Patents

Literature

39results about How to "Fire in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

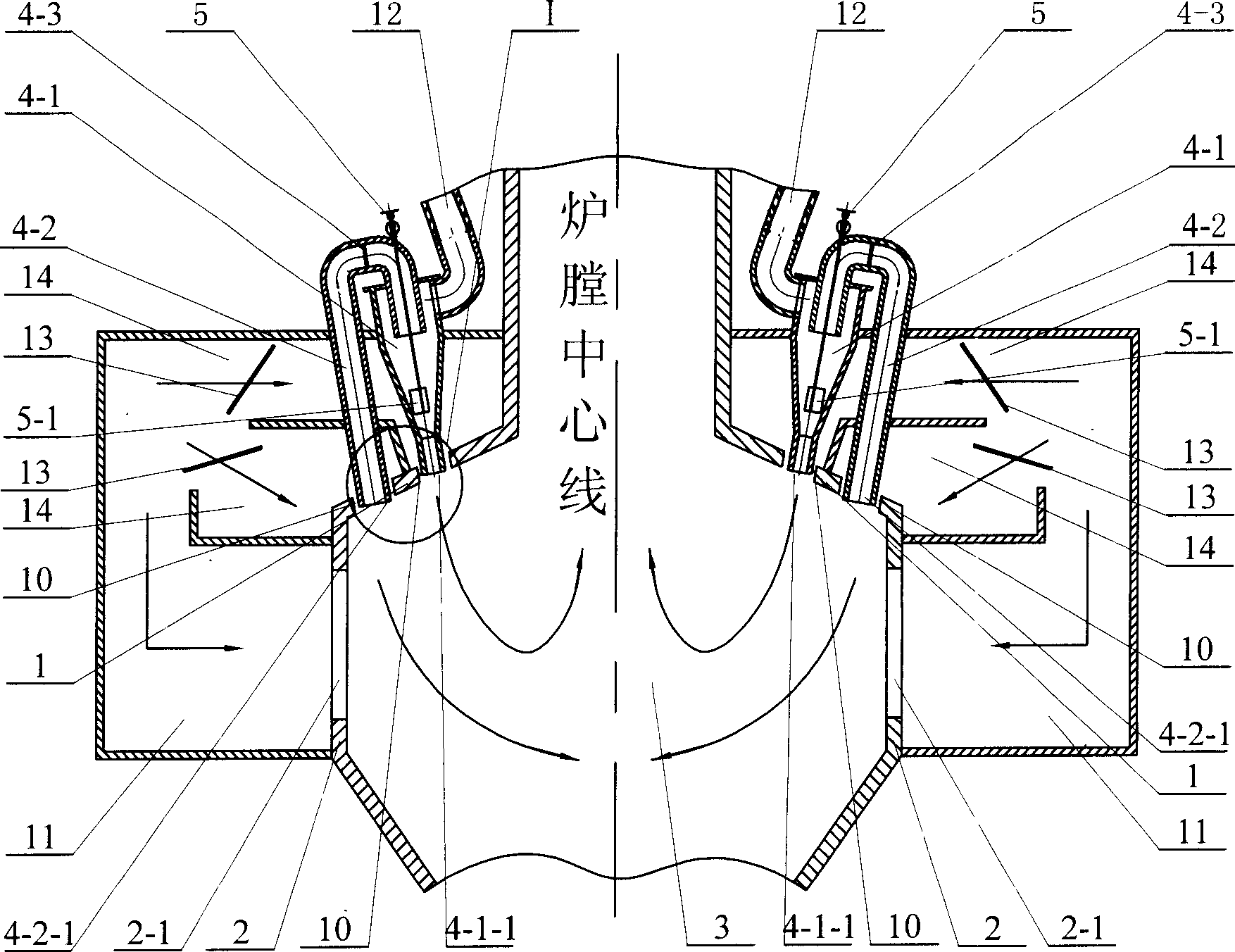

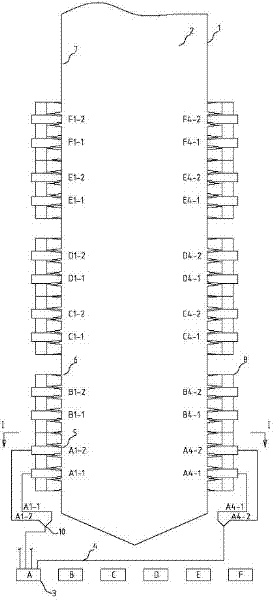

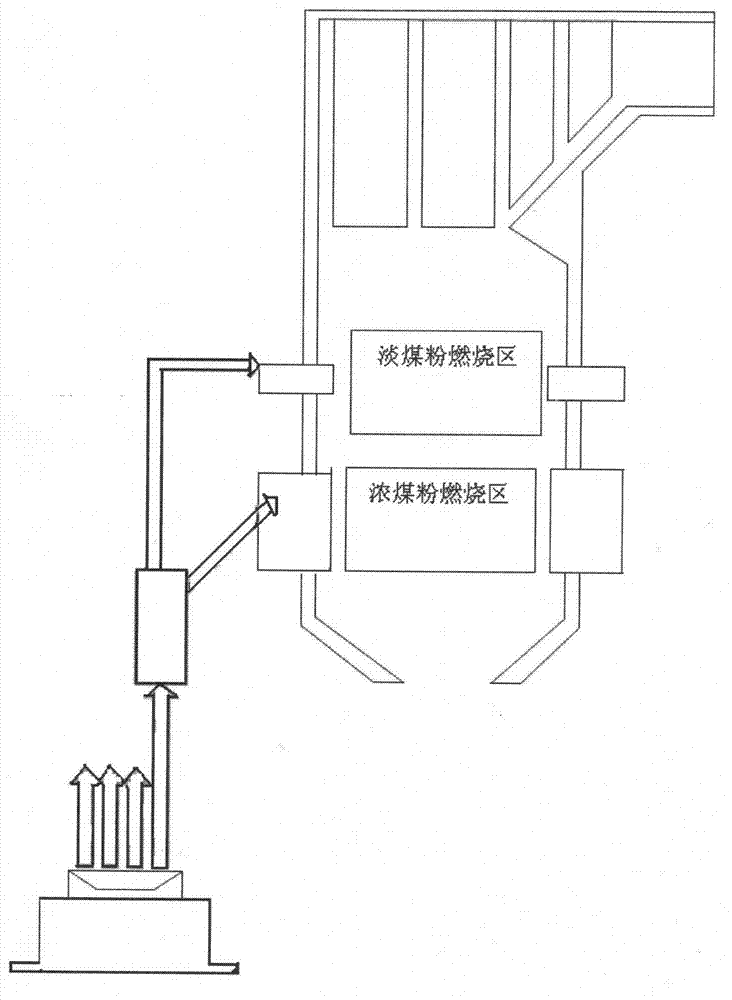

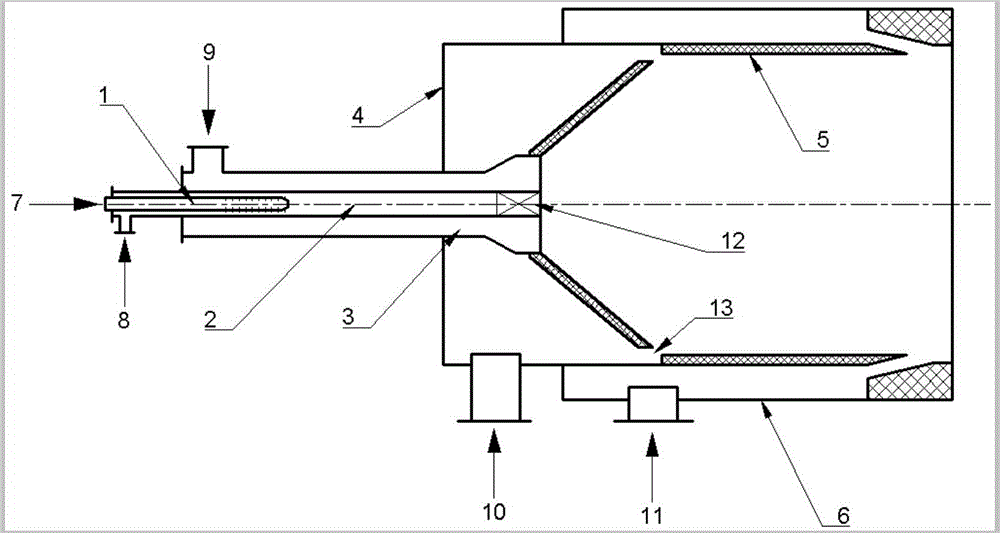

W-shape flame furnace with gradation coal burner

ActiveCN1707160AHigh melting temperaturePrevent high temperature corrosionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorHearth

The present invention is one W-shaped flame furnace with dense and dilute coal powder combustion and relates to one kind of burning plant. The improved W-shaped flame furnace includes furnace arch, side wall, hearth formed with the furnace arch and the side wall, and burner. The burner includes dense coal powder flow flame nozzle in the center of the hearth and dilute coal powder flow flame nozzle near the side wall. The present invention has greatly raised ash melting temperature to avoid slagging of the water cooled wall and prevent high temperature corrosion while reaching the aims of timely igniting and stable combustion.

Owner:HARBIN INST OF TECH

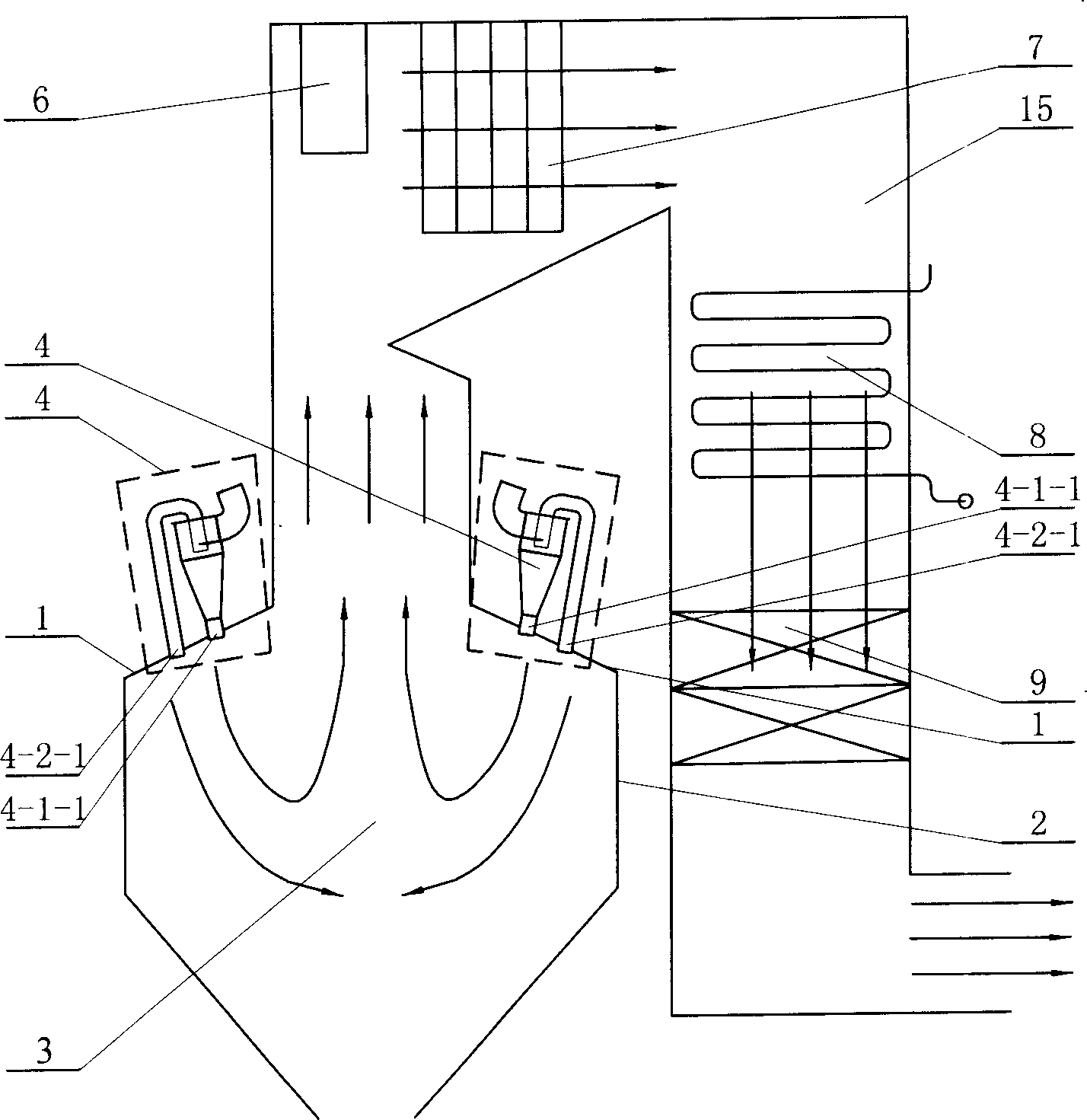

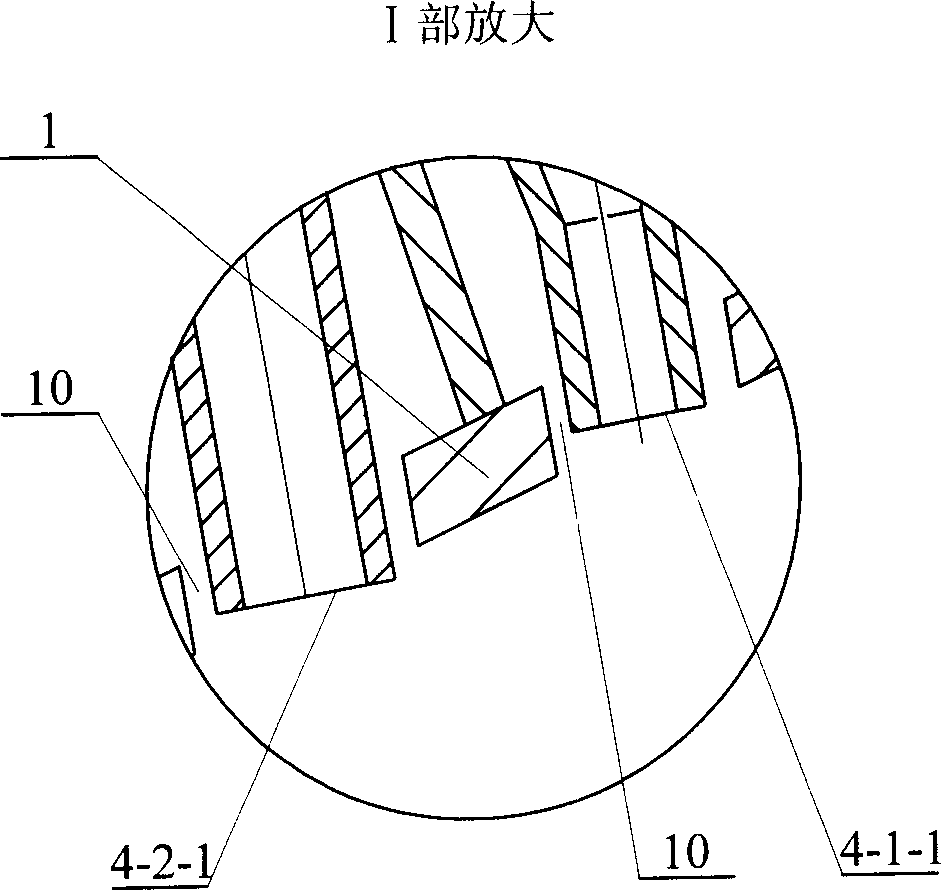

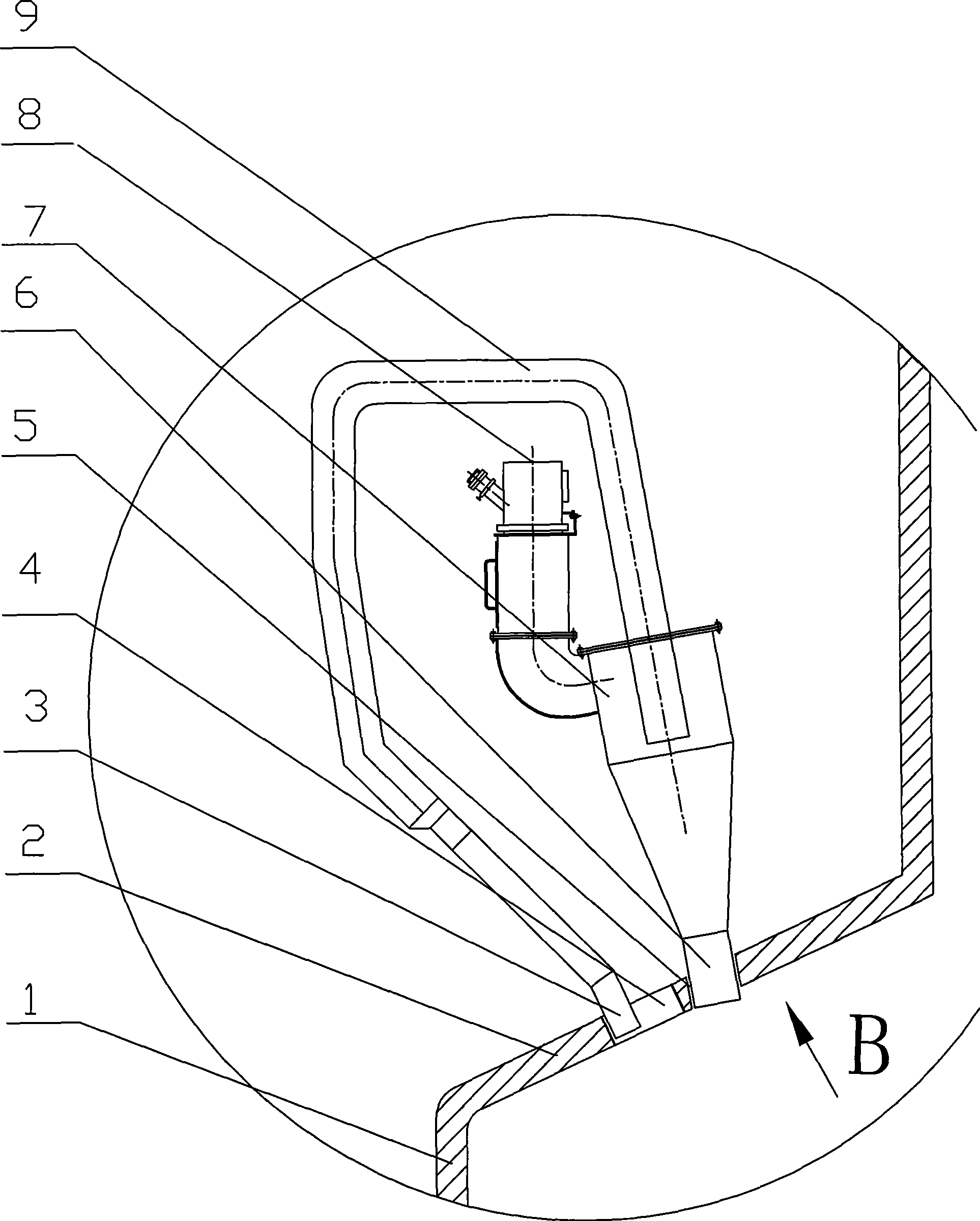

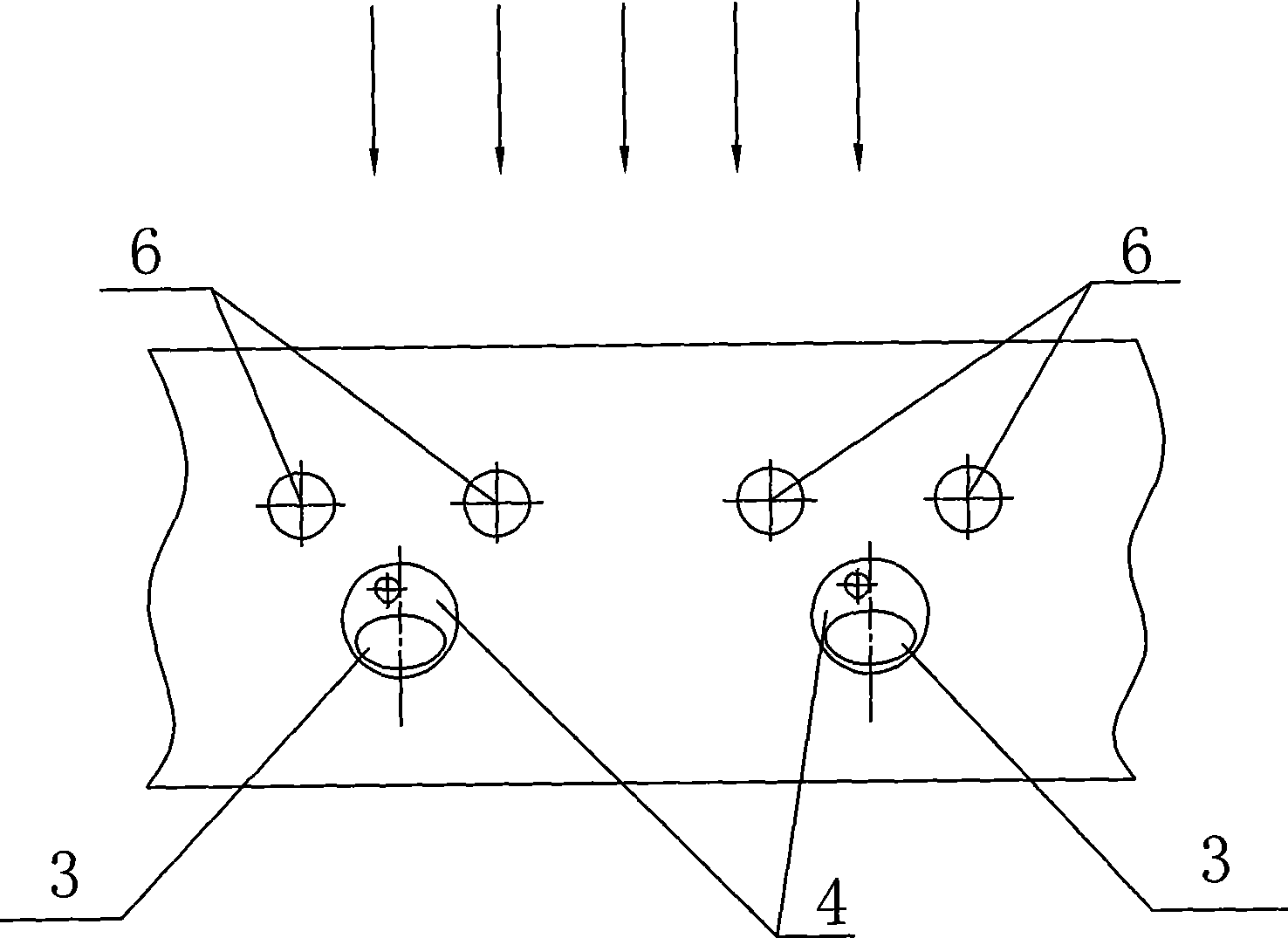

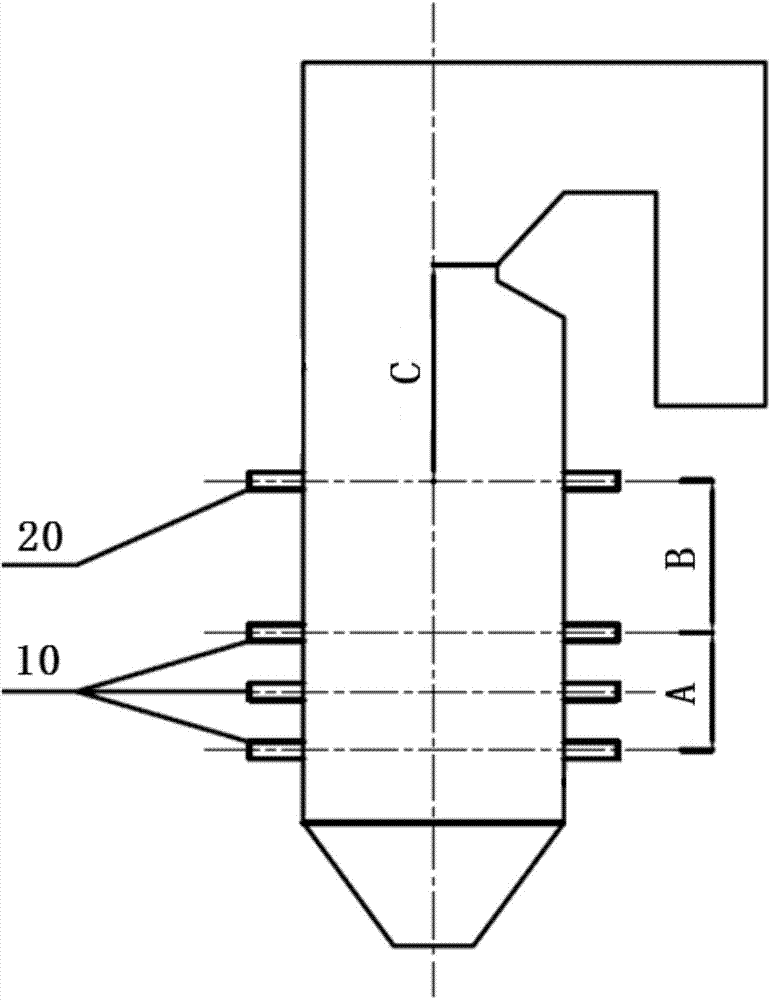

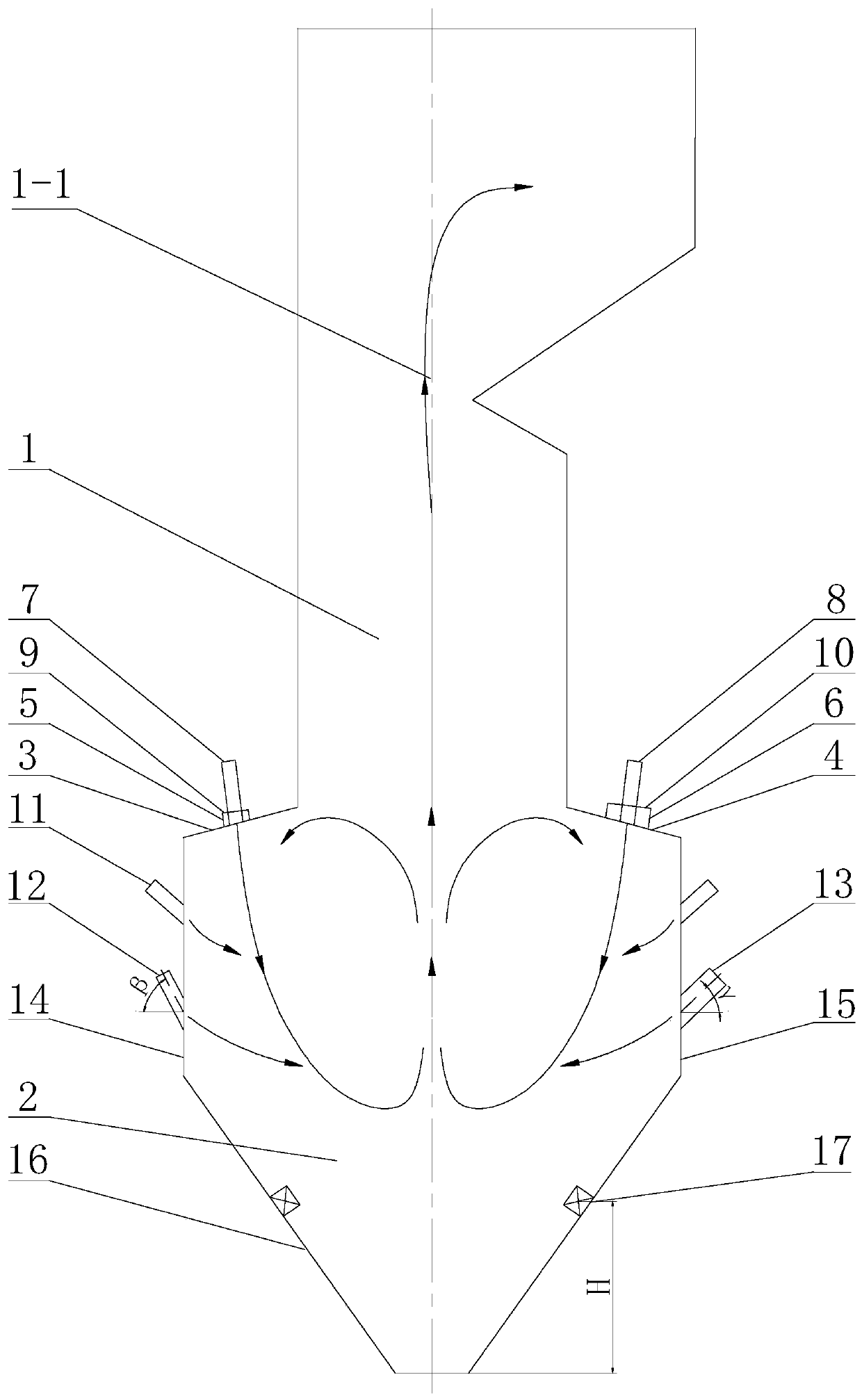

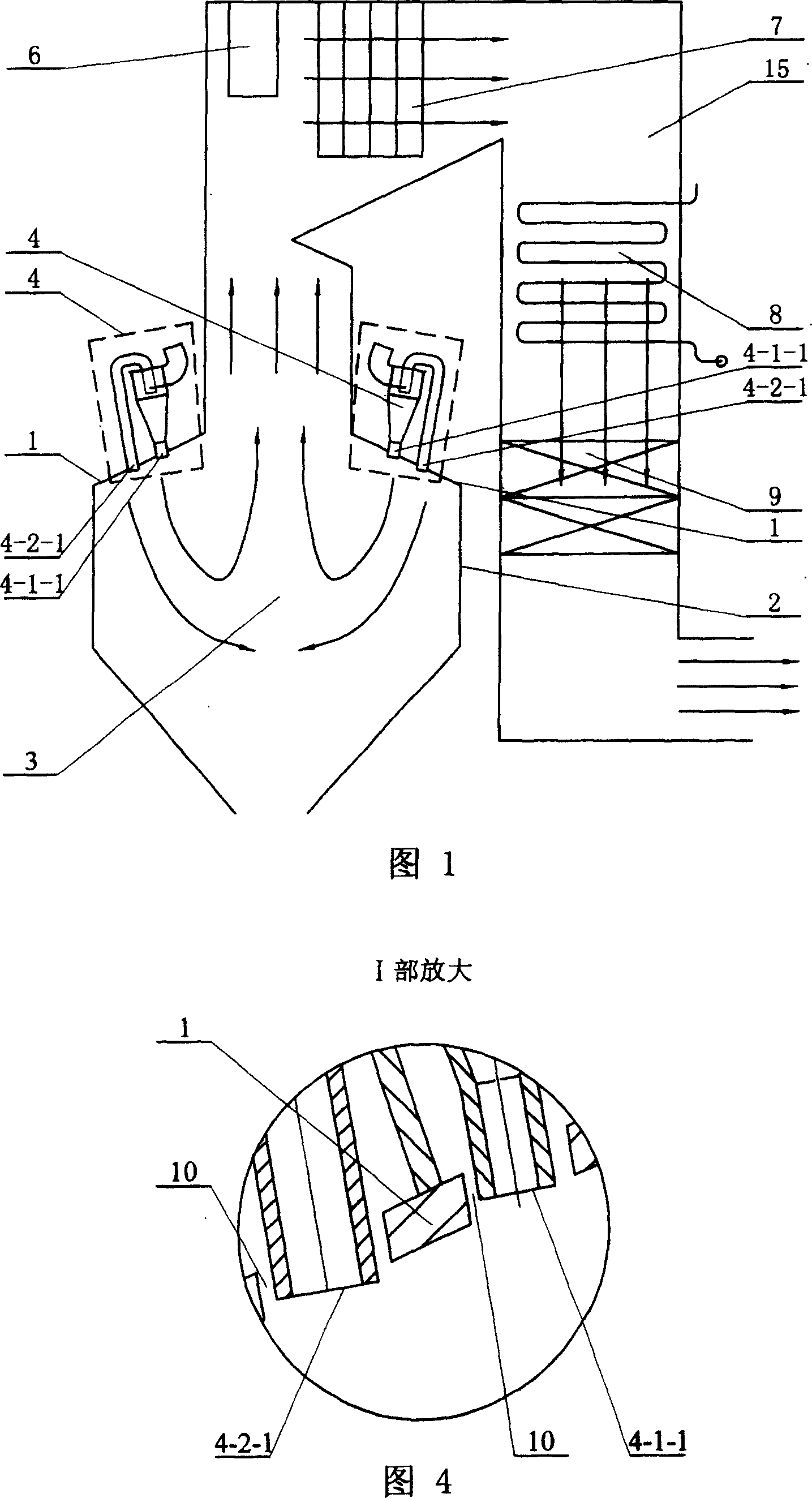

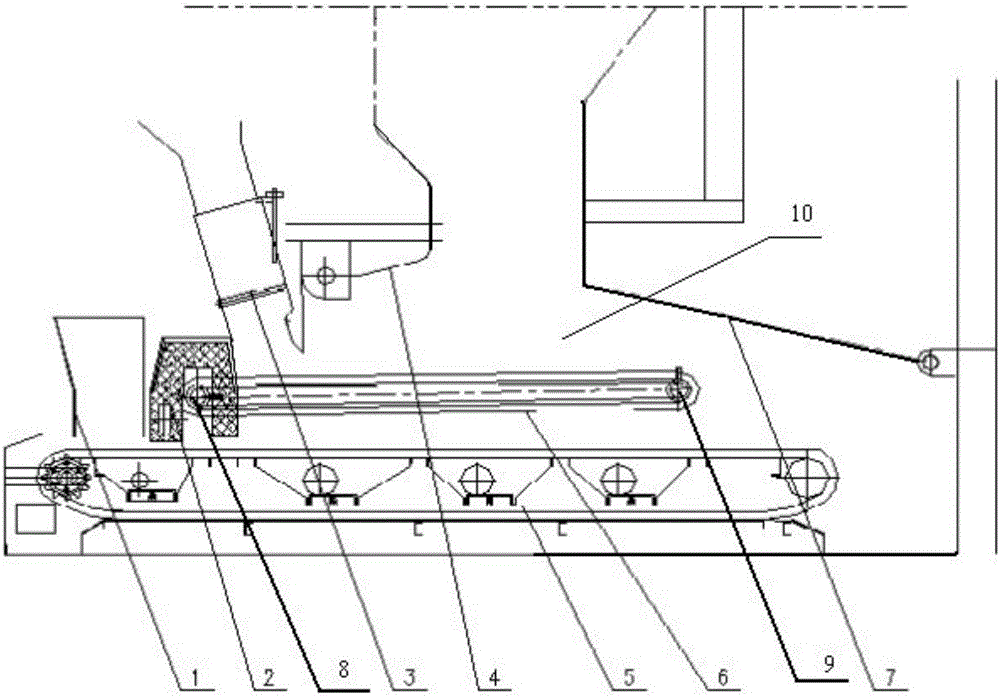

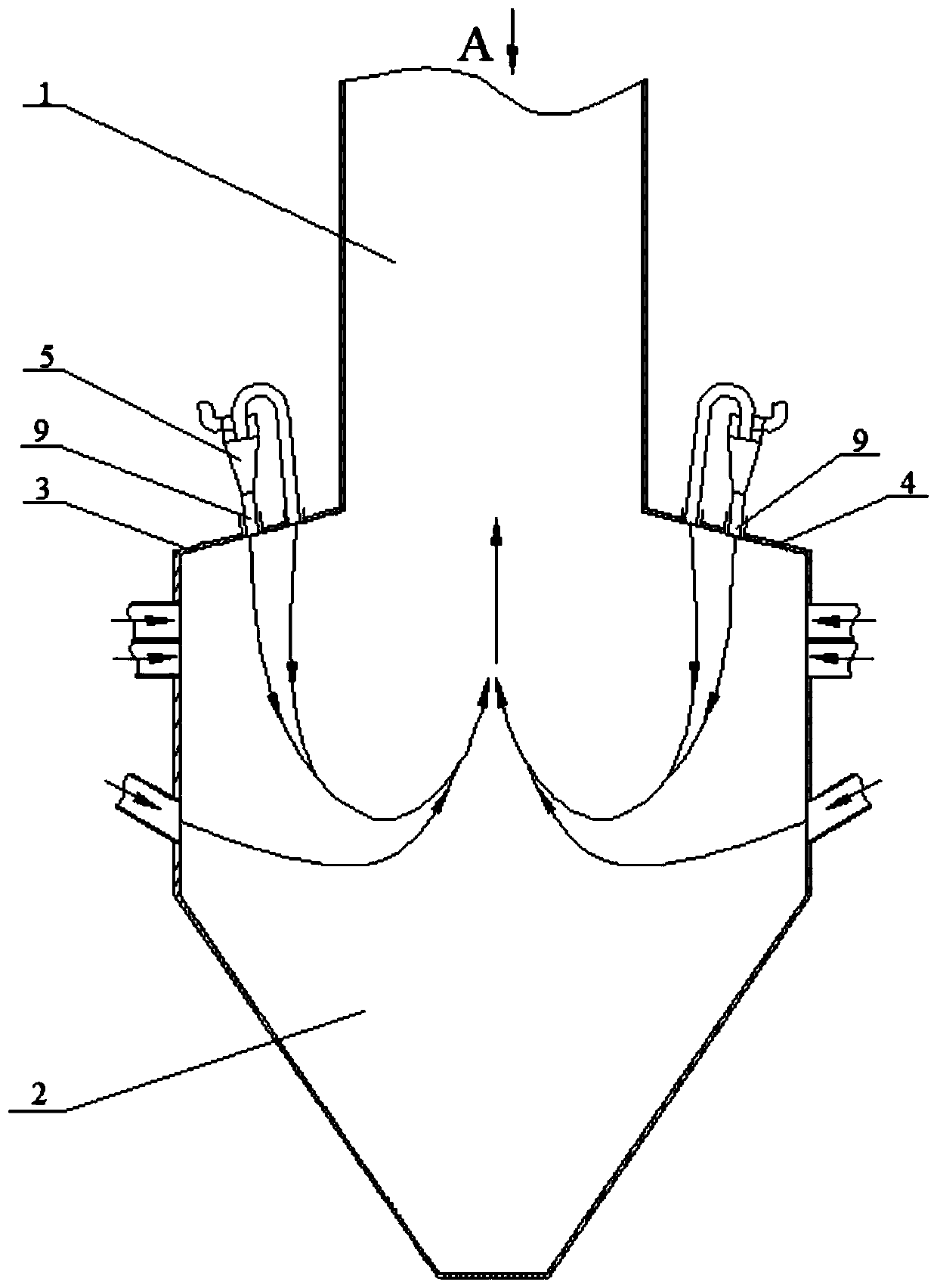

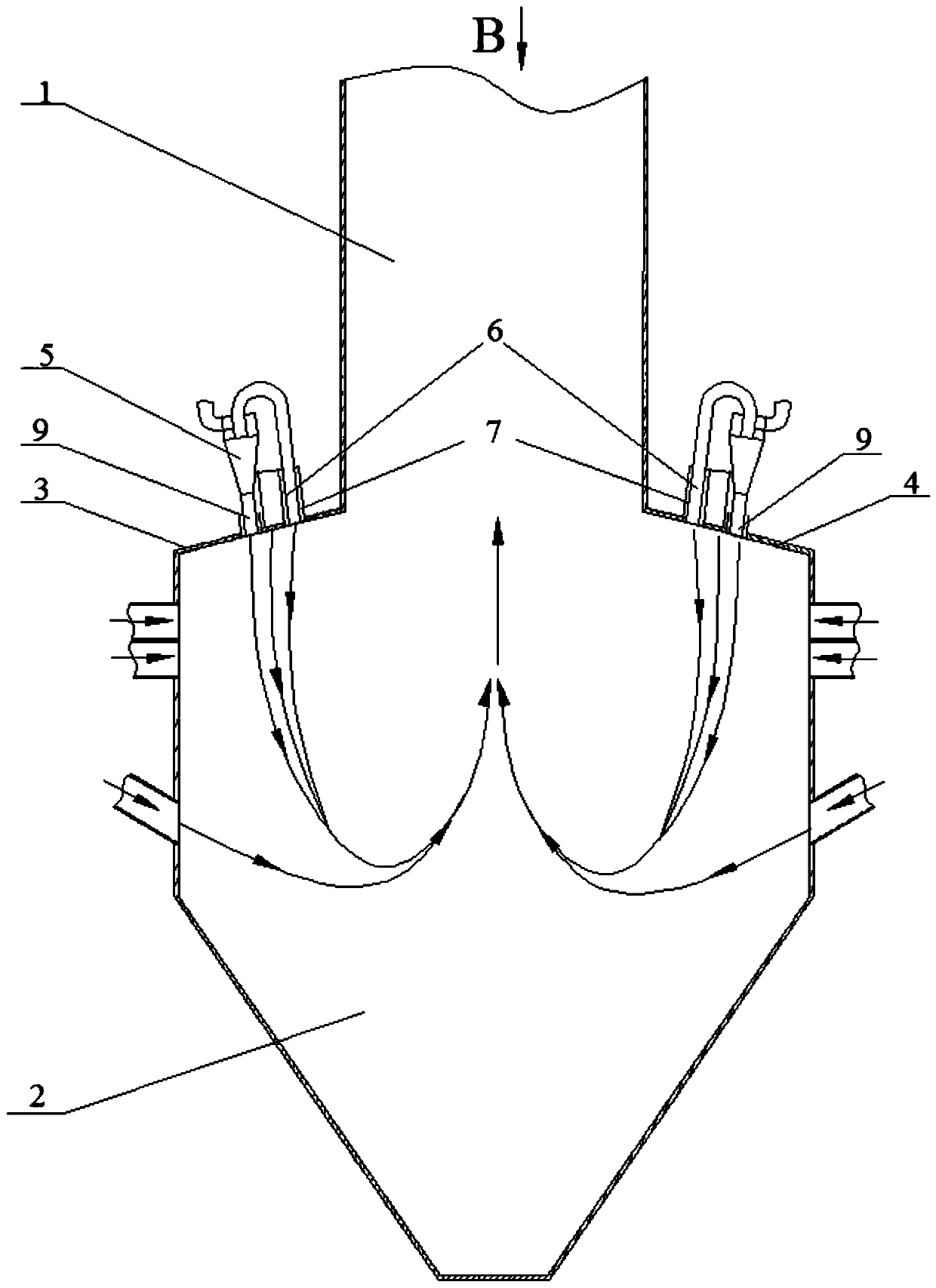

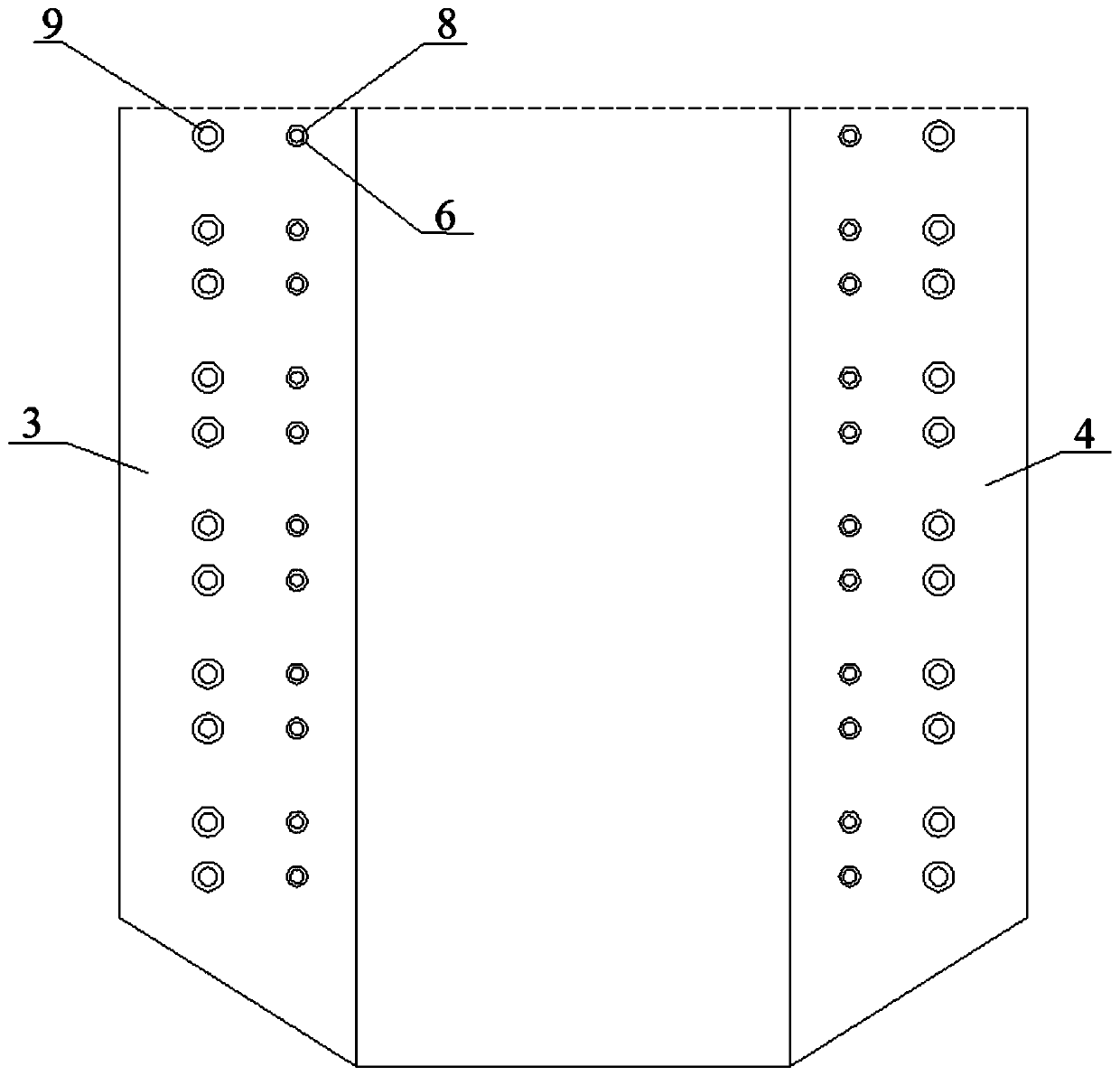

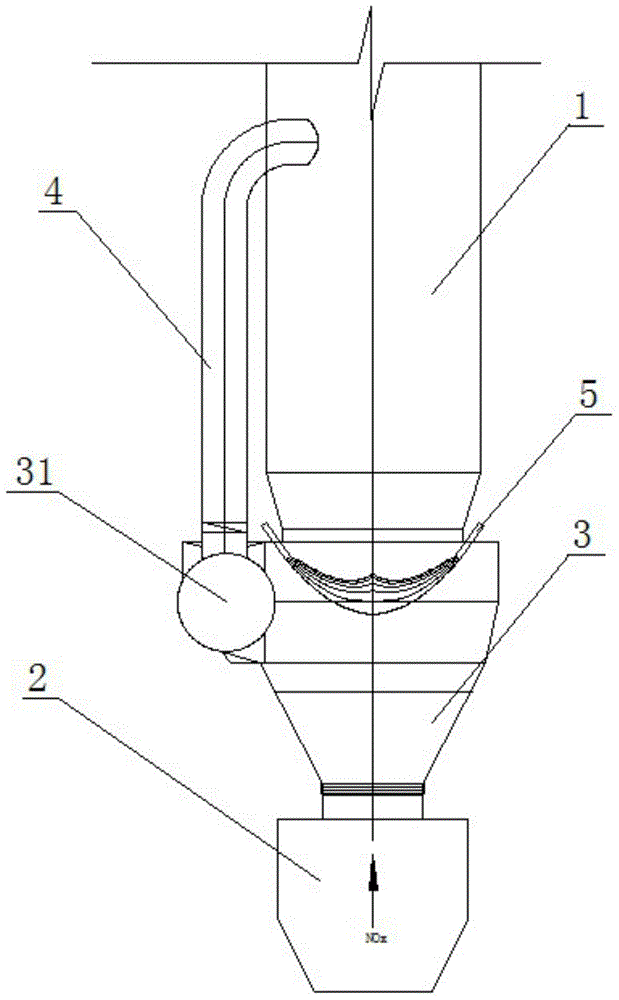

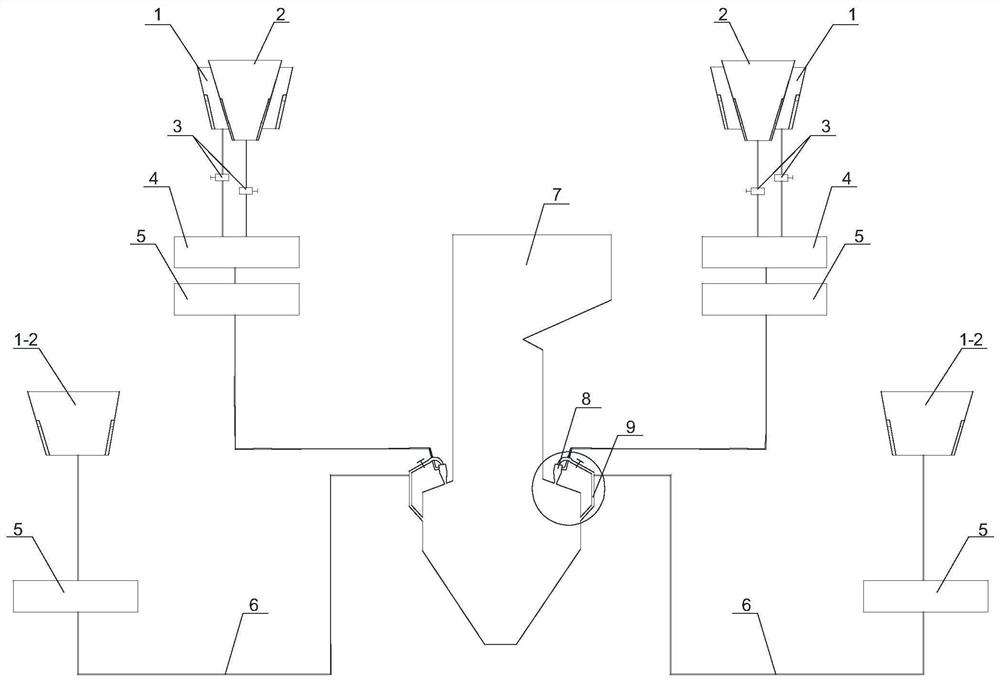

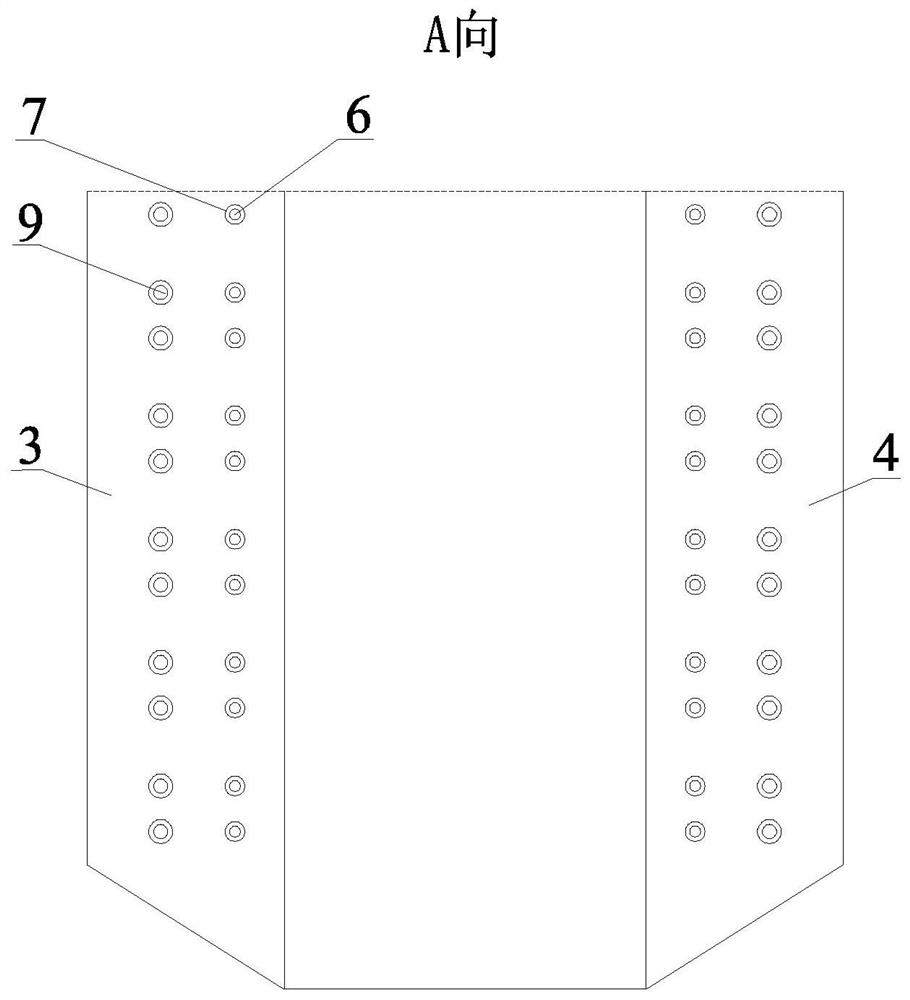

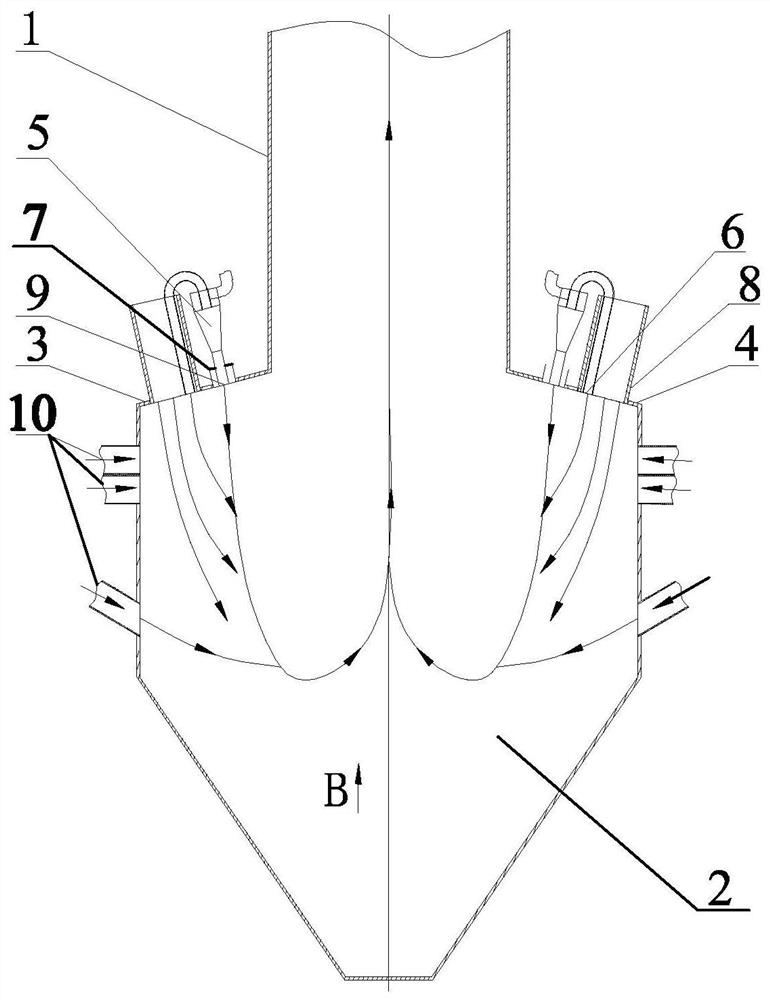

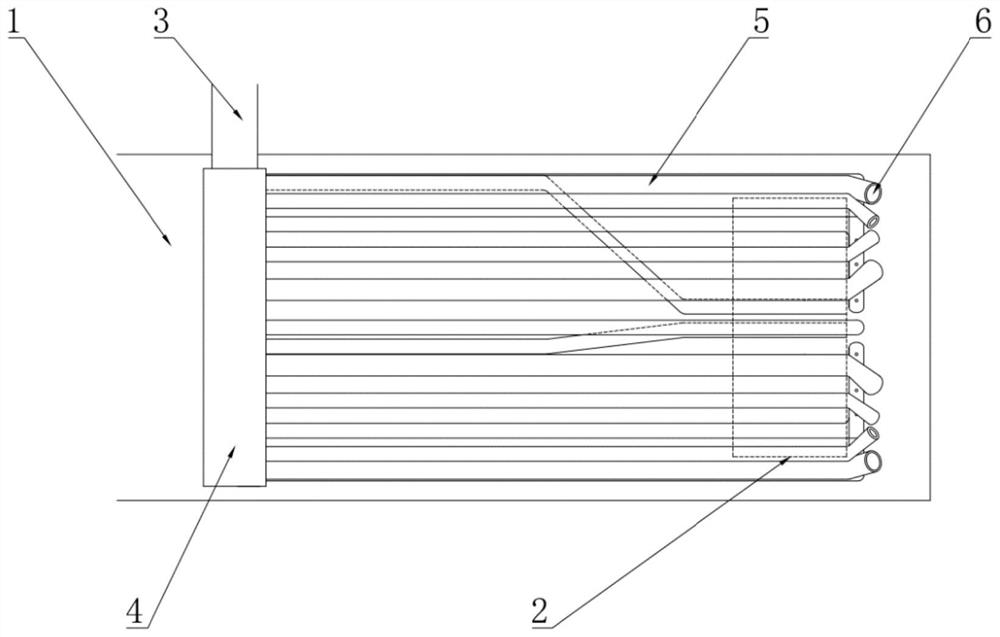

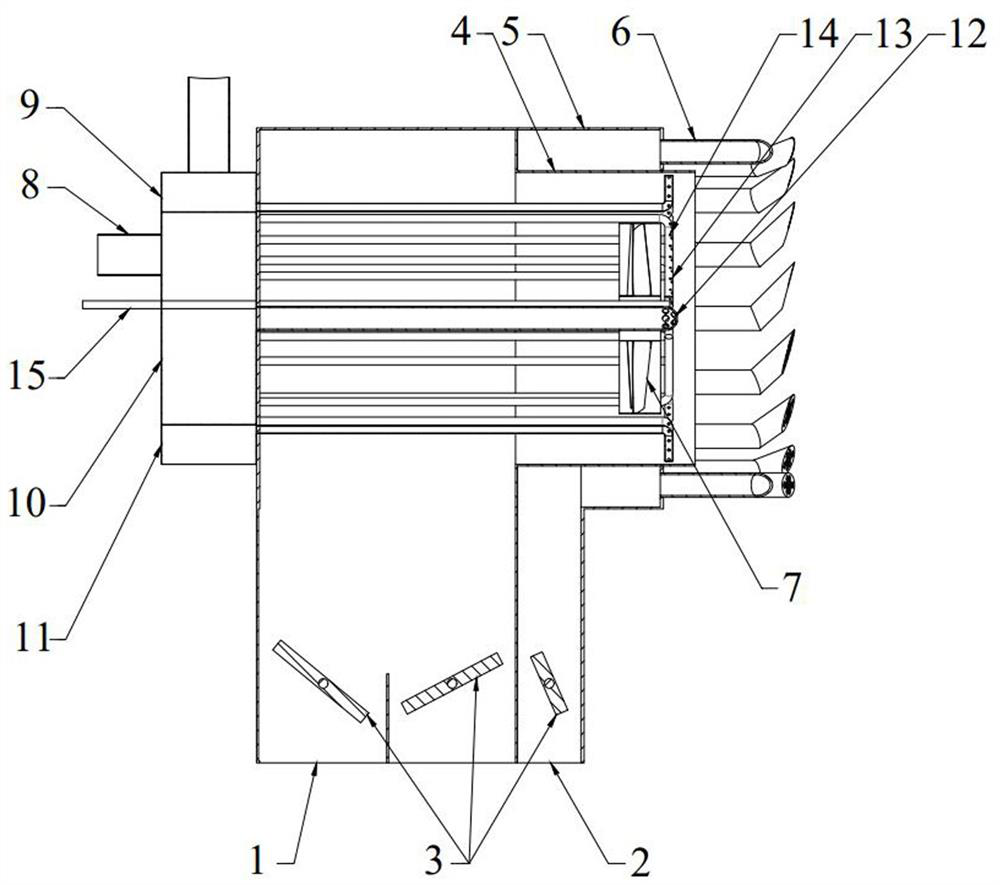

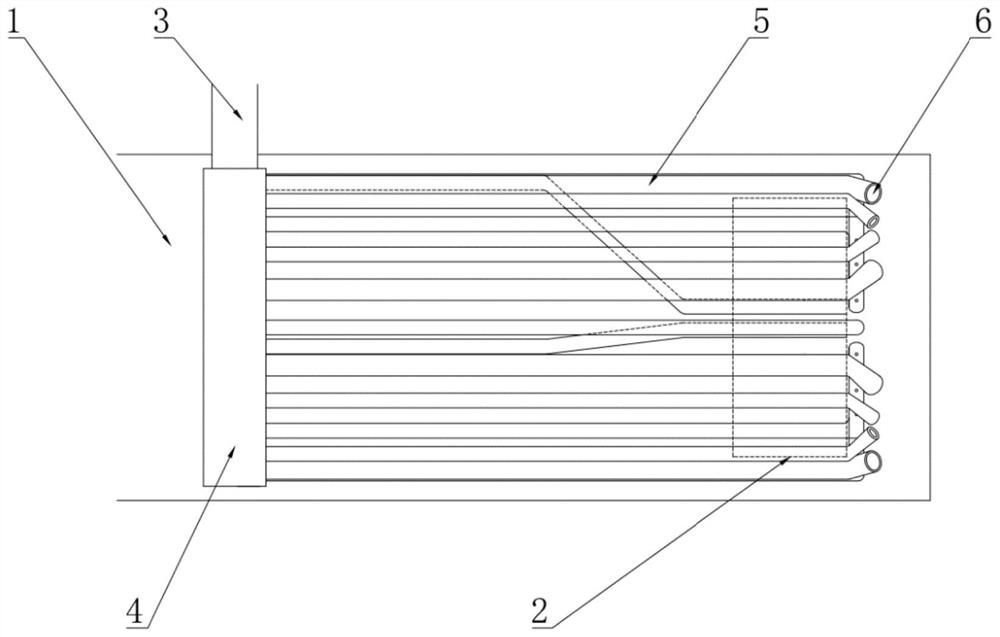

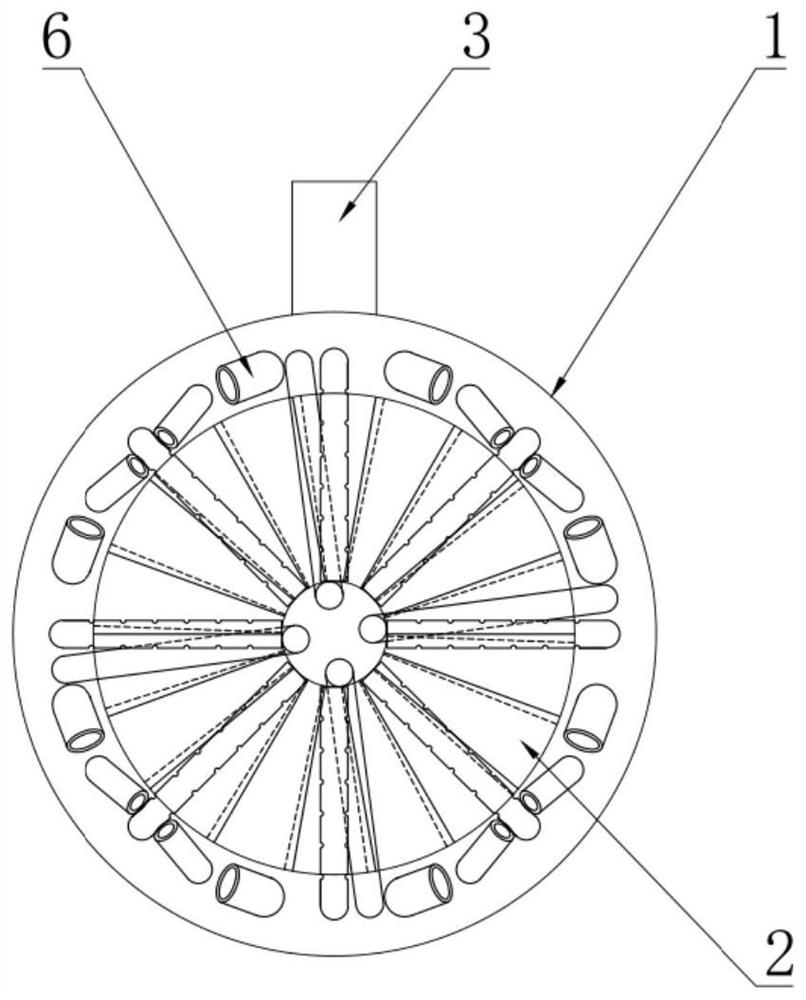

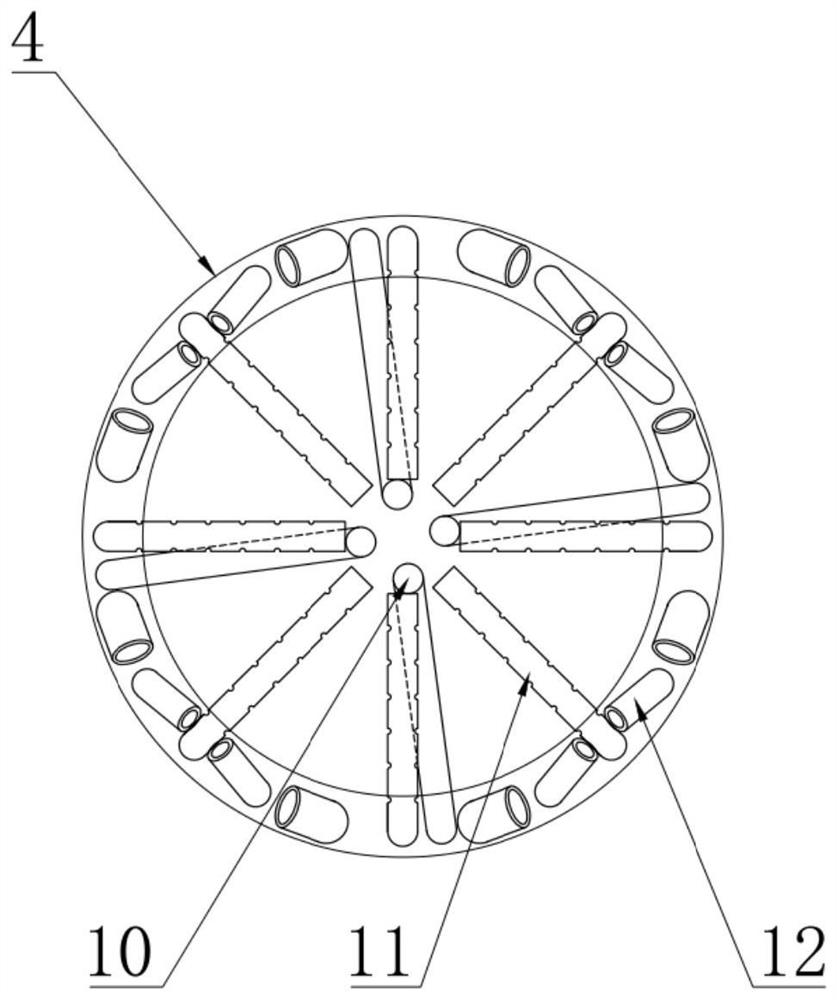

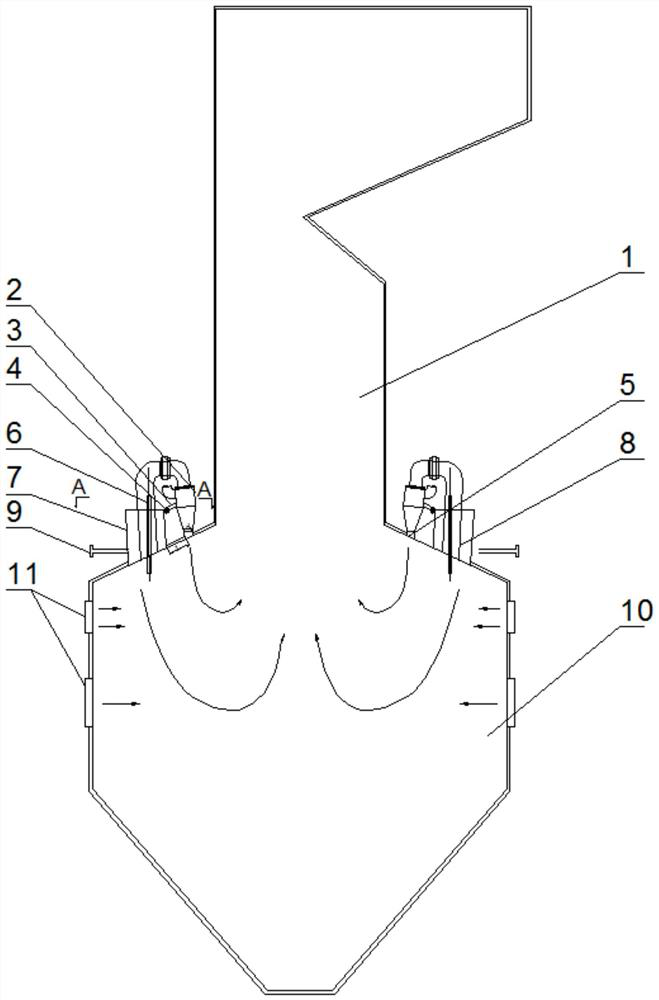

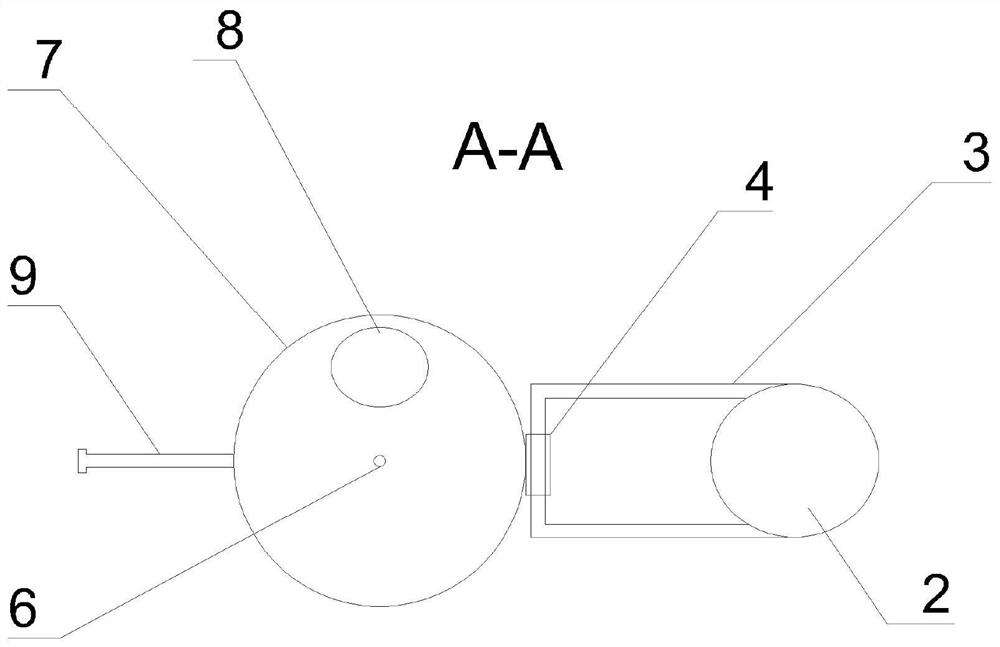

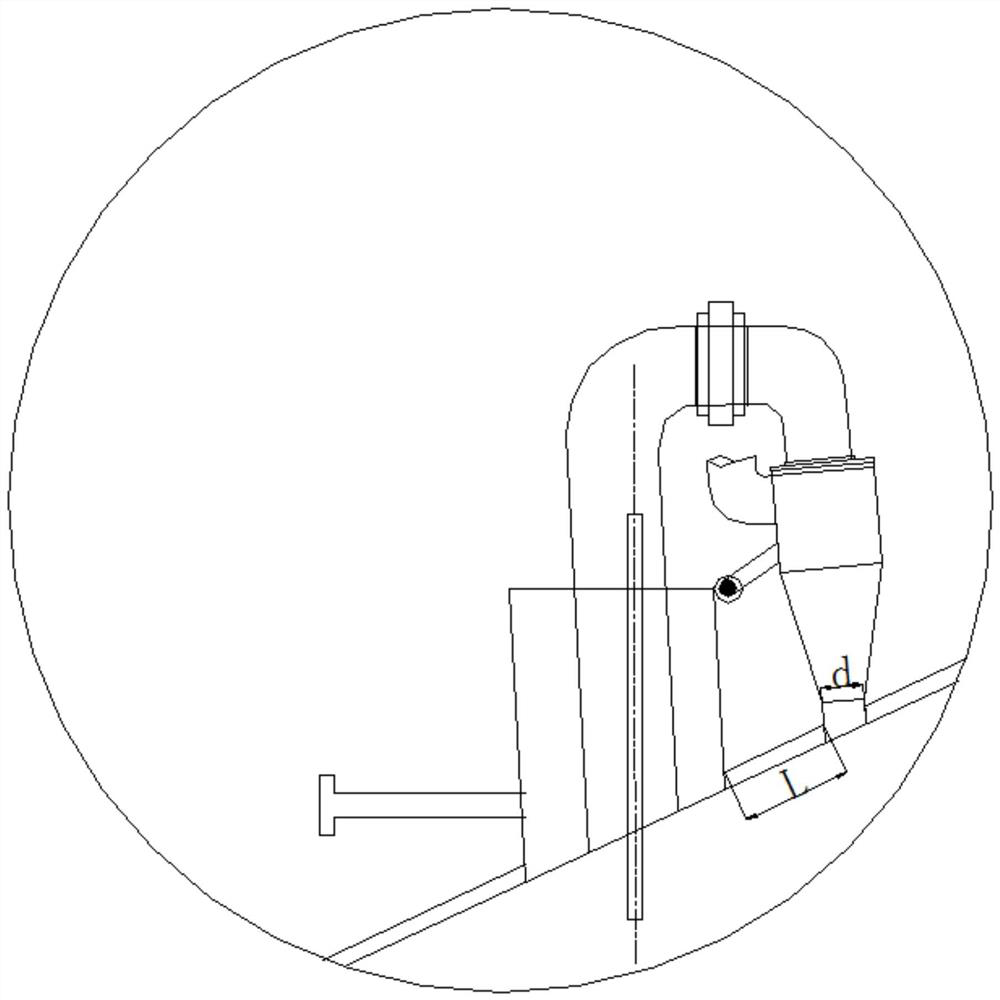

Combustion device with thin and thick breeze airflow stagger arrangement used for W-shaped flame furnace

InactiveCN101476719AEmission reductionReduce combustible contentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelHearthEngineering

The invention provides a combustion device used for staggeredly arranging rich / lean pulverized coal airflow on a W-shaped flame furnace, and relates to the combustion device. The combustion device solves the problems of unstable combustion and non timely ignition of the prior W-shaped flame furnace. A lean pulverized coal airflow nozzle (3) is inserted into an oil secondary air spout (4) and communicated with a furnace hearth, and the oil secondary air spout (4) is arranged on a furnace arch (2) close to a front wall or a rear wall (1). Rich pulverized coal airflow nozzles (6) are arranged on the furnace arch (2) close to the center of the furnace hearth and communicated with the furnace hearth, and a gap between the rich pulverized coal airflow nozzles (6) and the side wall of the furnace arch (2) is a perimeter air port (5); and the lean pulverized coal airflow nozzle (3) is arranged between the two rich pulverized coal airflow nozzles (6). The invention provides the rich / lean pulverized coal combustion device with high-efficiency and stable combustion and low NOx. The device can make the lean pulverized coal airflow receive radiant heat from a high temperature area in the middle of the furnace hearth well, ignite in time, reduce the fly ash combustible content, and realize low NOx combustion.

Owner:HARBIN INST OF TECH

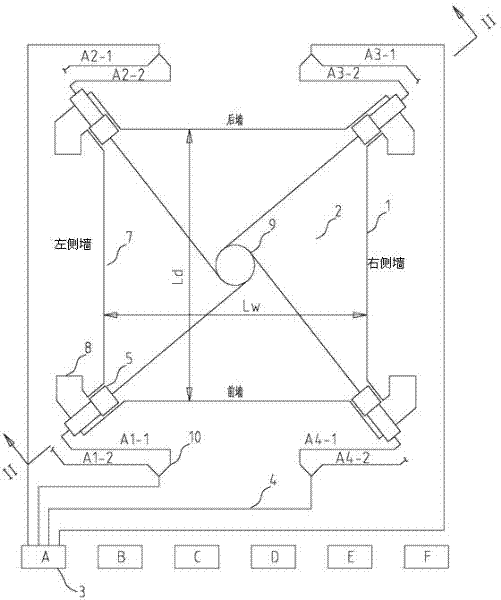

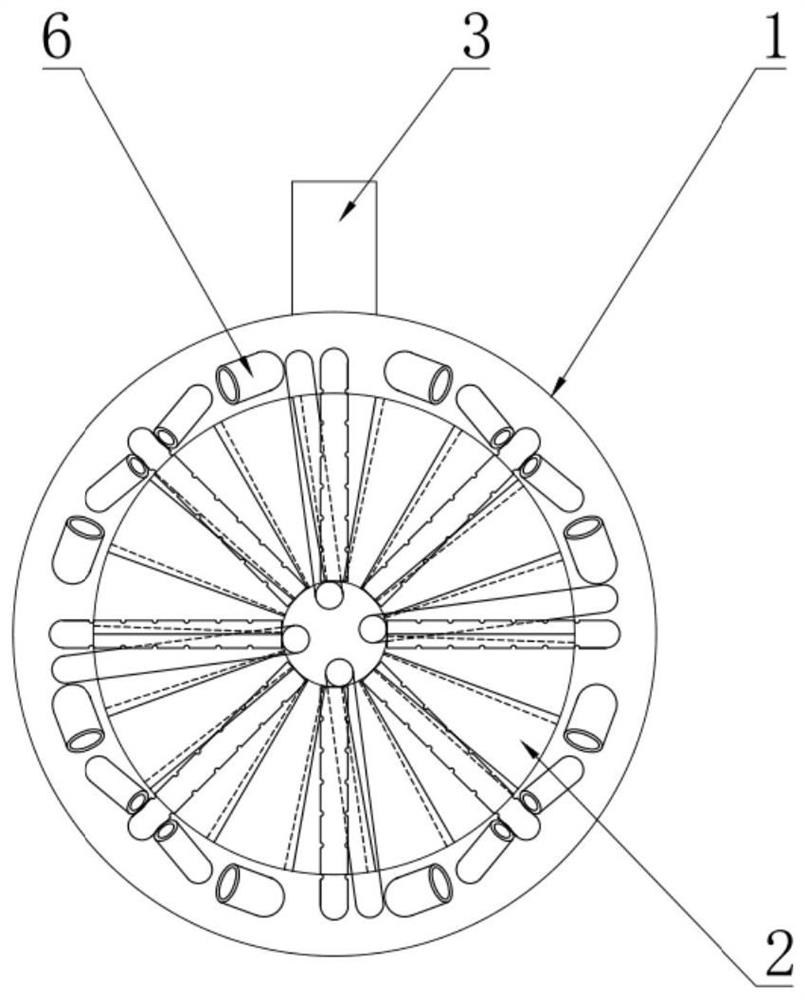

Coal dust thickness-thinness separating and distributing structure of single-fireball eight-corner direct-flow burner

ActiveCN102563634AIncrease concentrationIncrease heat loadPulverulent fuel combustion burnersWater-tube boilersDistributed structureBurns temperature

The invention discloses a coal dust thickness-thinness separating and distributing structure of a single-fireball eight-corner direct-flow burner. Eight groups of burners are arranged on a boiler body, two groups of the burners are arranged on each water cooled wall, each group of the burners comprises a plurality of the burners with nozzles facing to the same direction, and a center line of each nozzle of the eight groups of the burners forms an imaginary inscribed circle along the same tangential direction in a boiler chamber. In the coal dust thickness-thinness separating and distributing structure, the eight groups of the burners are distributed on four water cooled wall of a boiler, therefore, the coal dust concentration of a thick coal dust area is increased, the heat load qHr of the wall face of the area of the lower burners is higher, and the burning temperature in the area can achieve the requirement of stable-combustion of firing of anthracite. The distance of jet flow from outlets of the nozzles to a downstream adjacent-angle airflow is short, a lower primary air coal dust airflow speed can be adopted, the intensity of a heat flow of the outlets of the nozzles is high, and passing convection and radiation heat transfer amount are improved to ensure timely firing of the airflow of anthracite coal dust and steady burning of the boiler in low load without oil.

Owner:SHANGHAI BOILER WORKS

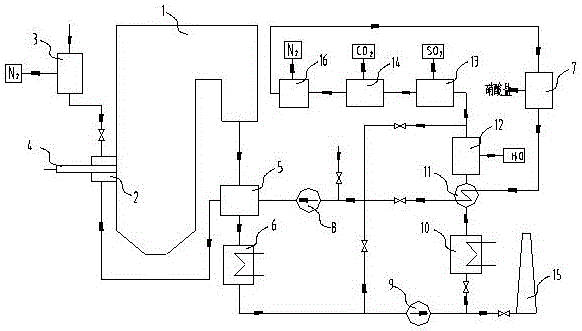

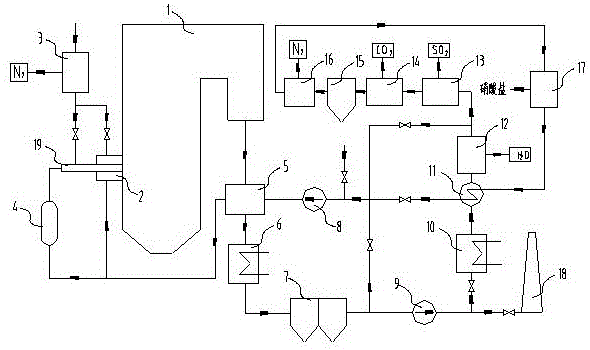

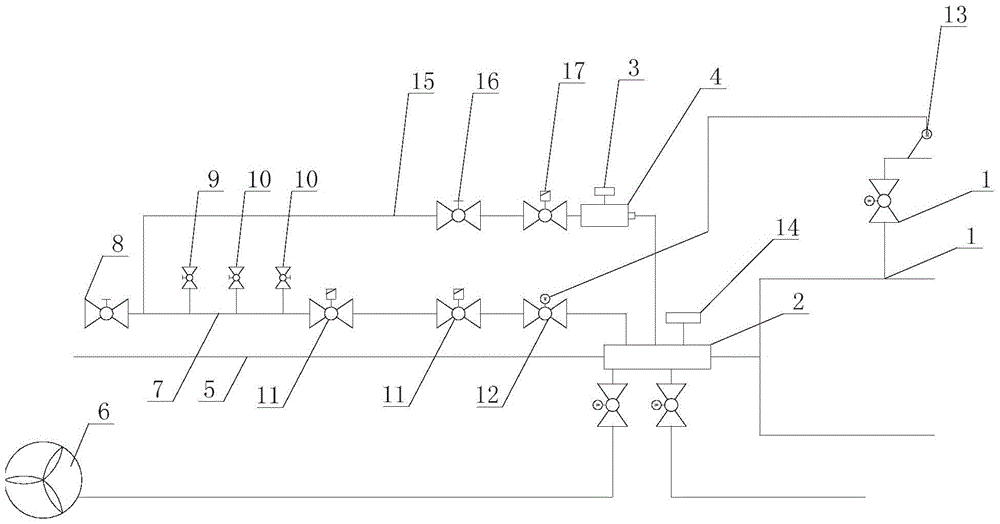

Fuel and gas-fired boiler oxygen-enriched combustion smoke nearly-zero-emission power generation system

InactiveCN105042575ASave waterGood commercial valueDirect carbon-dioxide mitigationIndirect carbon-dioxide mitigationBurning outZero emission

The invention provides a fuel and gas-fired boiler oxygen-enriched combustion smoke nearly-zero-emission power generation system. The fuel and gas-fired boiler oxygen-enriched combustion smoke nearly-zero-emission power generation system is composed of a boiler, an air bellow, an air separation device, a burner, a multi-stage heat exchanger, a recirculating fan, an induced draft fan, a dehydration device, an SO2 separation device, a CO2 capturing device, a N2 separator, a NOx reaction device and the like. The concentration of oxygen of secondary air is changed so as to ensure that fuel and gas catch fire in time, burn stably and burn out, the boiler efficiency is improved, and adaptability of the boiler to loads is enhanced. By recycling water steam, SO2, NOx, CO2 and the like brought by burning smoke of fuel and gas, integrated desorption of harmful gas and trace elements in smoke is achieved; meanwhile, the temperature of exhausted smoke is reduced to approach the atmosphere temperature, nearly-zero emission of burning smoke is achieved, the environment is protected, and maximum utilization of resources is also achieved.

Owner:SICHUAN CHUANGUO BOILER

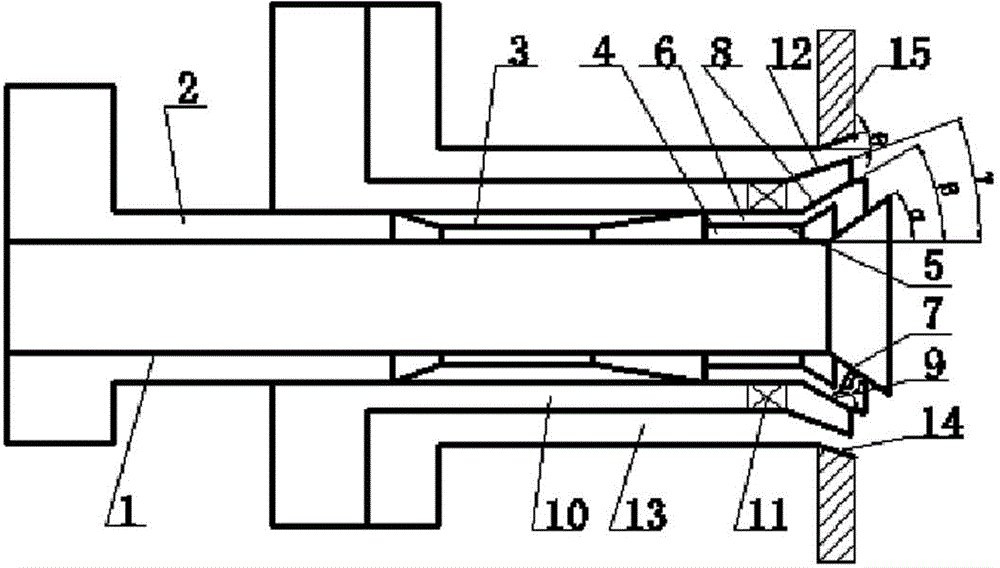

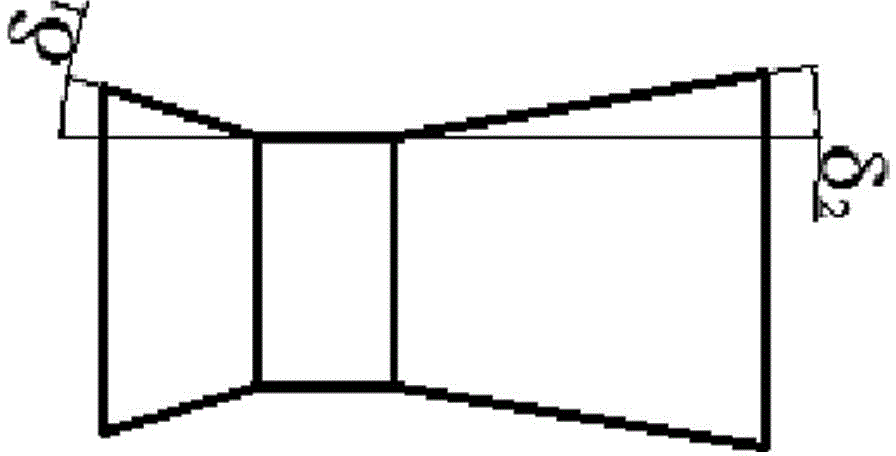

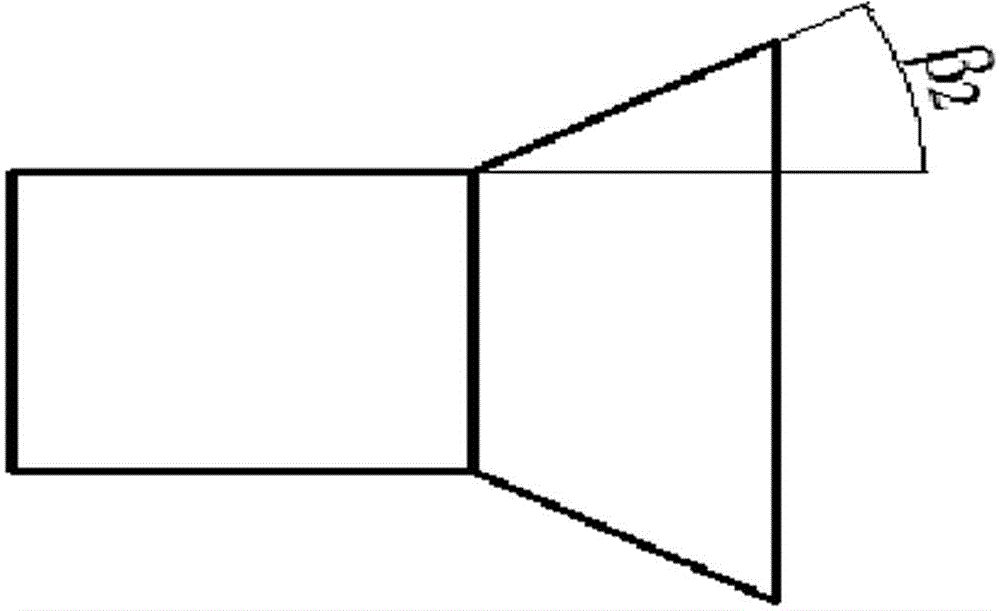

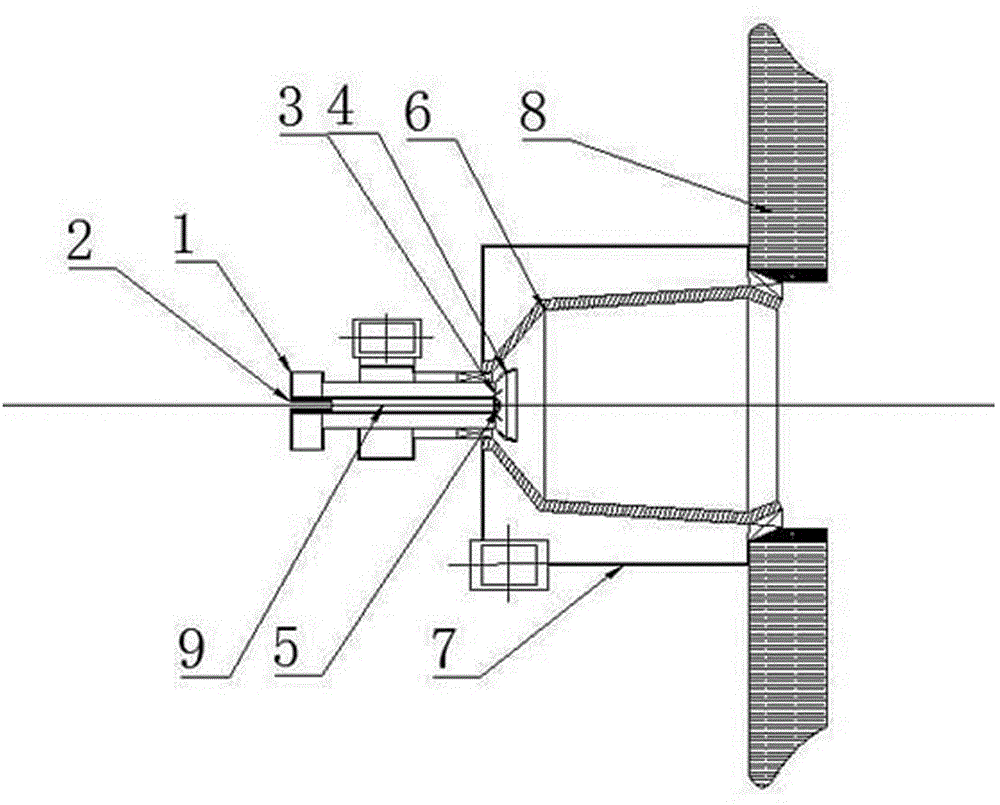

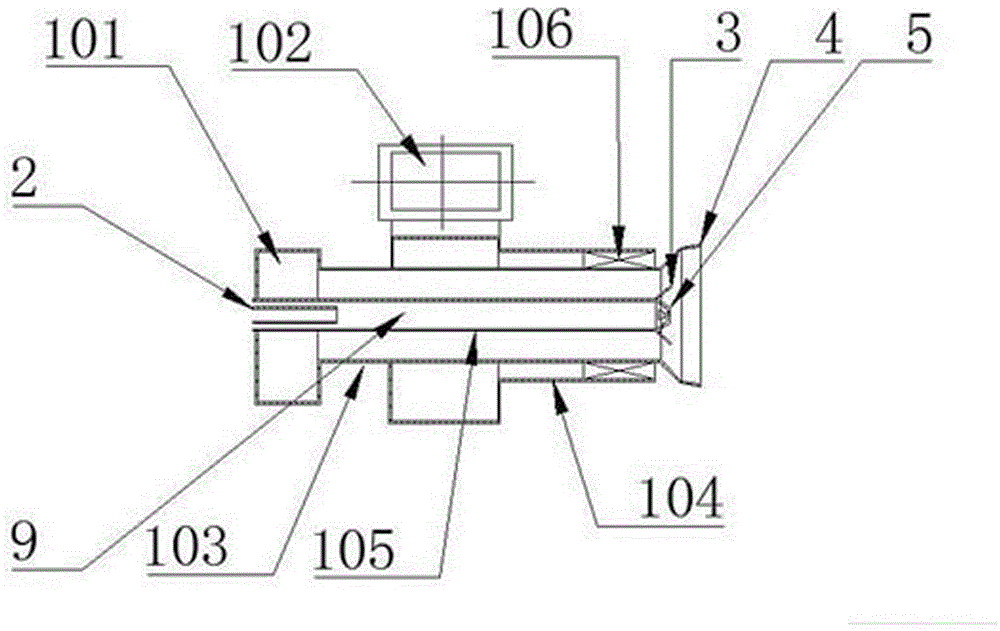

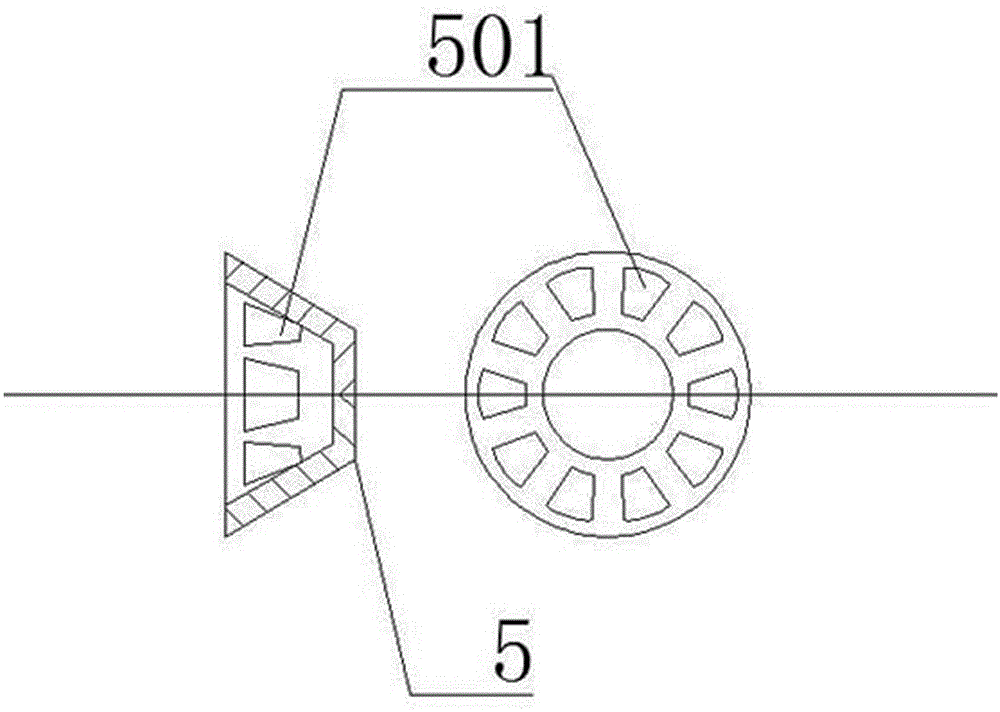

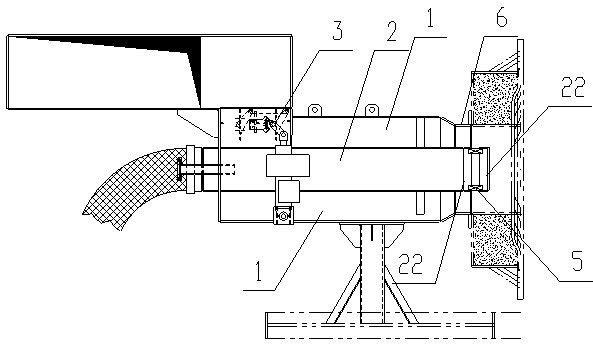

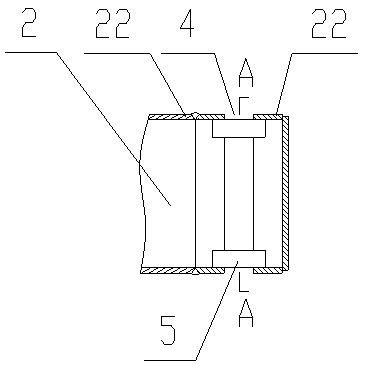

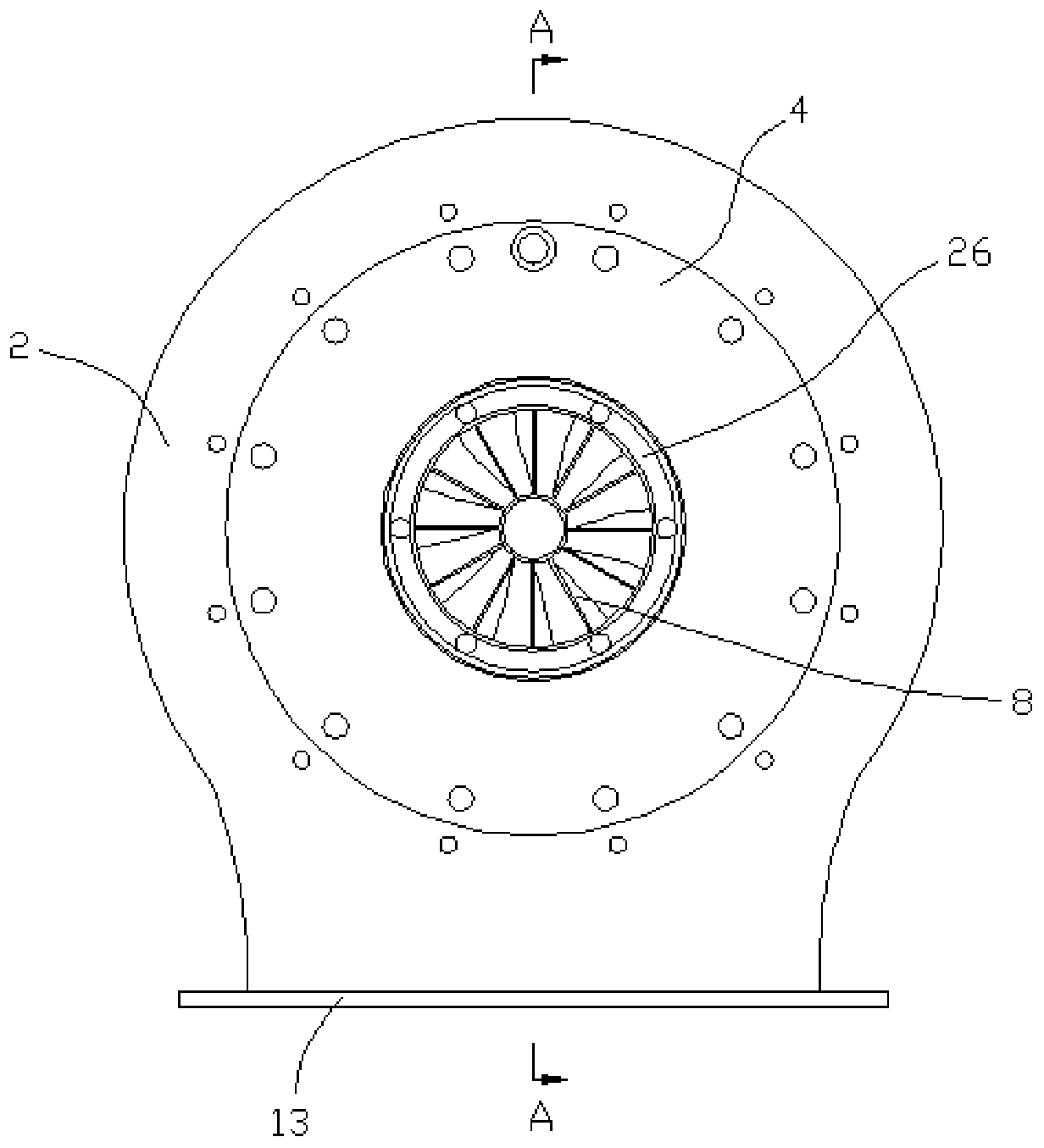

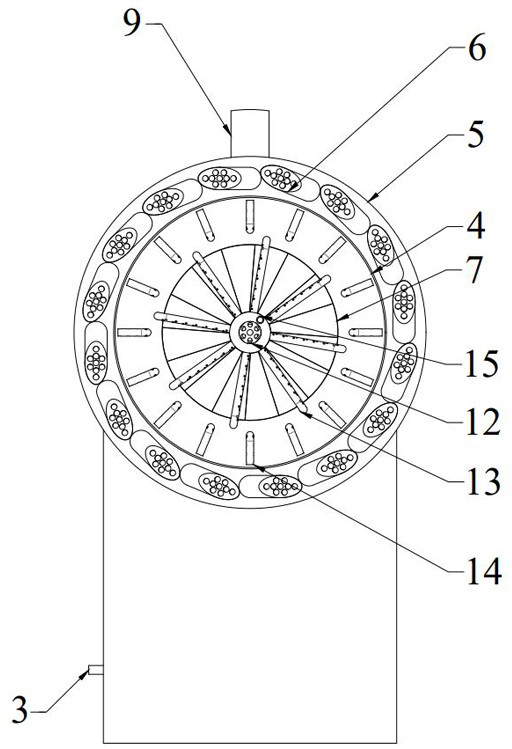

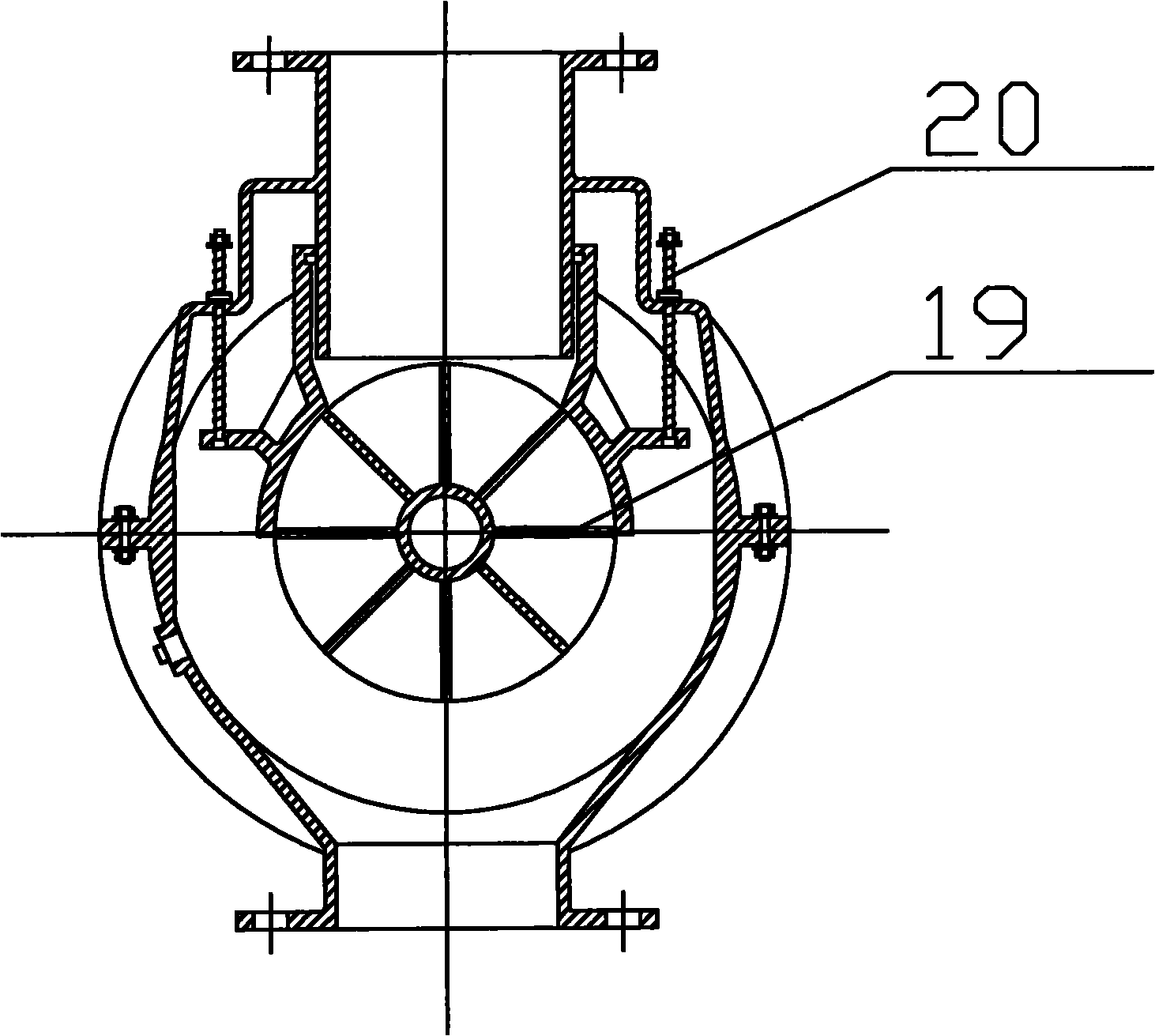

Novel cyclone bias pulverized coal burner

InactiveCN104832918AImprove stabilityEfficient combustionPulverulent fuel combustion burnersAir channelCyclone

The invention discloses a novel cyclone bias pulverized coal burner. The novel cyclone bias pulverized coal burner is characterized by comprising a central pipe, a pulverized coal concentration device, a primary air channel, a pulverized coal bias separating cylinder, a central pipe flaring, a primary air pipe flaring, a secondary air channel, a cyclone, a tertiary air channel and a tertiary air pipe flaring from inside to outside. According to the novel cyclone bias pulverized coal burner, the ignition and the burning of anthracite are supported in a mode of supplementing high-quality bituminous coal, the effect of increasing volatile matters of pulverized coal in a disguised form is achieved in the preliminary burning stage of the pulverized coal, and the timely ignition, the stable burning and the efficient burnout of low-volatile-matter pulverized coal are guaranteed. The novel cyclone bias pulverized coal burner is simple in structure, convenient to transform, and capable of efficiently burning the low-volatile-matter coal and particularly suitable for the structural transformation of burners of medium and small-sized industrial boilers, and can be widely applied to burning of low-volatile-matter anthracite duff for the industrial boilers.

Owner:JIMEI UNIV

Coal-powder boiler oxygen-enriched combustion smoke near-zero emission and power generation system

InactiveCN105066113AAchieve integrated removalLow running costIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyBurn outPower generation system

The invention provides a coal-powder boiler oxygen-enriched combustion smoke near-zero emission and power generation system. The system is composed of a boiler, a burner, an air separation device, a powder production system, a multi-stage heat exchanger, a multi-stage deduster, a recirculation draught fan, an induced fan, a dewatering device, an SO2 separation device, a CO2 capture device, an N2 separator, an NOx reaction device and the like. It is ensured that coal powder of different coal types is ignited in time, burns stably and burns out by changing the oxygen concentration of primary air and secondary air and the total oxygen amount, the efficiency of the boiler is improved, and the adaptability of the boiler to loads and coal types is enhanced. Dust, vapor, SO2, NOx, CO2 and the like caused by combustion smoke of coal powder are recycled through all the devices, so that harmful gas, fine particles and microelements in smoke are integrally removed. Meanwhile, the smoke exhaust temperature is reduced to be close to the atmospheric temperature, so that near-zero emission of smoke is achieved, environment protection is achieved, and resource utilization is maximized.

Owner:SICHUAN CHUANGUO BOILER

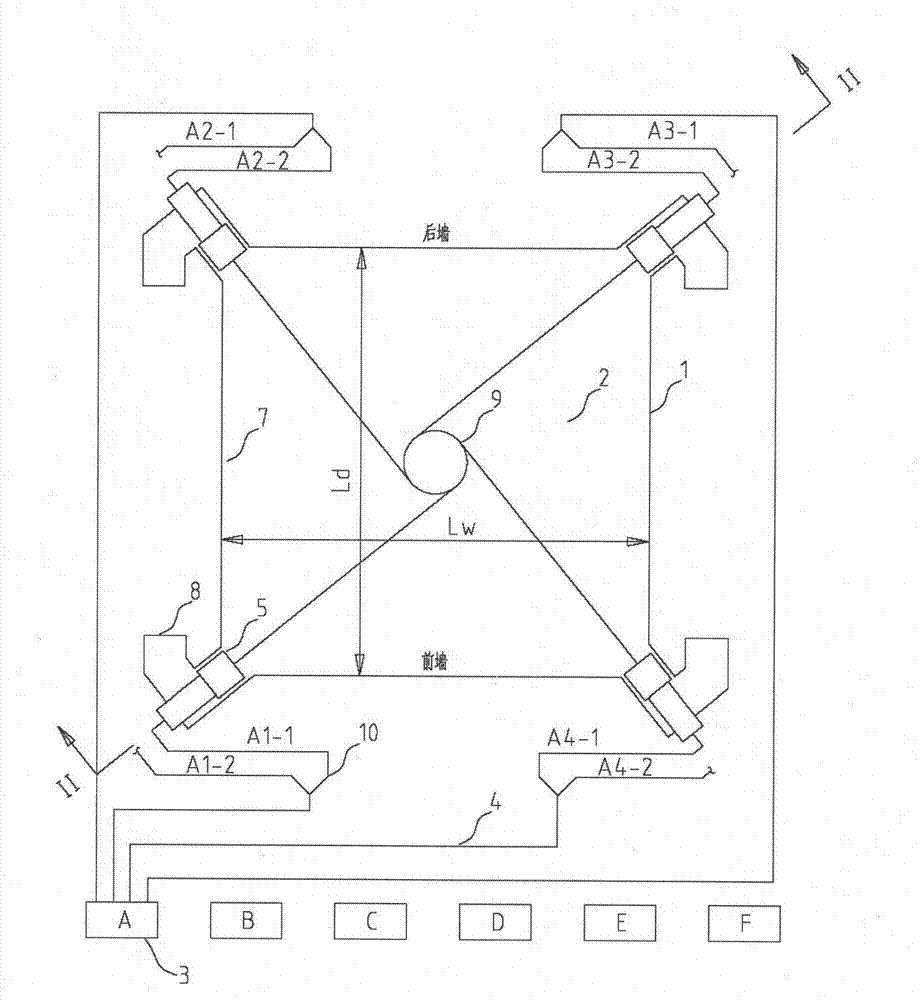

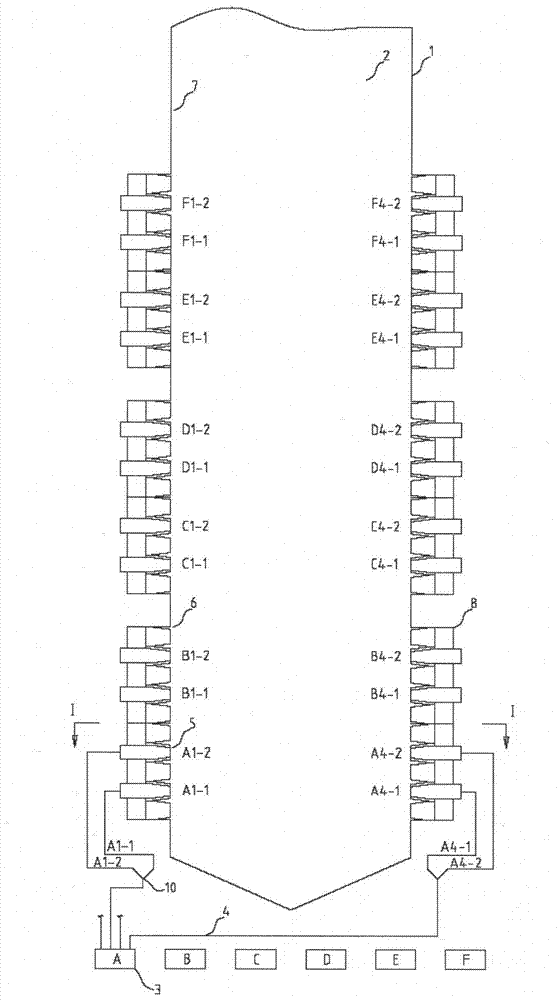

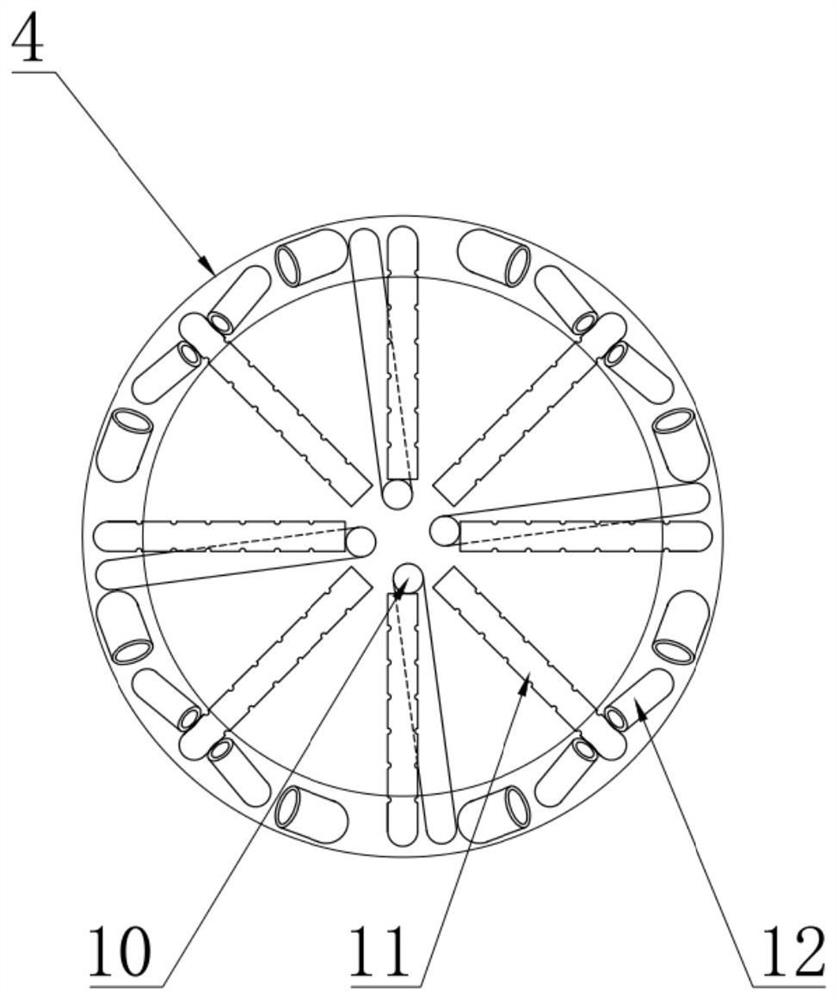

Pulverized coal shade separate arrangement mode of direct-current burner with double fireballs

ActiveCN103090368AIncrease concentrationGuaranteed not to oilCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorLow load

The invention provides a pulverized coal shade separate arrangement mode of a direct-current burner with double fireballs for burning anthracite coal. The pulverized coal shade separate arrangement mode is characterized in that each boiler is provided with eight groups of burners; the eight groups of burners are at the same level; four groups of burners form an imaginary circle inside a hearth; the other four groups of burners form another imaginary circle inside the hearth; each group of burners are divided into two small groups in the vertical direction; the first small group of burners are named as 'primary air / thick pulverized coal' burners; and the second small group of burners are named as 'primary air / thin pulverized coal' burners. The thermal load qHr of the wall surface of a burner zone is high under the premise of ensuring the power of the entire boiler; and timely inflaming of anthracite pulverized coal air flow and low-load stable combustion of the boiler without oil can be ensured.

Owner:SHANGHAI BOILER WORKS

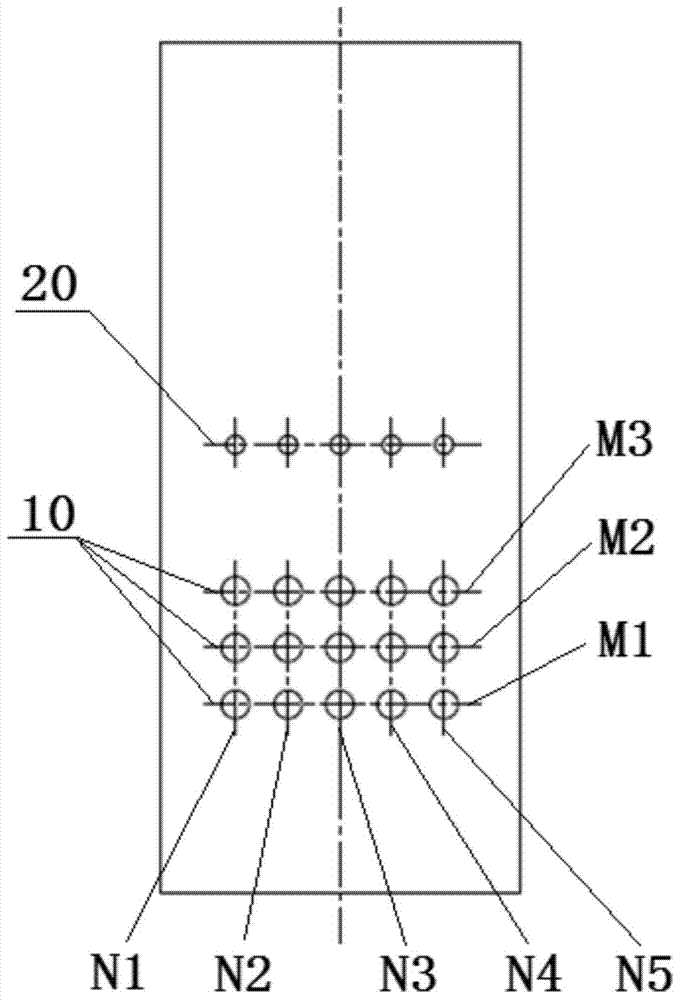

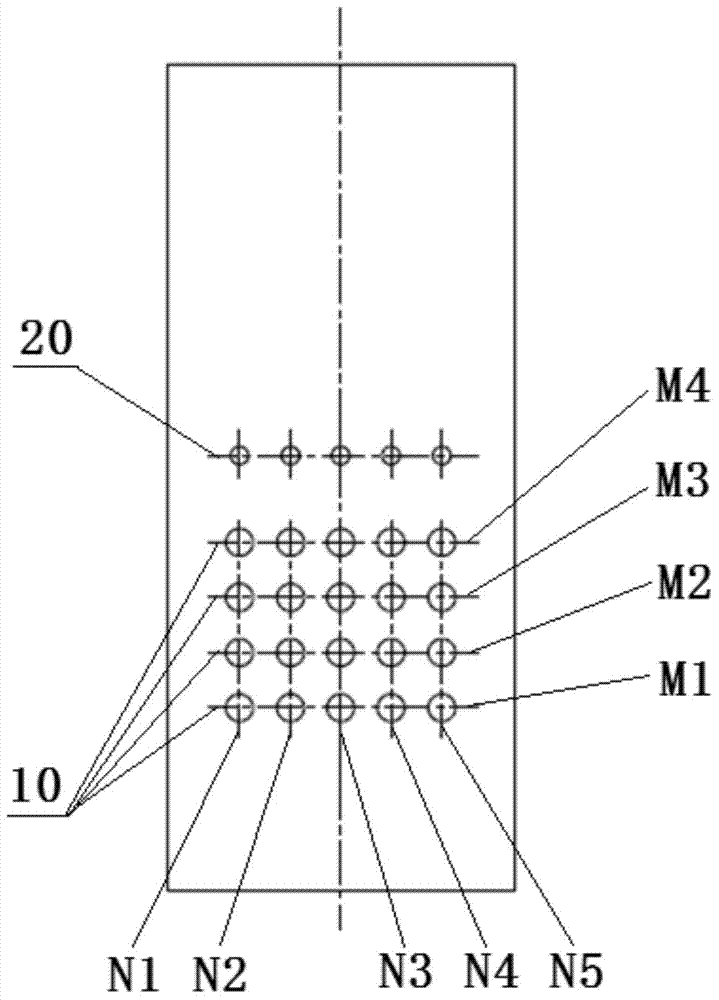

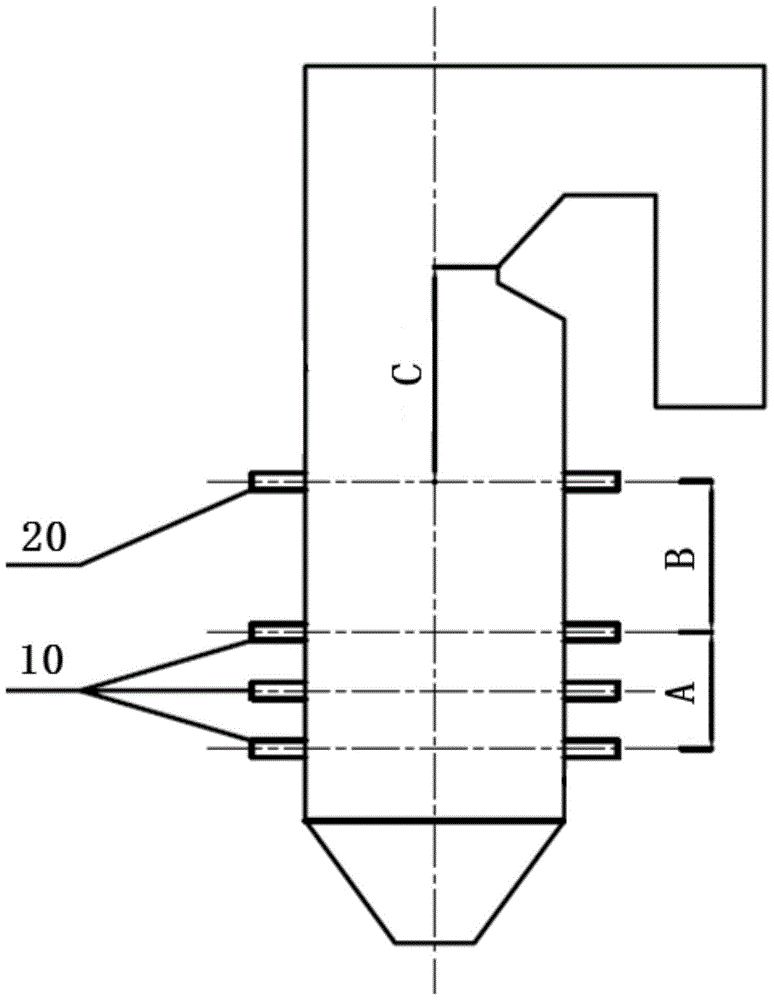

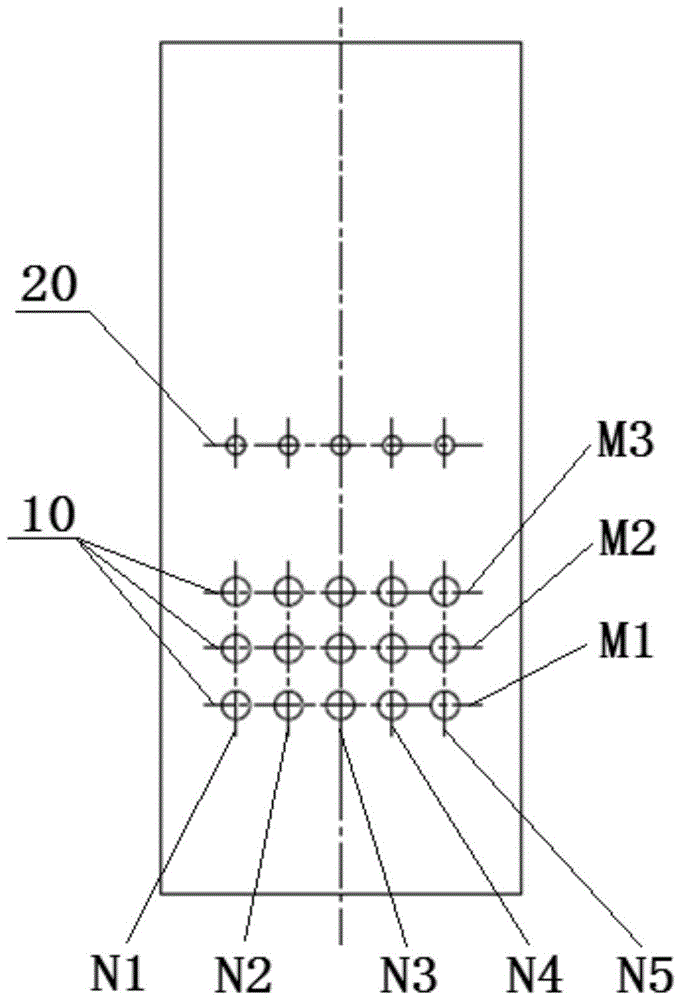

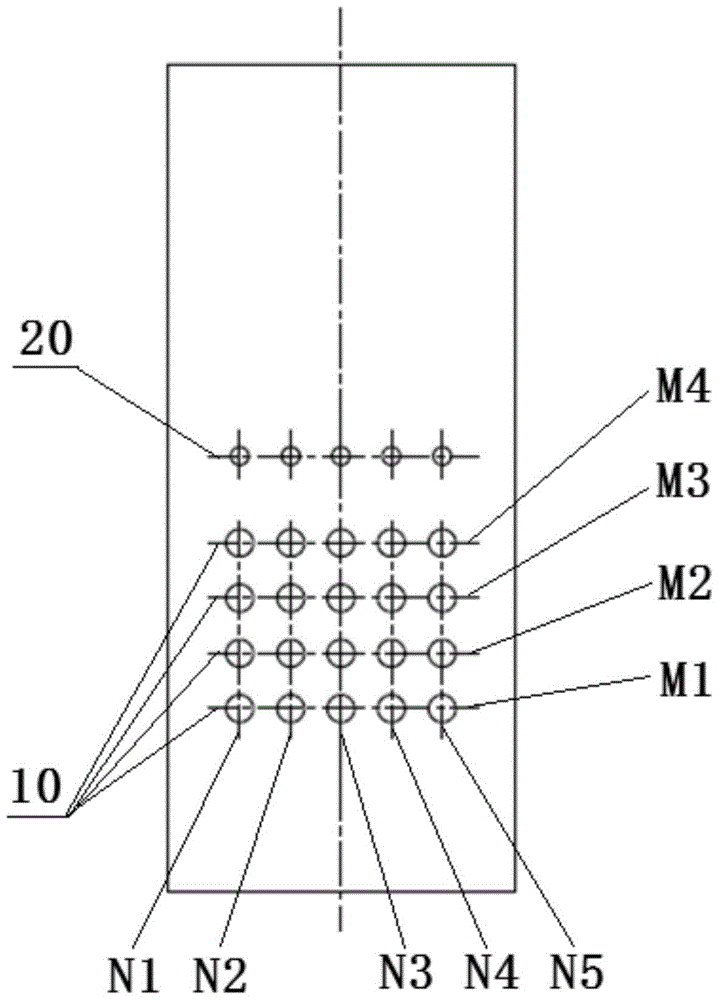

Firing method of wall type opposed firing boiler

The invention discloses a firing method of a wall type opposed firing boiler. A plurality of burners and over-fire air spraying openings located above the multiple burners are arranged on a front wall and a back wall of the wall type opposed firing boiler respectively or are arranged on the front wall of the wall type opposed firing boiler only, and the multiple burners are arranged in a matrix mode, are arranged to be in M lines from bottom to top and are arranged to be in N columns from left to right, wherein the M is an integer larger than or equal to 2, and the N is an integer larger than or equal to 1. The firing method includes the steps of controlling the average excess air coefficient of a main firing area where the multiple burners are located to be smaller than 1, controlling the average excess air coefficient of a firing area between the over-fire air spraying openings and a hearth outlet of the boiler to be larger than 1 so as to achieve in-boiler air grading firing, and controlling the average excess air coefficient of the burners in the first line to be larger than the average excess air coefficient of the burners in the second line to the Mth line. By means of the firing method, the aim of in-time firing can be achieved.

Owner:YANTAI LONGYUAN POWER TECH

Low-load stable-combustion direct-current combustor

PendingCN106838895ATo achieve the purpose of premixingPrevent deflagrationPulverulent fuel combustion burnersCombustorSlag

A low-load stable-combustion direct-current combustor comprises a natural gas pipeline. The natural gas pipeline extends to a central air duct to supply natural gas, a cyclone arranged at the outlet of the central air duct conveys mixed gas to a precombustion chamber for combustion, a primary air pipe providing primary pulverized coal to the precombustion chamber is arranged outside the central air duct, an internal secondary blowdryer providing internal secondary air to the precombustion chamber is arranged outside the primary air pipe, an external secondary blowdryer providing external secondary air to the precombustion chamber is arranged outside the internal secondary blowdryer, the precombustion chamber is divided into an expansion section and a horizontal section along the inlet direction of the mixed gas, an internal-secondary-air annular nozzle is arranged in the intersection of the expansion section and the horizontal section, the internal secondary air is in annular direct-current incidence from the internal-secondary-air annular nozzle, combustion supporting function is achieved, slag build-up and pulverized-coal accumulation can be avoided; the external secondary air is injected in a direct-current oblique manner to supplement air needed for subsequent combustion of pulverized coal flow, and meanwhile, formation of NOx is reduced. By the arrangement, low-load stable combustion of a pulverized-coal combustor can be realized, and deep participation in peak regulating of a coal-fired power plant is favorably improved.

Owner:HUANENG CLEAN ENERGY RES INST +1

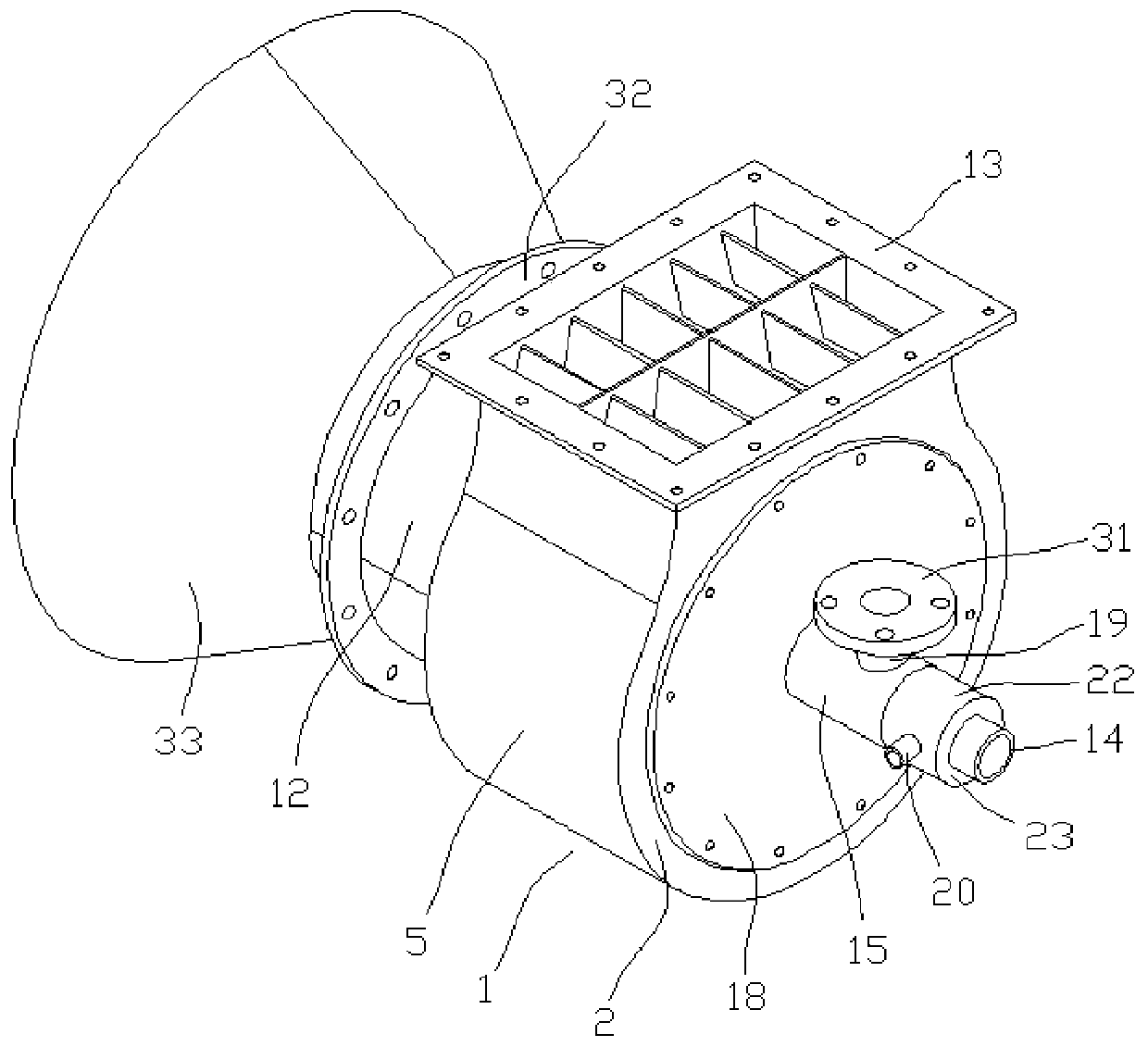

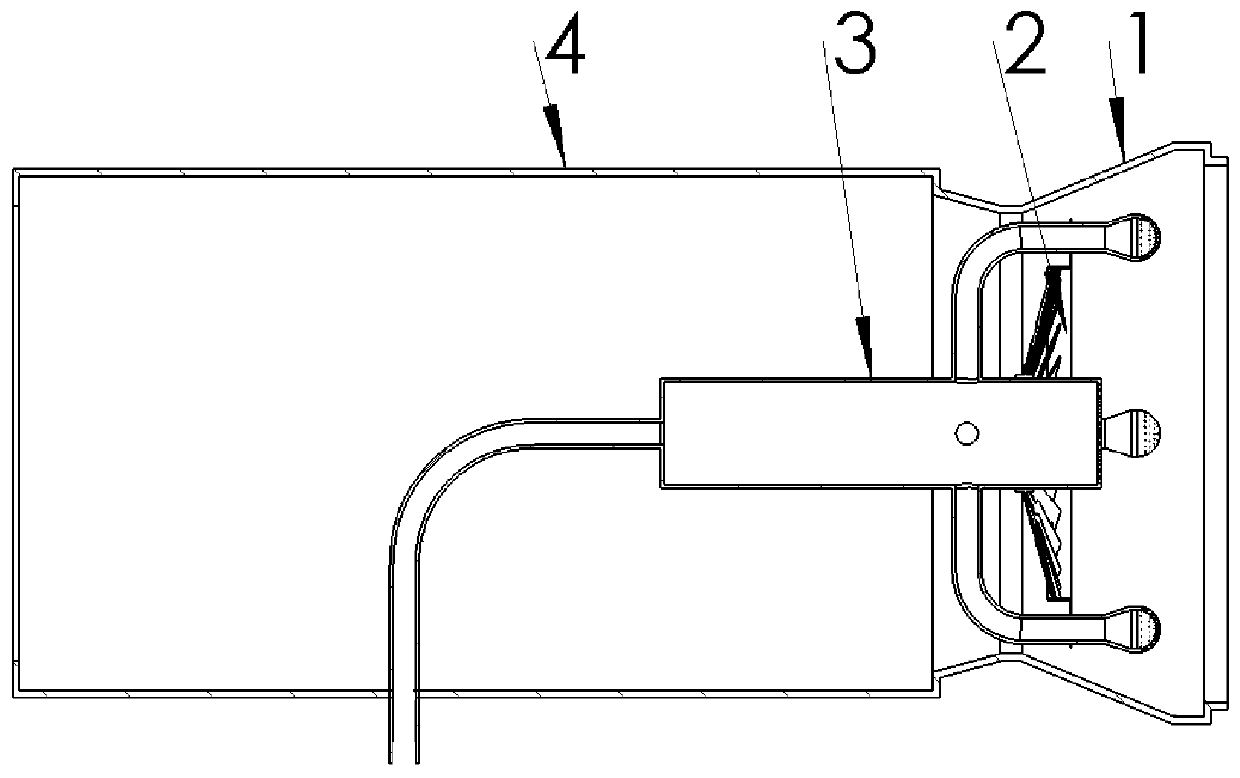

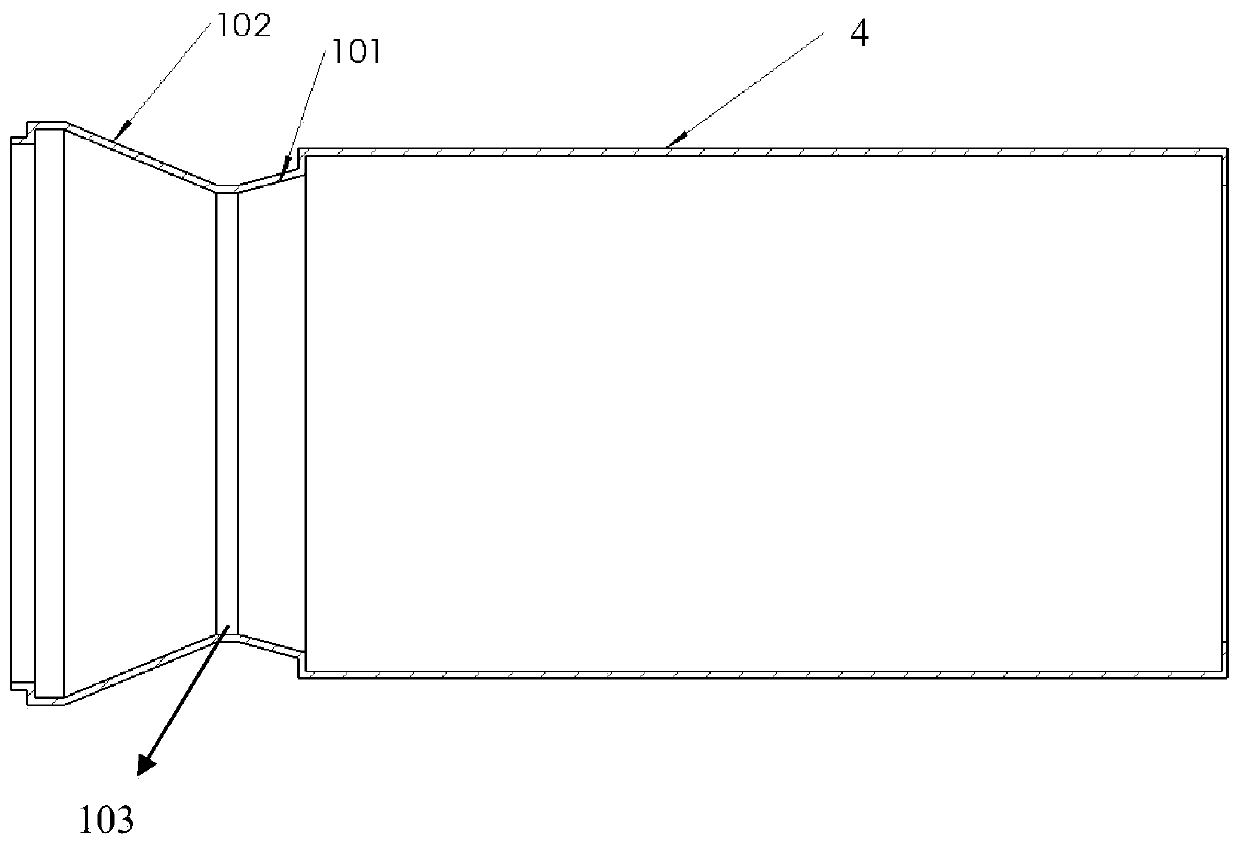

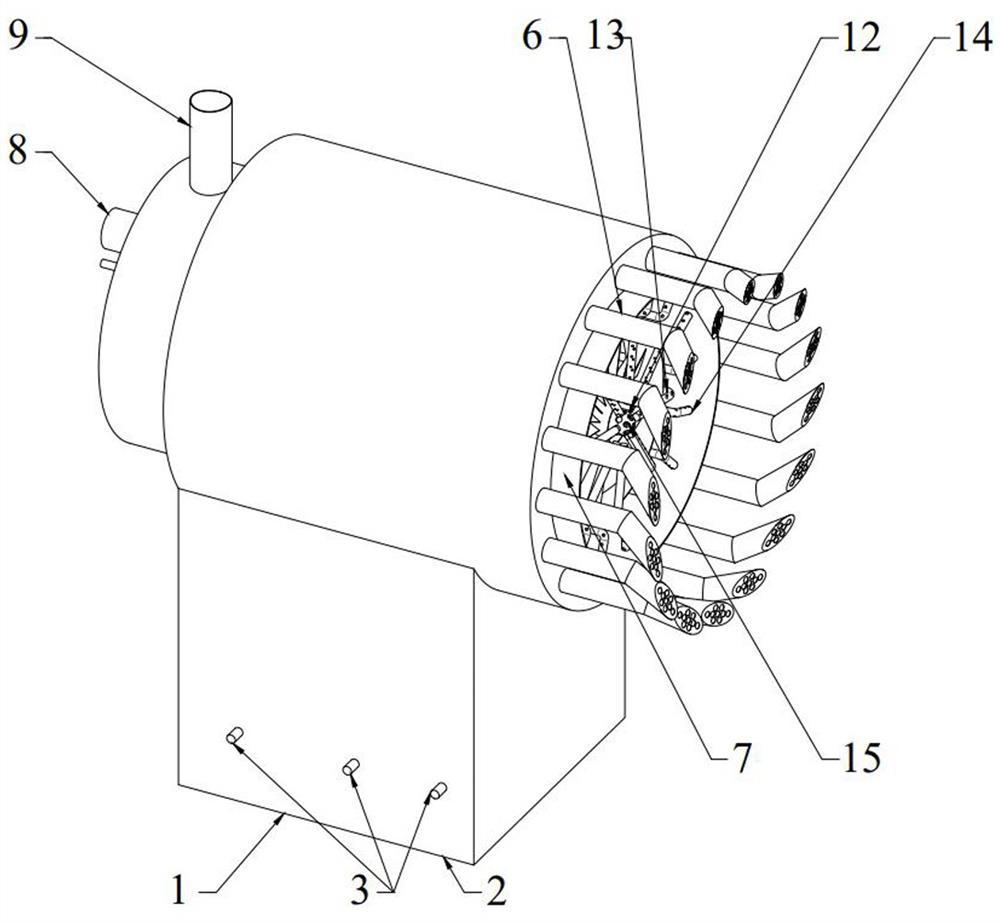

Double-volute swirl type pulverized coal burner provided with natural gas spray pipe and pre-burning chamber

ActiveCN104613466AIncrease volatile contentFire in timeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermodynamicsCombustor

The invention discloses a double-volute swirl type pulverized coal burner provided with a natural gas spray pipe and a pre-burning chamber. The burner mainly comprises a double-volute burner, the natural gas spray pipe, a natural gas-air nozzle, a central air pipe flaring, a primary air pipe flaring, the pre-burning chamber and a rear secondary air duct. Combustion of low-volatile coal is supported in a natural gas feeding manner, and the natural gas can increase coal dust volatiles through phase conversion at the preliminary stage of pulverized coal combustion through reasonable structure design; a good air dynamic field is organized through structure design and reasonable air distribution, so that the low-volatile pulverized coal can be timely ignited, stably burned and efficiently burnt out. The double-volute swirl type pulverized coal burner is simple in structure, convenient to modify, capable of efficiently burning the low-volatile pulverized coal and particularly suitable for structure transformation of a small industrial boiler burner, and can be widely applied to the low-volatile pulverized coal burnt on an industrial boiler.

Owner:JIMEI UNIV

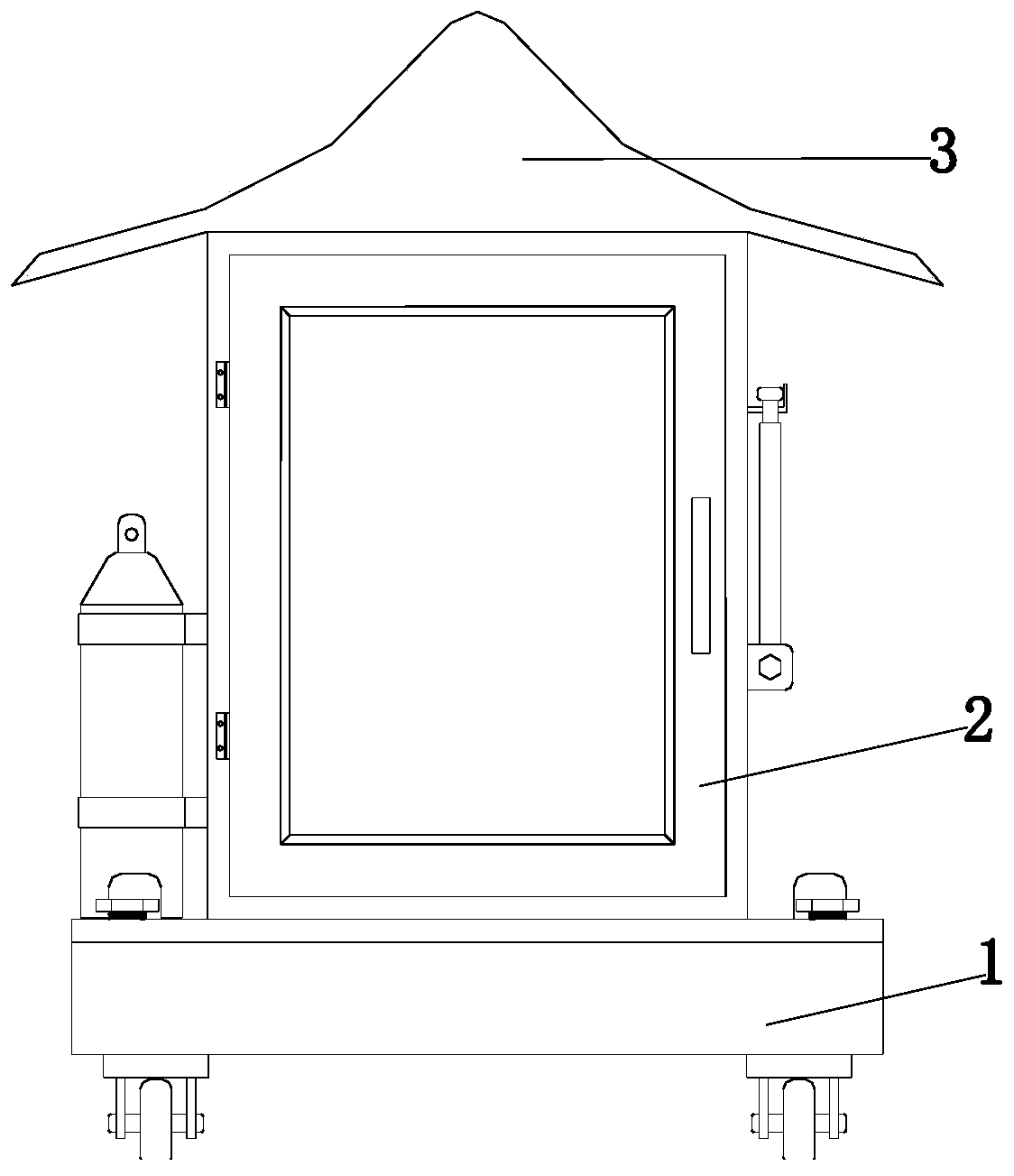

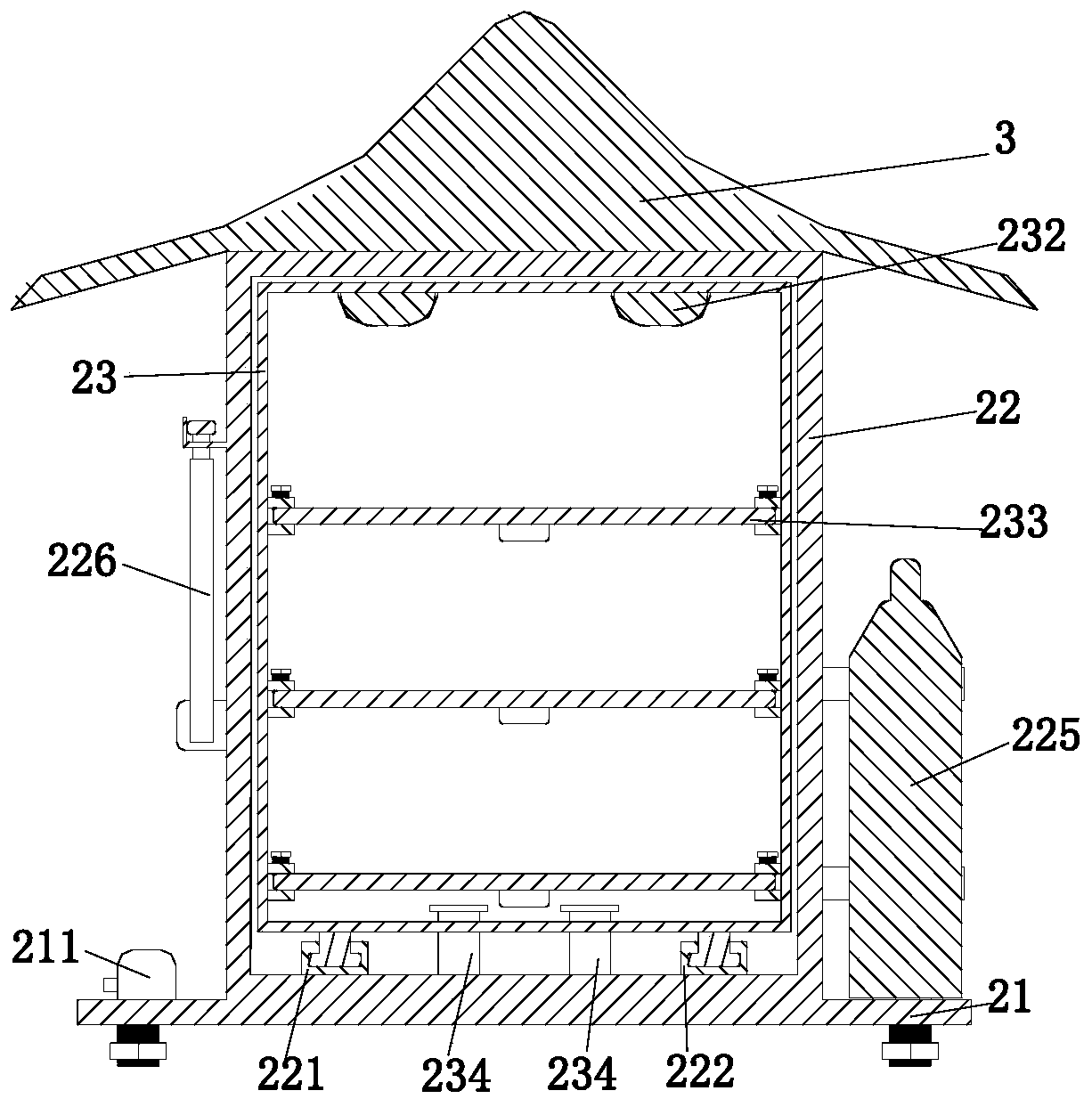

Multifunctional power distribution equipment

InactiveCN110364944ASolve the problem of not being able to movePrevent movementSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringScrew joint

The invention discloses multifunctional power distribution equipment and belongs to the technical field of power distribution equipment. The equipment comprises a movable base, a distribution box bodyand a top cover. The distribution box body is arranged on the top of the movable base. The movable base and the distribution box body are fixed in a screw joint manner. The top cover is located on the top of the distribution box body. The top cover and the distribution box body are fixed in a screw joint manner. The distribution box body comprises a bottom plate, a shell and a mounting box. The bottom plate is an insulating plate, and the bottom plate and the base are fixed in a screw joint mode. The shell is fixedly installed in the center of the upper portion of the bottom plate. The mounting box is arranged in the shell and is in sliding connection with the shell. Through the arrangement of the movable base, the power distribution equipment can be moved at any time and the problem thattraditional power distribution equipment cannot be moved is solved. Through sliding fit between the mounting box and the shell, the mounting box can be pulled out in a sliding mode at any time, so electrical elements in the mounting box can be disassembled and overhauled conveniently, and the problem that it is inconvenient to disassemble and maintain parts in a traditional power distribution boxis solved.

Owner:常德三欣电力电子科技有限公司

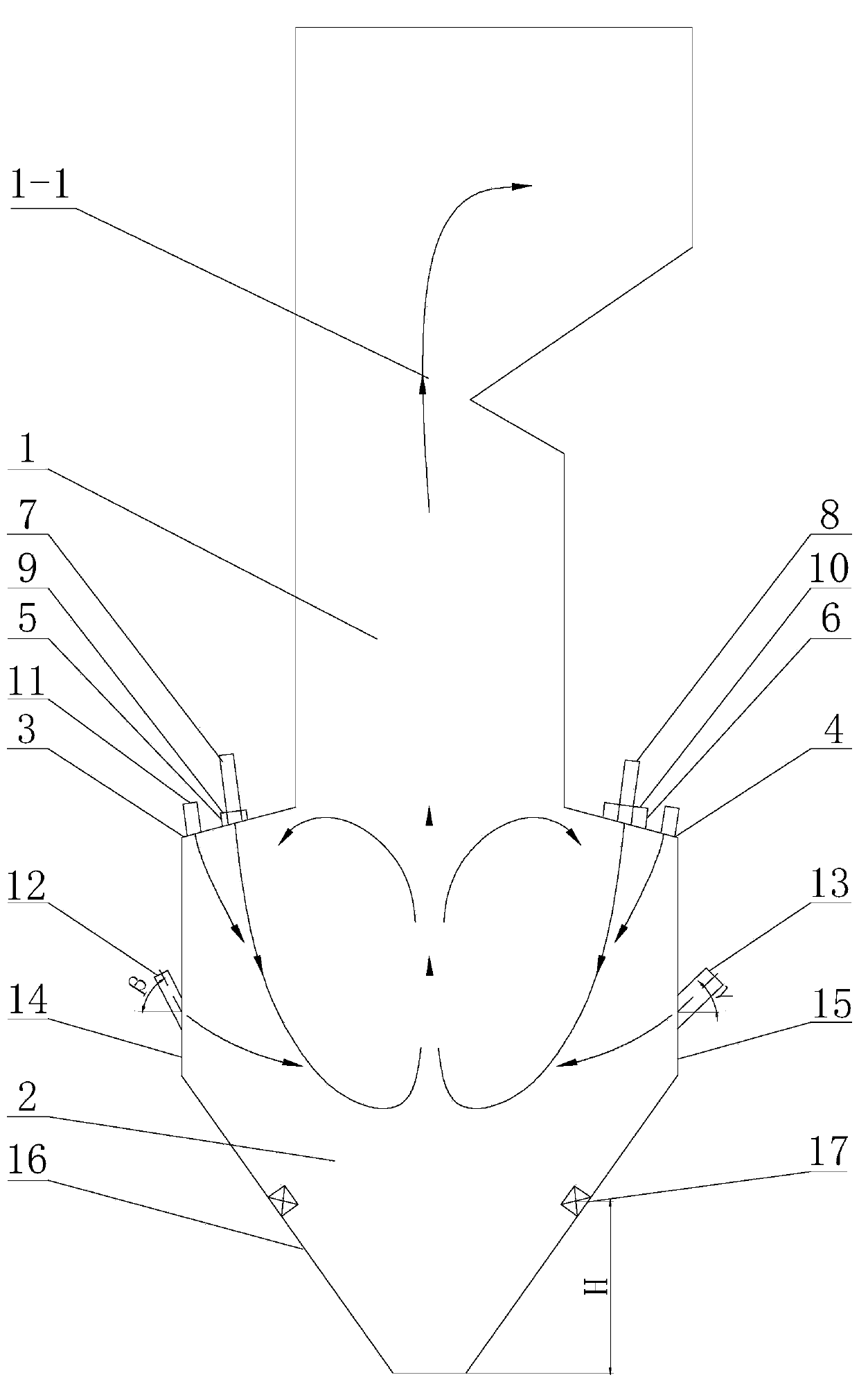

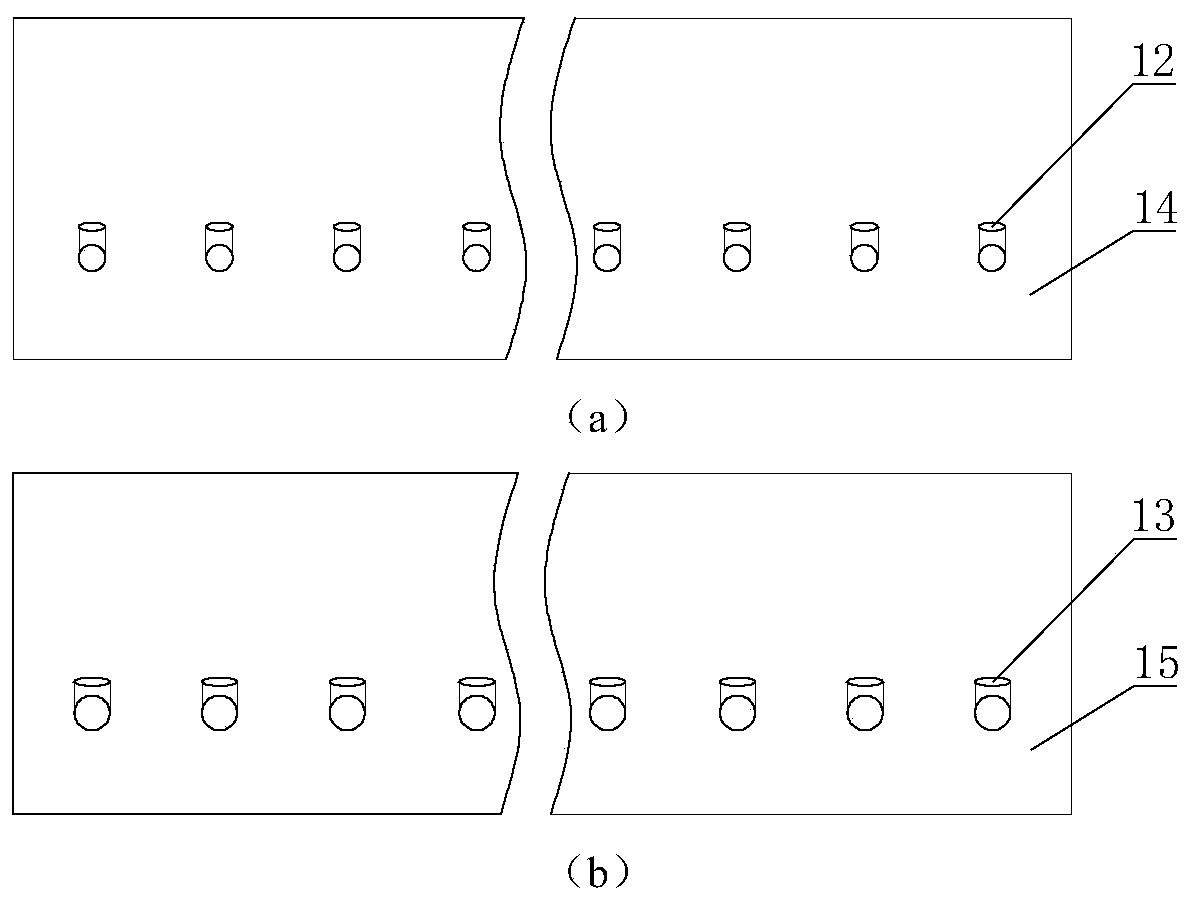

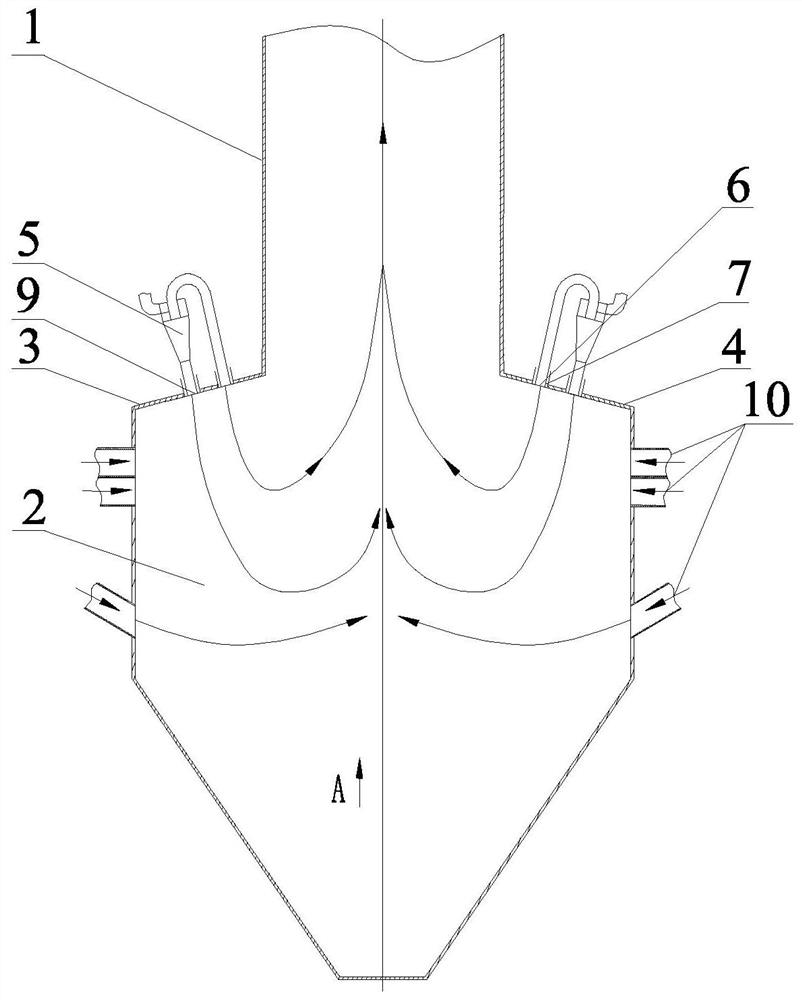

W flame boiler with asymmetric front wall and rear wall secondary wind

ActiveCN109945167AImprove combustion stabilityReduce extrusionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelNozzlePulverized coal-fired boiler

The invention discloses a W flame boiler with asymmetric front wall and rear wall secondary wind, relates to a pulverized coal boiler, and aims at solving the problem of deflected internal flow fieldin a W flame boiler. The boiler comprises an upper furnace, a lower furnace, a front arch, a rear arch, multiple first pulverized coal combustion devices, multiple second pulverized coal combustion devices, multiple front arch lower secondary air nozzles and multiple rear arch lower secondary air nozzles. Each first pulverized coal combustion device comprises a front arch primary air nozzle and afront arch upper secondary air nozzle, each second pulverized coal combustion device comprises a rear arch primary air nozzle and a rear arch upper secondary air nozzle, multiple front arch lower secondary air nozzles are installed on a front wall in the width direction of the furnace, multiple rear arch lower secondary air nozzles are installed on the rear wall in the width direction of the furnace, the areas of cross sections of the front arch upper secondary air nozzles are smaller than that of the rear arch upper secondary air nozzles, and the areas of the cross sections of the front archlower secondary air nozzles are smaller than that of the rear arch lower secondary air nozzles. The invention belongs to the technical field of boiler combustion.

Owner:HARBIN INST OF TECH

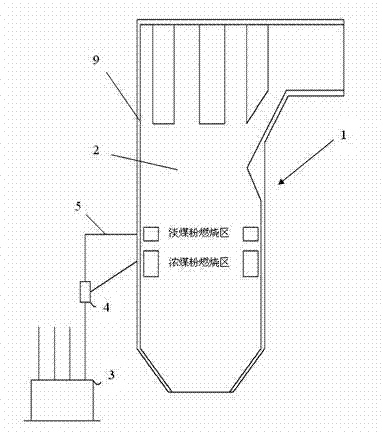

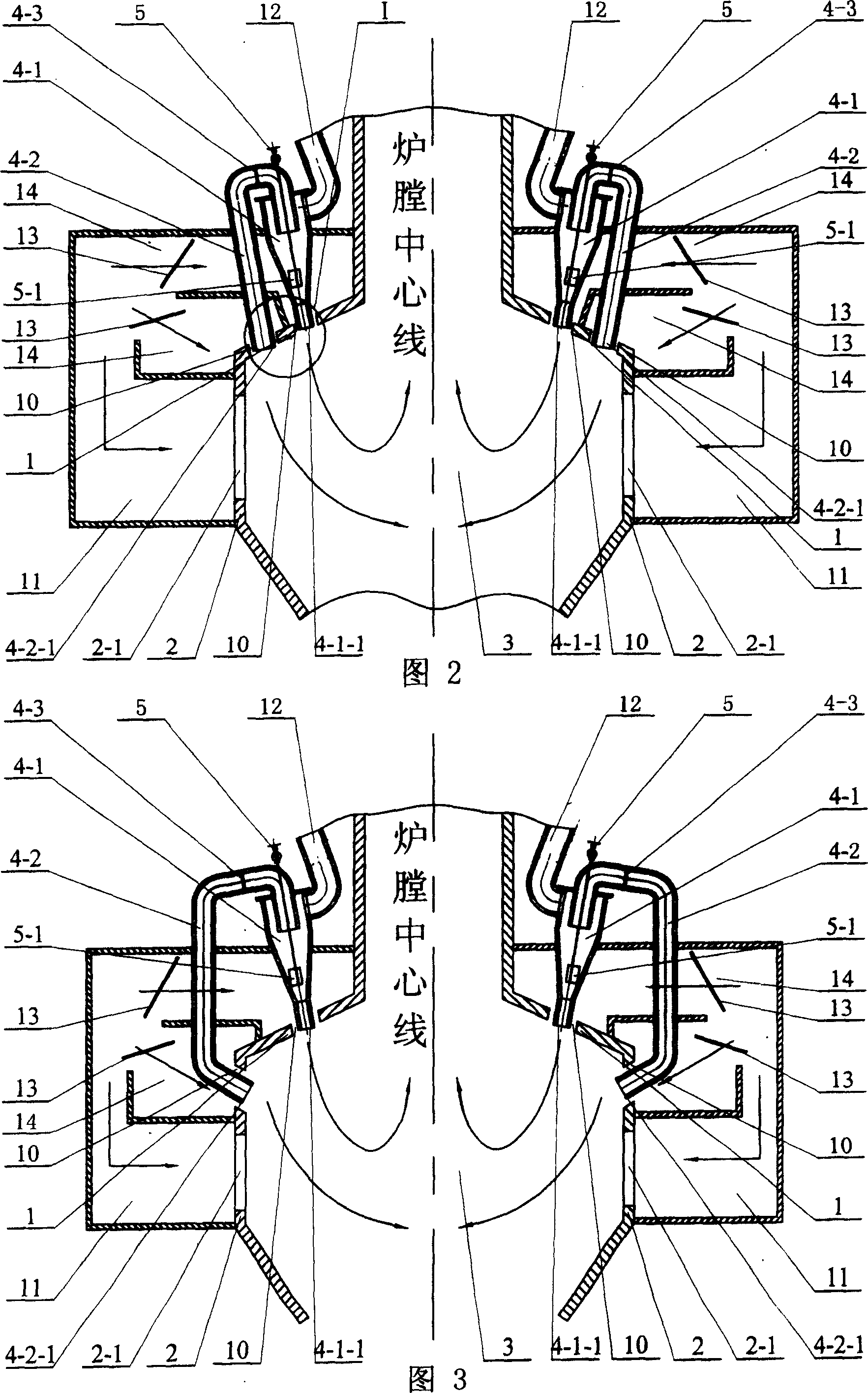

W-shape flame furnace with gradation coal burner

ActiveCN1333199CHigh melting temperaturePrevent high temperature corrosionCombustion using gaseous and pulverulent fuelLiquid fuel feeder/distributionCombustorEngineering

The present invention is one W-shaped flame furnace with dense and dilute coal powder combustion and relates to one kind of burning plant. The improved W-shaped flame furnace includes furnace arch, side wall, hearth formed with the furnace arch and the side wall, and burner. The burner includes dense coal powder flow flame nozzle in the center of the hearth and dilute coal powder flow flame nozzle near the side wall. The present invention has greatly raised ash melting temperature to avoid slagging of the water cooled wall and prevent high temperature corrosion while reaching the aims of timely igniting and stable combustion.

Owner:HARBIN INST OF TECH

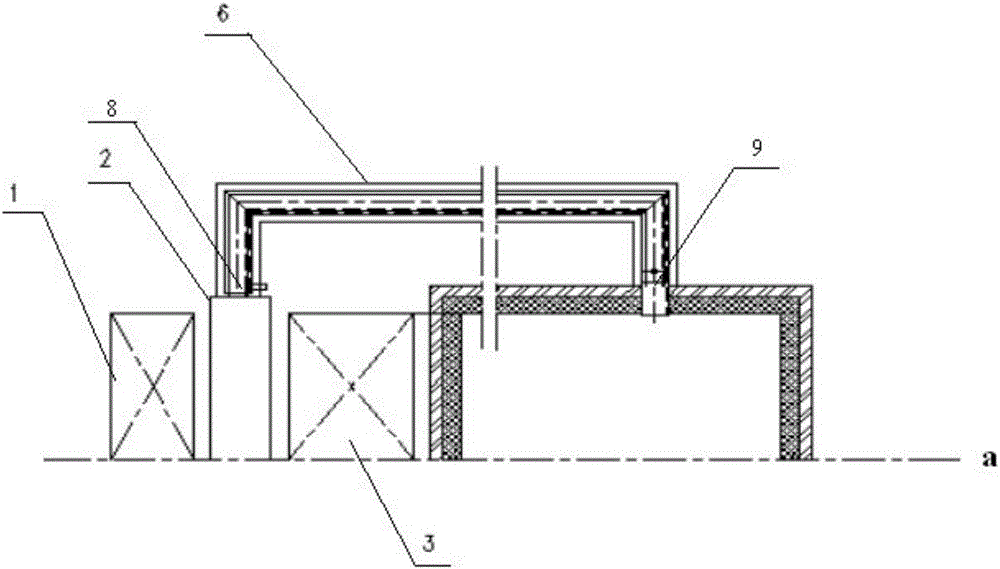

Double-hopper and double-fuel-layer layer-burning incineration device for village and town domestic garbage

The invention relates to a double-hopper and double-fuel-layer layer-burning incineration device for village and town domestic garbage. The double-hopper and double-fuel-layer layer-burning incineration device for the village and town domestic garbage aims at solving the problem that an existing incineration device is not suitable for combusting the village and town domestic garbage, and comprises a chain fire grate, a briquetted coal feed hopper, a pre-combustion chamber, a pre-combustion chamber flue, a domestic garbage hopper and a hearth provided with a front arch and a rear arch. Briquetted coal entering the briquetted coal feeding hopper can be pre-ignited in the pre-combustion chamber, an ignited coal layer is formed on the chain fire grate, the domestic garbage in the garbage hopper falls onto the ignited coal layer, coal which is not ignited is located between the ignited coal and high-temperature flue gas of the hearth, two-side ignition is achieved, and it is ensured that the domestic garbage is ignited in time. Meanwhile, by means of heat generated by combustion of the briquetted coal on the lower layer, the temperature of the hearth can be raised, and it is ensured that combustion of the domestic garbage is stable. The double-hopper and double-fuel-layer layer-burning incineration device is applied to the field of combustion of the village and town domestic garbage.

Owner:HEILONGJIANG COLLEGE OF CONSTR

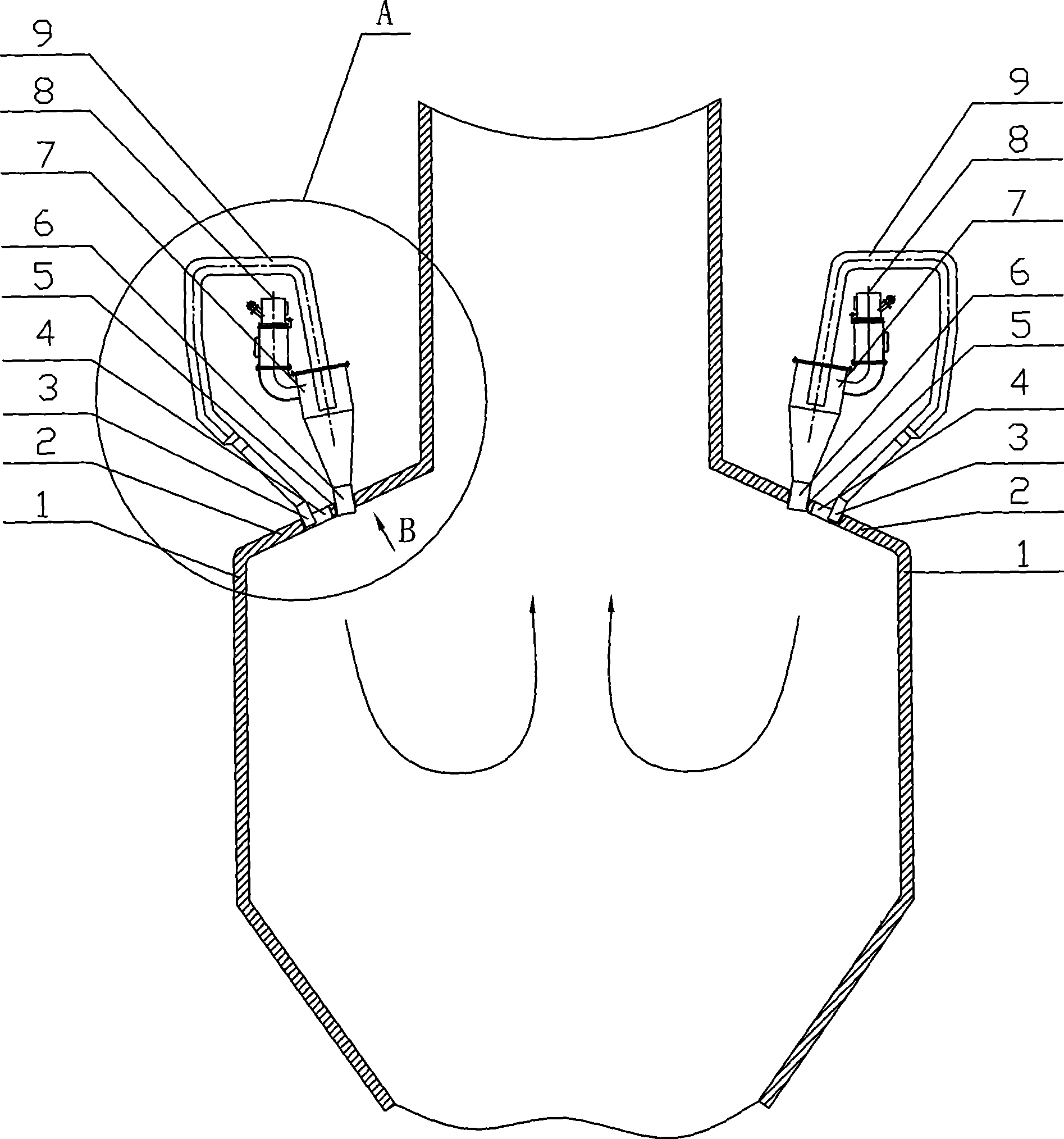

Exhaust steam front-loading W flame boiler with on-arch secondary air spraying openings and air distribution method

ActiveCN111503623AOptimize layoutPromote fireCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelAir volumeThermodynamics

The invention discloses an exhaust steam front-loading W flame boiler with an on-arch secondary air spraying openings and an air distribution method and relates to a coal-fired power plant. The exhaust steam front-loading W flame boiler with the on-arch secondary air spraying opening and the air distribution method aim at solving the problems that W flame boiler coal dust airflow fire catching islate, the burnout is poor and the on-arch and under-arch secondary air volume distribution is not reasonable, and consequently the classification combustion level in the boiler is low, the NOX generation amount in the boiler is high, the combustion organization manner of the boiler cannot be changed fundamentally, and the above problems cannot be thoroughly solved. The exhaust steam front-loadingW flame boiler further comprises two rows of double-cyclone-cylinder dense-lean coal dust combustors, and each double-cyclone-cylinder dense-lean coal dust combustor comprises an exhaust steam spraying opening, an on-arch secondary air spraying opening, surrounding air spraying openings and thick coal dust airflow spraying openings, wherein the thick coal dust airflow spraying openings are symmetrically formed in the two sides of the on-arch secondary air spraying opening, the exhaust steam spraying opening is formed in the on-arch secondary air spraying opening, the exhaust steam spraying opening is arranged close to the center face of a hearth, and the exhaust steam spraying opening, the on-arch secondary air spraying opening, the two surrounding air spraying openings and the two thick coal dust airflow spraying openings communicate with the lower hearth. The exhaust steam front-loading W flame boiler with the on-arch secondary air spraying opening and the air distribution method belong to the technical field of boiler combustion.

Owner:HARBIN INST OF TECH

Mixed gas combustor

The invention discloses a mixed gas combustor, relating to a gas combustor. The mixed gas combustor comprises two channels which are embedded inside and outside, a combustion air channel is arranged on the periphery and a fuel channel is arranged in the center, a burner nozzle is formed on the front end of the combustion air channel, and the front end of the fuel channel is provided with a spraying orifice for enabling fuel in the fuel channel to be radially outwards spirally spayed. The invention aims at providing the novel gas combustor, which has better stable combustion while combusting low-heat-value gas fuel with large flow, can not cause nozzle burning and coking problems while combusting high-heat-value gas fuel with small flow, and can combust a mixed fuel of a low-heat-value gas fuel and a high-heat-value gas fuel.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Integrated combustor suitable for incineration of high-salinity organic wastewater

The invention discloses a combustor which comprises a shell, a first air inlet assembly, a second air inlet assembly and a wastewater spray gun. The shell comprises a wind box front plate, a wind boxback plate, a wind box partition plate, a wind box side plate, a central cylinder, a spray gun fixing pipe I, a cyclone, an inner throat fixing plate, an inner ring throat straight section, an inner throat flaring section and an outer throat. An air inlet is formed in the wind box side plate, and the air inlet is divided into two air inlet channels. The central cylinder is perpendicular to the wind box partition plate, the spray gun fixing pipe I is arranged in the central cylinder and is coaxial with the central cylinder, and the cyclone sleeves the spray gun fixing pipe I. The first air inlet assembly comprises a spray gun fixing pipe II, a sleeve, an inner ring gun, an outer ring gun and a panel, and a spray gun rod of the wastewater spray gun penetrates through the spray gun fixing pipe II and the spray gun fixing pipe I. The combustor is an integrated combustor suitable for incineration of high-salinity organic wastewater, and is compact in structure, good in wastewater atomization effect, stable in ignition and combustion and high in combustion efficiency.

Owner:CHONGQING UNIV

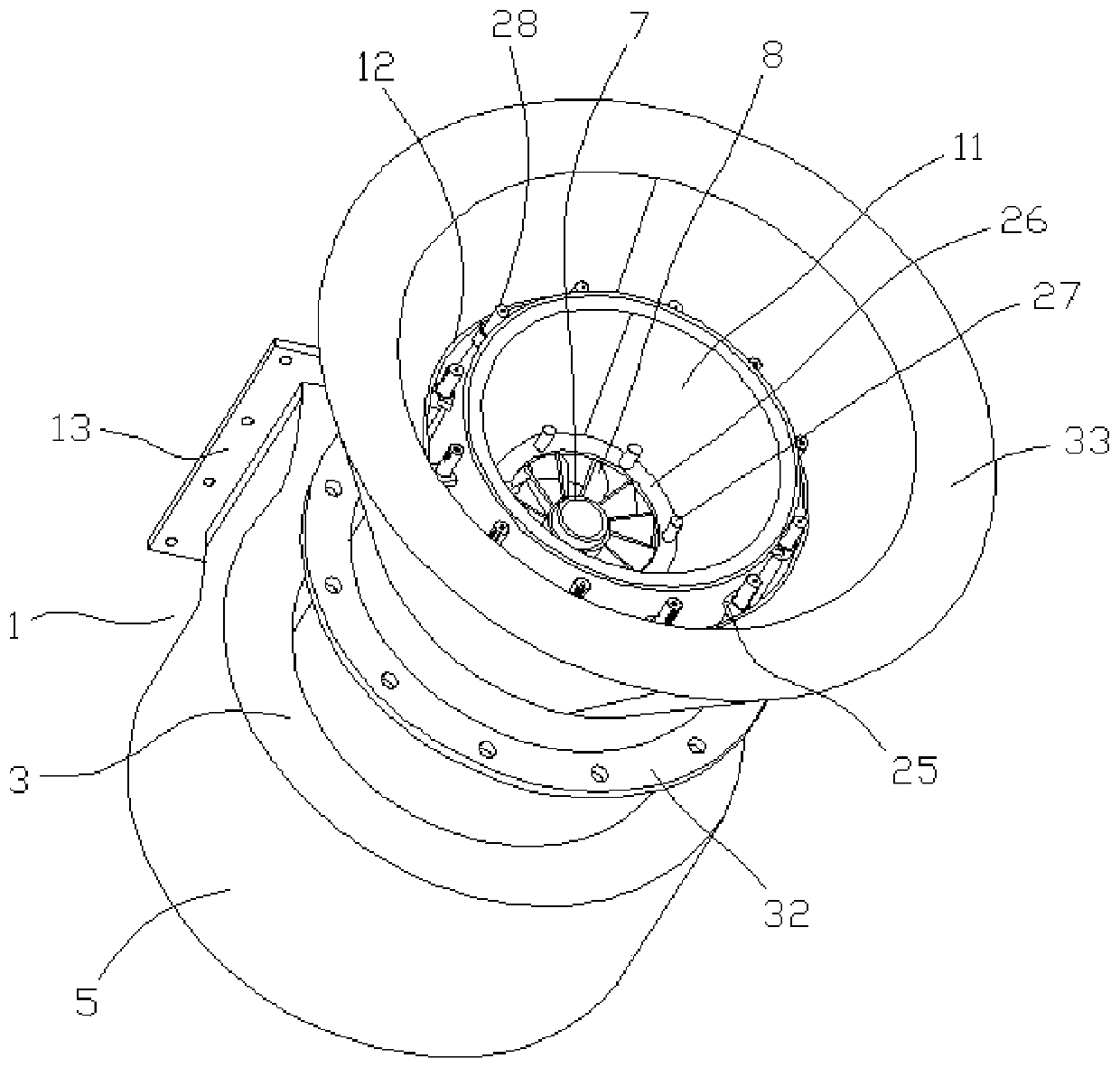

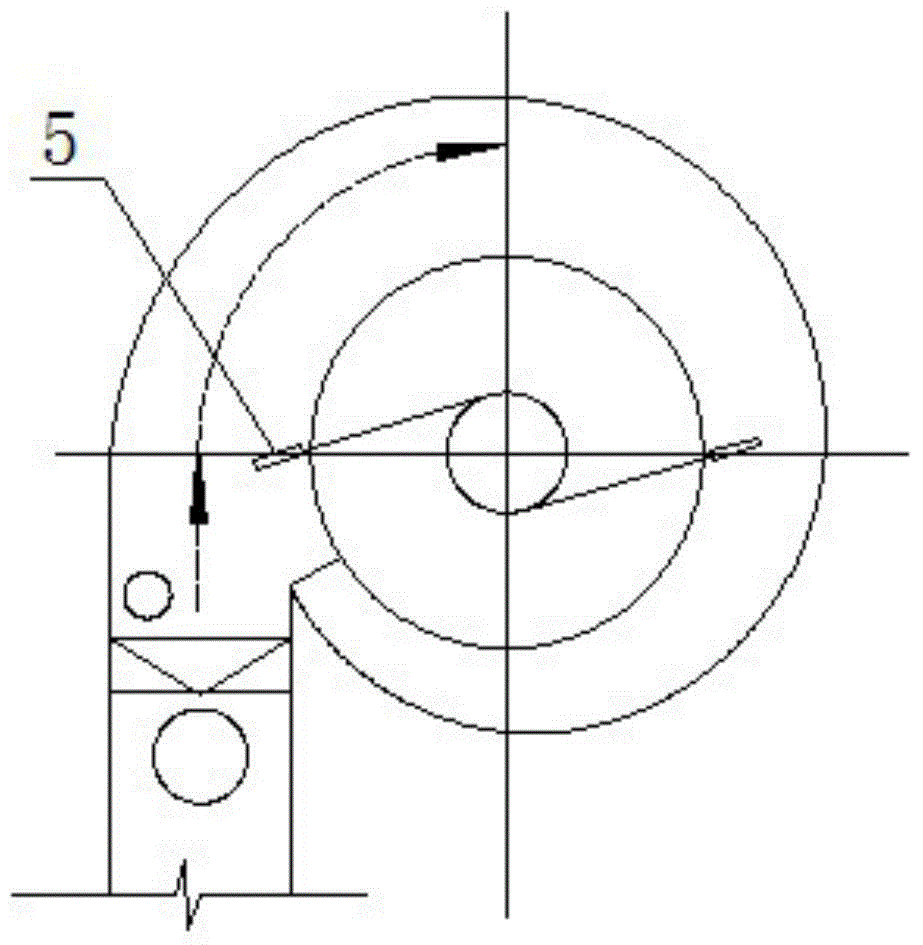

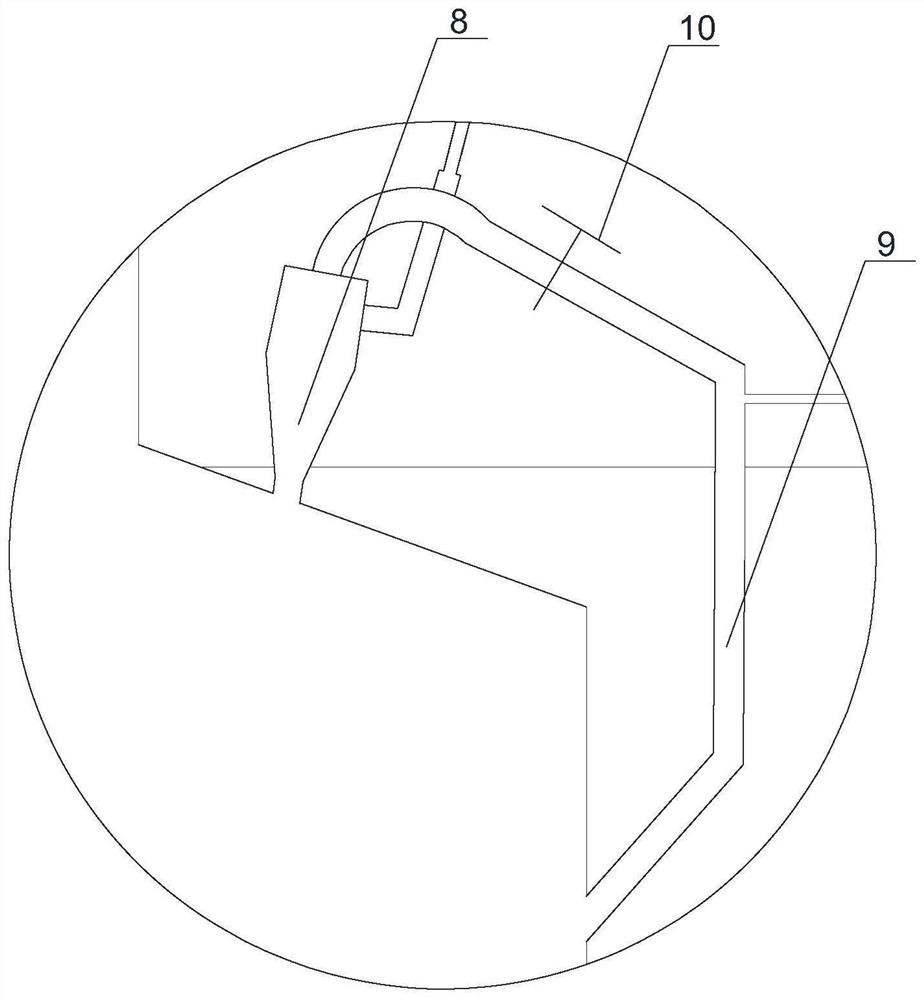

Cement kiln decomposing furnace with low-nitrogen type on-line rotational flow prechamber

InactiveCN104864704AFire in timeThe ignition temperature is timelyRotary drum furnacesShunt DeviceEngineering

The invention relates to a cement kiln decomposing furnace with a low-nitrogen type on-line rotational flow prechamber. The cement kiln decomposing furnace comprises a decomposing pipeline and a feed-end chamber which are vertically arranged, wherein the rotational flow prechamber is arranged between the decomposing pipeline and the feed-end chamber; the rotational flow prechamber is connected and communicated with the decomposing pipeline and the feed-end chamber; the rotational flow prechamber is of an involute volute shape; an air inlet is formed in the side face of the rotational flow prechamber; the air inlet is connected and communicated with the upper part of the decomposing pipeline by a tertiary air shunting device; at least two pulverized coal spray guns are also arranged on the rotational flow prechamber; and nozzles of the at least two pulverized coal spray guns stretch into an inner cavity of the rotational flow prechamber and are oppositely arranged. The invention provides the cement kiln decomposing furnace capable of effectively reducing NOx concentration in cement production waste gas.

Owner:南京圣火环境科技有限公司

Low-nitrogen combustor

The invention provides a low-nitrogen combustor. The combustor comprises a combustor barrel body, a combustor head cover and a fuel gas injection device; one end of the combustor barrel body is fixedly connected with the combustor head cover; the fuel gas injection device comprises a main fuel gas injection pipe and auxiliary fuel gas injection pipes, wherein the auxiliary fuel gas injection pipescommunicate with the main fuel gas injection pipe, the pipe diameter of the main gas injection pipe is greater than that of the auxiliary fuel gas injection pipes, auxiliary fuel gas nozzles are arranged at the tail ends of the auxiliary fuel gas injection pipes, and a plurality of small circulation holes are formed in the tail end of the main fuel gas injection pipe; and the end, away from the auxiliary fuel gas injection pipes, of the main fuel gas injection pipe is arranged in the combustor barrel body, and the end, close to the auxiliary fuel gas injection pipes, of the main fuel gas injection pipe and the auxiliary fuel gas injection pipes are all arranged in the combustor head cover. According to the technical scheme, the effects of high combustion efficiency and low NOx emission can be achieved.

Owner:HUAQIAO UNIVERSITY

Gas-solid dual-fuel low-nitrogen combustion machine

The invention relates to a combustion machine, in particular to a gas-solid dual-fuel low-nitrogen combustion machine. The gas-solid dual-fuel low-nitrogen combustion machine solves the problems that an existing combustor for a boiler is insufficient in combustion, gas combustion and mixing control are insufficient, and the combustion efficiency is influenced. The gas-solid dual-fuel low-nitrogen combustion machine comprises a dual-fuel hot water boiler, a dual-fuel left combustion device, an igniter, an ignition nozzle, a braize conveying pipe, a combustion air blower and a natural gas transportation pipe; and the dual-fuel left combustion device is connected with the dual-fuel hot water boiler; the braize conveying pipe and the natural gas transportation pipe are both connected with the dual-fuel left combustion device, and the igniter is installed in the ignition nozzle. The gas-solid dual-fuel low-nitrogen combustion machine belongs to the field of boilers.

Owner:天津佳乐鑫科技有限公司

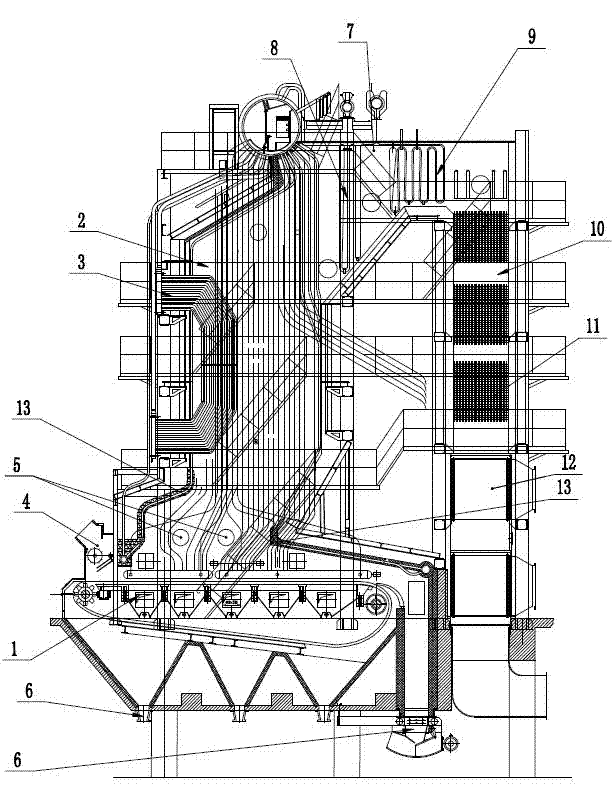

Boiler peak regulation method of W flame boiler for flexible peak regulation of double-layer coal bunker

ActiveCN113883501AAchieve full loadGuaranteed uptimeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion systemThermodynamics

The invention discloses a boiler peak regulation method of a W flame boiler for flexible peak regulation of a double-layer coal bunker, relates to the W flame boiler for flexible peak regulation and the boiler peak regulation method, and aims to solve the problems that a very few of existing W flame boilers can realize 30% ultra-low load stable combustion, the difficulty of the peak regulation technology is high, and the requirements for flexible peak regulation and deep peak regulation of a current electric environment can be hardly met. The W flame boiler comprises a W flame boiler combustion system and a coal bunker system, the W flame boiler combustion system comprises a hearth and two sets of double-cyclone-cylinder combustors, and the coal bunker system comprises coal blending bunkers and the double-layer coal bunker. The method is realized according to the following steps that step 1, preparation work is conducted, wherein inferior anthracite and meagre coal are daily stored in main coal bunkers and coal blending bunkers, and high-quality anthracite is daily stored in inner-layer coal blending bunkers; step 2, combustion work is conducted, wherein the W flame boiler is started to work; and step 3, peak regulation work is conducted, wherein peak regulation work is set according to requirements. The boiler peak regulation method is used in the field of boiler combustion.

Owner:HARBIN INST OF TECH +1

Airless rear-mounted w-flame boiler with secondary air nozzles on the arch and air distribution method

ActiveCN111520705BFire in timeLower emission levelsNon-combustible gases/liquids supplyLump/pulverulent fuel feeder/distributionAir volumeCombustor

A post-exhaust W-flame boiler with an arched secondary air nozzle and an air distribution method, belonging to the technical field of boilers, to solve the problem of late ignition of the pulverized coal airflow of the double-cyclone dense and light pulverized coal burner W flame boiler, poor burnout and poor burnout. Unreasonable distribution of secondary air volume above and below the arch, low level of staged combustion in the furnace, and high NOx emissions. The invention includes a furnace body, two rows of double cyclone thick and thin pulverized coal burners, and secondary air nozzles on the arch; the two exhaust gas nozzles of each double cyclone tube burner are combined into one near secondary air nozzle arranged on the corresponding arch. At the center side of the furnace, the invention also proposes a combustion adjustment method for a W flame boiler using the secondary air on the arch and the exhaust air behind it. The invention optimizes the secondary air ratio of the boiler and reduces the NOx emission level of the boiler. At the same time, the reasonable arrangement of the thick and thin pulverized coal airflow is beneficial to promote the ignition and combustion of the pulverized coal airflow and prevent the slagging of the front and rear walls of the boiler.

Owner:HARBIN INST OF TECH

Combustion method of wall-type counter-firing boiler

The invention discloses a firing method of a wall type opposed firing boiler. A plurality of burners and over-fire air spraying openings located above the multiple burners are arranged on a front wall and a back wall of the wall type opposed firing boiler respectively or are arranged on the front wall of the wall type opposed firing boiler only, and the multiple burners are arranged in a matrix mode, are arranged to be in M lines from bottom to top and are arranged to be in N columns from left to right, wherein the M is an integer larger than or equal to 2, and the N is an integer larger than or equal to 1. The firing method includes the steps of controlling the average excess air coefficient of a main firing area where the multiple burners are located to be smaller than 1, controlling the average excess air coefficient of a firing area between the over-fire air spraying openings and a hearth outlet of the boiler to be larger than 1 so as to achieve in-boiler air grading firing, and controlling the average excess air coefficient of the burners in the first line to be larger than the average excess air coefficient of the burners in the second line to the Mth line. By means of the firing method, the aim of in-time firing can be achieved.

Owner:YANTAI LONGYUAN POWER TECH

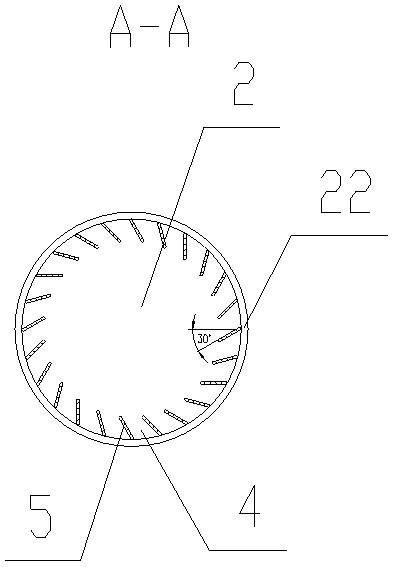

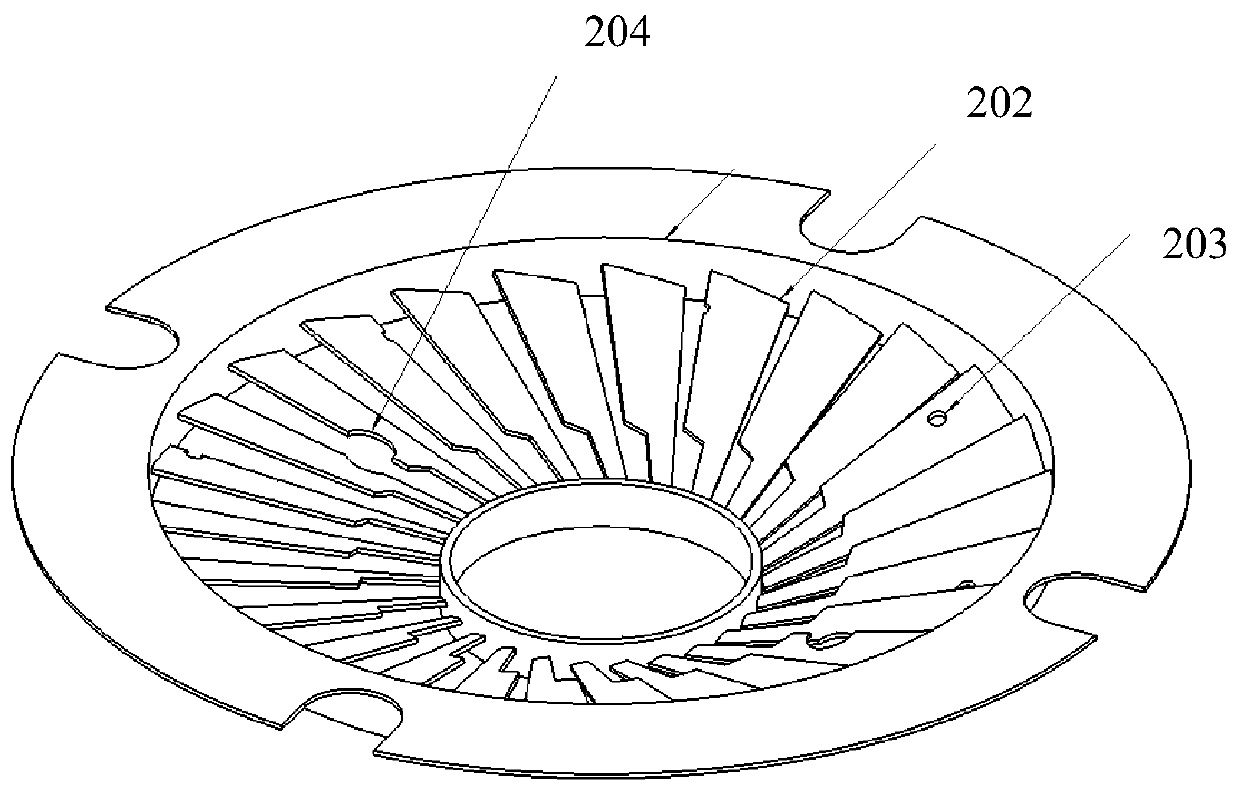

Nozzle-adjustable low-NOx burner suitable for medium-low calorific value fuel gas

ActiveCN112628732ASolve combustion instabilitySuppress generationIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorNitrogen oxides

The invention provides a nozzle-adjustable low-NOx burner suitable for medium-low calorific value fuel gas, and aims to solve the problems that a conventional fuel gas burner adopted for recycling the medium-low calorific value fuel gas is difficult to ignite, unstable in burning and low in burning efficiency, and nitric oxide generated in the burning process is difficult to effectively restrain. The nozzle-adjustable low-NOx burner comprises a fuel gas inlet flow channel, an air flow channel, an air rotational flow device and a fuel gas shunt ring, wherein the fuel gas inlet flow channel penetrates through the upstream side wall of the air flow channel; the fuel gas shunt ring is sleeved with the upstream portion of the air flow channel and is communicated with the fuel gas inlet flow channel; the end face of the fuel gas shunt ring is connected with a plurality of first fuel gas branch pipes, a plurality of second fuel gas branch pipes and a plurality of third fuel gas branch pipes; the air rotational flow device comprises a rotational flow inner ring, a rotational flow outer ring and a plurality of rotational flow blades arranged between the rotational flow inner ring and the rotational flow outer ring in the circumferential direction; and the three fuel gas branch pipes are arranged in a staggered mode from the center to the outer side, and supplies fuel gas in a graded mode in the radial direction and the circumferential direction.

Owner:XI AN JIAOTONG UNIV

Low-NOx gas burner capable of realizing flexible adjustment of variable loads

PendingCN113390080AReduce Excess Air CoefficientSlow down the combustion reactionGaseous fuel burnerEngineeringNitric oxide

The invention discloses a low-NOx gas burner capable of realizing flexible adjustment of variable loads. The low-NOx gas burner comprises an air supply pipeline, a gas supply pipeline and an igniter pipeline; the air supply pipeline comprises a primary air inlet, a secondary air inlet, a primary air flow channel, a secondary air flow channel, a secondary air branch pipe and an air cyclone; the gas supply pipeline comprises an inner ring gas inlet pipeline, an outer ring gas inlet pipeline, an inner ring gas flow dividing box, an outer ring gas flow dividing box, a center gas branch pipe, an inner ring gas branch pipe and an outer ring gas branch pipe. An air classification technology, an air rotational flow technology, an air porous dispersion jet flow technology, a gas load adjustable technology and a gas porous dispersion jet flow technology are adopted, and the problems that in the natural gas combustion process, it is difficult for the generation amount of nitric oxide to meet the ultralow nitrogen emission requirement, and serious pollution is caused to the environment are solved.

Owner:HANGZHOU BOILER GRP CO LTD

An adjustable nozzle low no gas suitable for medium and low calorific value gas x burner

ActiveCN112628732BSolve combustion instabilitySuppress generationIndirect carbon-dioxide mitigationGaseous fuel burnerThermodynamicsNitrogen oxides

In order to solve the problems of difficult ignition, unstable combustion, low combustion efficiency, and difficulty in effectively suppressing the nitrogen oxides generated during the combustion process of the conventional gas burner used in the recovery and utilization of medium and low calorific value gas, the present invention provides a Adjustable nozzle low NO for medium and low calorific value gas x The burner includes a gas inlet flow channel, an air flow channel, an air swirl device and a gas distribution ring; the gas inlet flow channel is set through the upstream side wall of the air flow channel; the gas distribution ring is sleeved and installed in the upstream of the air flow channel, It communicates with the gas inlet channel; the end face of the gas diversion ring is connected with a plurality of first gas branch pipes, a plurality of second gas branch pipes and a plurality of third gas branch pipes; the air swirl device includes a swirl inner ring, a swirl outer ring, and A plurality of swirl blades are arranged circumferentially between the swirl inner ring and the swirl outer ring; three kinds of gas branch pipes are arranged alternately from the center to the outside, and the gas is supplied radially and circumferentially in stages.

Owner:XI AN JIAOTONG UNIV

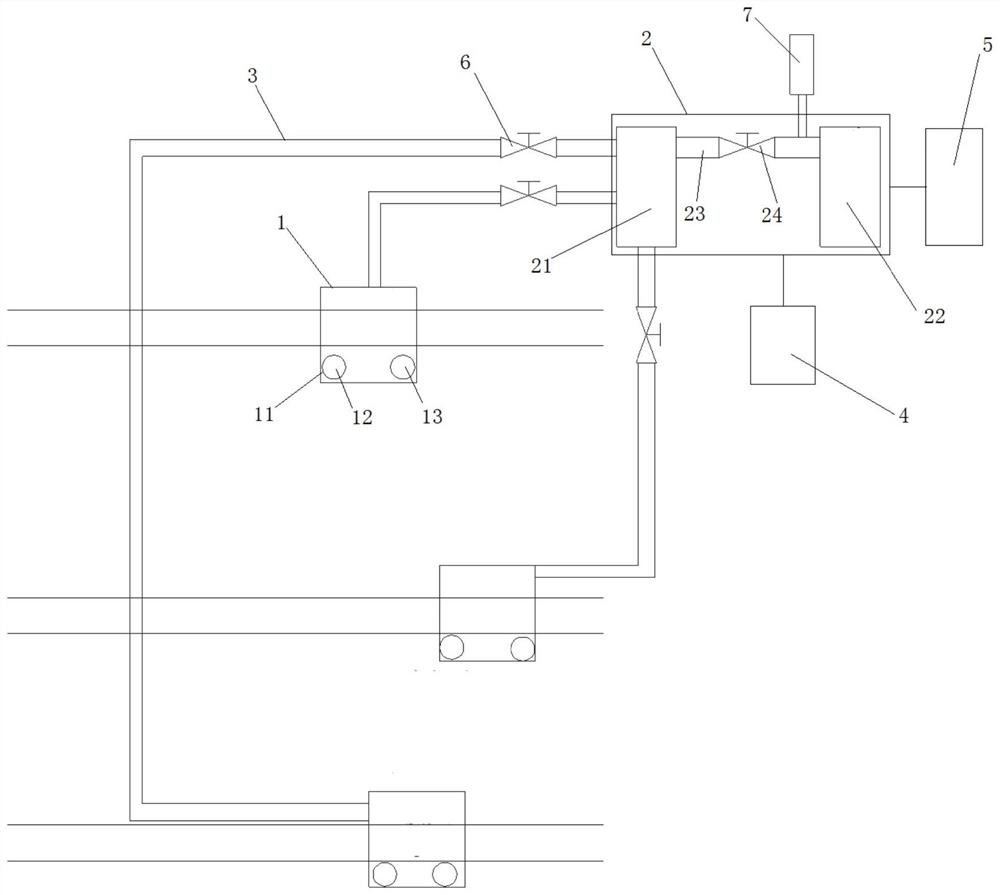

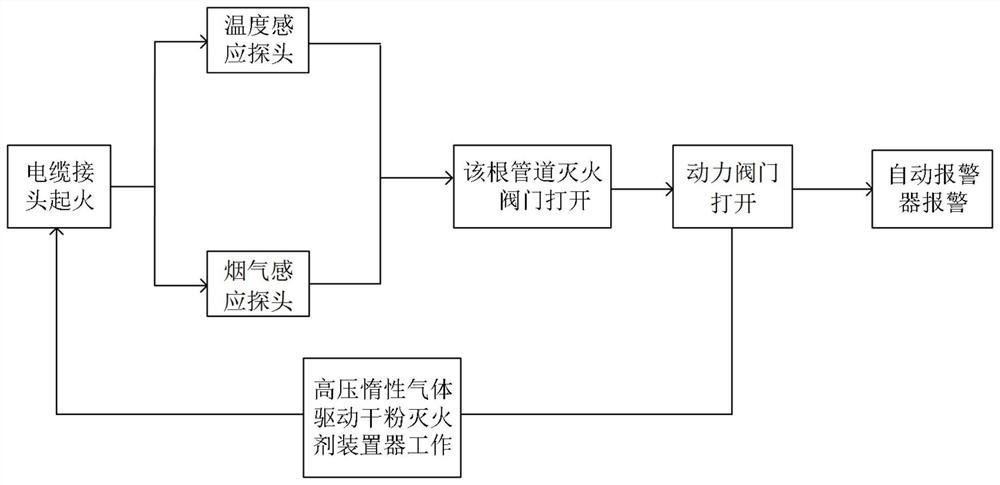

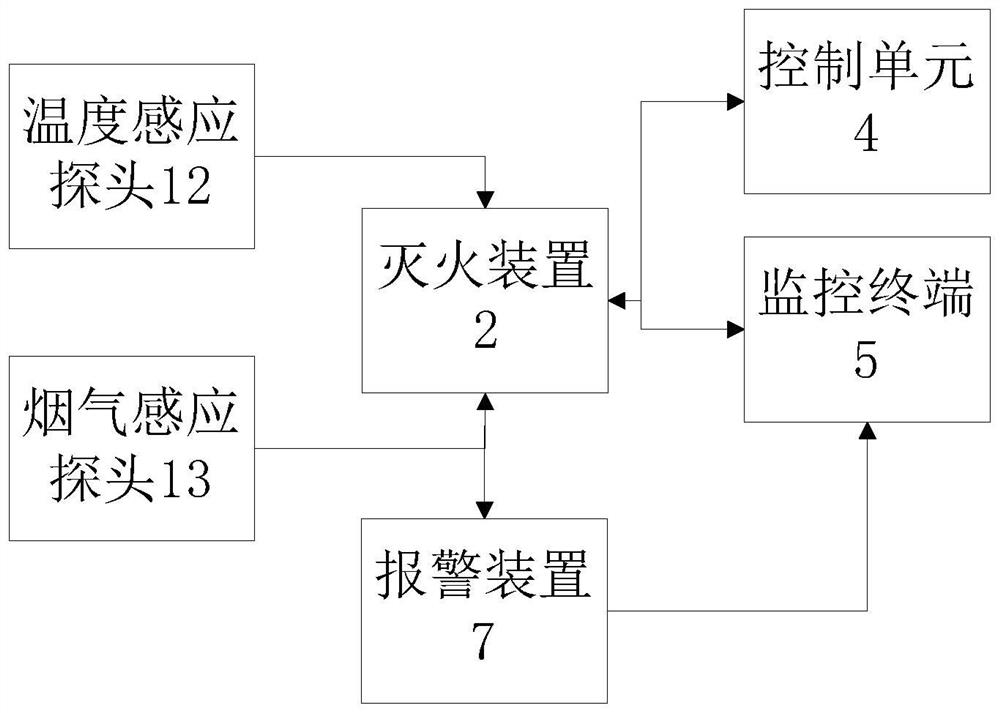

Cable joint fire monitoring and automatic fire extinguishing system

PendingCN114129935AGuaranteed uptimeAchieve extinguishFire rescueAutomatic fire suppressionControl cell

The invention provides a cable joint fire monitoring and automatic fire extinguishing system which comprises a wrapping shell wrapping a cable joint in a sealed mode and a fire extinguishing device, the fire extinguishing device is communicated with the wrapping shell through a fire extinguishing pipeline, a detection structure used for sensing a fire is arranged in the wrapping shell, and the detection structure is in signal connection with the fire extinguishing device. The fire extinguishing device collects induction signals of the detection structure and transmits the induction signals to the control unit and the monitoring terminal. The cable fire is extinguished from the source, real-time monitoring is achieved, fire extinguishing is timely, the occupied space is small, fire extinguishing is conducted on multiple cable joints through the same fire extinguishing device according to needs, the fire can be predicted in advance through background monitoring, overhauling treatment is conducted in advance, fire is avoided, and safe and reliable operation of an electric power system is guaranteed.

Owner:STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST +1

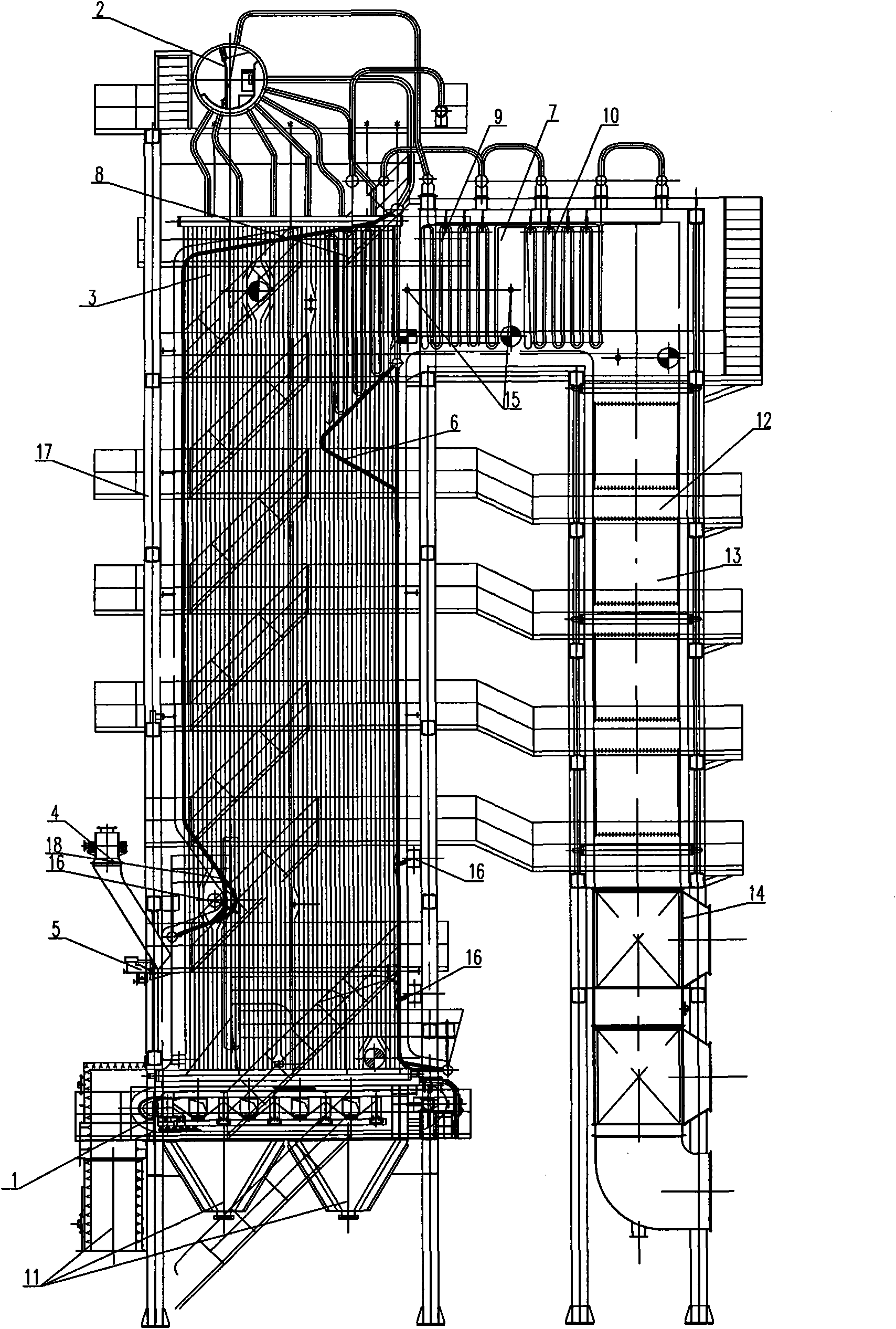

Biomass fuel boiler

InactiveCN101858589AShort construction periodLow investment costCasings/liningsSteam boilersElectricityCombustion

The invention relates to a boiler which can combust all kinds of biomass fuel to generate steam and is used for supplying steam and generating electricity. The invention adopts the following technical scheme that: a biomass fuel boiler is characterized by comprising a steel frame and a hearth; wherein the hearth is arranged on the steel frame; a boiler barrel is arranged over the hearth; a crossbeam-type chain grate stoker is arranged on the lower part of the hearth and is directly supported on the steel frame; a slag-out and ash-out device is arranged below the crossbeam-type chain grate stoker; an outlet of the hearth is provided with a horizontal flue and a tail flue; and the at least one set of feed device and a spray seeding device are arranged in front of the hearth along the width direction uniformly. Due to the adoption of the technical scheme, the defect in the prior art is overcome; and a novel biomass fuel boiler is provided and has the advantages of low investment cost, short construction cycle and high combustion efficiency.

Owner:WAI MING ENVIRONMENTAL PROTECTION EQUIP

Oil secondary air assisted ignition self-stabilization combustion W flame boiler and self-stabilization combustion method

ActiveCN111947137AGuaranteed underdrawing depthUndershoot Depth GuaranteedDamper arrangementNon-combustible gases/liquids supplyCombustorHearth

The invention relates to a W flame boiler and a self-stabilization combustion method, in particular to an oil secondary air assisted ignition self-stabilization combustion W flame boiler and a self-stabilization combustion method, and aims to solve the problems that when the pressure load capacity of a W flame boiler is insufficient, the minimum load of the boiler can only be maintained at about 50% of the full load, and the stable combustion effect is poor during low-load operation. An upper hearth, a lower hearth, a front wall and a rear wall form a furnace body, a plurality of cyclone combustors are linearly arranged and installed on a front furnace arch and a rear furnace arch of the upper hearth correspondingly, and a plurality of adjustable oil secondary air nozzles are linearly arranged and movably connected to a front furnace arch and a rear furnace arch of the upper hearth; and each adjustable oil secondary air nozzle is correspondingly arranged close to one cyclone combustor,each adjusting pull rod is installed on one adjustable oil secondary air nozzle, and an ignition oil gun and an exhaust gas nozzle are installed in each adjustable oil secondary air nozzle. The invention belongs to the field of boiler combustion.

Owner:HARBIN INST OF TECH

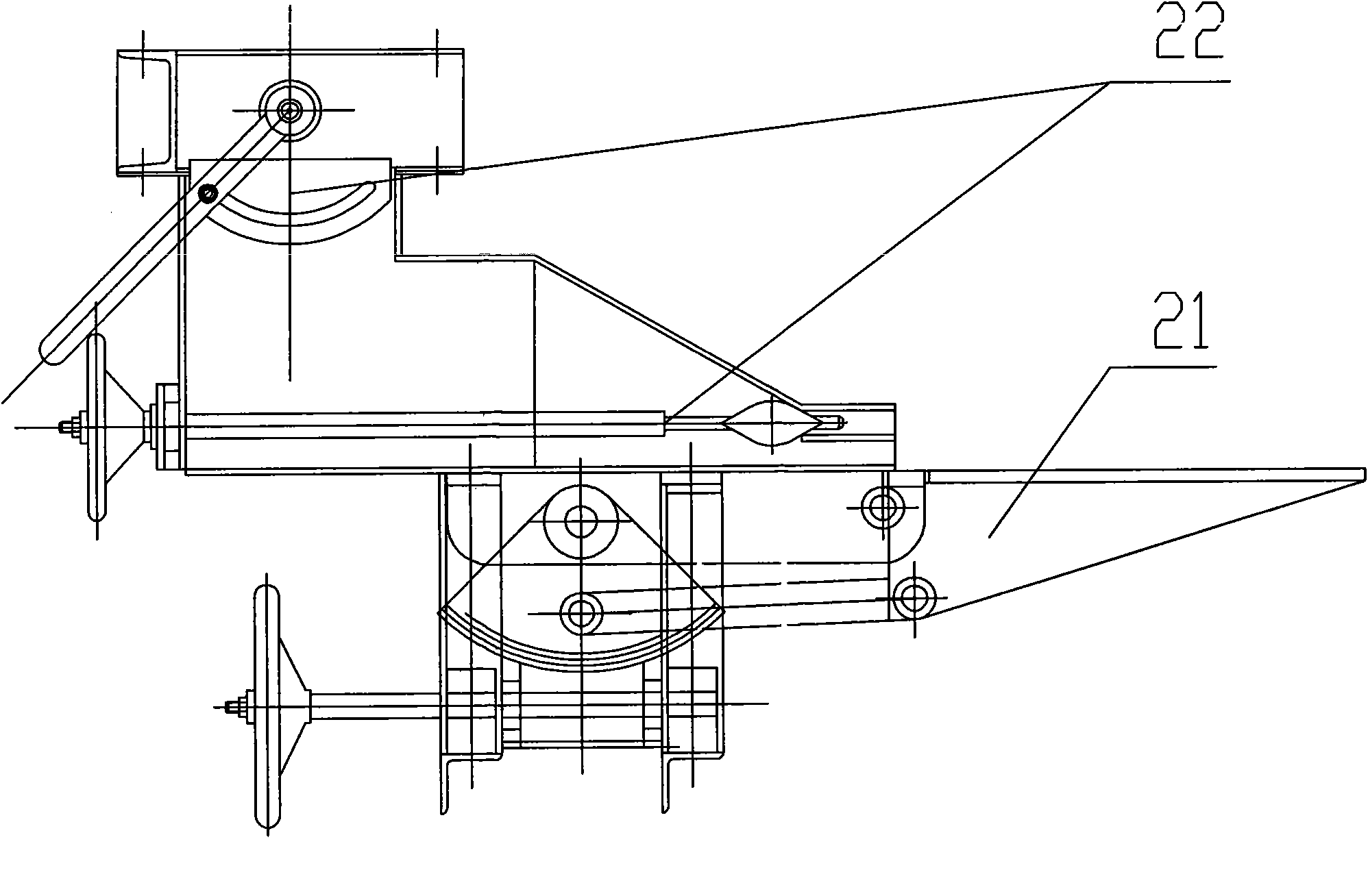

Boiler for carrying out mixed combustion on carbon black tail gas and coal

ActiveCN102128446BStable combustionFire in timeCombustion using lump and gaseous fuelAir preheaterCombustor

The invention discloses a boiler for carrying out mixed combustion on carbon black tail gas and coal so as to produce steam for steam supply and power generation. The technical scheme adopted by the invention is as follows: a boiler for carrying out mixed combustion on carbon black tail gas and coal comprises a hearth, a horizontal flue, a tail flue, a combustion device and a slag tapping and ashdischarging device, wherein the hearth, the horizontal flue and the tail flue constitute a square-n-shaped structure; the combustion device comprises an interstratified coal hopper, a clockwise-rotating flake type coal tight grate, and carbon black tail gas combustors; the slag tapping and ash discharging device is arranged below the clockwise-rotating flake type coal tight grate; the lower part of the hearth and two side walls above the clockwise-rotating flake type coal tight grate are respectively provided with a carbon black tail gas combustor; the inside of the horizontal flue is provided with a multistage superheater; and the inside of the tail flue is provided with a coal economizer and an air preheater. By the use of the technical scheme above, the invention solves the existing technical problems, and provides a new boiler for carrying out mixed combustion on carbon black tail gas and coal.

Owner:WAI MING ENVIRONMENTAL PROTECTION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com