Gas-solid dual-fuel low-nitrogen combustion machine

A low-nitrogen combustion, gas-solid technology, applied in the field of boilers, can solve the problems of affecting combustion efficiency, insufficient mixing of gas and control, insufficient fuel combustion, etc., and achieve the effects of strong flame rigidity, slagging prevention, and reasonable air distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

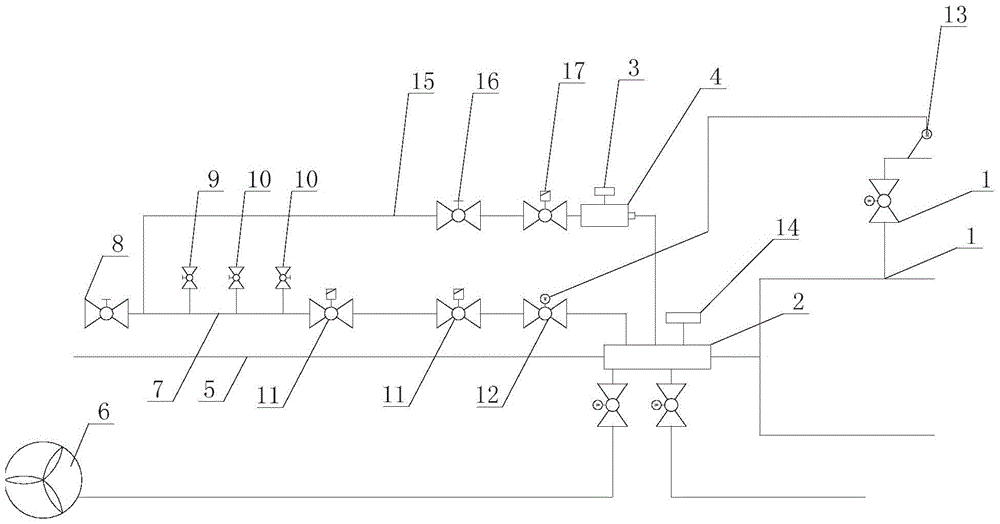

[0012] Specific implementation mode one: combine figure 1 Describe this embodiment. A gas-solid dual-fired low-nitrogen burner described in this embodiment includes a dual-fired hot water boiler 1, a dual-fuel left burner 2, an igniter 3, an ignition burner 4, and a pulverized coal delivery pipeline 5. Combustion blower 6 and natural gas delivery pipeline 7, dual-fuel left burner 2 is connected with dual-fired hot water boiler 1, pulverized coal delivery pipeline 5 and natural gas delivery pipeline 7 are connected with dual-fuel left burner 2, igniter 3 is installed on In the ignition burner 4, the ignition burner 4 is connected to the natural gas delivery pipeline 5 through the pipeline, the combustion blower 6 is connected to the dual-fuel left burner 2 through the pipeline, and the dual-fuel left burner 2 is connected to the clean flue gas at the tail of the boiler through the pipeline plumbing connections.

specific Embodiment approach 2

[0013] Specific implementation mode two: combination figure 1 To illustrate this embodiment, a manual valve 8 is provided at the inlet end of the natural gas delivery pipeline 7 of a gas-solid dual-fuel low-nitrogen burner described in this embodiment. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination figure 1 To illustrate this embodiment, a pressure gauge 9, two pressure switches 10, two A safety cut-off solenoid valve 11 and an electric regulating valve 12. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com