Three-ring fire burner and gas stove

A burner and ring fire technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of small heat exchange area between the pot and the flame, reduced heat utilization rate of the pot, high heat load and thermal efficiency, etc., and achieve structural Effect of compact size, longer heat exchange time, and higher heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

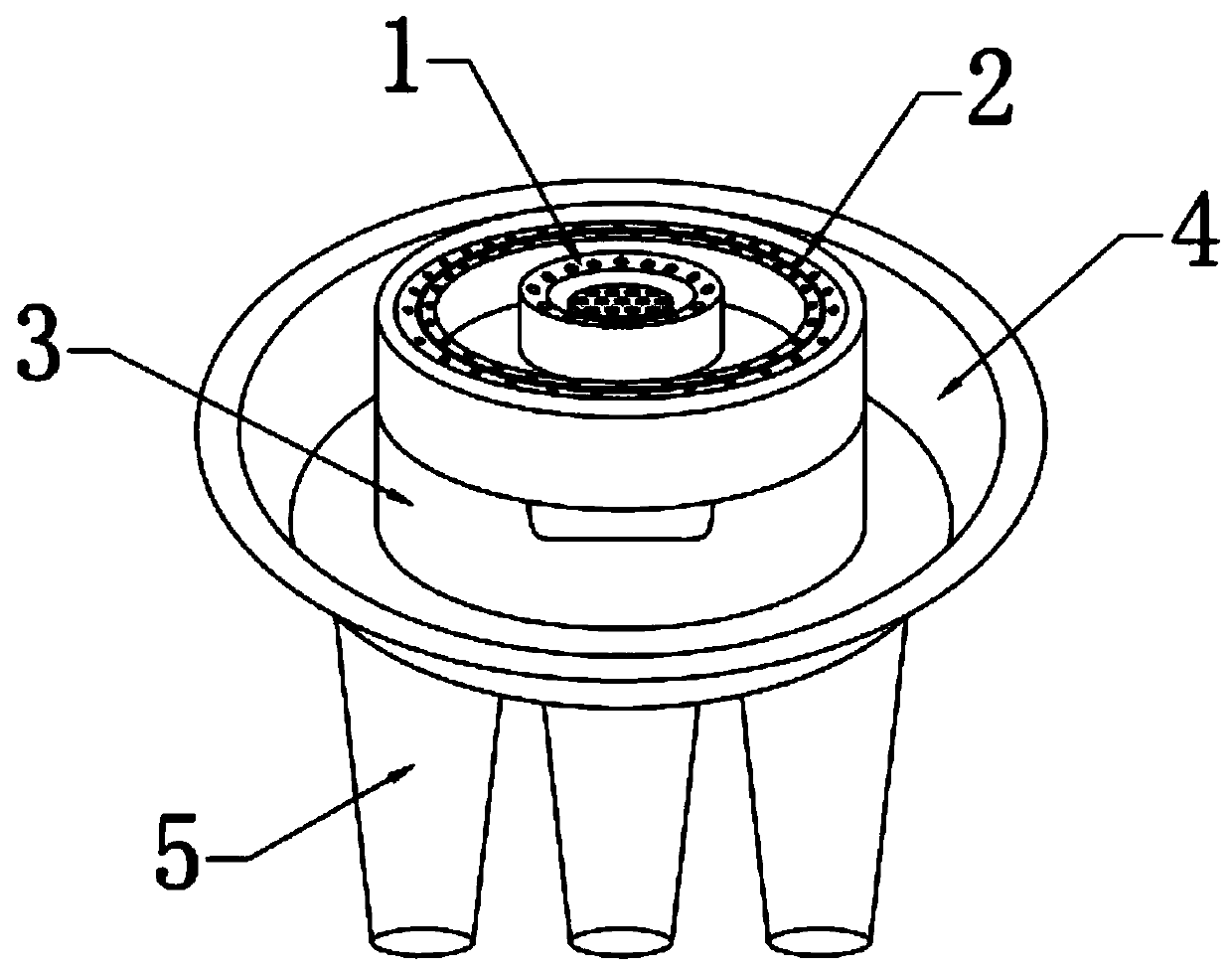

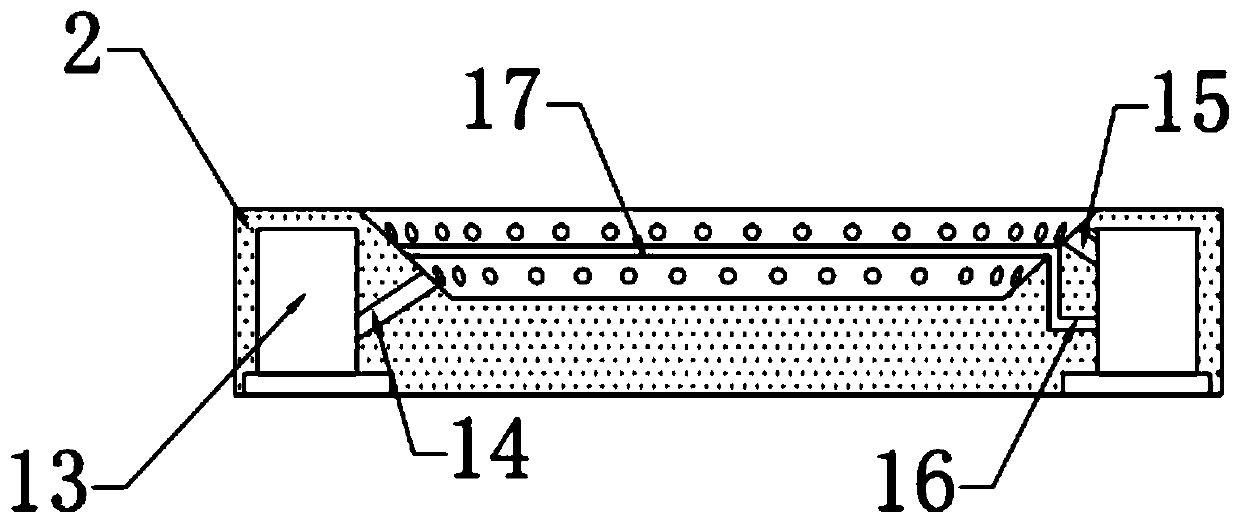

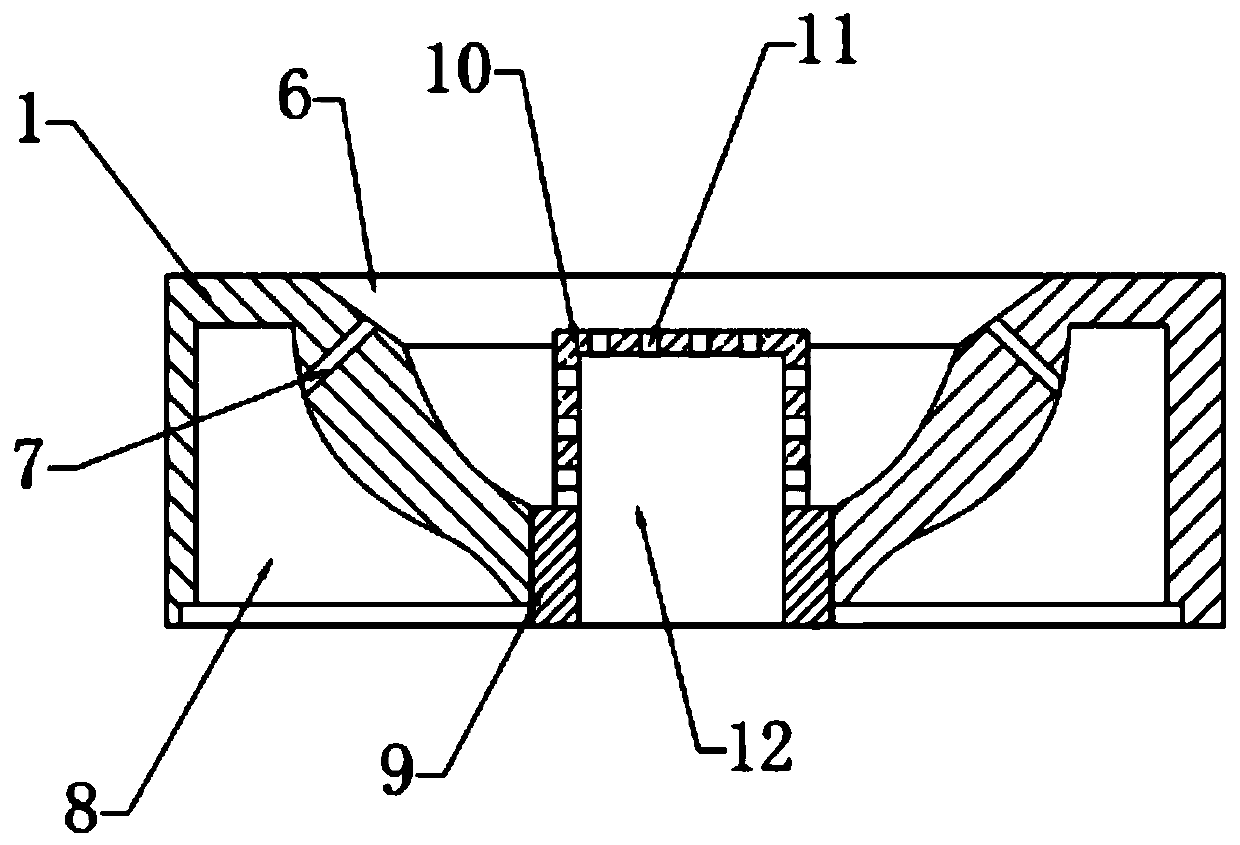

[0028] see Figures 1 to 4 , in an embodiment of the present invention, a three-ring fire burner and a gas stove include a gas distribution seat 3, and the top of the gas distribution seat 3 is sequentially provided with an outer ring fire cover 2 and an inner ring fire cover 1, The inner side of the outer ring fire cover 2 is provided with several fire holes, and a fire groove 17 is arranged between the fire holes. The fire hole and fire groove 17 in the central area can gather heat for combustion, improve heating efficiency, and reduce heat loss. The bottom of the gas distribution seat 3 is provided with a water receiving tray 4, and the bottom of the water receiving tray 4 is provided with a guide Shooting tube 5.

[0029] In this embodiment, the fire hole is provided with two circles, including the second fire hole 14 and the third fire hole 15, the second fire hole 14 is arranged on the lower side of the third fire hole 15, and the second fire hole 14 and the third fire...

Embodiment 2

[0036] A domestic gas stove, comprising the three-ring fire burner described in Embodiment 1.

[0037]The three-ring fire burner and the gas stove, by setting the fire hole and the fire groove 17 pointing to the central area of the burner, can collect heat and burn, improve the heating efficiency, and reduce the heat loss. The three fire holes 15 can increase the area of the fire holes, so that the burner can generate stronger fire power under the condition of high thermal efficiency. In the event of unstable combustion such as flame separation and tempering, by setting the partition plate 9, the structure of the inner ring fire cover 1 can be made more compact, the volume of the top of the burner can be reduced, and the heat exchange time between the bottom of the pot and the flame can be shortened. And the heat exchange area is increased, the thermal efficiency of the gas stove is improved, and the cost of the burner is reduced.

[0038] The working principle of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com