Regulation of an air spring

A technology of air spring and compressed air, which is applied in the direction of the relative movement between the chassis and the bogie, the railway car body parts, the bogie, etc., and can solve the problems affecting the height of the car bogie

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

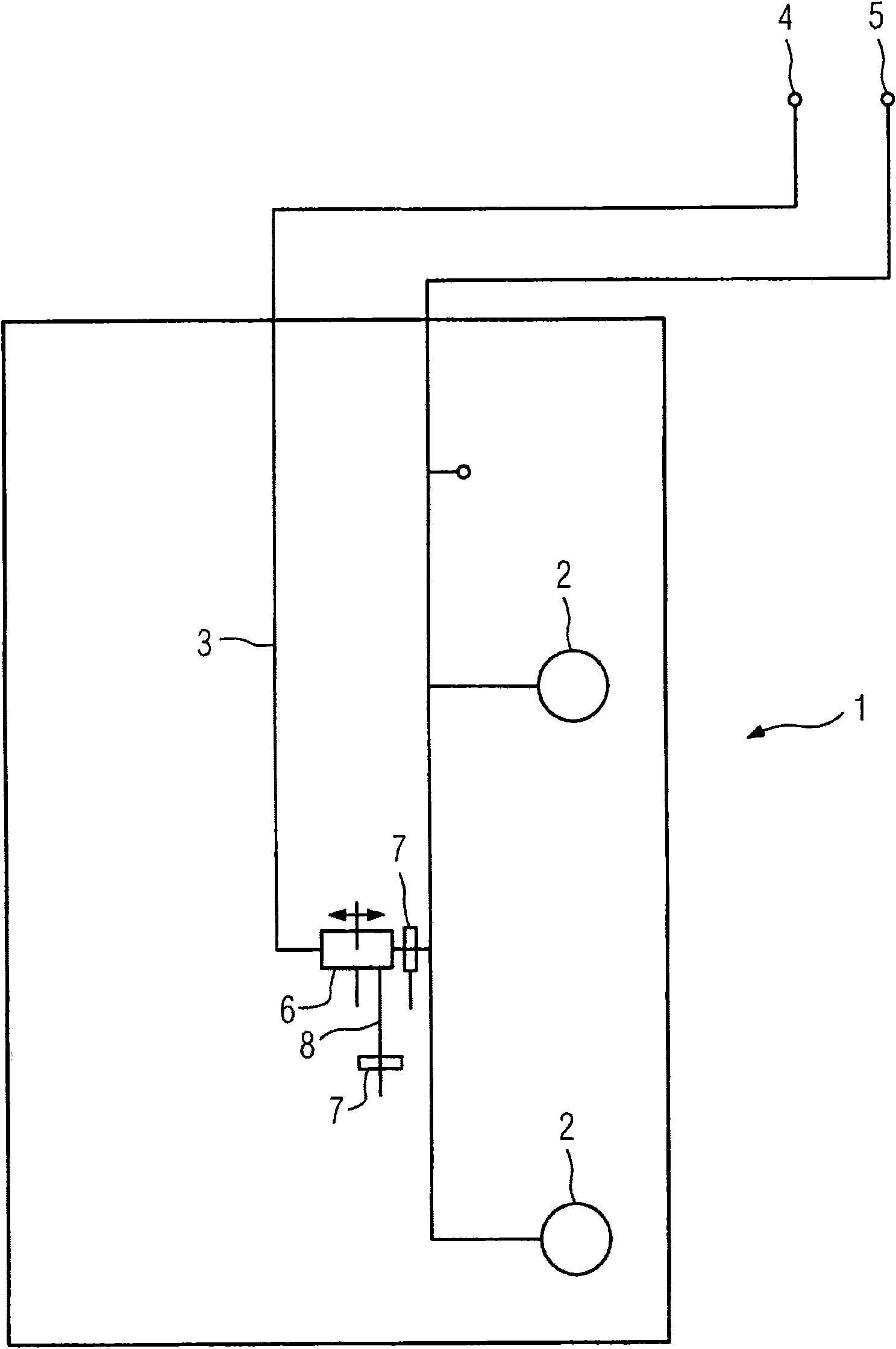

[0022] figure 1 An embodiment of a device 1 according to the invention is schematically shown in , which has an air spring 2 comprising two parts and fixed on figure 1 on bogies that are not visible in . The carriage body, also not shown, is supported on air springs 2 , wherein, in addition to a primary spring system, for example consisting of coil springs, the air spring 2 is arranged on the bogie to provide a spring and damping effect for the carriage body.

[0023] The air spring communicates via a compressed air line 3 with a compressed air source 4 which is only schematically shown in the figure. The weight or load of the vehicle body is detected by the measuring sensor 5, whereby the pressure in the air spring can be determined. By means of said pressure, the load of the pushed-out carriage can be returned. An air spring valve 6 is provided for regulating the pressure and volume of compressed air in the air spring 2 , wherein the air spring 2 is evacuated via the inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com