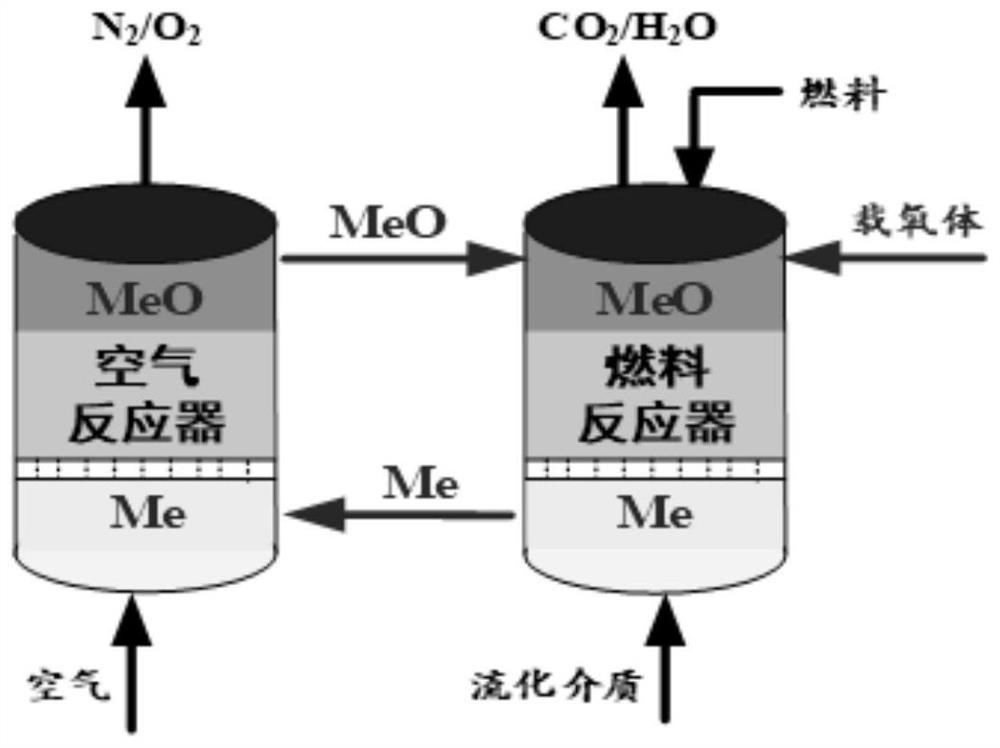

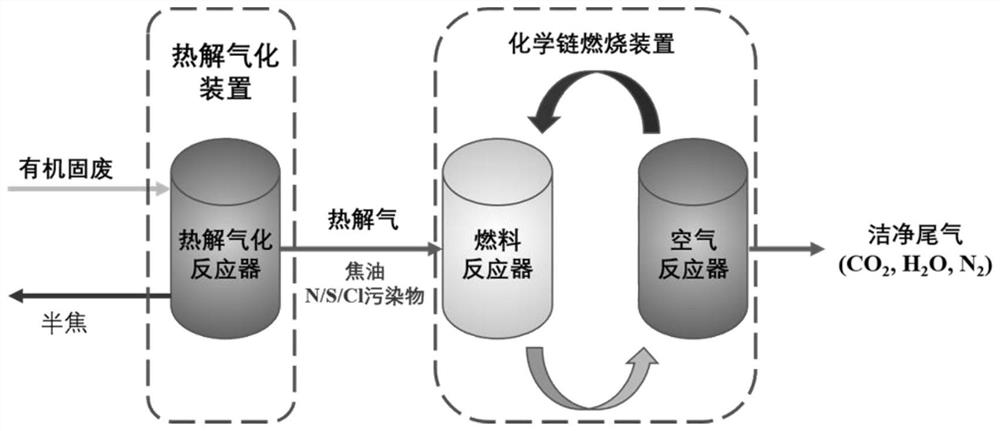

A method and device for removing pollutants by thermally decoupled chemical chain combustion of organic solid waste

A chemical chain combustion, organic solid waste technology, applied in the combustion method, combustion type, incinerator, etc., can solve the problems of reducing the cyclic reaction activity and life of the oxygen carrier, sintering and corrosion of the oxygen carrier, and improving the removal performance. , Improve the service life, the effect of small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

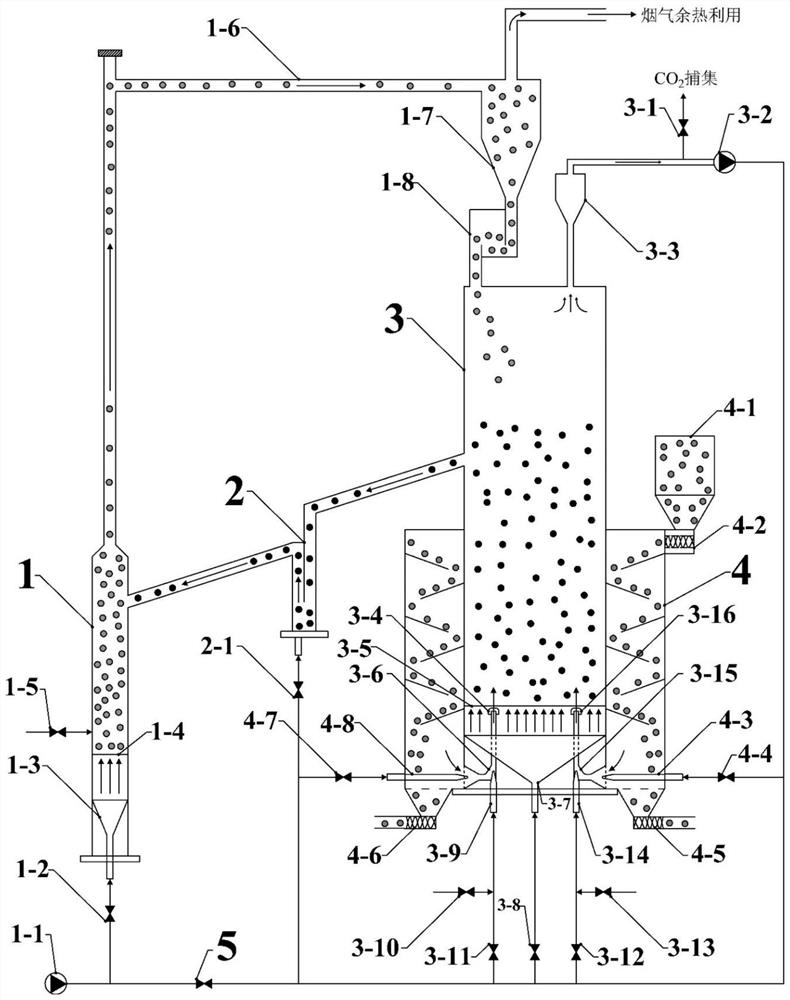

[0046] A method for organic solid waste thermal decoupling chemical chain combustion to remove pollutants is realized by the above-mentioned device for organic solid waste thermal decoupling chemical chain combustion to remove pollutants, comprising the following steps:

[0047] S1: Place the 5% Ca-loaded iron ore oxygen carrier in the air reactor 1, U-shaped reverter 2, oxygen carrier reverter 1-8 and fuel reactor 3, respectively, and start the air booster supplying air. Compressor 1-1, uses air as fluidizing gas, opens air switching valve 5, and controls air control valve 1-2, return gas control valve 2-1, first jet gas control valve 3-11, fluidizing The gas control valve 3-8 and the second jet gas control valve 3-12 control the gas flow rate of the air reactor 1, the fuel reactor 3, the U-shaped return material 2 and the oxygen carrier return material 1-8 to realize the oxygen carrier Circulation fluidization of the body;

[0048]S2: Open the second natural gas control val...

Embodiment 2

[0052] The difference from Example 1 is that the oxygen carrier is changed to a 5% K-supported iron ore oxygen carrier.

Embodiment 3

[0054] The difference from Example 1 is that the oxygen carrier is changed to a 5% Na-supported iron ore oxygen carrier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com