Oil secondary air assisted ignition self-stabilization combustion W flame boiler and self-stabilization combustion method

A secondary air and boiler technology, which is applied in combustion methods, combustion equipment, and non-flammable liquid/gas transportation, etc., can solve the problems of insufficient pressure load capacity and poor combustion stabilization effect of flame boilers, and achieve large-scale lifting and lowering. load, favoring ignition, optimizing the effect of the burner structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

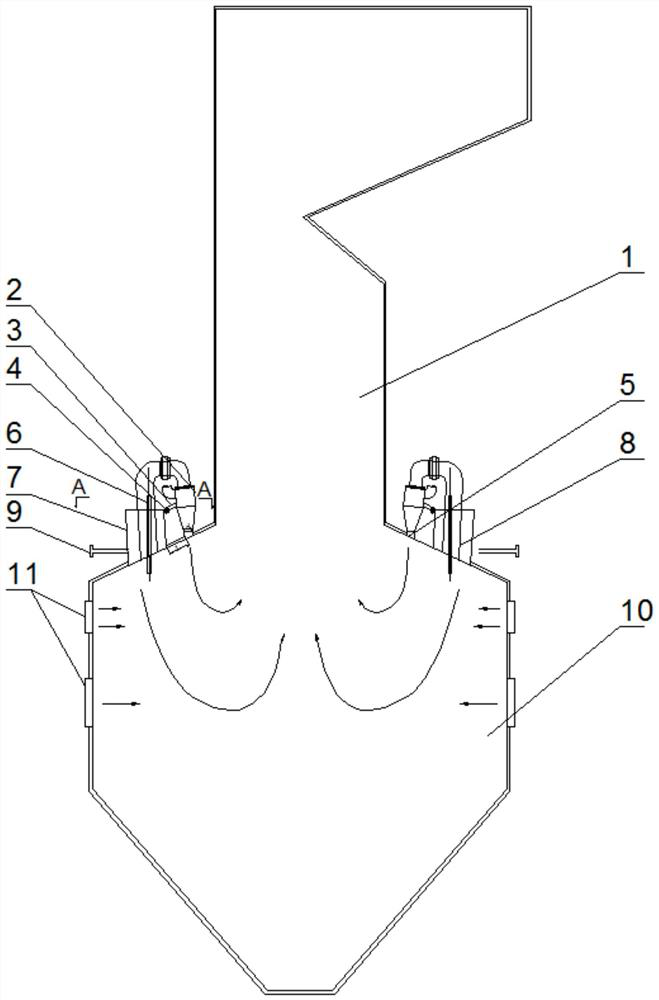

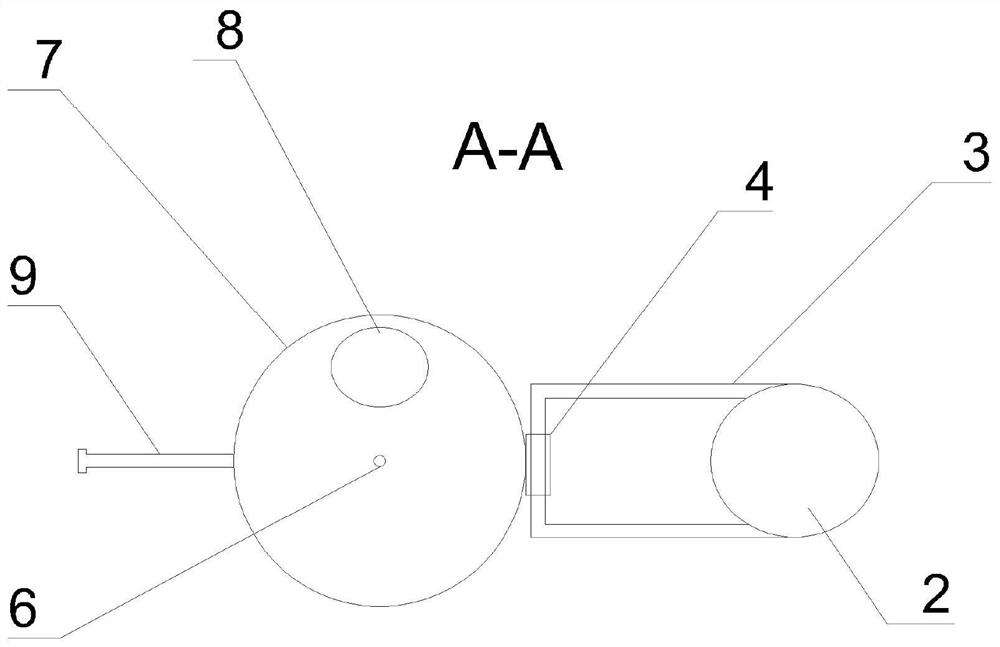

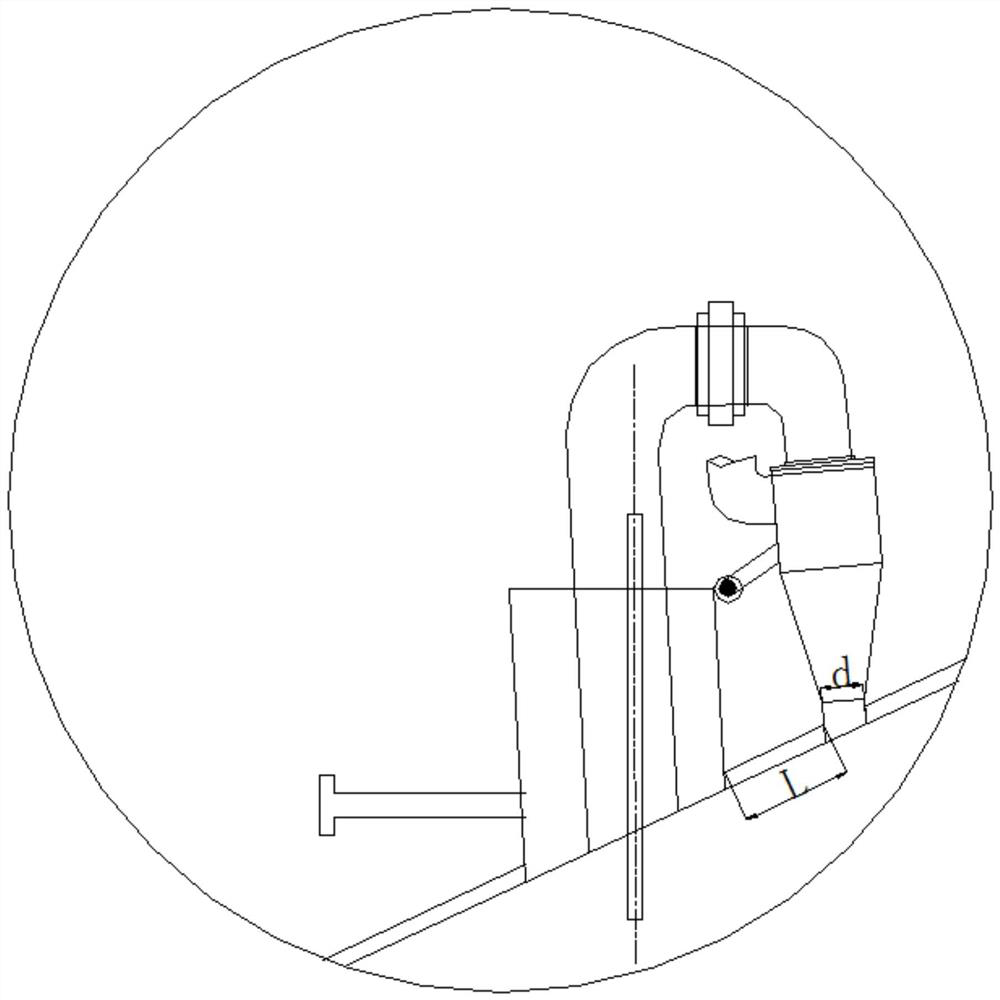

[0031] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment, the oil secondary air assists ignition self-stable combustion W flame boiler in this embodiment, it includes upper furnace 1, lower furnace 10, front wall, rear wall, multiple cyclone burners 2, multiple ignition Oil gun 6 and multiple adjustable oil secondary air nozzles 7, cyclone burner 2 includes multiple exhaust gas nozzles 8 and multiple adjustment rods 9;

[0032] The upper furnace 1, the lower furnace 10, the front wall and the rear wall constitute the furnace body, and multiple cyclone burners 2 are arranged in a straight line and installed on the front furnace arch and the rear furnace arch of the upper furnace 1 respectively. The air nozzles 7 are arranged in a straight line and are movable connected and installed on the front furnace arch and the rear furnace arch of the upper furnace 1. Each oil-adjustable secondary air nozzle 7 is arranged correspondingly close to a cycl...

specific Embodiment approach 2

[0033] Specific implementation mode two: combination Figure 1-Figure 4 Describe this embodiment, the oil secondary air assisted ignition self-stable combustion W flame boiler in this embodiment, it also includes a plurality of support rods 3 and a plurality of sleeves 4, each sleeve 4 is sleeved on a support rod 3 , the outer wall of each cyclone burner 2 is fixedly connected to both ends of the support rod 3, and the sleeve 4 on the support rod 3 is fixedly connected to the outer wall of the top of the cyclone burner 2 corresponding to the adjustable oil secondary air nozzle 7 The outlet of the cyclone burner 2 is connected with the upper furnace 1 through the thick coal powder nozzle 5, the central axis of the oil-adjustable secondary air nozzle 7 rotates around the center line of the casing 4, and the outer wall of the cyclone burner 2 is in contact with the upper furnace 1. Both ends of the support rod 3 are rigidly connected, and the cross-sectional area of the exhaust...

specific Embodiment approach 3

[0034] Specific implementation mode three: combination Figure 1-Figure 4 Describe this embodiment, the oil secondary air assists ignition self-stable combustion W flame boiler in this embodiment, it also includes multiple groups of secondary air nozzles 11, and multiple groups of secondary air nozzles 11 are evenly distributed on the front wall. Groups of secondary air spouts 11 are evenly distributed on the back wall, and other methods are the same as in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com