W-shape flame furnace with gradation coal burner

A combustion device, thick and thin pulverized coal technology, applied to the flame furnace. It can solve problems such as poor adaptability of coal types, poor flame stability, and slagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

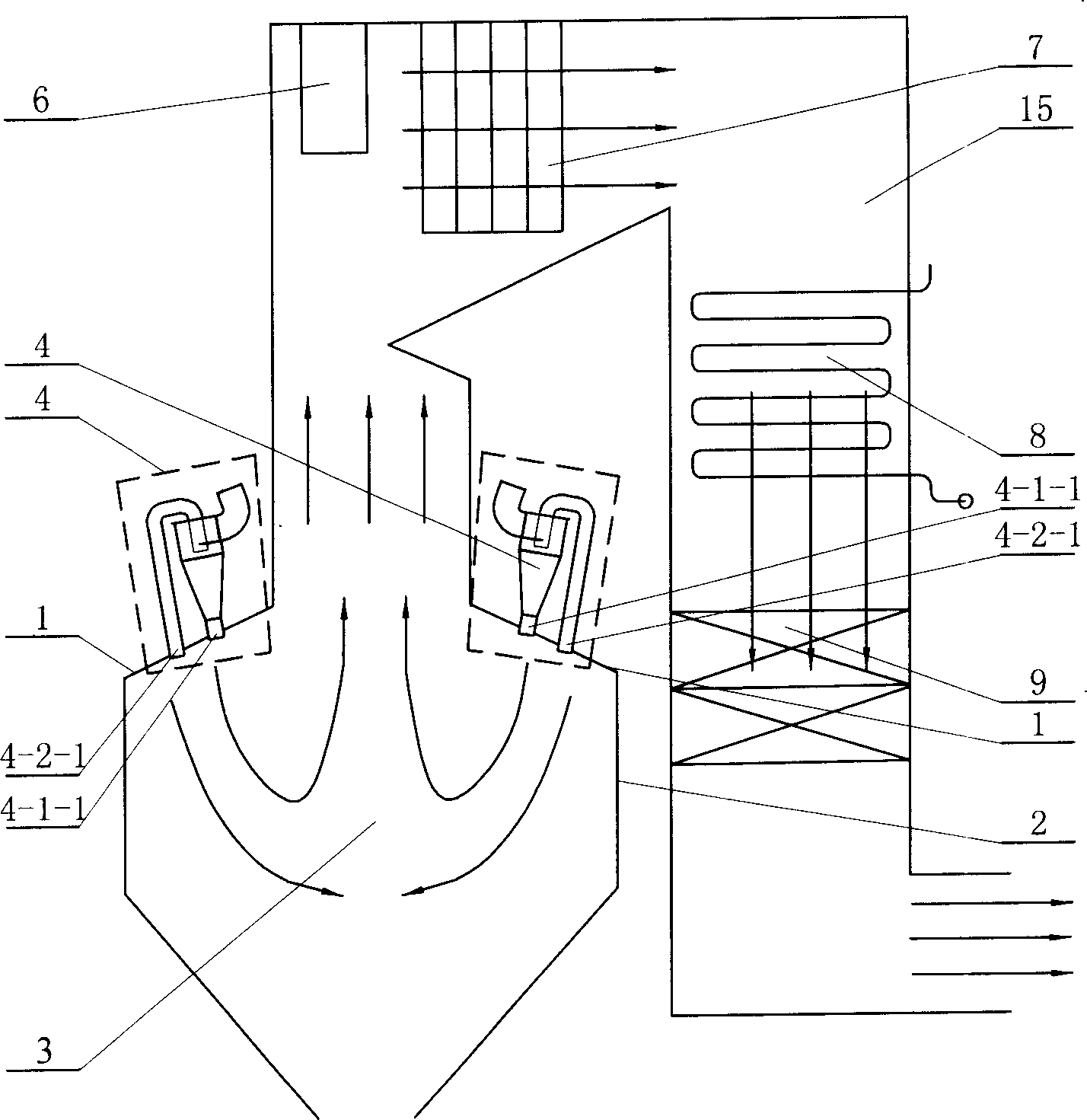

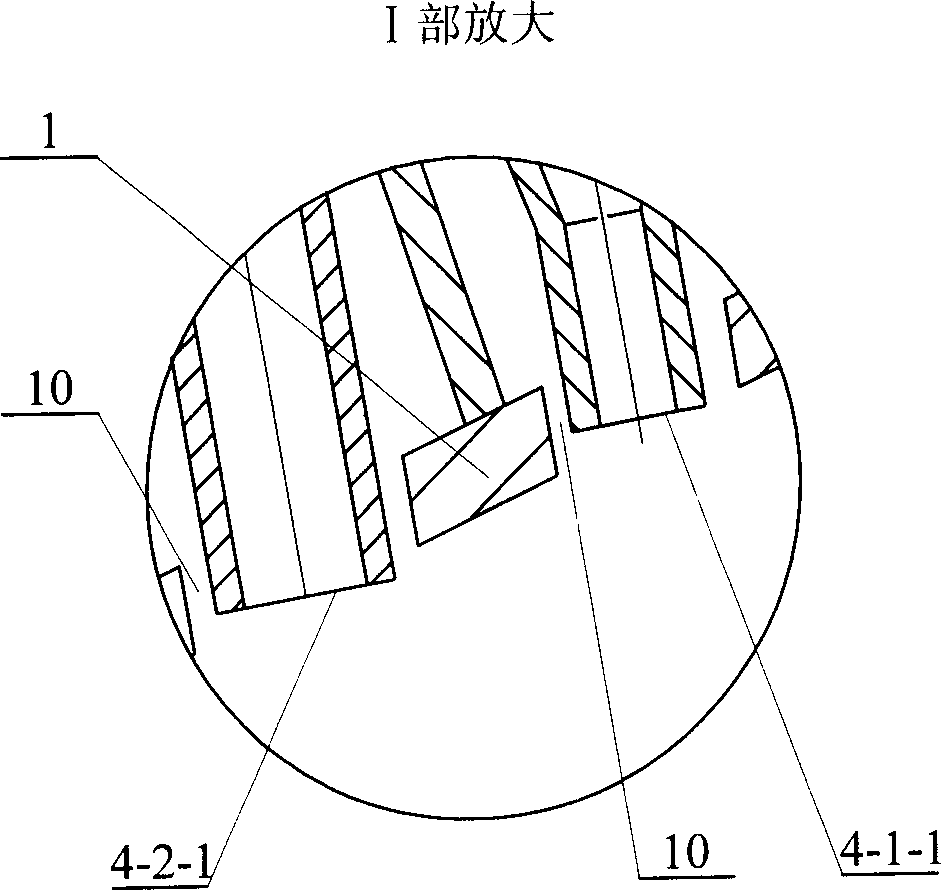

[0005] Specific embodiment 1: This embodiment includes a furnace arch 1, a side wall 2, a furnace 3 surrounded by a furnace arch 1 and a side wall 2, and a burner 4, and the burner 4 includes a burner 4-1 with a dense coal powder flow -1 and light coal powder flow burner 4-2-1, the thick coal powder flow burner 4-1-1 is arranged near the center of the furnace 3, and the light coal powder flow burner 4-2-1 is close to the side wall 2 set up. Since the burner 4-1-1 of the dense coal powder flow is close to the center of the furnace 3, the injected dense coal gas flow is close to the high temperature area in the center of the furnace. The purpose of timely ignition and stable combustion. Since the light coal powder flow nozzle 4-2-1 is close to the side wall 2, the injected light coal powder flow is close to the side wall of the furnace, thereby forming an oxidizing atmosphere near the water wall, which greatly increases the melting temperature of the ash , to avoid slagging of...

specific Embodiment approach 2

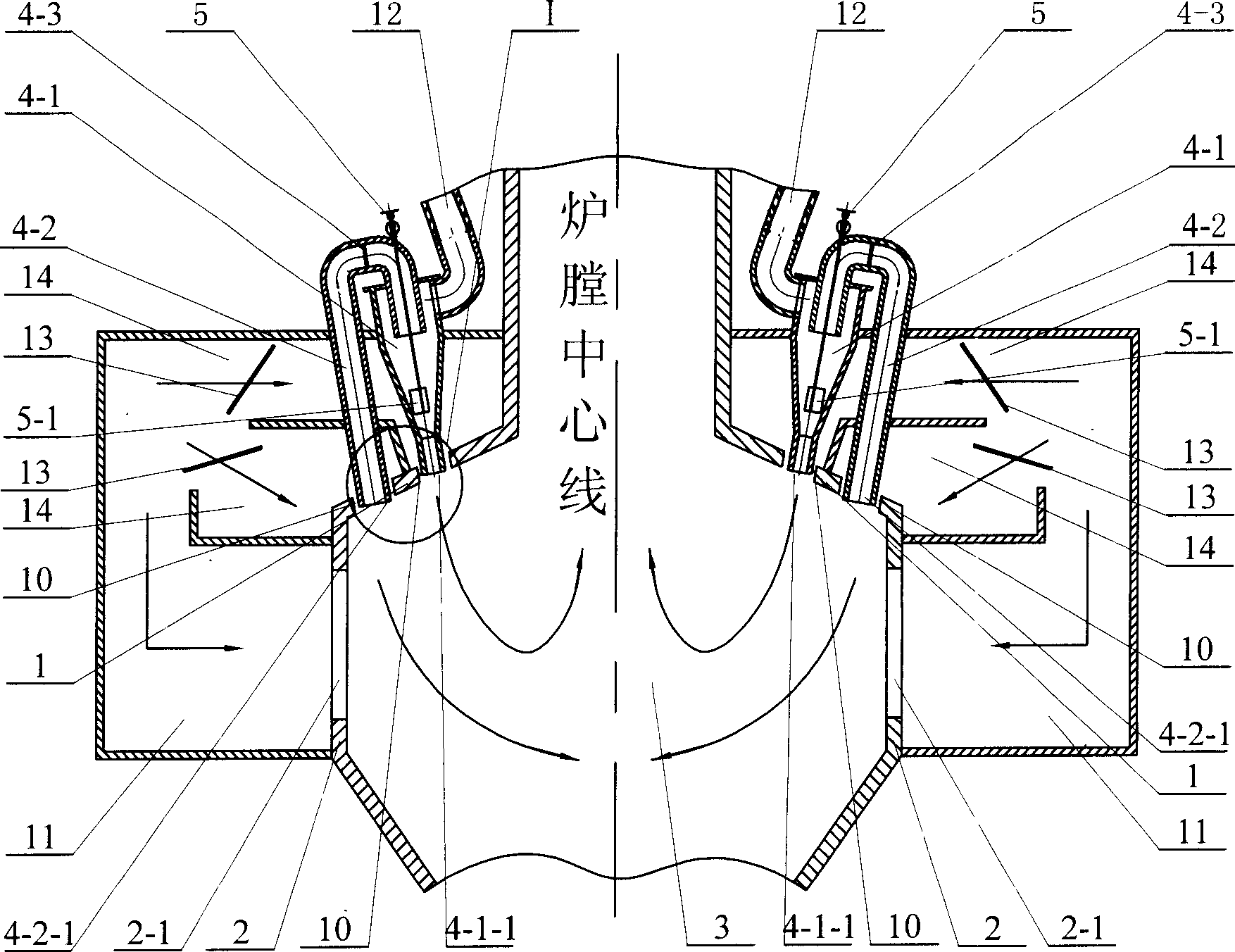

[0006] Specific embodiment two: In addition to the problems of unstable combustion, furnace wall slagging and high-temperature corrosion, existing combustion devices also have NO x The effect of reducing emissions is not obvious. refer to figure 2 , the burner 4 of this embodiment is formed by connecting the cyclone 4-1 and the exhaust pipe 4-2, the lower end of the cyclone 4-1 is a burner 4-1-1 for the dense coal powder flow, and the exhaust The lower end of the trachea 4-2 is a light coal powder flow burner 4-2-1, and the thick coal powder flow burner 4-1-1 and the light coal powder flow burner 4-2-1 are all arranged on the furnace arch 1 Above, wherein, the dense coal powder flow burner 4-1-1 is close to the center of the furnace 3, the light coal powder flow burner 4-2-1 is close to the side wall 2, and the cyclone 4-1 is equipped with a blade 5 -1 adjustment lever 5 to adjust the air swirl degree. The gap between the outlet of the light pulverized coal air flow burner...

specific Embodiment approach 3

[0008] Specific implementation mode three: refer to image 3 , the thick pulverized coal air flow burner 4-1-1 of the present embodiment is arranged on the furnace arch 1, and the light pulverized coal air flow burner 4-2-1 is arranged on the side wall 2, thereby making the thick pulverized coal flow The distance between burner 4-1-1 and light coal powder air flow burner 4-2-1 is further increased, which delays the mixing of airflow and further strengthens the effect of thick and thin combustion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com