Process for producing molded item of thermosetting resin and injection molding machine therefor

An injection molding device and manufacturing method technology, applied to the field of manufacturing of molded products made of thermosetting resins and injection molding devices, capable of solving problems such as time-consuming removal of burrs, low viscosity, reduced strength and quality of molded products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

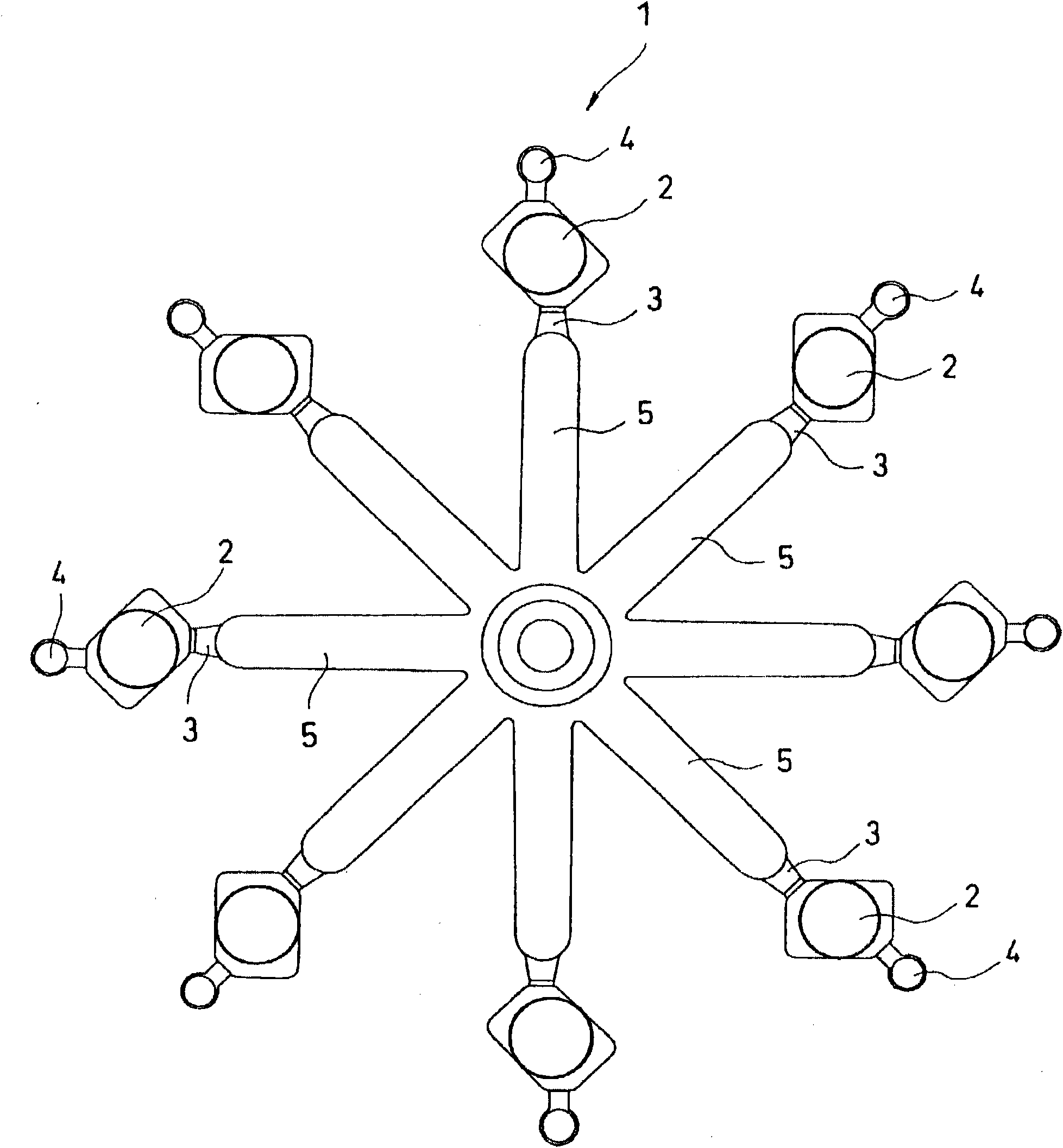

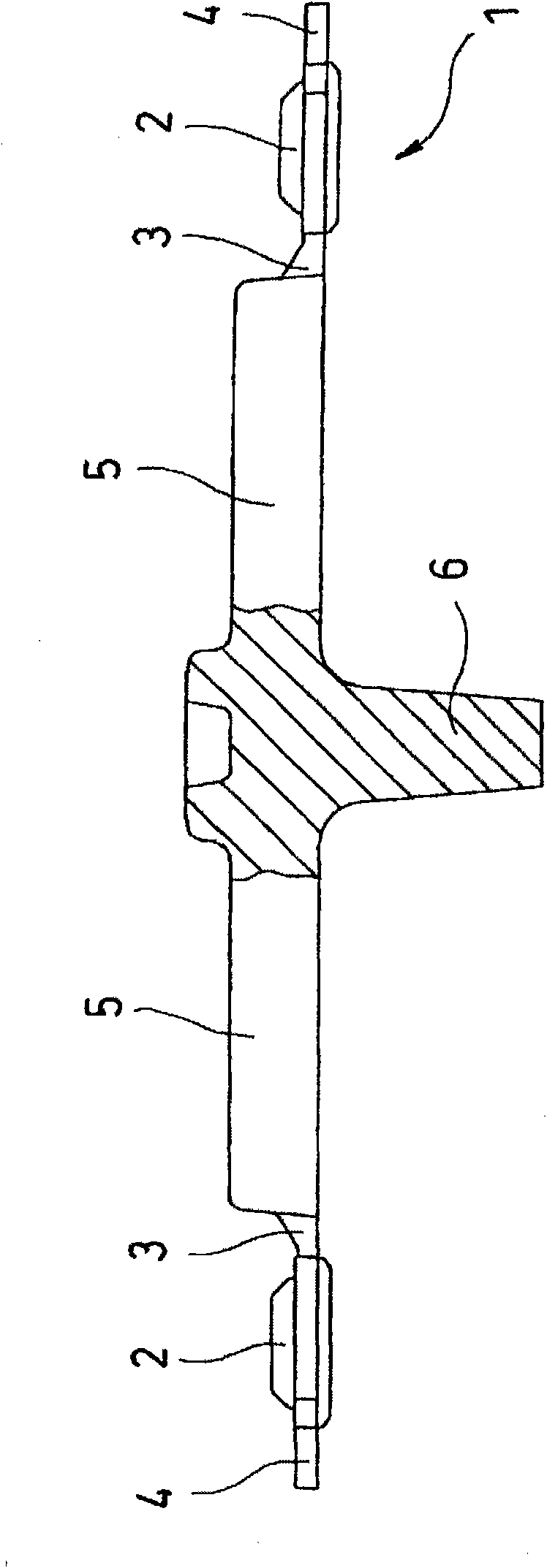

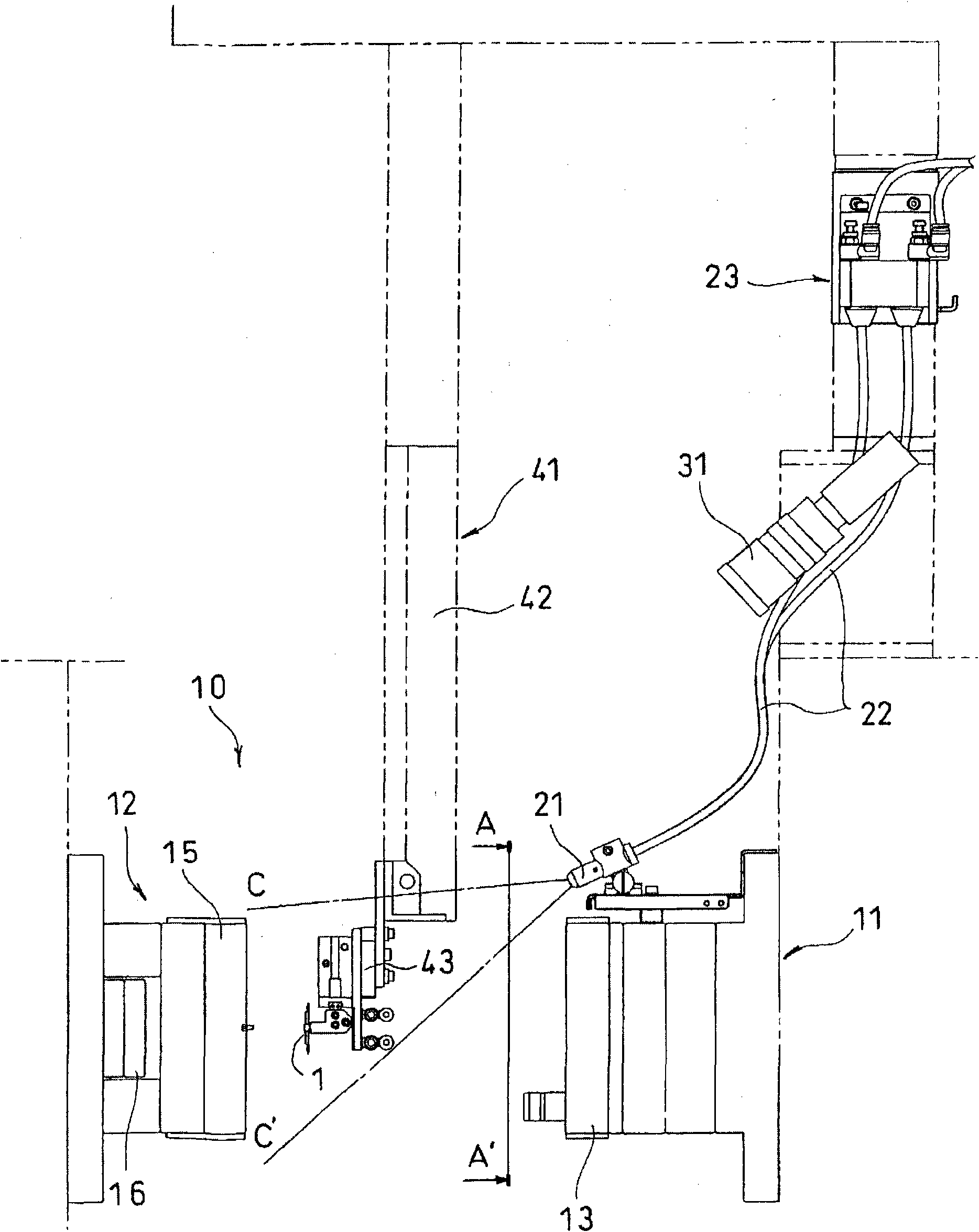

[0145] Figure 1 to Figure 7 It is a figure which shows 1st Embodiment of this invention.

[0146] First, the resin molded article of this embodiment will be described.

[0147] Such as figure 1 and figure 2 As shown, this resin molded product 1 is a molded product obtained by molding by liquid resin injection molding (LIM method) using the mold proposed by the present applicant in Japanese Patent Application No. 2006-73625. That is, when the product part (in this example, a lens (such as a convex lens, a Fresnel lens, etc.) in a transparent optical element) 2 is molded by liquid resin injection molding from a thermosetting resin such as silicone resin, an overflow is provided on the mold. Receiving part to prevent residual air bubbles in product part 2. Therefore, the resin molded product 1 obtained by using the technical solution of the aforementioned Japanese patent application has the overflow portion 4 formed in the aforementioned overflow receiving portion in additi...

no. 2 Embodiment approach

[0207] Next, a second embodiment of the present invention will be described.

[0208] First, the resin molded article according to this embodiment has the same configuration as that of the first embodiment.

[0209] Next, the injection molding apparatus according to this embodiment will be described.

[0210] The configuration of the injection molding apparatus of the present embodiment is the same as that of the first embodiment except for the mold, so description of the entire injection molding apparatus will be omitted, and only the mold will be described.

[0211] Figure 8 ~ Figure 12 It is a figure which shows the mold of the injection molding apparatus concerning this embodiment. Figure 8 is the profile diagram of the mold, Figure 9 yes Figure 8 The enlarged view of the main part, Figure 10 is a schematic cross-sectional view of the mold on the fixed side of the mold, Figure 11 It is a schematic cross-sectional view of the mold on the movable side of the mold...

no. 3 Embodiment approach

[0254] Next, a third embodiment of the present invention will be described.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com