Integrated combustor suitable for incineration of high-salinity organic wastewater

An organic waste water, integrated technology, applied in the direction of burner, combustion type, combustion method, etc., can solve the problems of long water evaporation time, poor combustion effect, long burn-out time, etc., and achieve the containment of toxic pollution such as dioxin The generation of objects, the convenience of disassembly, and the effect of reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

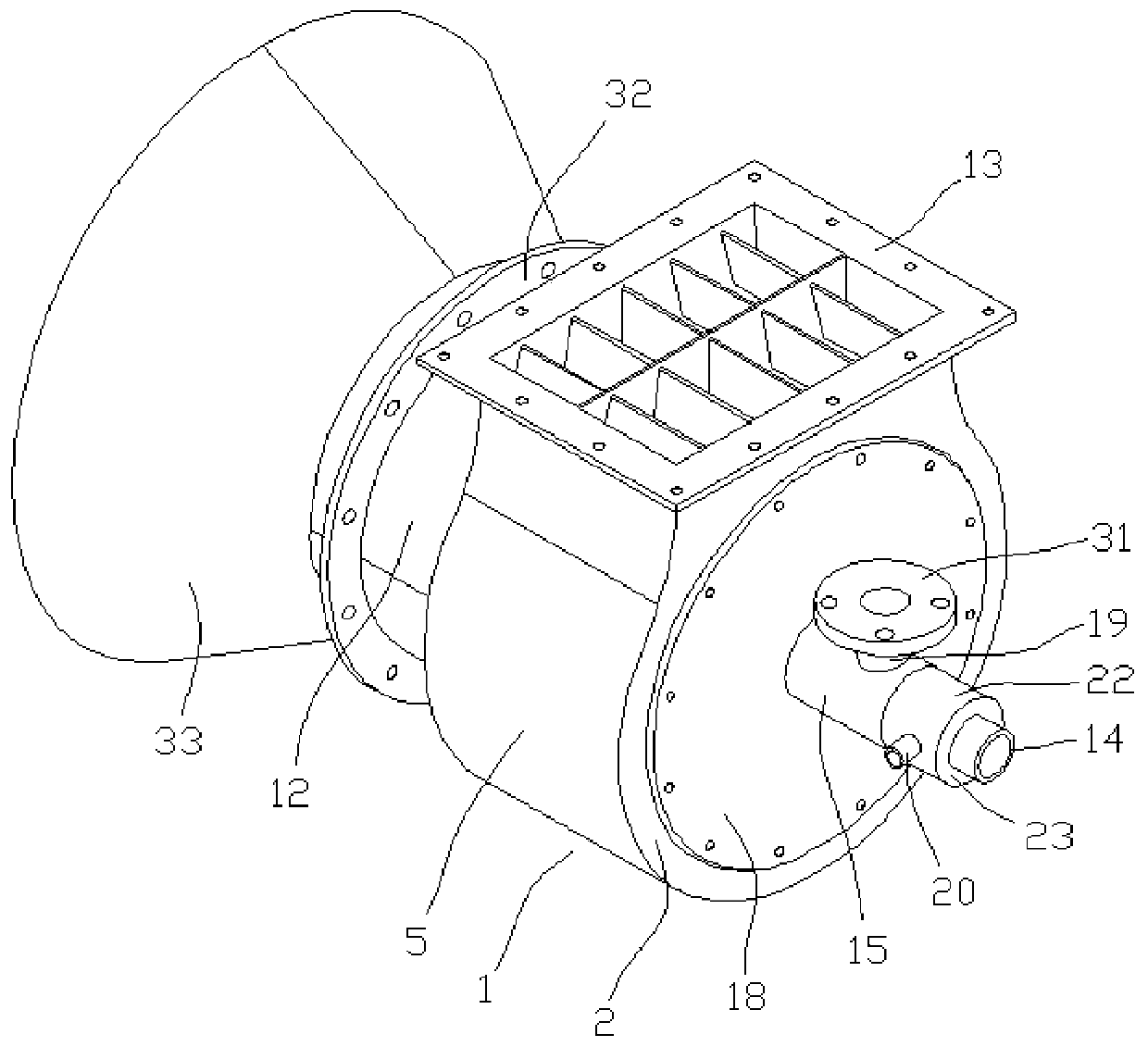

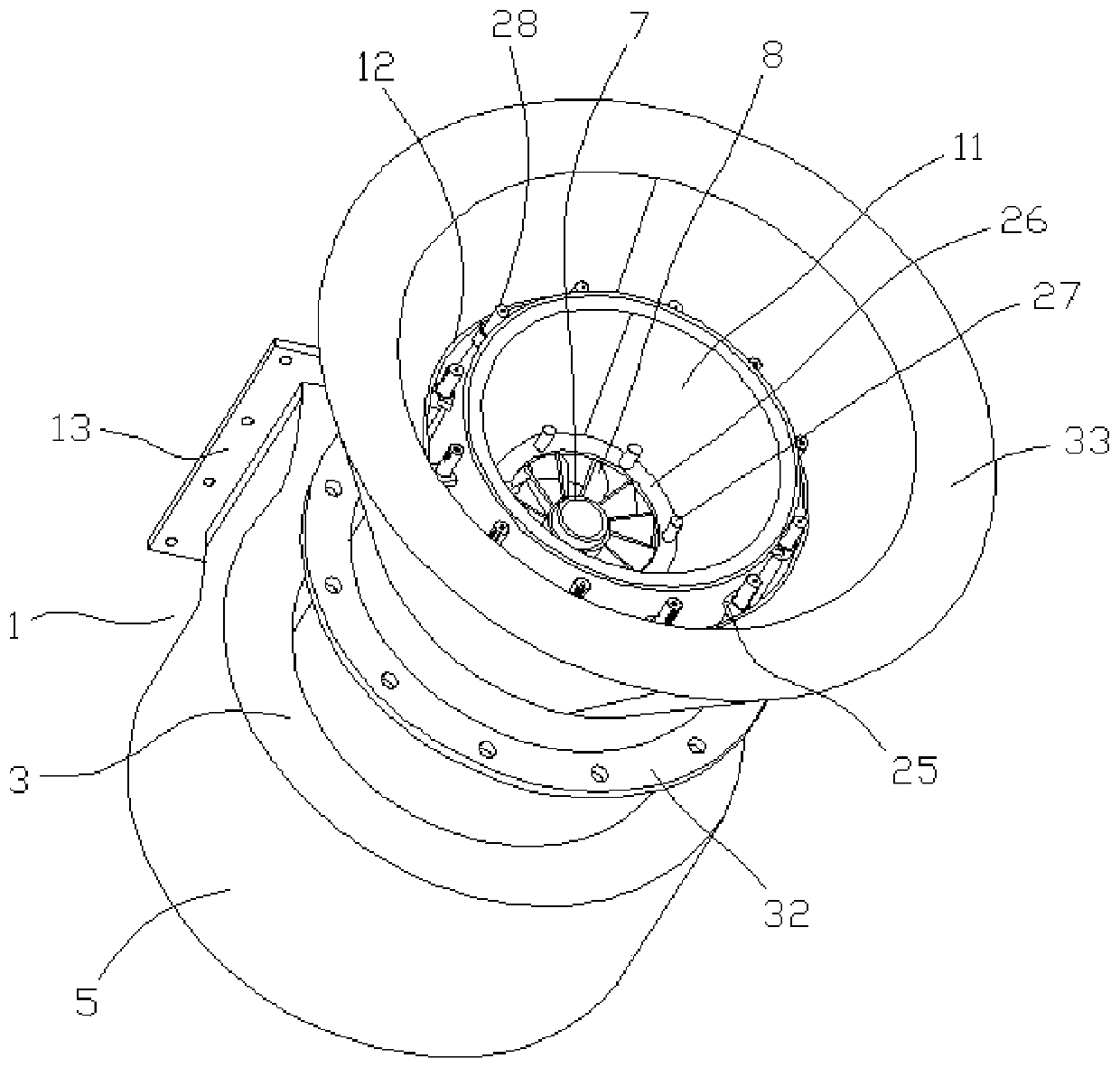

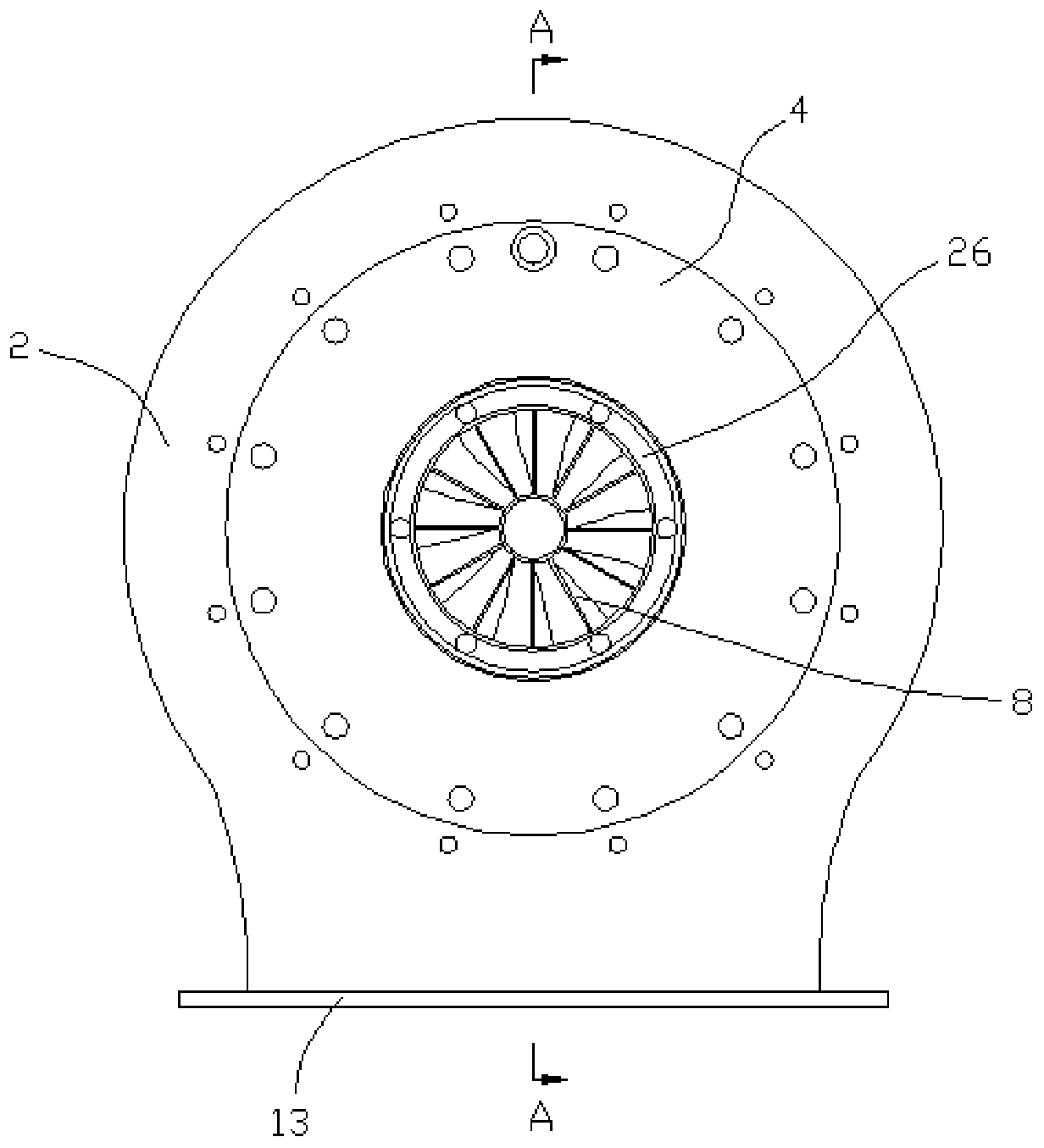

[0039] Such as Figure 1-10 As shown, an integral burner suitable for high-salt organic wastewater incineration includes a shell 1 , an air intake assembly 1 , an air intake assembly 2 and a waste water spray gun 34 .

[0040] The structure of the shell is as Figure 3-6 As shown, the housing 1 includes the bellows front plate 2, the bellows back plate 3, the bellows partition plate 4, the bellows side plate 5, the central tube 6, the spray gun fixing pipe I7, the cyclone 8, the inner bellows fixing plate 9, the inner ring Throat straight section 10, inner throat flaring section 11 and outer throat 12. The bellows front plate 2 , the bellows back plate 3 and the bellows dividing plate 4 are all provided with inner circular holes, and the inner circular holes of the bellows dividing plate 4 are smaller than the inner circular holes o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com