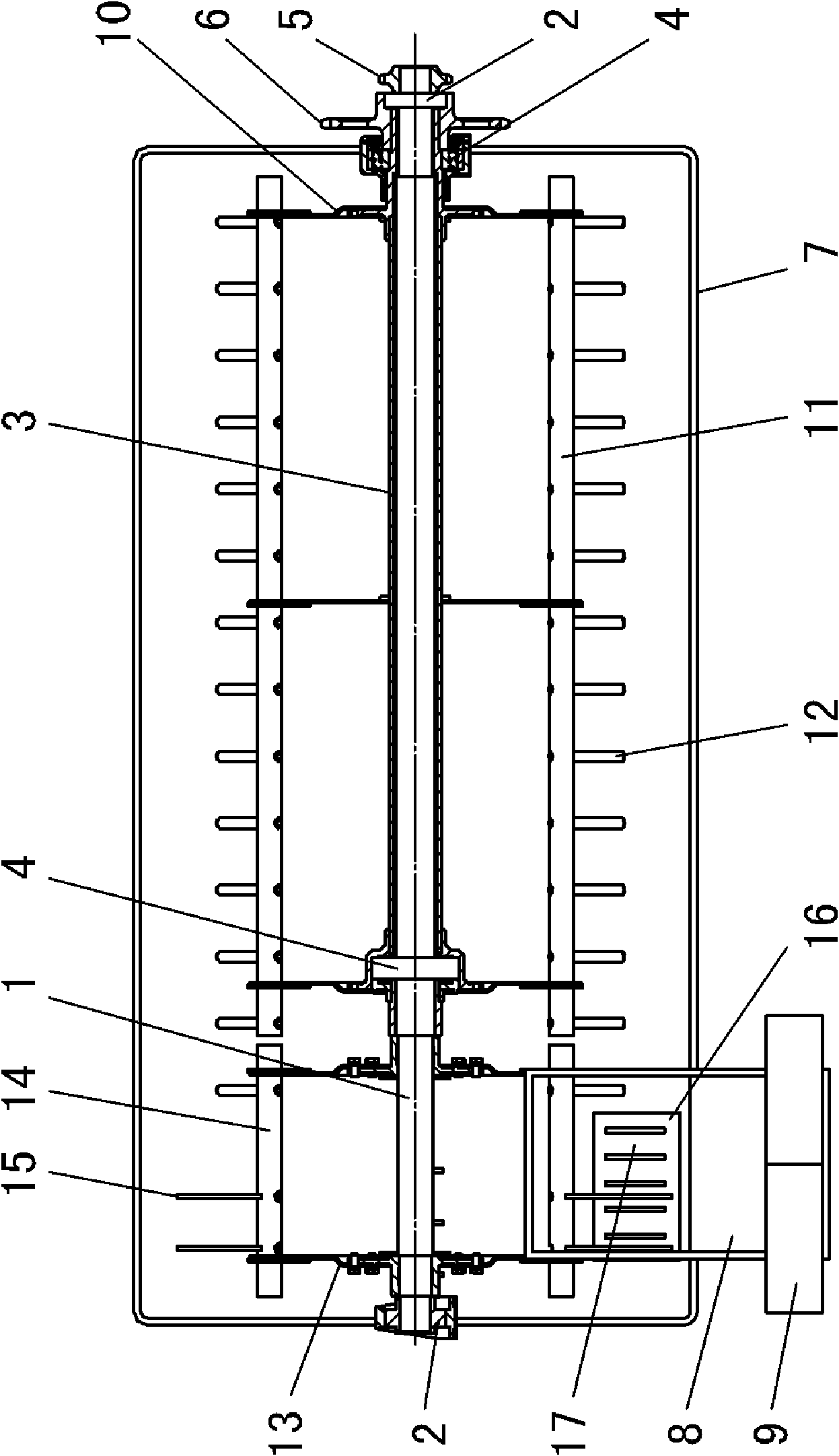

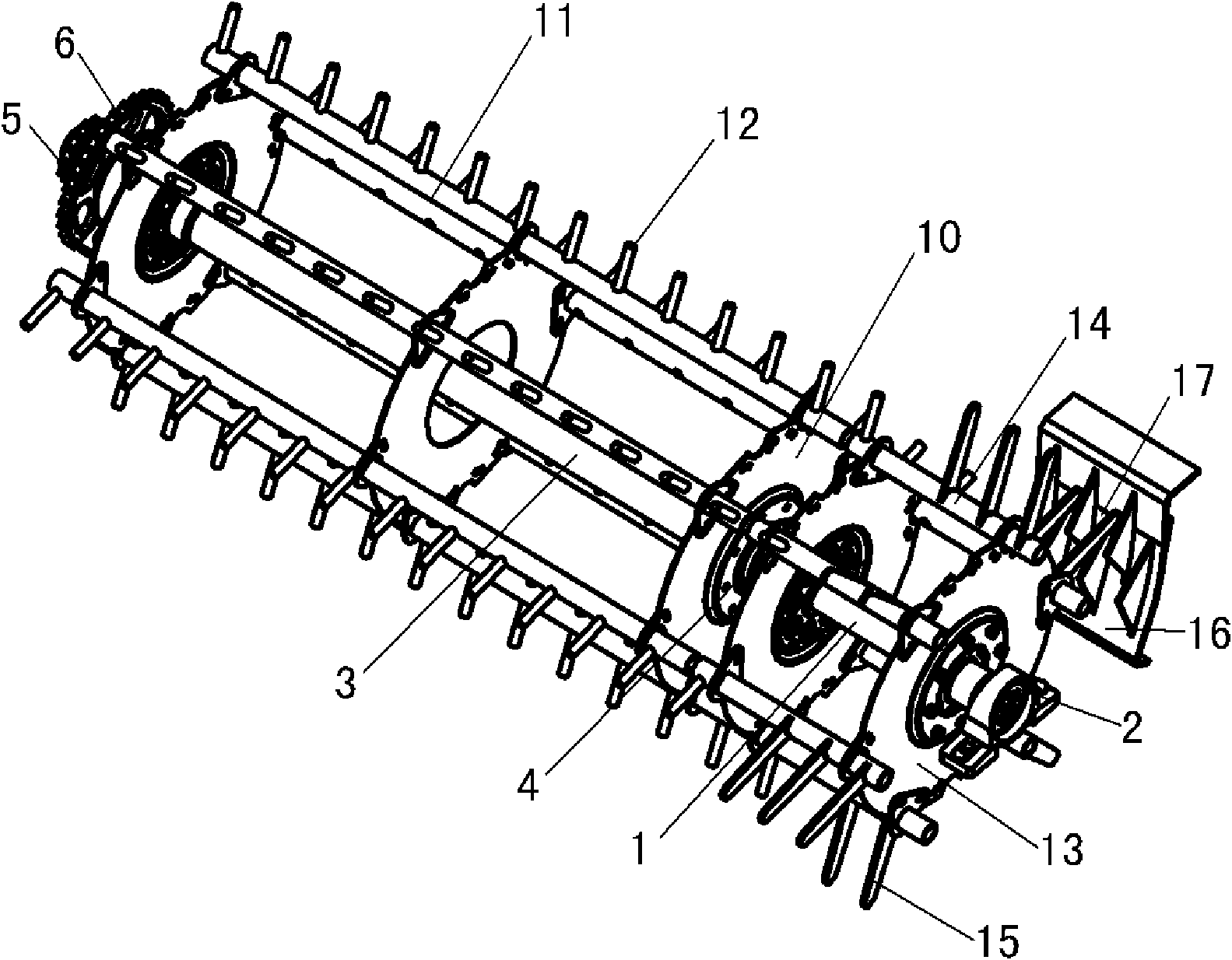

[0018] Example. Such as figure 1 and figure 2 shown. Comprising a solid shaft 1 and a housing 7, a crushing web 13 is connected to the solid shaft 1, a crushing rack 14 is mounted on the crushing web 13, and crushing fingers 15 are arranged on the crushing rack 14, and the crushing fingers 15 can be Finger-shaped teeth, plate-shaped teeth or cutters of any shape with cutting edges, the pulverizing finger teeth 15 correspond to the pulverizing knife 17 mounted on the inner wall of the housing 7, and the pulverizing knife 17 is installed or welded on the pulverizing plate 16, Pulverizing tooth bar 14 drives pulverizing finger tooth 15 rotations when rotating, and pulverizing finger tooth 15 is by cooperating with pulverizing knife 17 on the crushing plate 16, stalk is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com