Lafutidine gastric-retention controlled-release composite

A lafutidine and controlled release technology, which is applied in the direction of drug combination, non-active ingredients of polymer compounds, drug delivery, etc., can solve the problems of incomplete absorption, low bioavailability, and limited clinical application of common oral dosage forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 (wet granule tabletting method)

[0047]

[0048] Preparation:

[0049] (1) Pulverize the raw materials and pass them through a 100-mesh sieve for later use.

[0050] (2) take the HPMC of recipe quantity K15M , stearic acid and microcrystalline cellulose are uniformly mixed to obtain a mixed controlled-release material.

[0051] (3) Using the "equivalent incremental" method, fully mix the prescribed amount of lafutidine with the mixed controlled-release material, add an appropriate amount of 70% ethanol solution to make soft material, pass through a 20-mesh sieve for granulation, and heat at 50-60°C dry.

[0052] (4) Pass the dry granules through a 20-mesh sieve and mix them evenly with sodium bicarbonate and magnesium stearate, determine the weight of the tablet, and press the tablet to control the hardness of the tablet to 60-80N.

[0053] Carry out in vitro floating test and in vitro release test according to the tablet prepared in Example 1, test...

Embodiment 2

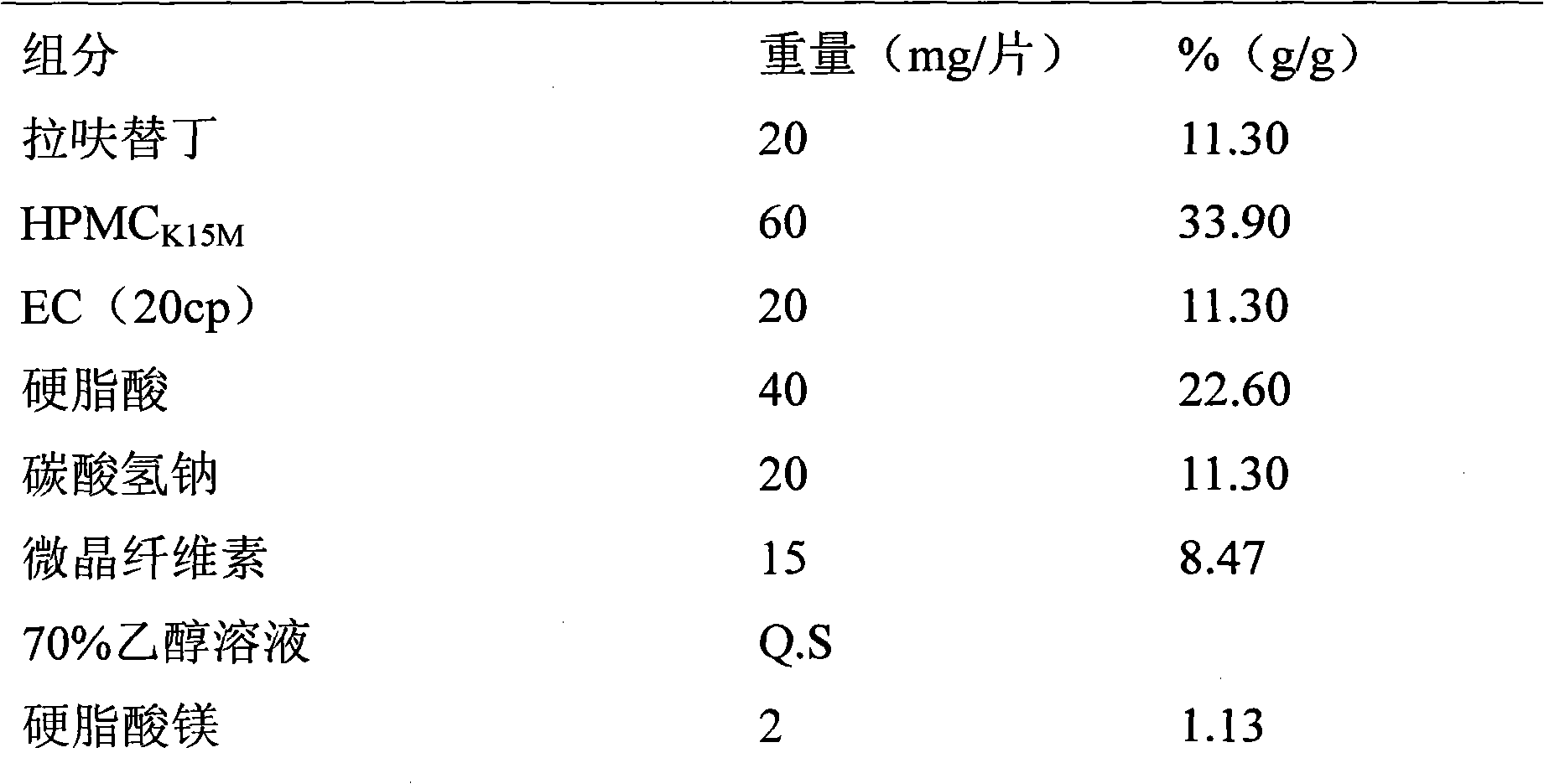

[0057] Embodiment 2 (dry granule tabletting method)

[0058] Component Weight (mg / tablet) % (g / g)

[0059] Lafutidine 20 11.30

[0060] HPMC K15M 60 33.90

[0061] EC(20cp) 20 11.30

[0062] Stearic acid 40 22.60

[0063] Sodium bicarbonate 20 11.30

[0064] Microcrystalline cellulose 15 8.47

[0065] Magnesium stearate 2 1.13

[0066] Preparation:

[0067] (1) Pulverize the raw materials and pass them through a 100-mesh sieve for later use.

[0068] (2) take the HPMC of recipe quantity K15M , stearic acid, sodium bicarbonate and microcrystalline cellulose are uniformly mixed to obtain a mixed controlled-release material.

[0069] (3) Using the "equivalent incremental" method, fully mix the prescribed amount of lafutidine with the mixed controlled-release material, and dry granulate.

[0070] (4) Pass the granules through a 20-mesh sieve and mix them evenly with magnesium stearate, determine the weight of the tablet, compress the tablet, and control the hardness of...

Embodiment 3

[0075] Embodiment 3 (powder direct compression tablet)

[0076] Component Weight (mg / tablet) % (g / g)

[0077] Lafutidine 20 11.30

[0078] HPMC K15M 60 33.90

[0079] EC(20cp) 20 11.30

[0080] Stearic acid 40 22.60

[0081] Sodium bicarbonate 20 11.30

[0082] Microcrystalline cellulose 15 8.47

[0083] Magnesium stearate 2 1.13

[0084] Preparation:

[0085] (1) Pulverize the raw materials and pass them through a 60-mesh sieve for later use.

[0086] (2) take the HPMC of recipe quantity K15M , stearic acid, sodium bicarbonate and microcrystalline cellulose are uniformly mixed to obtain a mixed controlled-release material.

[0087] (3) Using the "equivalent incremental" method, fully mix the prescribed amount of lafutidine with the mixed controlled-release material.

[0088] Determine the tablet weight, compress the tablet, and control the tablet hardness to 60-80N.

[0089] Carry out in vitro floating test and in vitro release test according to the tablet prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com