Novel energy-saving kiln

A kiln and a new type of technology, applied in the field of ceramic kilns, can solve the problems of high energy consumption, easy collapse of the kiln, and poor heat insulation performance, and achieve short maintenance intervals, obvious energy-saving effects, thermal expansion and contraction The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

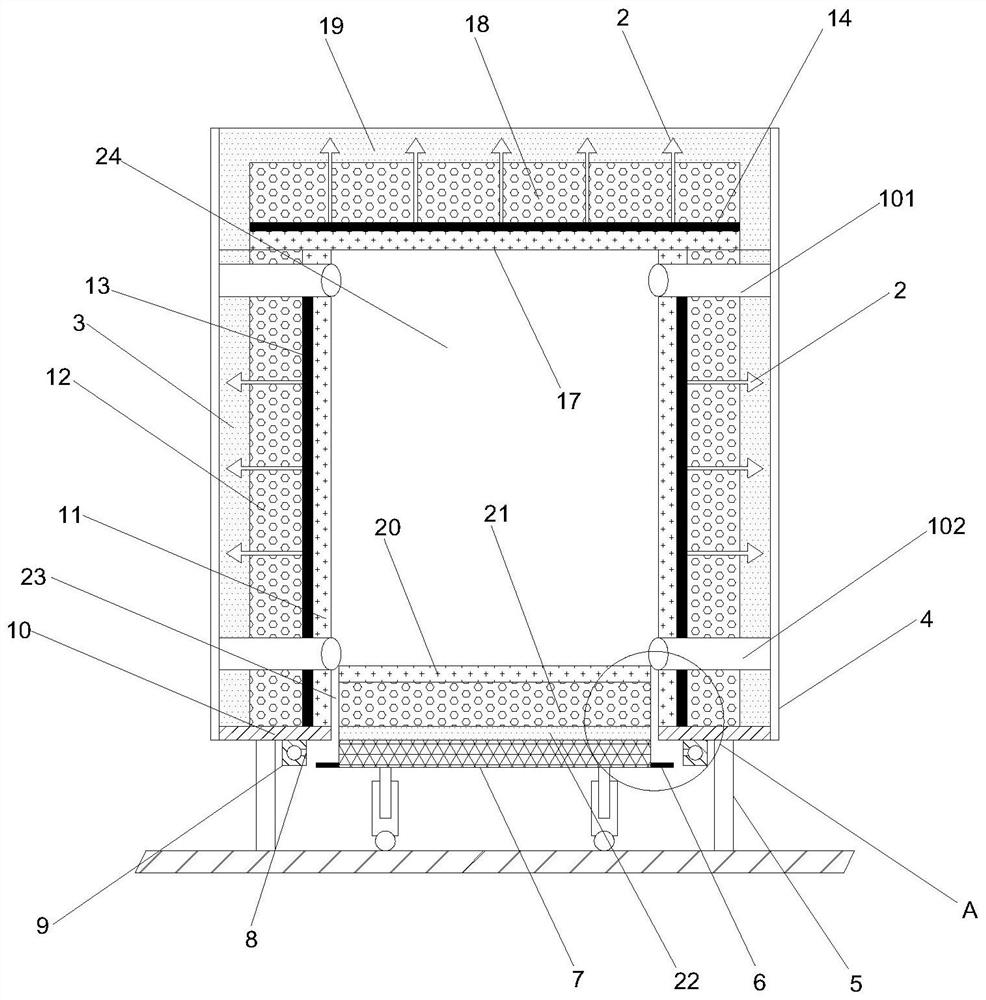

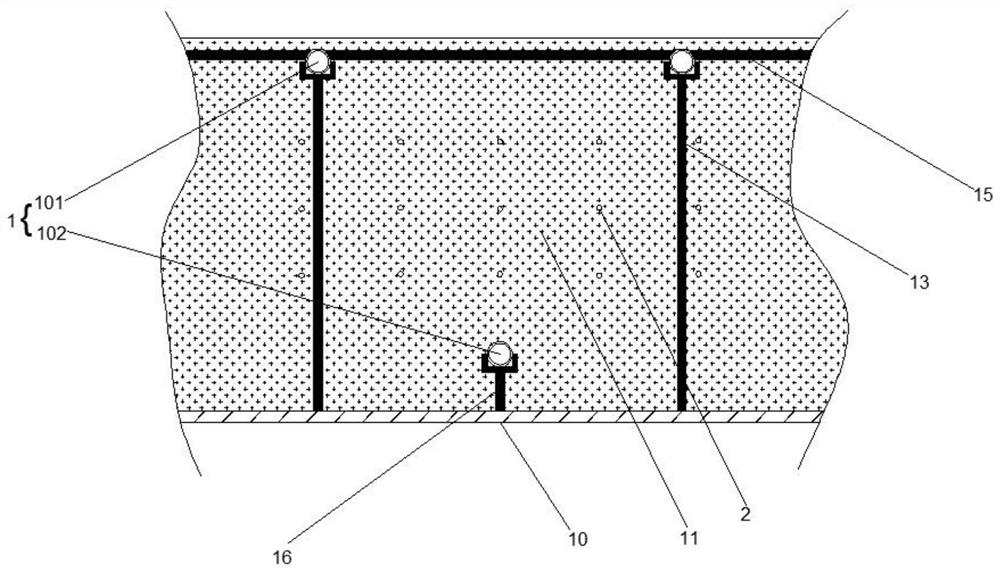

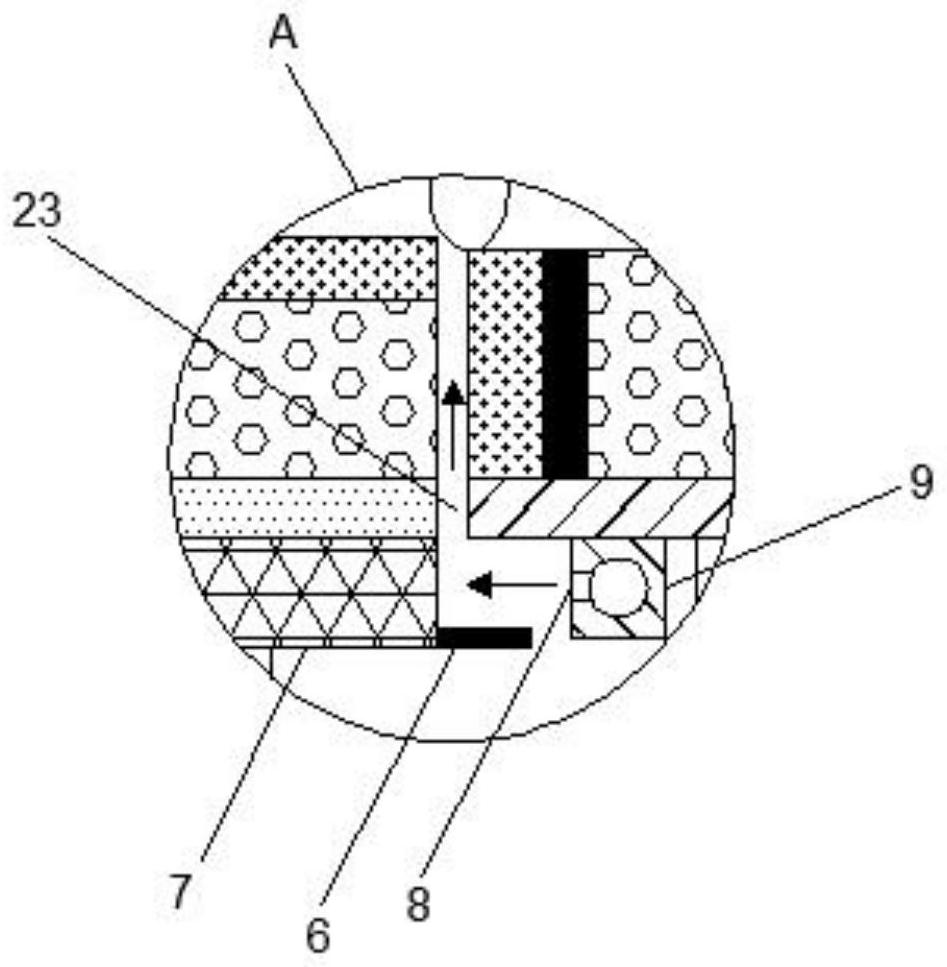

[0032] The following is attached Figure 1~3 The present invention is described in further detail.

[0033] A new energy-saving kiln, comprising a kiln wall and a kiln roof, the kiln wall and the kiln roof enclose a furnace cavity 24, the kiln roof is built on the kiln wall, and the kiln wall The body is respectively provided with a first polycrystalline cotton layer 11, a first zirconium-containing asbestos layer 12 and a first ordinary asbestos layer 3 from the inside to the outside, and the kiln roof is respectively provided with a second polycrystalline cotton layer 17, In the second zirconium-containing cotton layer 18 and the second ordinary asbestos layer 19, the high temperature resistance of polycrystalline cotton, zirconium-containing cotton and ordinary asbestos decreases in turn, and the first zirconium-containing asbestos layer 12 is locked on the first ordinary asbestos layer by self-locking nails 2. On the asbestos layer 3, the second zirconium-containing asbes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com