Coal-powder boiler oxygen-enriched combustion smoke near-zero emission and power generation system

An oxygen-enriched combustion and near-zero emission technology, applied in the field of coal-fired boilers in power stations, can solve problems such as recycling, increasing operating costs, and resource waste, and achieve the effects of reducing scaling, slowing down the greenhouse effect, and improving commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

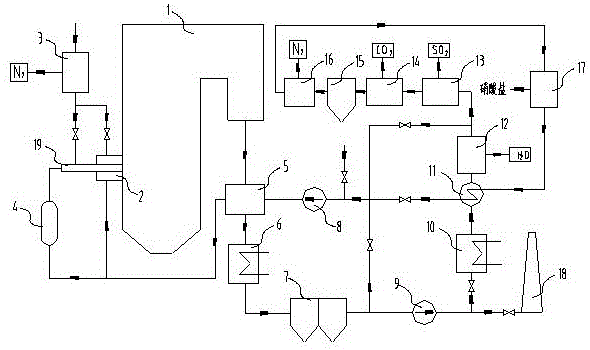

[0025] figure 1 It is an example of a pulverized coal furnace oxygen-enriched combustion flue gas near-zero emission power generation system. The pulverized coal furnace oxygen-enriched combustion flue gas near-zero emission power generation system consists of a boiler (1), a burner (2), an air separation device (3), and a system. Powder system (4), flue gas preheater (5), low temperature heat exchanger (6), dust collector (7), recirculation fan (8), induced draft fan (9), ultra-low temperature heat exchanger (10), Condensation heat exchanger (11), dehydration device (12), SO2 separation device (13), CO2 capture device (14), filter dust collector (15), N 2 Separator (16), NOx reaction device (17) and chimney (18).

[0026] The air separation device (3) is connected with the burner (2) and the primary air pipe (19), and the separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com