Gas stove

A gas stove and stove body technology, which is applied in the field of gas stoves, can solve the problems of insufficient natural air and achieve the effects of promoting combustion and reducing the production of carbon monoxide and nitrogen compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

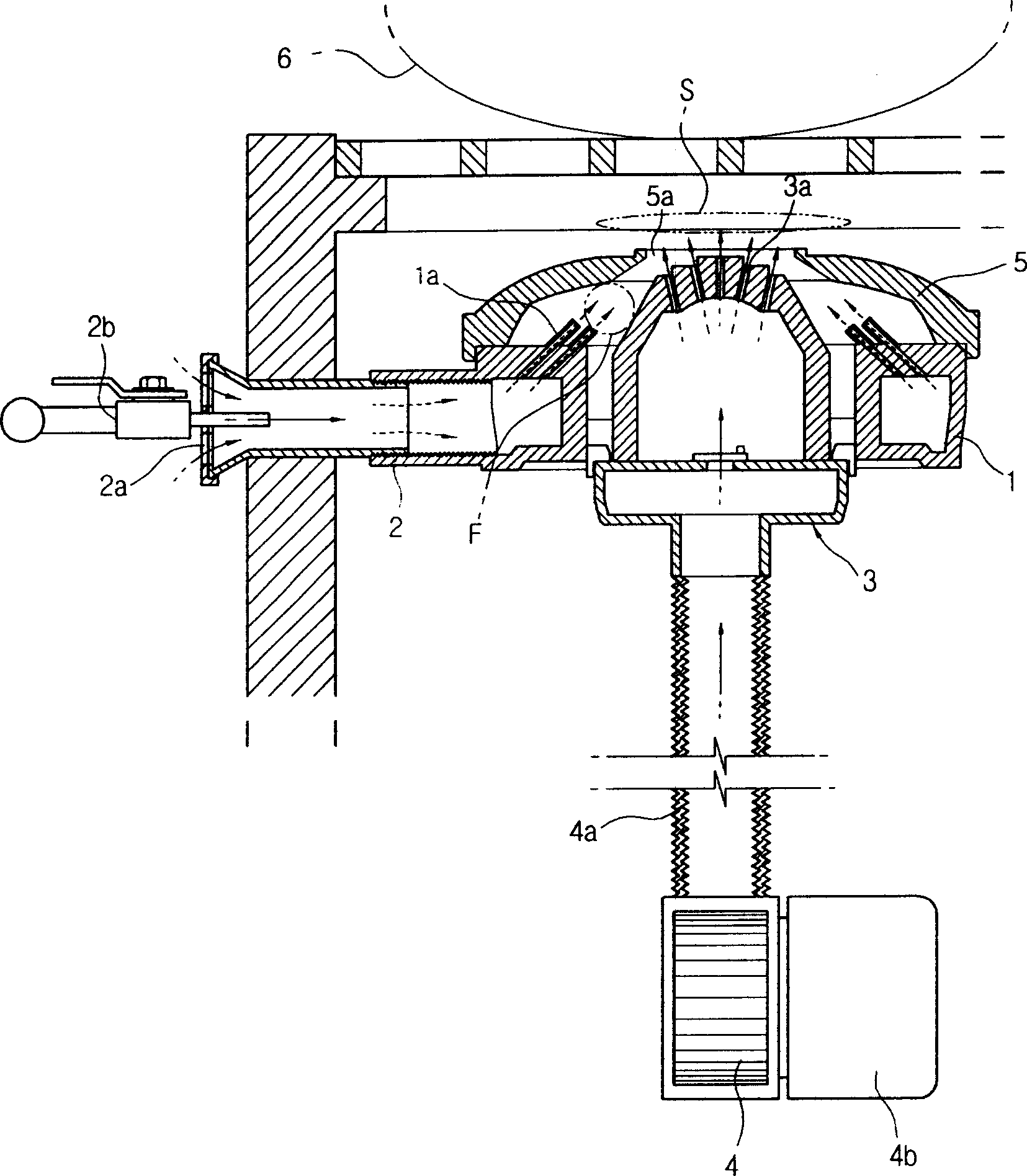

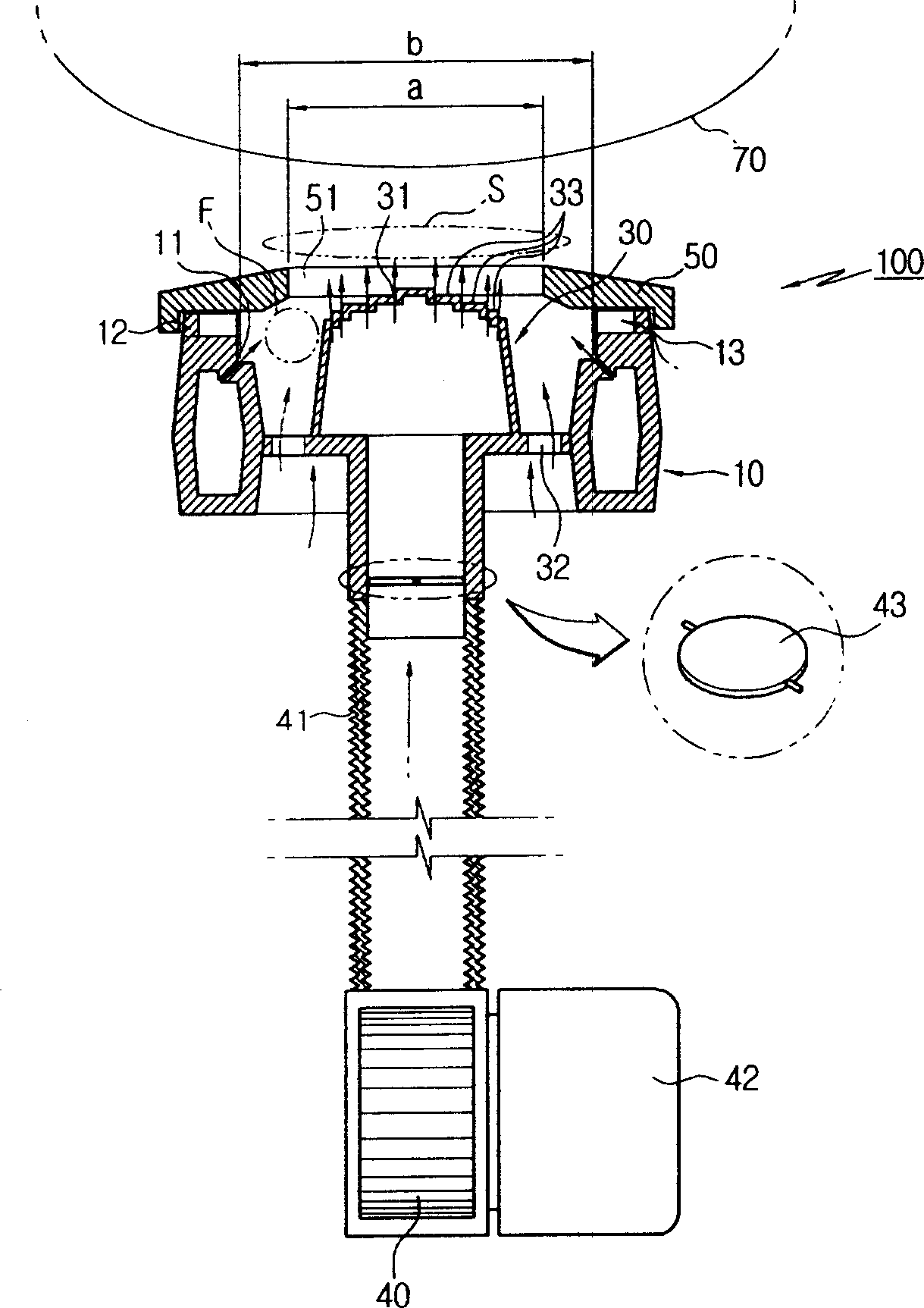

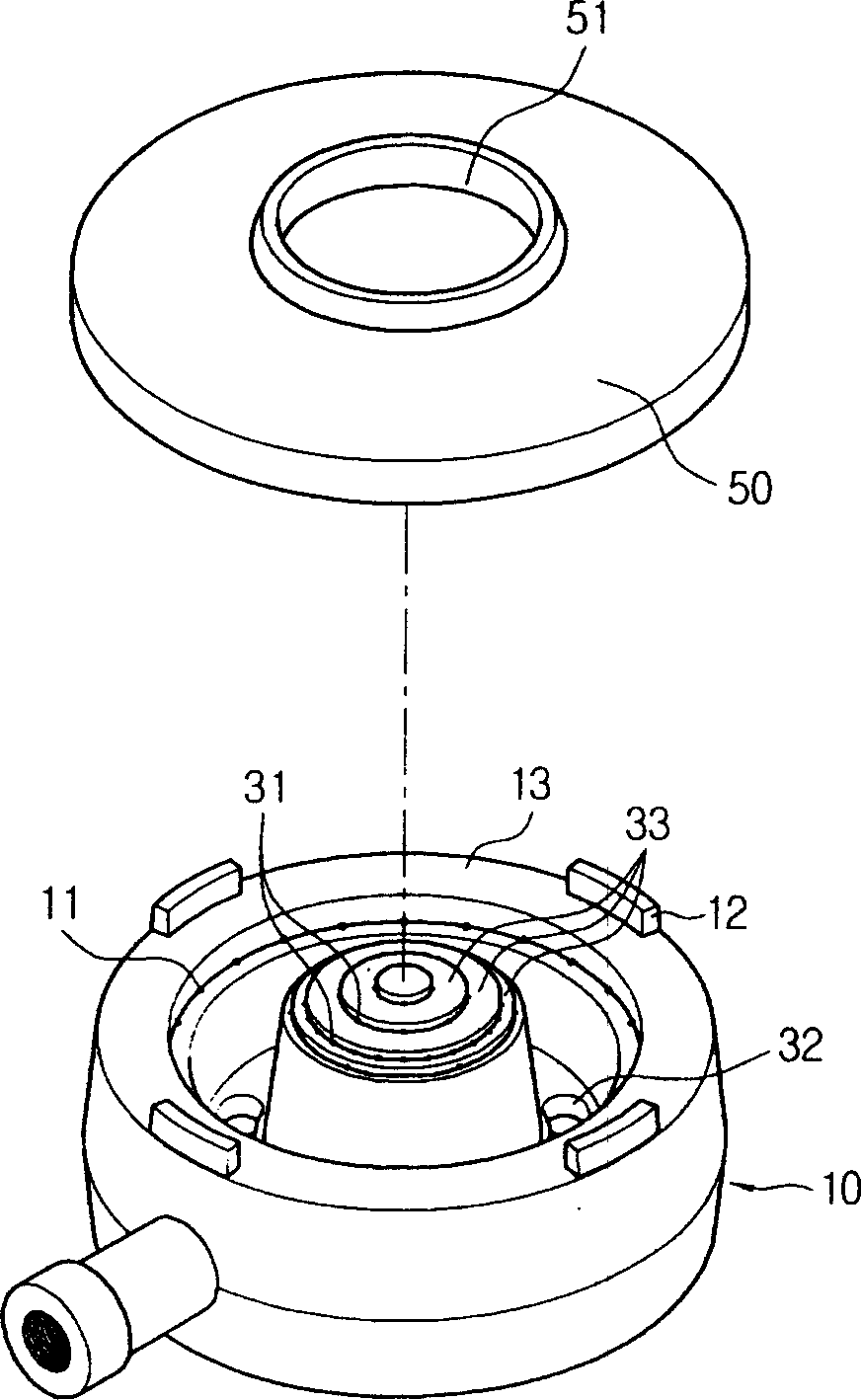

[0042] With reference to the drawings, the following detailed description is applied to the embodiments of the present invention. Figure 2 to Figure 4 It is a schematic diagram of an embodiment of a gas stove developed according to the present invention. As shown in the figure, the gas stove 100 is composed of a stove body (10), a mixing pipe 20, a first air box 30, a blower 40 and an upper cover 50.

[0043] The stove body 10 has a ring structure; on the inner upper peripheral surface, a plurality of mixed gas injection ports 11 are provided along the circumference.

[0044] In addition, above the stove body 10, at least three bosses 12 should be arranged along the circumference; four bosses 12 are most suitable; the gap formed between the bosses 12 and the upper cover 50 covered above it 13. Supply natural air (secondary natural air) and inject it to the mixed gas injection port 11 for combustion; therefore, in order to obtain a more obvious enhanced firepower from the general c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com