Bidirectional environment-friendly energy saving boiler with three return strokes

An environmentally friendly, energy-saving, three-pass technology, applied in the field of bituminous coal-fired boilers, can solve problems such as unreasonable structure, polluted air, and insufficient utilization of thermal energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

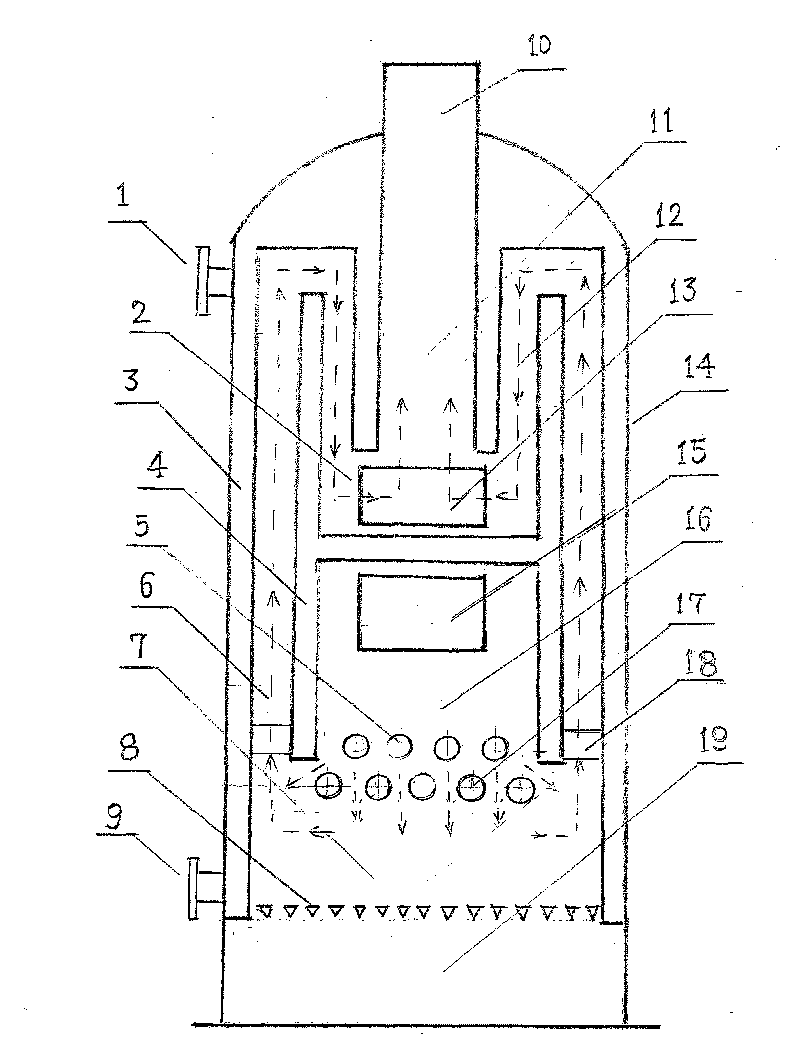

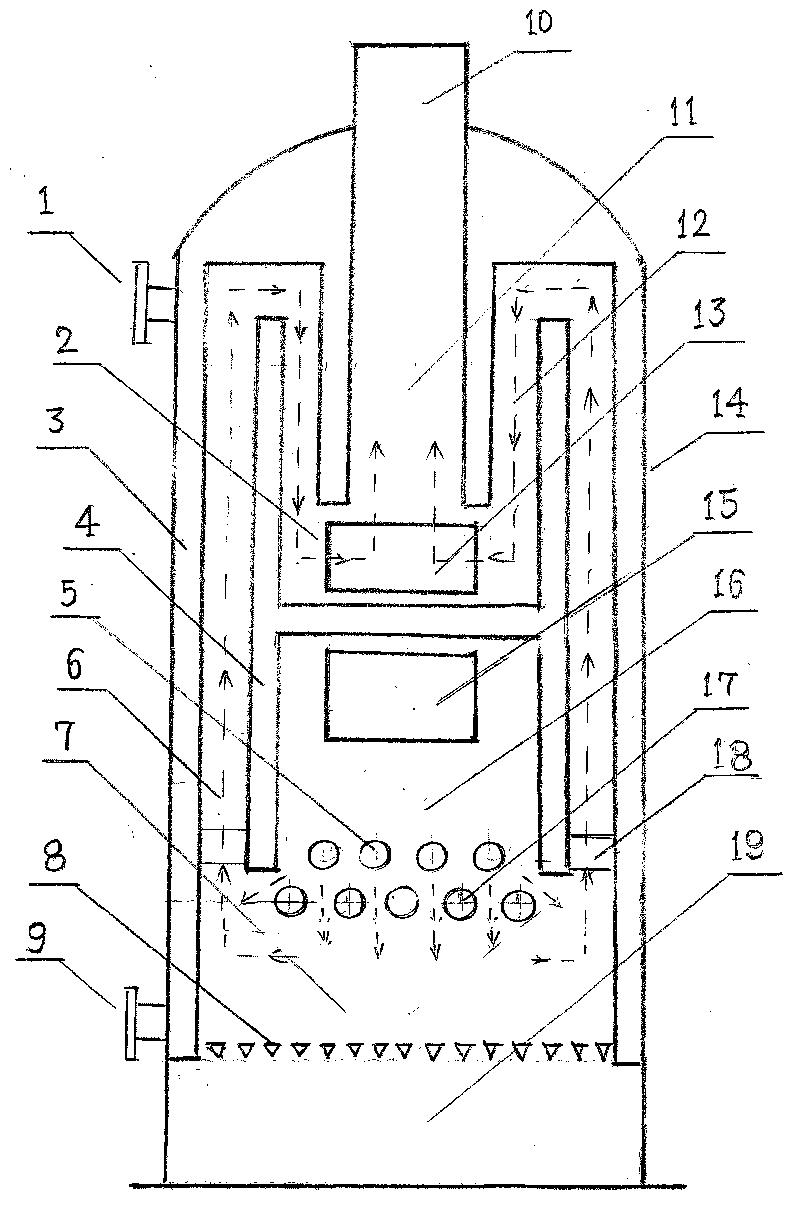

[0007] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0008] A two-way three-pass environmental protection and energy-saving boiler, such as figure 1 As shown, it includes the furnace body 14 composed of the outer water jacket 3 and the inner and outer cylinders, and an inner water jacket 4 is added in the furnace body 14. The inner water jacket 4 is divided into upper and lower parts, both of which are composed of an inner layer and an inner layer. The outer layer is composed of a coal charging door 15 in the lower part. Bituminous coal and combustible garbage are fed through the coal charging door 15 and enter the anti-burning chamber 16. Since the upper part of the anti-burning chamber is not connected with the chimney, it depends on the suction of the chimney outside. The burning flame burns downwards, and double-layer water tube furnace grates are arranged below the counter-burning chamber, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com