Boiler for carrying out mixed combustion on carbon black tail gas and coal

A technology of mixed combustion and exhaust gas is applied in the field of boilers where carbon black exhaust gas and coal are mixed combustion, which can solve problems such as environmental pollution and energy waste, and achieve the effects of improving combustion efficiency, strengthening disturbance and improving fullness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

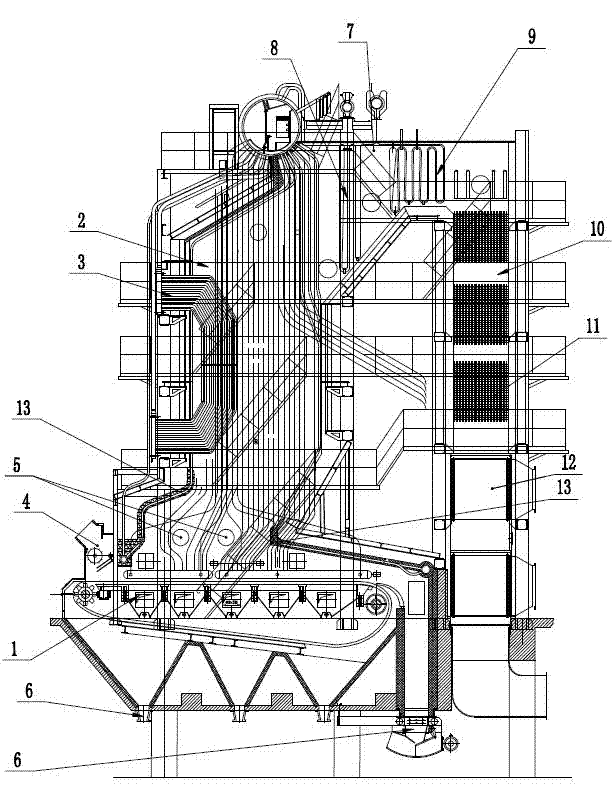

[0019] Such as figure 1 Shown as follows: 1 is the scale-type non-leaking coal grate that rotates forward, 2 is the furnace, 3 is the water-cooled screen, 4 is the layered coal hopper, 5 is the carbon black exhaust gas burner, 6 is the slag and ash discharging equipment, 7 It is a horizontal flue, 8 is a high temperature superheater, 9 is a low temperature superheater, 10 is a tail flue, 11 is an economizer, 12 is an air preheater, and 13 is a front and rear arch.

[0020] A boiler for mixed combustion of carbon black tail gas and coal, comprising a furnace 2, a horizontal flue 7, a tail flue 10, combustion equipment and slag and ash discharge equipment 6, a furnace 2, a horizontal flue 7 and a tail flue 10 The combustion equipment includes a layered coal hopper 4, a scale-type non-spill coal grate 1 that rotates forward, and a carbon black exhaust gas burner 5, where the carbon black exhaust gas burner 5 and the scale-type carbon black exhaust gas burner are used. Combustion o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com