Coal slime drying treatment device

A drying treatment and coal slime technology, which is applied in the direction of drying gas arrangement, drying solid materials, and drying solid materials without heating, can solve the problems of insufficient drying of the inner layer, overheating and decomposition of the outer layer, and uneven heating of coal slime, etc., to achieve High sliver drying efficiency, environmental protection, and reduced splicing difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

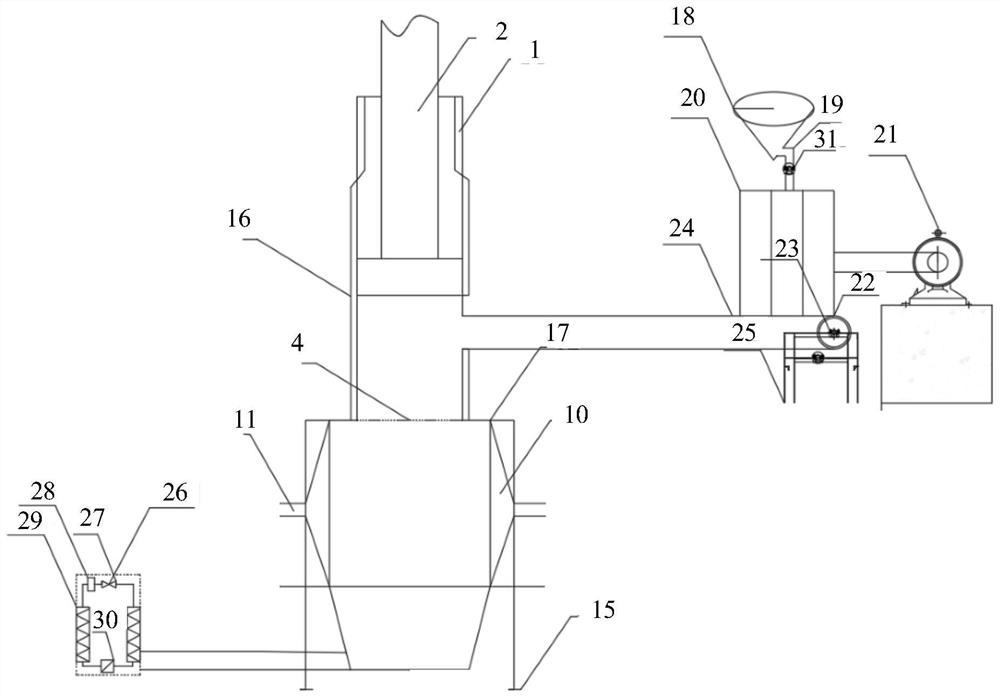

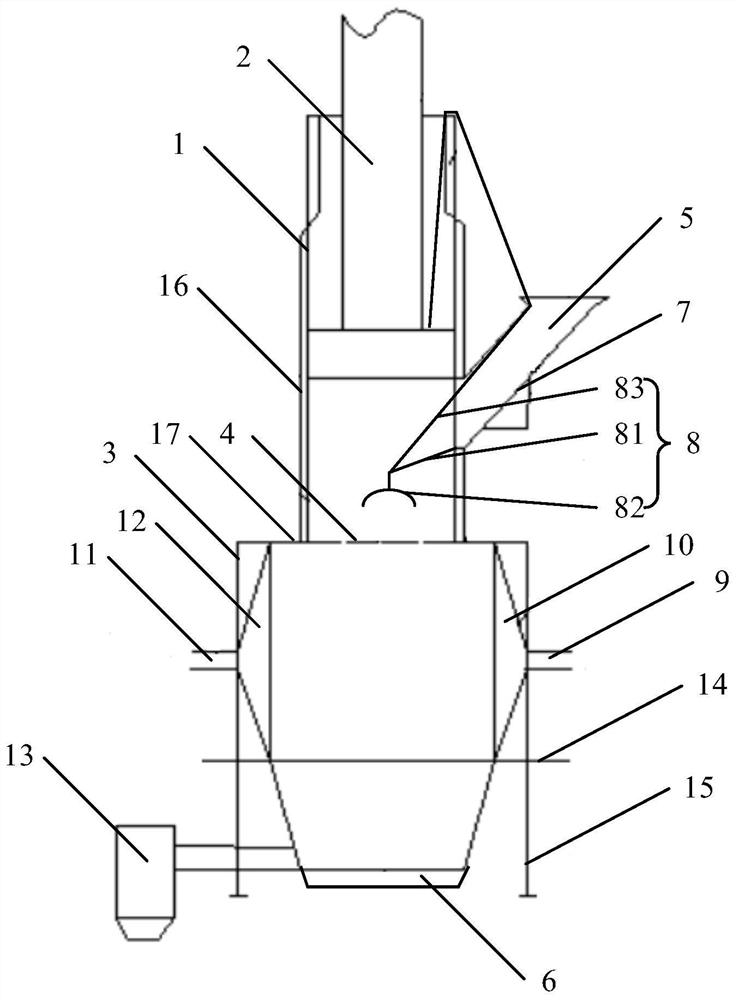

[0057] This embodiment provides a coal slime drying treatment device, see Figure 1 to Figure 2 , including a concentration unit, a filter press unit and a sliver drying unit connected in sequence, wherein the sliver drying unit includes an extrusion assembly, a drying assembly below the extrusion assembly, and a sliver hole between the extrusion assembly and the drying assembly Plate 4, wherein the extrusion assembly includes an extrusion cylinder 1 and a piston 2 located in the extrusion cylinder 1, the drying assembly includes a drying cylinder 3 and an air supply unit for providing dry gas in the drying cylinder 3, the extrusion cylinder 1 The space between the middle piston 2 and the sliver orifice 4 is an extrusion cavity, and the inside of the drying cylinder 3 is a drying cavity, the extrusion cavity communicates with the feed pipe 5, and the drying cylinder 3 communicates with the discharge pipe 6; Vertically, the piston 2, extrusion chamber, sliver orifice 4, and dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com