Rotating electrical machine

A technology for rotating electrical machines and rotors, applied to synchronous motors with stationary armatures and rotating magnets, electric components, electrical components, etc., can solve problems such as complex structures, achieve simplified structures, improve responsiveness, and improve maintainability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0032] [rotating motor]

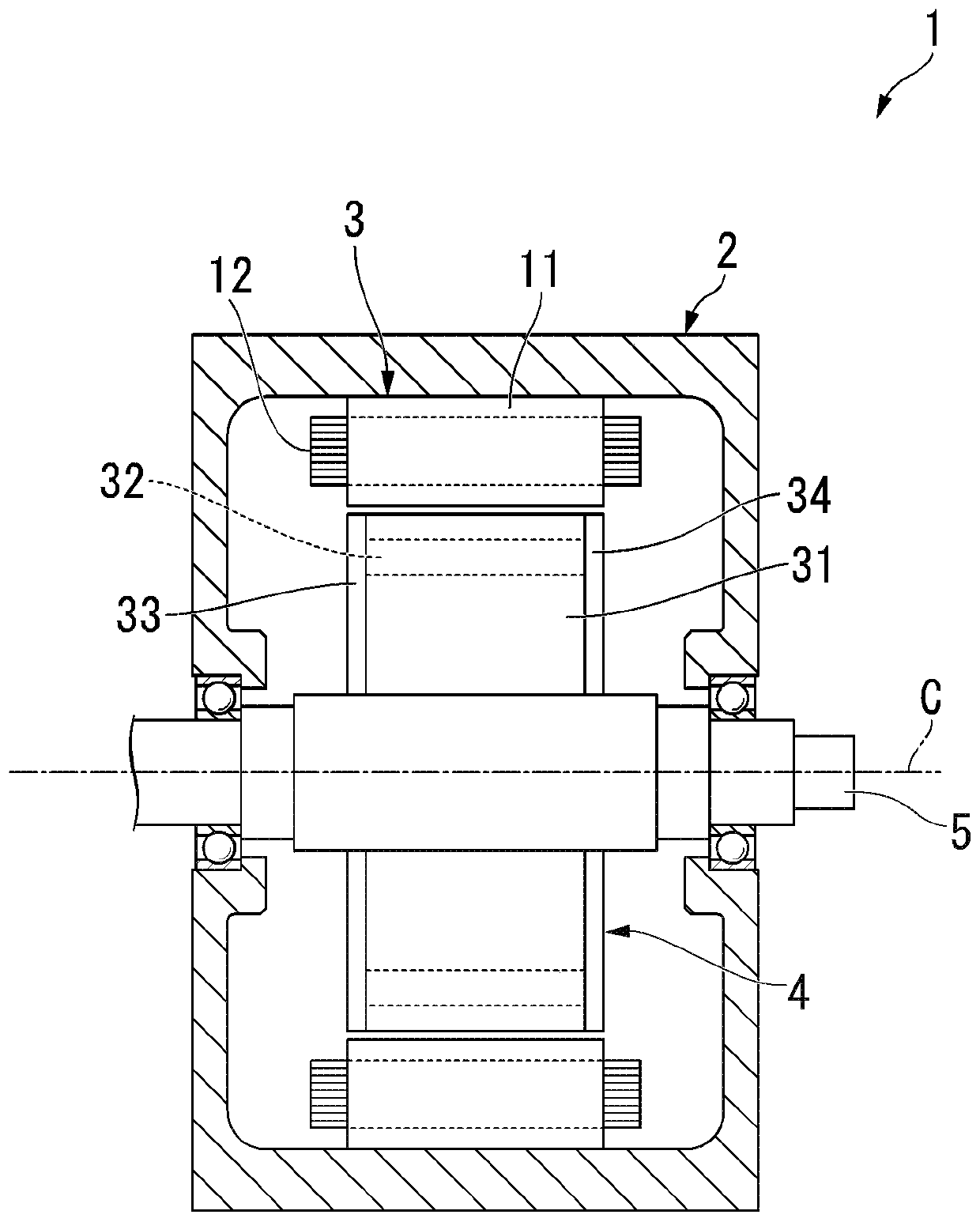

[0033] figure 1 It is a schematic configuration diagram (sectional view) showing the overall configuration of the rotating electric machine 1 of the first embodiment.

[0034] figure 1 The rotating electric machine 1 shown is, for example, a running motor mounted in a vehicle such as a hybrid vehicle or an electric vehicle. However, the configuration of the present invention is not limited to running motors, and may be applied to motors for power generation, motors for other purposes, and rotating electric machines (including generators) other than vehicles.

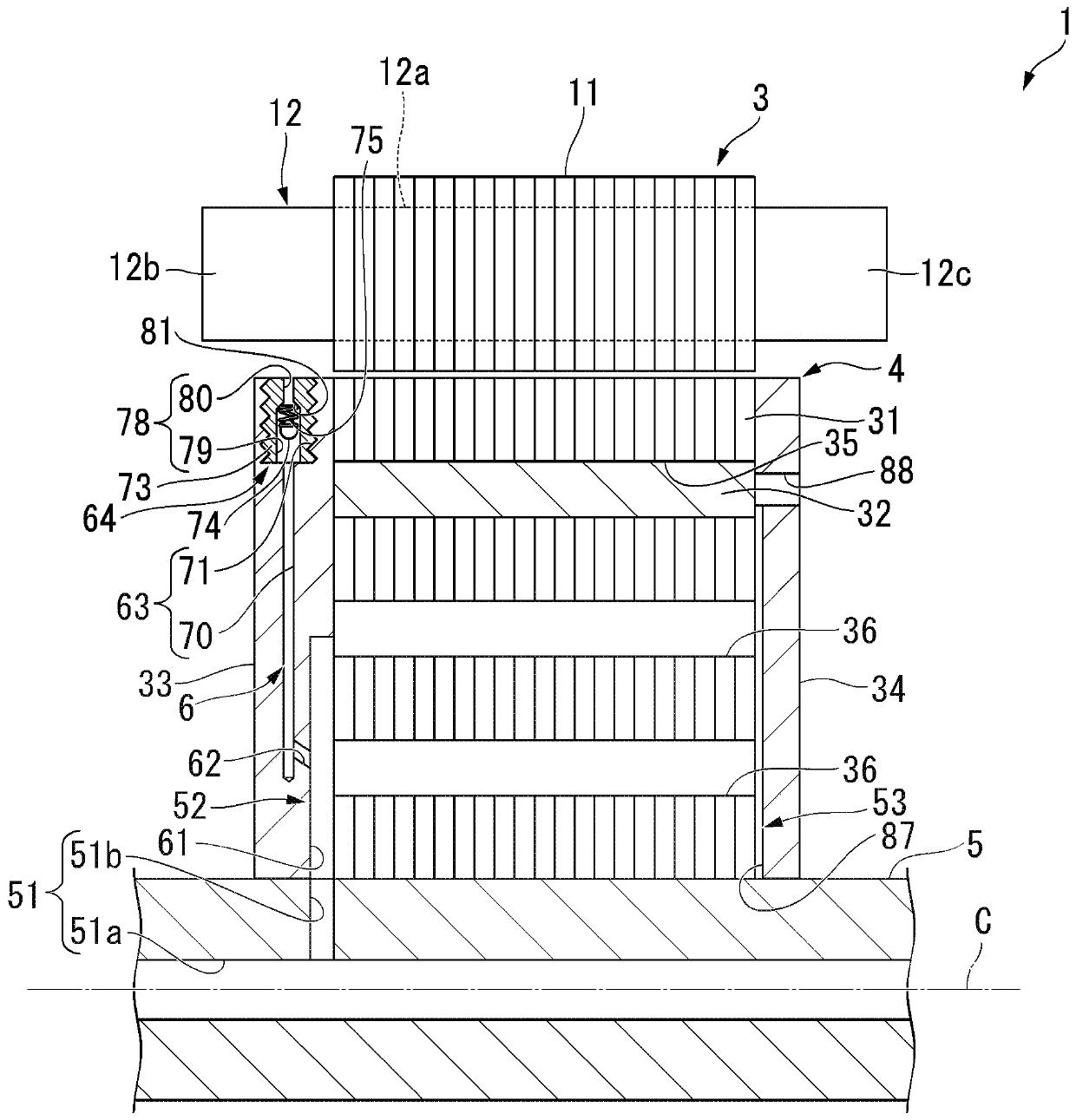

[0035] The rotating electrical machine 1 includes a housing 2, a stator 3, a rotor 4, an output shaft 5, and a refrigerant supply mechanism 6 (see figure 2 ).

[0036] The casing 2 accommodates a stator 3 , a rotor 4 and an output shaft 5 . A refrigerant (not shown) is accommodated in the casing 2 . The stator 3 is arranged in a state in which a part of the stator 3 is immersed in the ref...

no. 2 approach

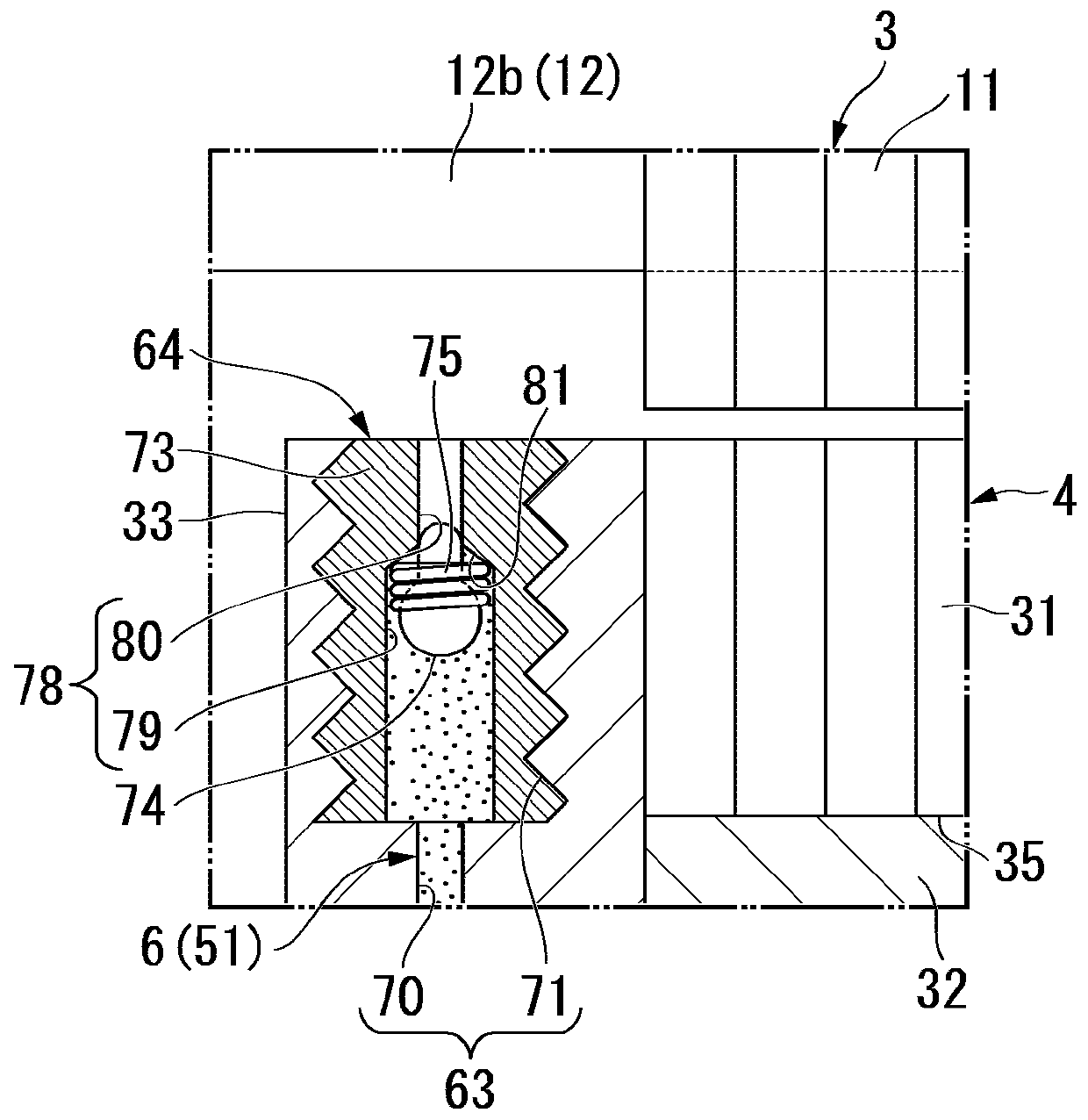

[0094] Next, a second embodiment of the present invention will be described. This embodiment differs from the above-described embodiment in that the opening and closing of the discharge port 80 is performed without using a biasing member. Figure 5 It is a partial sectional view of the rotating electric machine 1 of the second embodiment. In the following description, the same reference numerals are assigned to the same configurations as those of the above-mentioned first embodiment, and description thereof will be appropriately omitted.

[0095] exist Figure 5 In the rotary electric machine 1 shown, the stator supply flow path 63 is connected to the radially outer end portion of the rotor inlet flow path 61 . The radial outer end portion of the stator supply flow path 63 terminates at the outer peripheral portion of the first end plate 33 .

[0096] The discharge flow path 78 is connected to the radial outer end portion of the stator supply flow path 63 and extends in the...

no. 3 approach

[0103] Next, a third embodiment of the present invention will be described. This embodiment differs from the above-described embodiments in that the urging member 100 is formed in a leaf spring shape.

[0104] exist Figure 7 In the illustrated rotating electrical machine 1 , a urging member 100 is provided in the spool accommodating portion 79 . The urging member 100 is formed in the shape of a leaf spring extending in the radial direction. The radial inner end portion of the biasing member 100 is fixed to the first end panel 33 by the fixing member 101 .

[0105] That is, the urging member 100 is configured to be elastically deformable in the axial direction starting from the radial inner end portion. A weight portion 102 is provided at a radially outer end portion of the biasing member 100 .

[0106] The opposing surface of the inner surface of the spool accommodating portion 79 that faces the urging member 100 in the axial direction constitutes an abutment surface 110 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com