Continuous annealing furnace with shielding gas recovery function

A technology of continuous annealing furnace and protective gas, which is applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of wasting resources and achieve energy saving, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

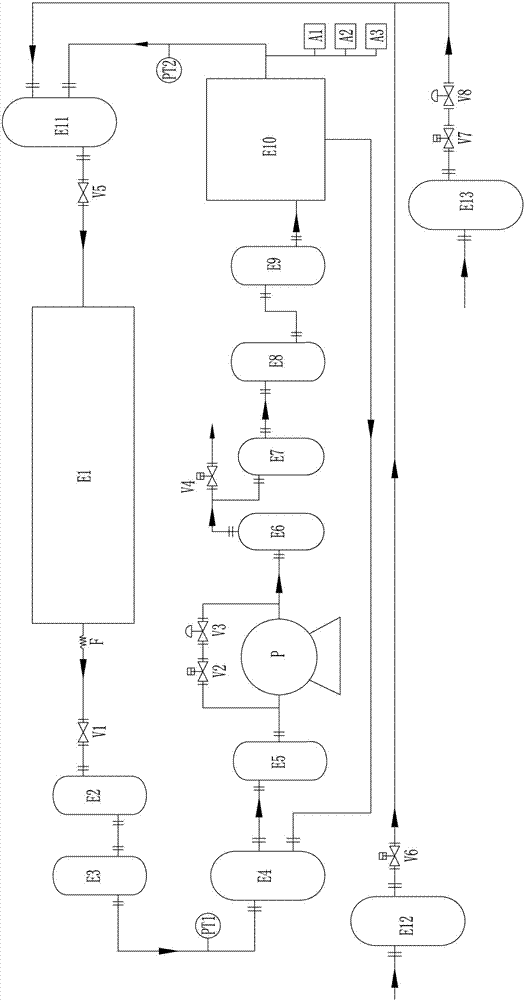

[0022] Embodiment one: as attached figure 1 As shown, a continuous annealing furnace with protective gas recovery function includes a furnace body E1 and a protective gas recovery and utilization device. The furnace body E1 has a shielding gas inlet for passing in the shielding gas and a shielding gas outlet for discharging the shielding gas, which are respectively located at both ends of the furnace body E1. The protective gas passed into the furnace body E1 is a mixed gas of hydrogen and nitrogen, while the protective gas discharged from the furnace body E1 contains a small amount of solid impurities (dust and fine particles), oxygen and other components, and the main components are hydrogen and nitrogen. The mixed gas (about 600 ℃).

[0023] The shielding gas recycling device connected to the furnace body E1 is used to purify the shielding gas discharged from the furnace body E1 and send it back to the furnace body E1 for recycling. The directly reused shielding gas is tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com