Device for treating high ammonia-nitrogen wastewater integrated with solid-phase denitrifying coupled membrane bioreactor and method

A membrane bioreactor, solid-state reverse nitrification technology, applied in biological water/sewage treatment, sustainable biological treatment, chemical instruments and methods, etc., can solve the problems of complicated system operation, increased denitrification cost, small amount or excess, etc. Achieve the effect of improving system nitrification efficiency, facilitating reproduction and growth, and reducing floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

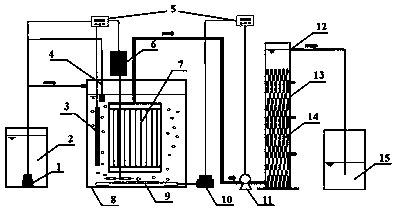

[0035] device see attached figure 1 , a solid phase nitrification coupling membrane bioreactor integrated high ammonia nitrogen wastewater treatment device, equipped with cube membrane bioreactor and cylindrical solid phase nitrification reactor, water inlet system, stirring system, aeration system, temperature control system, Outlet system and automatic control system, membrane bioreactor 8 is equipped with submerged membrane module 7, aeration disc 9, stirring device 6, temperature controller 3 and liquid level controller 4, liquid level controller 4 controls the pump 1. Pump the high-ammonia-nitrogen waste water in the raw water tank 2 into the membrane bioreactor 8 during the 2 min water intake stage; the aeration pump 10 continuously supplies oxygen through the aeration disc 9; the reactor sludge is fluidized through the stirring device 6; The water from the membrane bioreactor is pumped into the cylindrical solid phase nitrification reactor 13 through the peristaltic pum...

Embodiment 2

[0042] device see attached figure 1 , a solid phase nitrification coupling membrane bioreactor integrated high ammonia nitrogen wastewater treatment device, equipped with cube membrane bioreactor and cylindrical solid phase nitrification reactor, water inlet system, stirring system, aeration system, temperature control system, Outlet system and automatic control system, membrane bioreactor 8 is equipped with submerged membrane module 7, aeration disc 9, stirring device 6, temperature controller 3 and liquid level controller 4, liquid level controller 4 controls the pump 1. Pump the high-ammonia-nitrogen waste water in the raw water tank 2 into the membrane bioreactor 8 during the 2 min water intake stage; the aeration pump 10 continuously supplies oxygen through the aeration disc 9; the reactor sludge is fluidized through the stirring device 6; The water from the membrane bioreactor is pumped into the cylindrical solid phase nitrification reactor 13 through the peristaltic pum...

Embodiment 3

[0049] device see attached figure 1 , a solid phase nitrification coupling membrane bioreactor integrated high ammonia nitrogen wastewater treatment device, equipped with cube membrane bioreactor and cylindrical solid phase nitrification reactor, water inlet system, stirring system, aeration system, temperature control system, Outlet system and automatic control system, membrane bioreactor 8 is equipped with submerged membrane module 7, aeration disc 9, stirring device 6, temperature controller 3 and liquid level controller 4, liquid level controller 4 controls the pump 1. Pump the high-ammonia-nitrogen waste water in the raw water tank 2 into the membrane bioreactor 8 during the 2 min water intake stage; the aeration pump 10 continuously supplies oxygen through the aeration disc 9; the reactor sludge is fluidized through the stirring device 6; The water from the membrane bioreactor is pumped into the cylindrical solid phase nitrification reactor 13 through the peristaltic pum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com