Combustion method of wall-type counter-firing boiler

A technology of hedging combustion and combustion method, which is applied in the field of thermal machinery and can solve the problems of insufficient desuperheating water, poor combustion stability, and low burnout rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

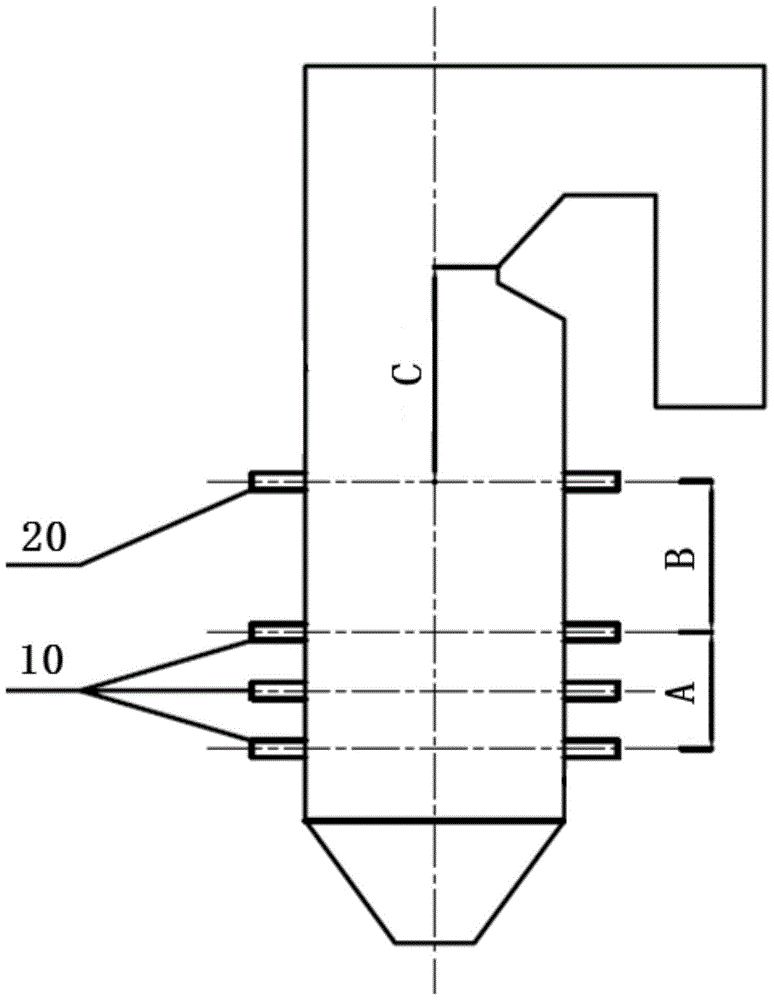

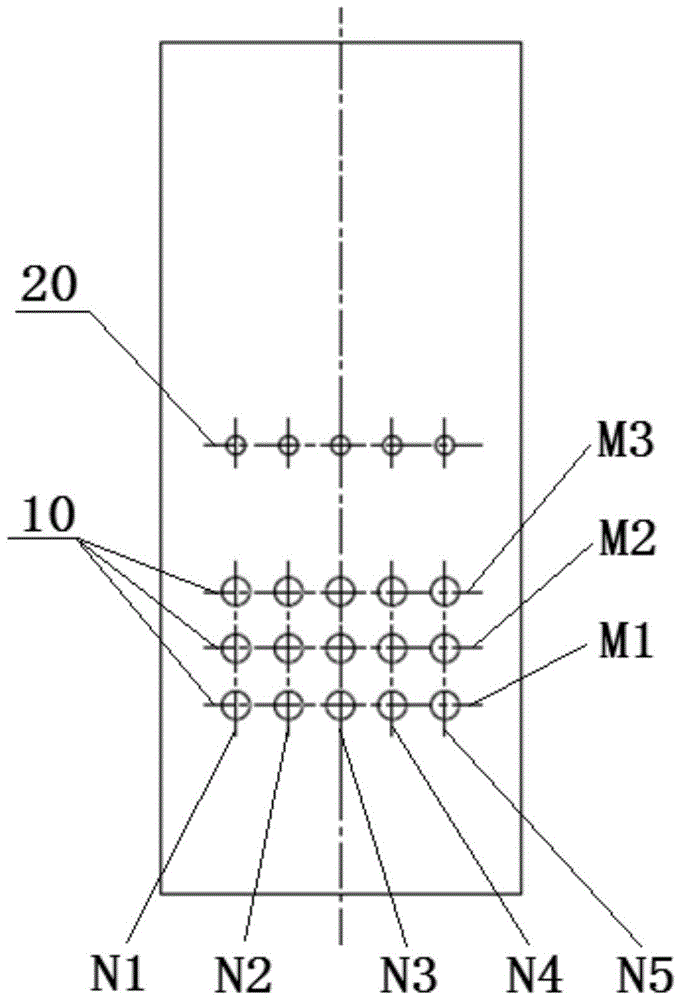

[0057] figure 2 It is a schematic diagram of the layout of the burner and the exhaust air nozzle on the boiler body of the wall-type opposed combustion boiler adopting the furnace air staged combustion technology corresponding to the first embodiment of the present invention.

[0058] In the wall-type opposed combustion boiler corresponding to the combustion method of the first embodiment, the front wall and the rear wall of the boiler are arranged as figure 2 Shown are a plurality of burners 10 and a plurality of overburning air nozzles 20 disposed above the plurality of burners 10 . Wherein, the burner 10 is specifically a swirl pulverized coal burner.

[0059] Such as figure 2 As shown, in the first embodiment, 15 burners 10 arranged in a matrix are arranged on the front wall of the boiler body, and the 15 burners 10 are divided into three rows and five columns, that is, in the first embodiment, M =3, N=5.

[0060] figure 2 Among them, the 15 burners 10 are the fir...

no. 2 example

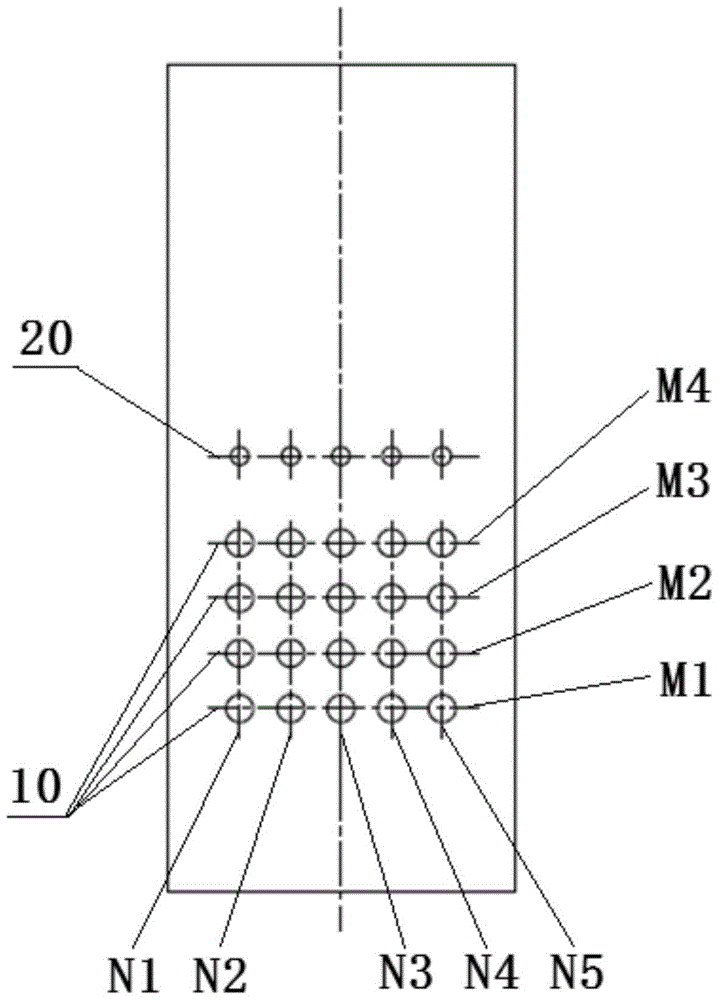

[0074] image 3 It is a schematic diagram of the layout of the burner and the exhaust air nozzle on the boiler body of the wall-type opposed combustion boiler adopting the furnace air staged combustion technology corresponding to the second embodiment of the present invention.

[0075] In the wall-type opposed combustion boiler corresponding to the combustion method of the second embodiment, the front wall and the rear wall of the boiler are arranged as image 3 Shown are a plurality of burners 10 and a plurality of overburning air nozzles 20 disposed above the plurality of burners 10 . Wherein, the burner 10 is specifically a swirl pulverized coal burner.

[0076] Such as image 3 As shown, in the second embodiment, 20 burners 10 arranged in a matrix are arranged on the front wall of the boiler body, and the 20 burners 10 are divided into four rows and five columns, that is, in the second embodiment, M =4, N=5.

[0077] image 3 Among them, the 20 burners 10 from bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com