Hot gas flow reversion burner

A technology of combustion device and hot air flow, which is applied to combustion equipment, solid fuel combustion, lighting and heating equipment, etc., can solve the problems of insufficient fuel combustion, waste of energy, pollute the environment, etc., achieve less ash, save fuel, powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

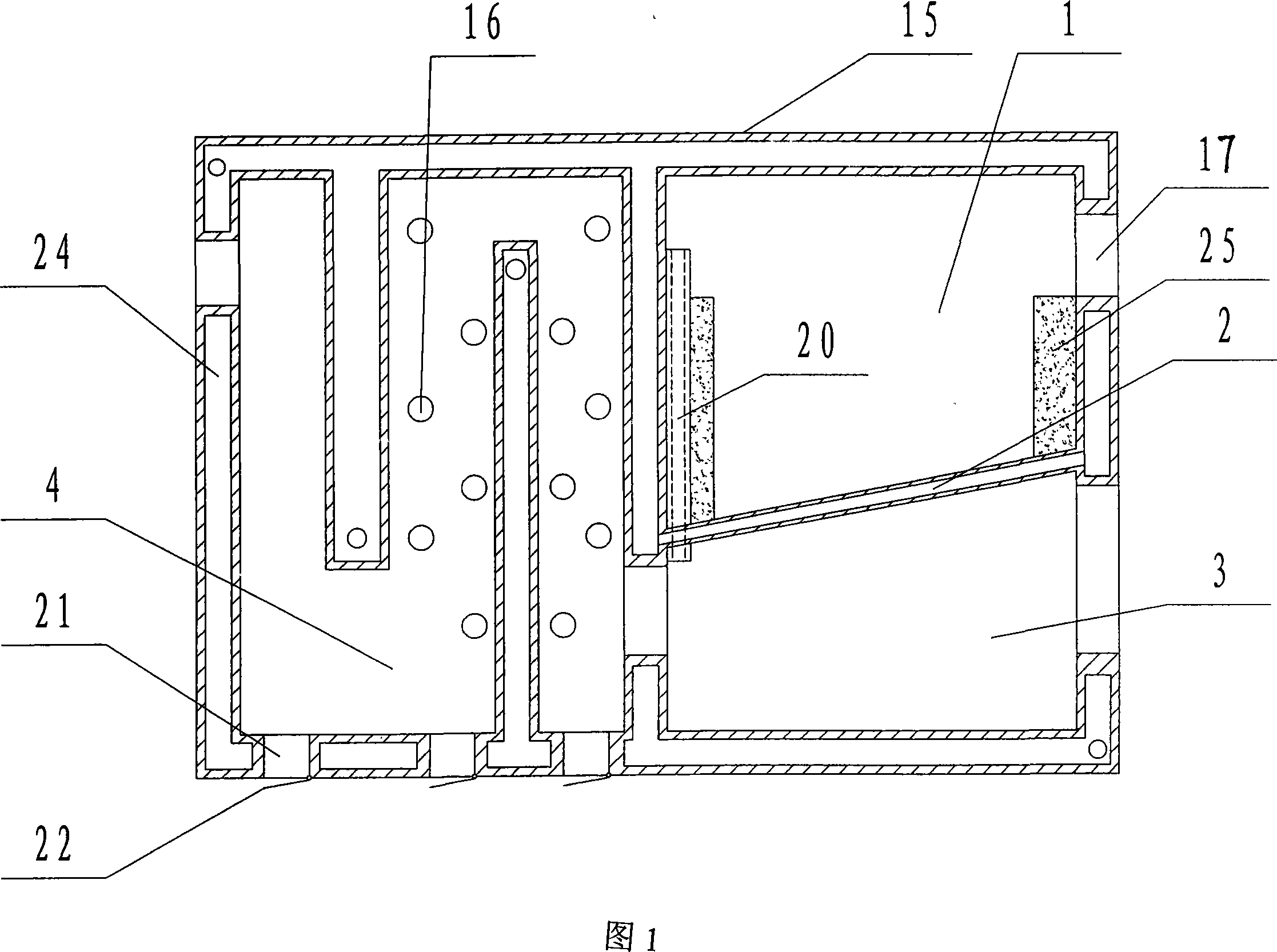

[0017] Example 1: Coal-fired hot air reverse combustion atmospheric pressure boiler, including furnace body 15, combustion chamber 1 inside furnace body 15, furnace bars 2 below combustion chamber 1, ash storage bin 3 below furnace bars 2, and flue 4 , Water barrier 24 is set in body of heater 2. The flue 4 communicates with the ash storage bin 3, and the flue 4 is the heating area. The grate 2 is a tubular structure, and its two ends are connected with water barriers 24 .

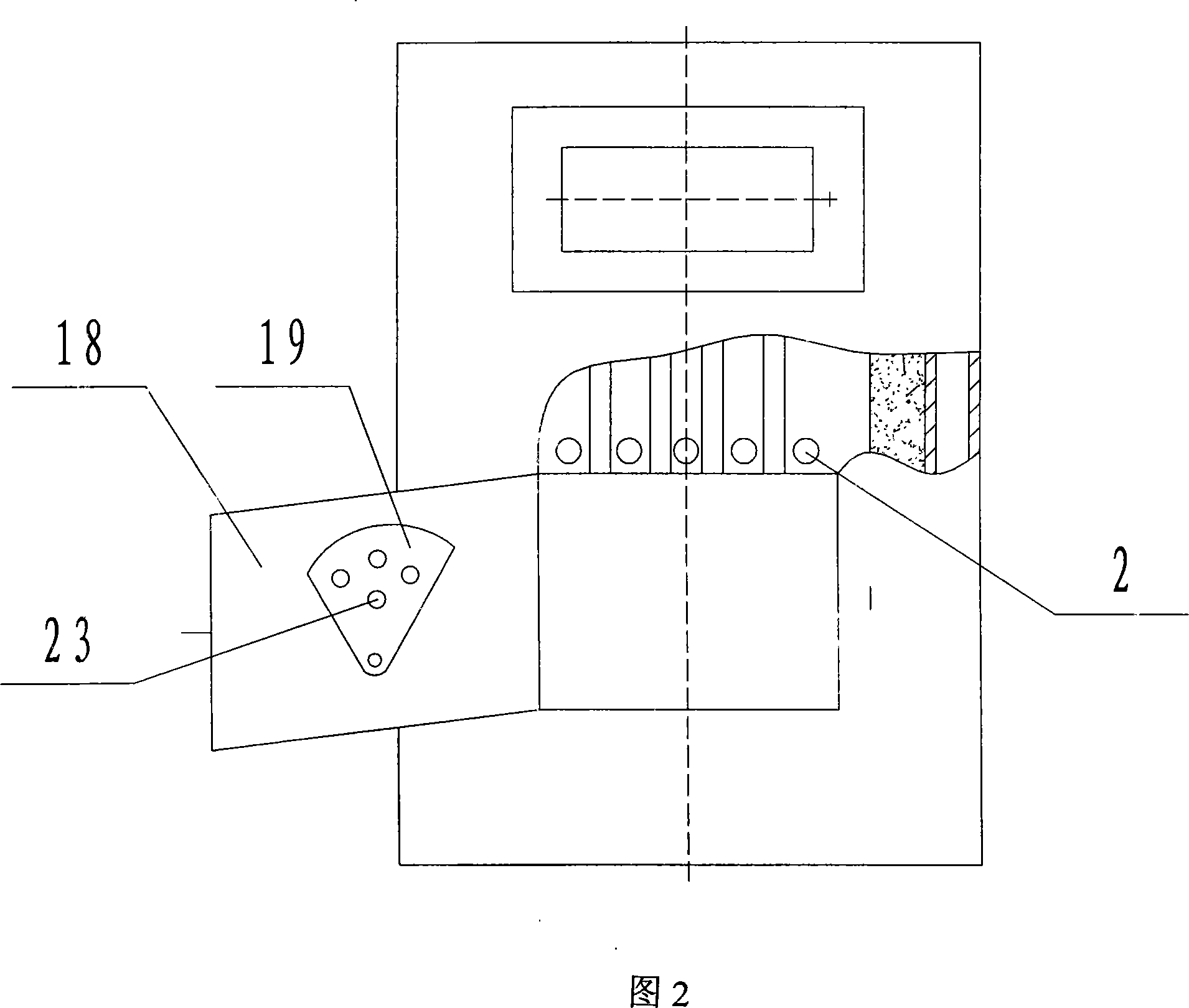

[0018] A safety combustion-supporting pipe 20 is arranged in the combustion chamber 1 , the upper part of the safety combustion-supporting pipe 20 extends above the combustion chamber 1 , and the lower end of the safety combustion-supporting pipe 20 extends into the ash storage bin 3 . The arrangement of the safety combustion tube 20 can provide more sufficient oxygen for the secondary combustion.

[0019] The ash bin door 18 is arranged at the ash bin mouth of the ash bin 3, and the ash bin door 18 is p...

Embodiment 2

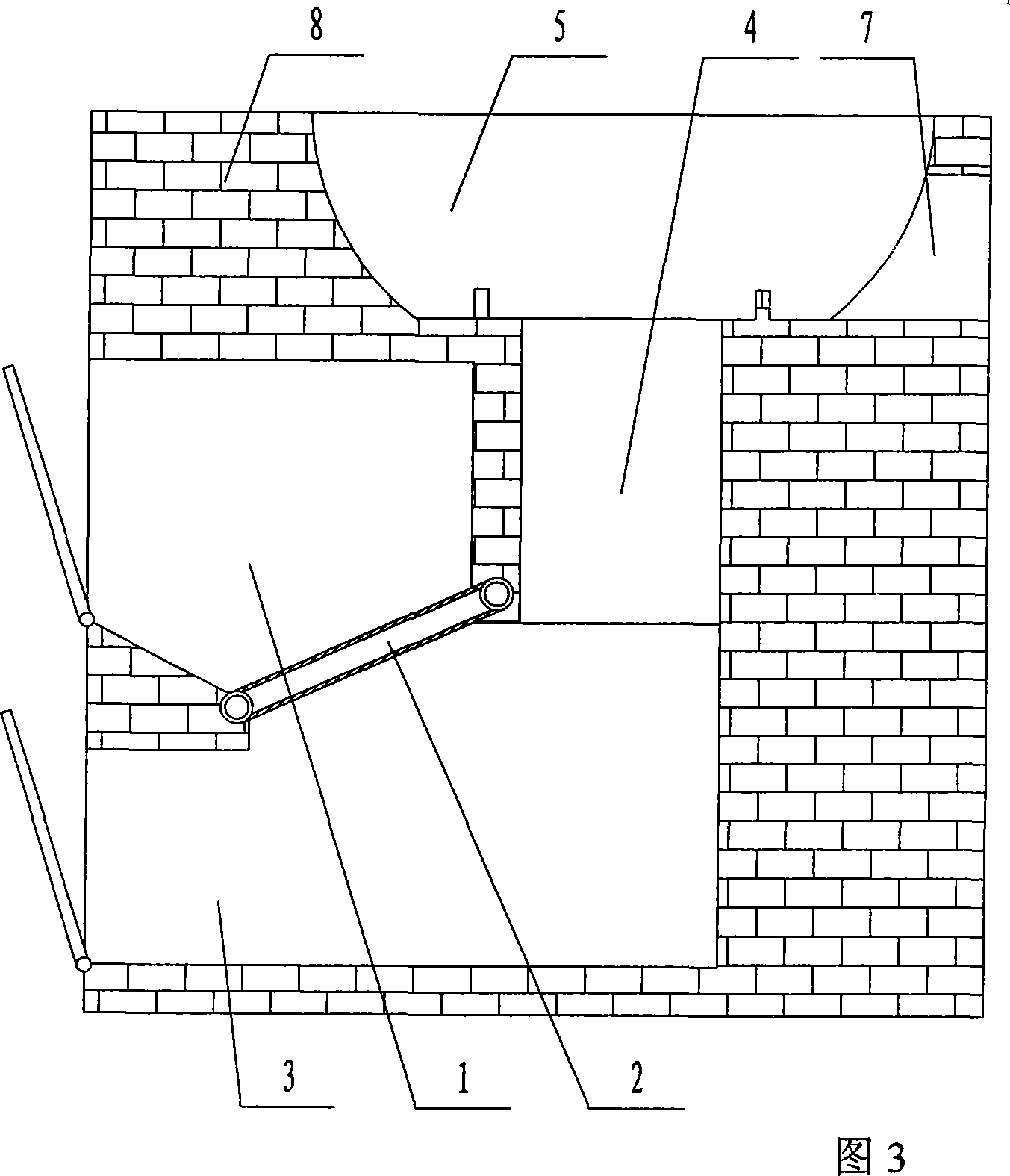

[0021] Embodiment 2: Coal-fired firewood reverse combustion cooker, including the combustion chamber 1 above the furnace bar 2, the ash storage bin 3 below the furnace bar 2, the stove 5 and the chimney 7 connected to one side of the stove 5, and the smoke chamber 5 is installed below the stove 5 Road 4, the flue 4 communicates with the ash storage bin 3. The grate 2 is a tubular structure, and its two ends are connected to the water tank. The upper portion of the flue opposite to the chimney 7 has an exhaust hole 6 .

[0022] After the fuel is burned, the smog containing the incomplete combustion material continues to burn countercurrently from the top of the combustion chamber 1, and the heat also counterflows downward thereupon, and finally enters the stove 5 to heat the pot. Simultaneously the water in the fire bar 2 is also heated for use. The fuel is fully burned throughout the process, with high thermal efficiency and less environmental pollution.

Embodiment 3

[0023] Embodiment 3: a reverse combustion boiler, including a furnace body 15, a combustion chamber 1 inside the furnace body 15, a furnace bar 2 below the combustion chamber 1, and an ashes storage bin 3 below the furnace rod 2, and a water barrier 24 is set in the furnace body 15 . The ash storage bin 3 is connected with the chimney 7 through the lower flue 11 , and the grate 2 is a tubular structure, and its two ends are connected with the water barrier 24 .

[0024] An upper smoking passage 10 is arranged above the combustion chamber 1 to connect with the chimney 7 , and a flip cover 13 is arranged above the upper smoking passage 10 and the lower smoking passage 11 , and the flip cover 13 is installed at the junction of the upper smoking passage 10 and the lower smoking passage 11 through a turning handle 14 .

[0025] The top of the upper smoking passage 10 and the lower smoking passage 11 are connected with the chimney 7 through the connection sleeve 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com