Low-NOx gas burner capable of realizing flexible adjustment of variable loads

A gas burner, flexible technology, applied in the direction of gas fuel burner, burner, combustion method, etc., can solve the problems such as difficult to meet the generation of nitrogen oxides, ultra-low nitrogen emission requirements, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Embodiment: Affect NO in gas combustion process x The main factors of formation are combustion temperature, residence time of fuel in the high temperature zone, and the mixture of fuel and air. Correspondingly, low NO x Combustion methods include reducing the gas combustion temperature, strengthening the rapid mixing of gas and air, and eliminating local high temperature areas.

[0034] The present invention is described in further detail below in conjunction with accompanying drawing:

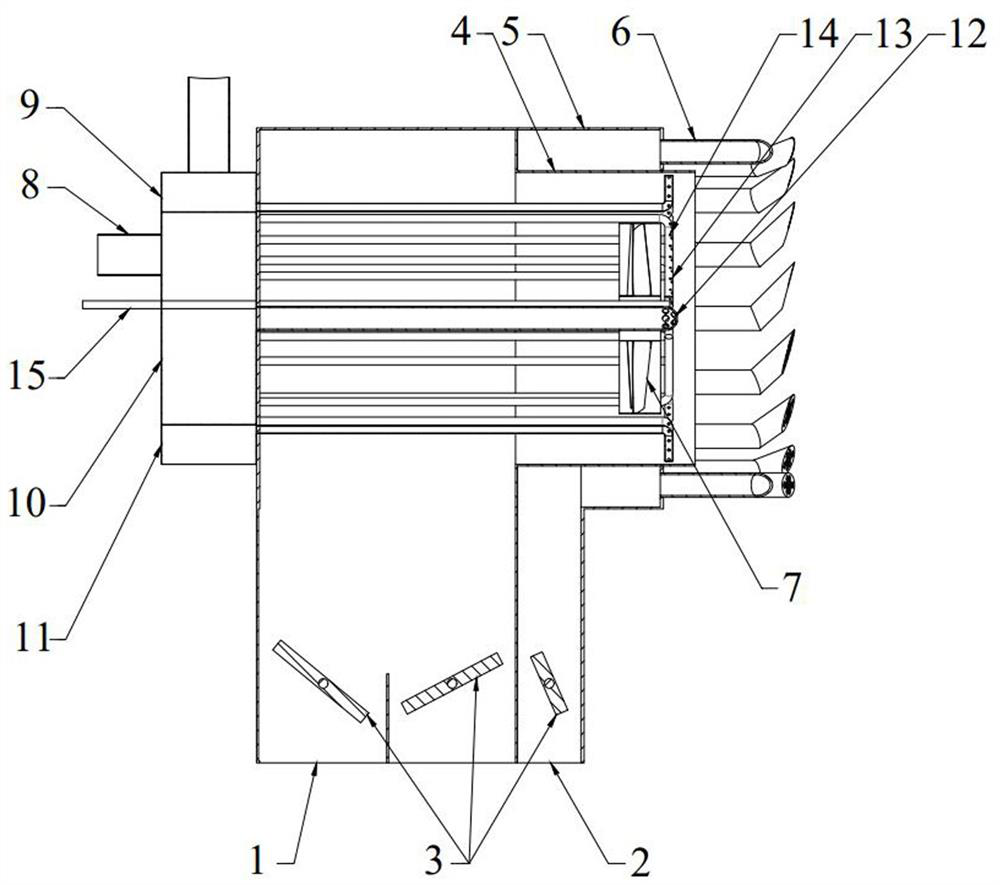

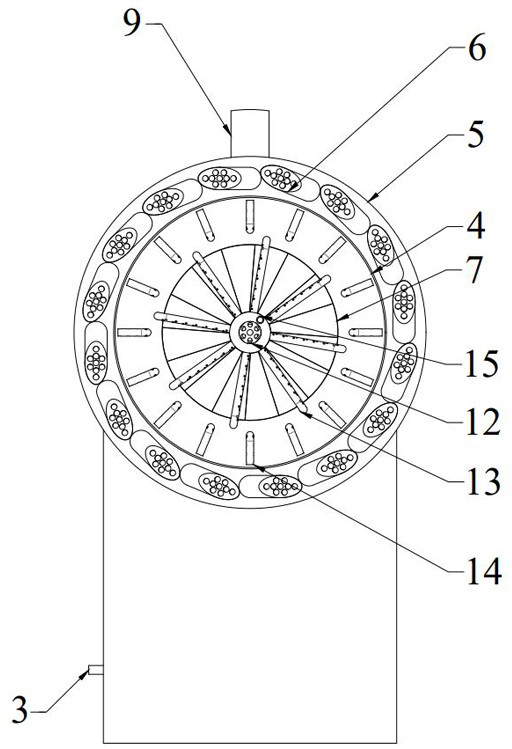

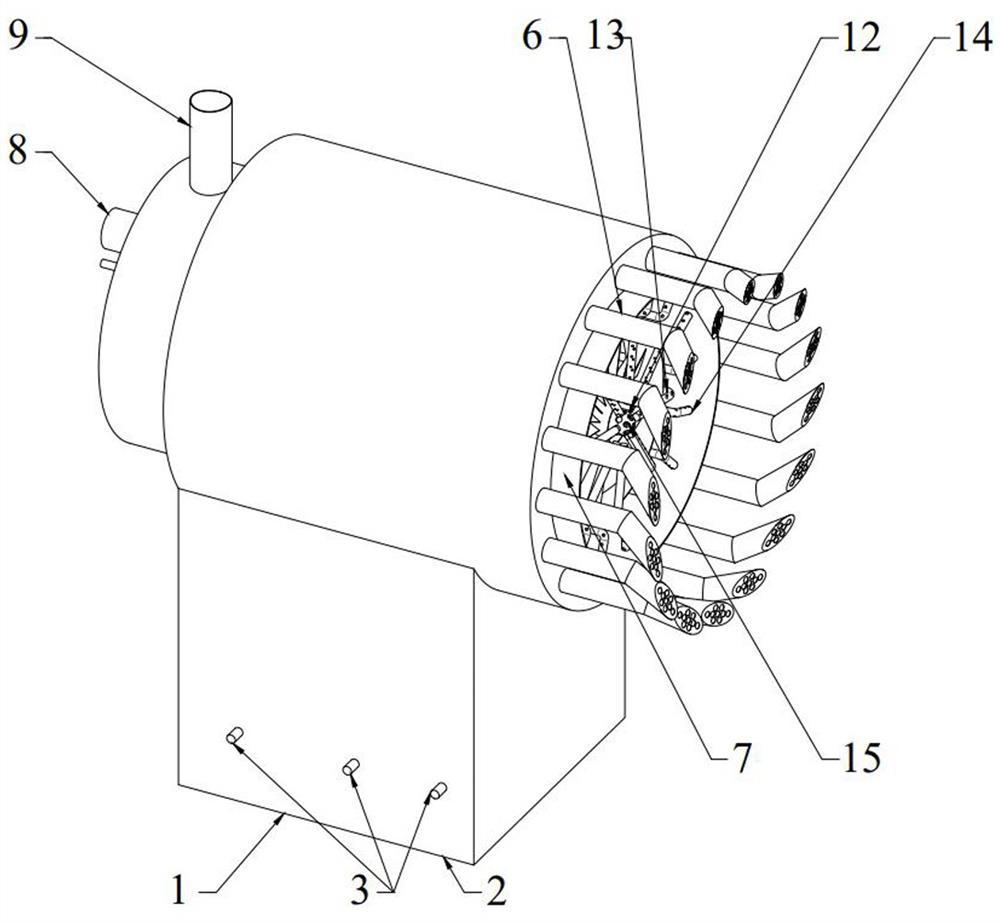

[0035] see Figure 1 to Figure 4, the present invention is a low NOx gas burner with variable load flexibility adjustment, which is composed of an air supply pipeline, a gas supply pipeline and an igniter pipeline 15. Among them, the air supply pipeline includes a primary air inlet 1, a secondary air inlet 2, an air volume regulating valve 3, a primary air flow channel 4, a secondary air flow channel 5, a secondary air branch pipe 6 and an air cyclone 7; the gas supply pipeline Inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com