Airless rear-mounted w-flame boiler with secondary air nozzles on the arch and air distribution method

A secondary air and air nozzle technology, applied in the field of boiler combustion, can solve the problems of late ignition of pulverized coal airflow, slagging, and low level of air classification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

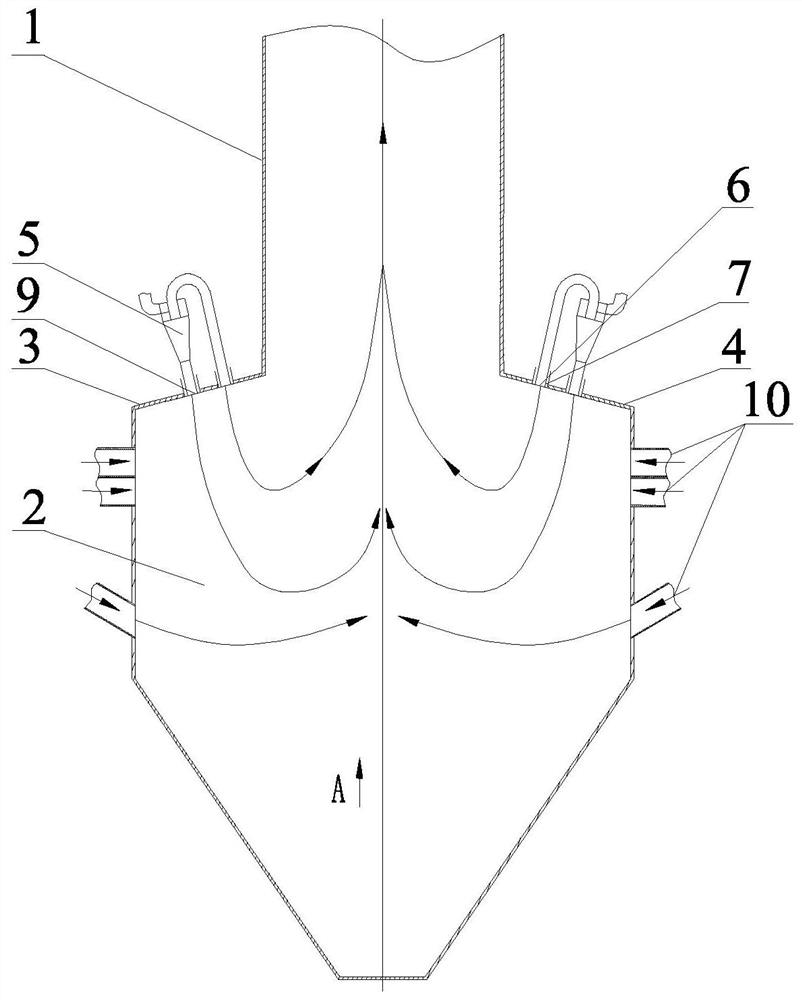

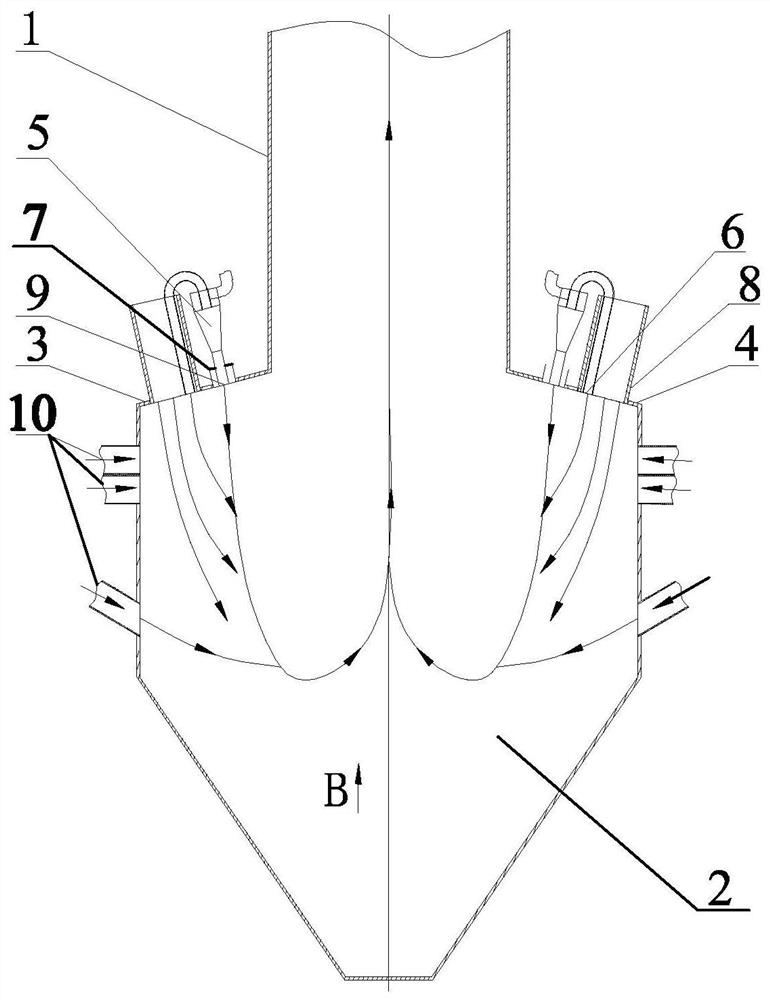

[0023] Embodiment 1: Combining image 3 and Figure 4 To illustrate this embodiment, the spent gas rear-mounted W-flame boiler with secondary air nozzles arranged on the arch in this embodiment includes an upper furnace 1, a lower furnace 2, a front furnace arch 3, a rear furnace arch 4, and two rows of double cyclone dense and light pulverized coal. The burner 5 and the secondary air nozzles 8 on the two rows of arches;

[0024] The upper furnace chamber 1 and the lower furnace chamber 2 are connected by the front furnace arch 3 and the rear furnace arch 4. The front furnace arch 3 and the rear furnace arch 4 are respectively provided with a row of double cyclone thick and light pulverized coal burners 5 and a row of secondary air nozzles on the arches. 8,

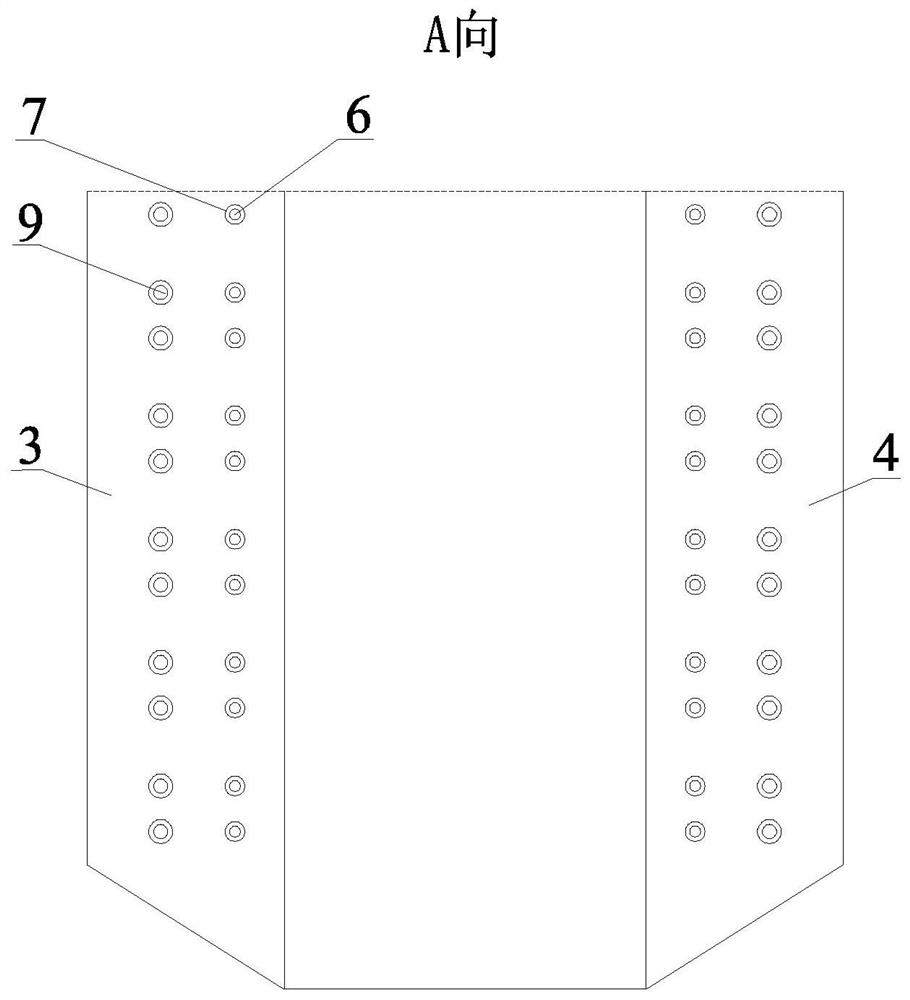

[0025] Each double cyclone rich and light pulverized coal burner 5 in each row of double cyclone rich and light pulverized coal burners 5 includes a spent gas nozzle 6, two peripheral air nozzles 7 and two rich pulveriz...

specific Embodiment approach 2

[0028] Specific implementation mode 2: Combining Figure 4 To illustrate this embodiment, in this embodiment, each exhausted gas nozzle 6 located on one side of the upper furnace 1 is arranged on the same side in the vertical direction of the centerline of the two rich pulverized coal gas flow nozzles 9 on each double cyclone rich and thin pulverized coal burner 5. on-line.

[0029] Other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation three: combination image 3 To illustrate this embodiment, in this embodiment, the secondary air nozzles 8 on each arch are arranged adjacent to the side wall of the lower furnace 2 .

[0031] Other components and connection relationships are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com