Hot water constant-temperature combustion biomass stove

A hot water and constant temperature technology, applied in the field of hot water and constant temperature biomass stoves, can solve the problems of inability to keep hot water at constant temperature, insufficient combustion, black smoke, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

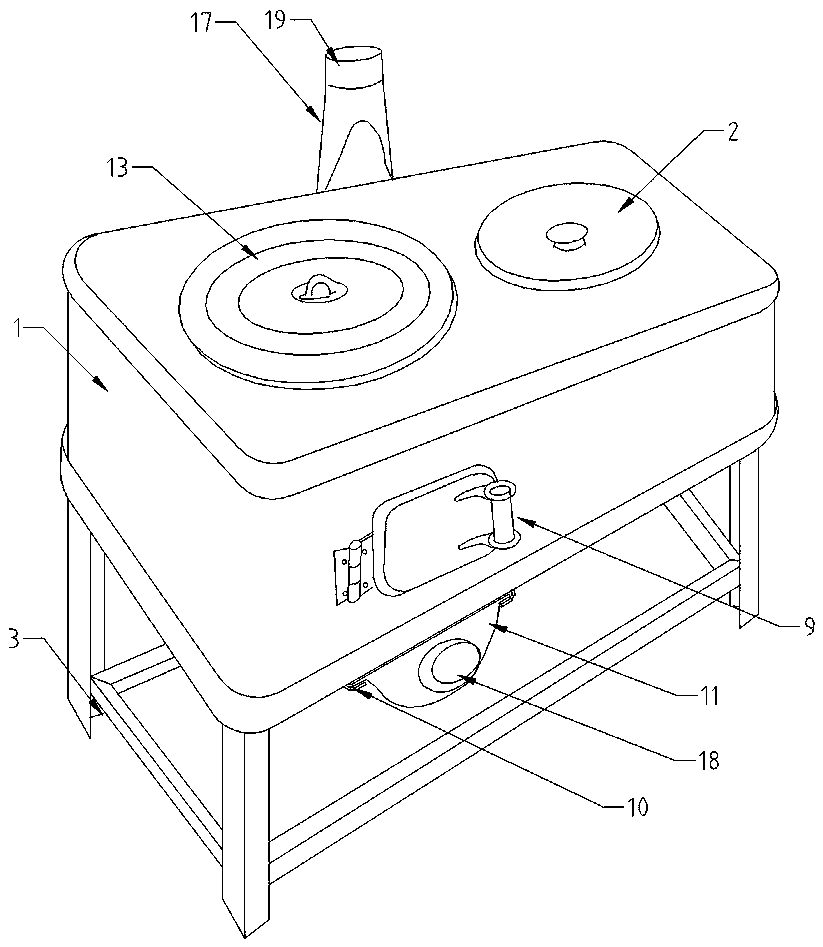

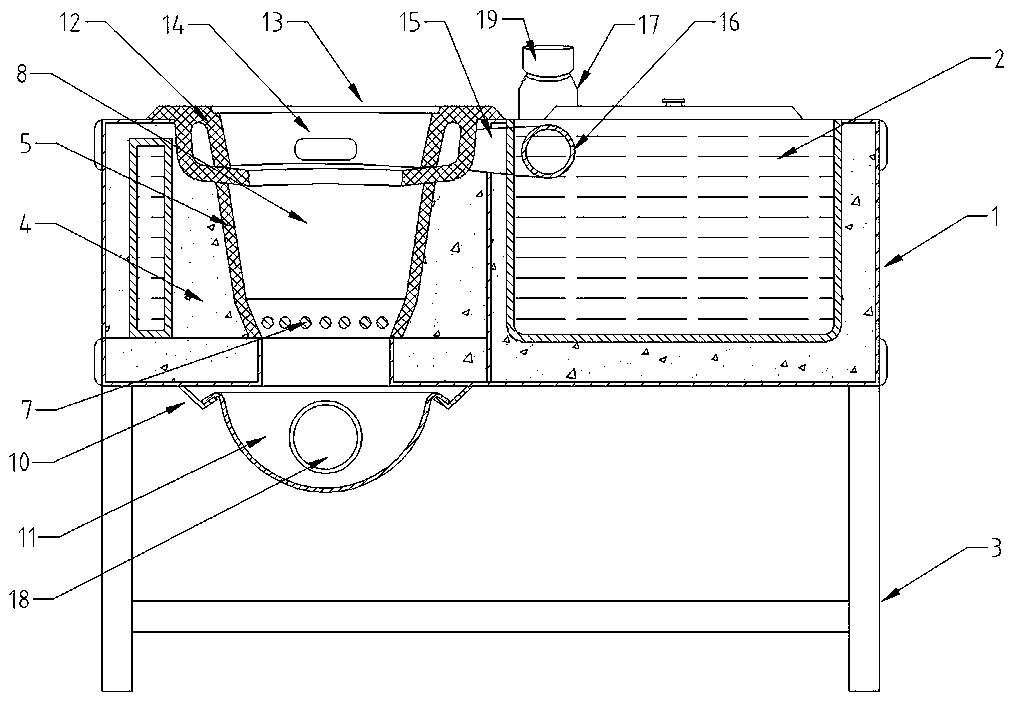

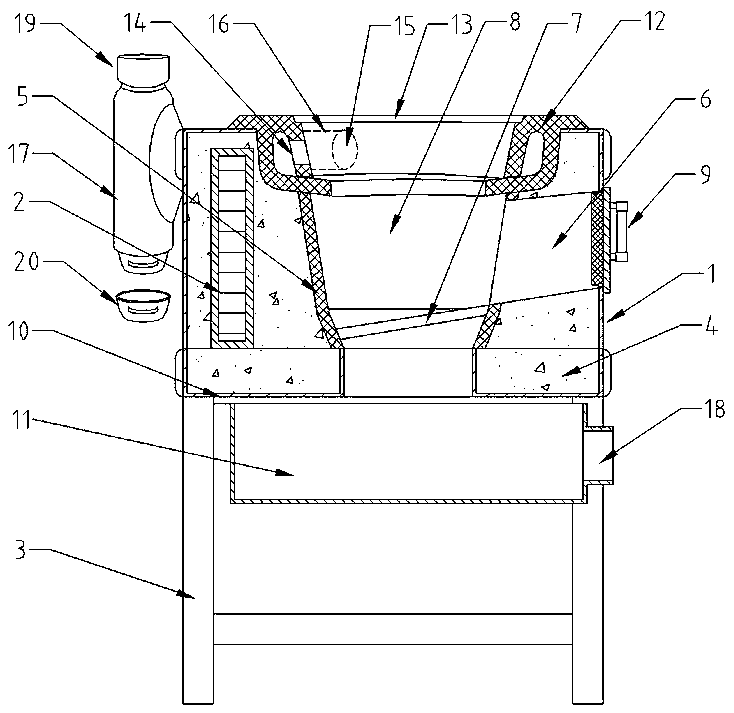

[0024] The preferred embodiment of the present invention is like this, with reference to Figure 1 to Figure 5 As shown, a hot water constant temperature biomass stove is composed of a stove shell 1, a stove component, a large-capacity water tank 2, and a tripod 3 that are welded by cold welding of pure aluminum. The tripod 3 supports the stove casing 1, and the large The capacity water tank 2 is located in the stove shell 1; half of the large-capacity water tank 2 is a hollow ring structure, and the stove components are contained by the ring structure of the large-capacity water tank; the stove shell 1, the large-capacity water tank 2 and the stove components Lightweight insulating material 4 is filled between two pairs; the above-mentioned stove component has a pig iron hearth 8 integrally cast by a trinity of parabolic heat-gathering furnace barrel 5, side firewood feeding port 6, and inclined-bottom furnace bridge 7 at the windward opening; There is a safety door 9 for add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com