Double-hopper and double-fuel-layer layer-burning incineration device for village and town domestic garbage

A domestic waste and dual-fuel technology is applied in the field of dual-hopper dual-fuel layer township domestic waste layer incineration equipment, which can solve the problem that the incineration equipment is not suitable for burning township domestic waste, and is conducive to burning out, ensuring combustion, and running smoothly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

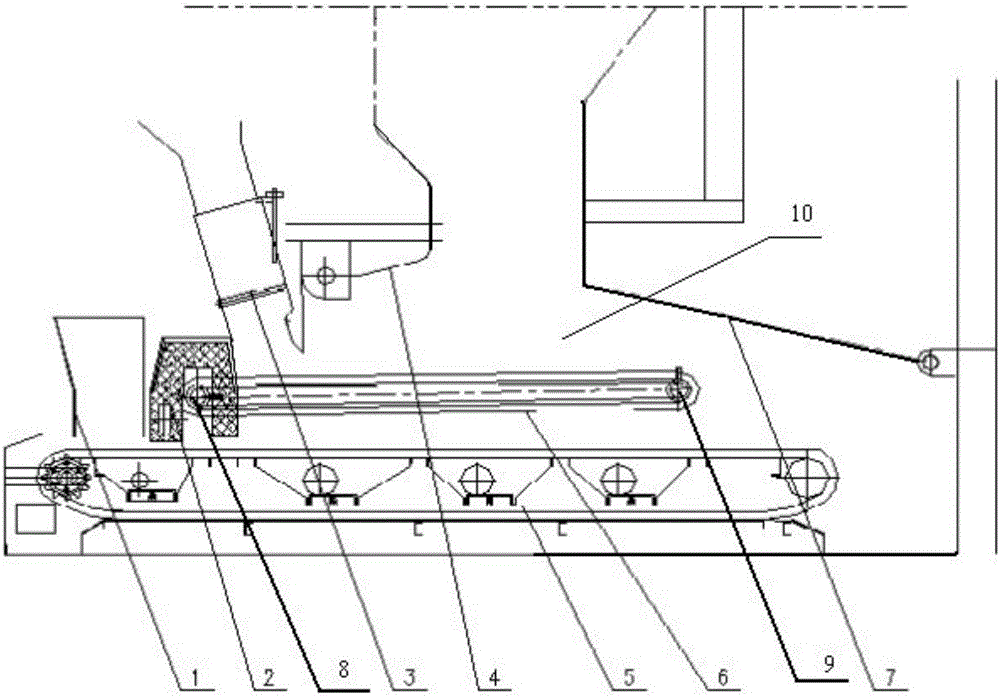

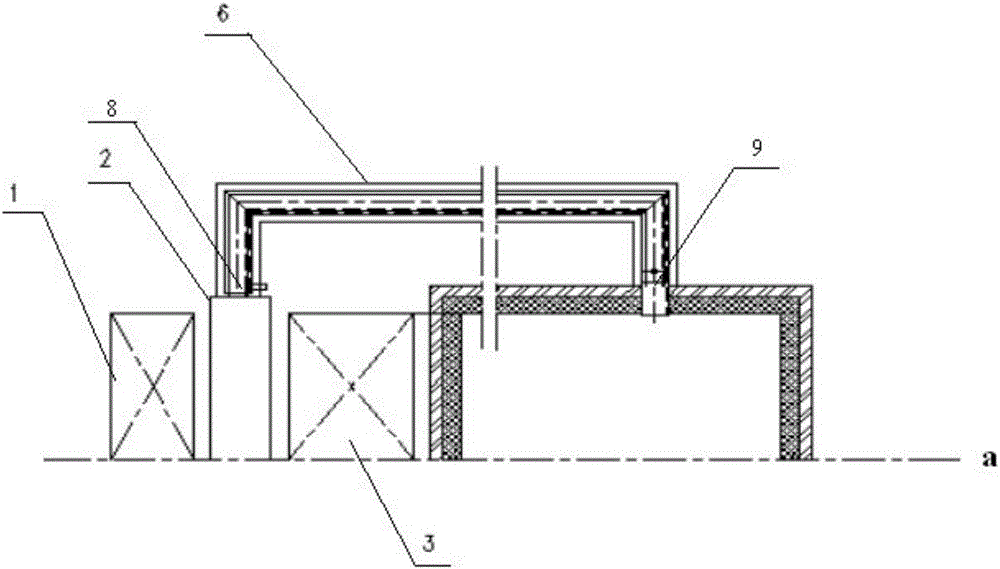

[0018] Specific Embodiment 1: In this embodiment, the double-hopper double-fuel layer township domestic waste layer burning and incineration equipment includes a chain grate 5, a briquette feed hopper 1, a pre-combustion chamber 2, a pre-combustion chamber flue 6, a domestic waste hopper 3 and There is a furnace 10 with a front arch 4 and a rear arch 7; a briquette feed hopper 1 is provided above the front end of the chain grate 5, and a household garbage hopper is provided between the front arch 4 and the briquette feed hopper 1 3 and the pre-combustion chamber 2, the pre-combustion chamber 2 is located between the domestic garbage hopper 3 and the briquette feed hopper 1; the outer wall of the pre-combustion chamber 2 is provided with a smoke exhaust port 8, and the side wall of the furnace 10 below the rear arch 7 There is a smoke inlet 9, and the smoke exhaust port 8 and the smoke inlet 9 communicate through the pre-chamber flue 6.

[0019] In this embodiment, the pre-comb...

specific Embodiment approach 2

[0027] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the temperature of the pre-combustion chamber 2 is 400-500°C. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the method of heating the pre-combustion chamber is: a heating chamber is set in the pre-combustion chamber 2 to increase the chamber temperature by burning wood. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com