Gluing and pressing tool and method for rectangular prism

A right-angle prism and tooling technology, which is applied in installation, instrumentation, optics, etc., can solve problems such as the inability to ensure the complete alignment of the light-transmitting surface and the end surface, and the inability to ensure the consistency of the thickness of the adhesive layer, so as to achieve consistent displacement and consistent thickness of the adhesive layer , improve the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

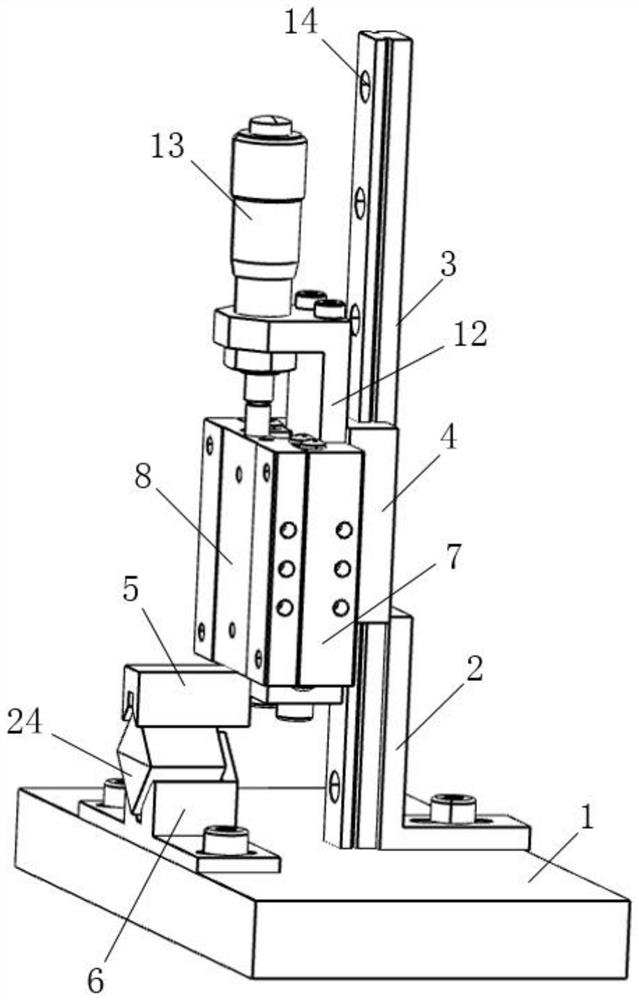

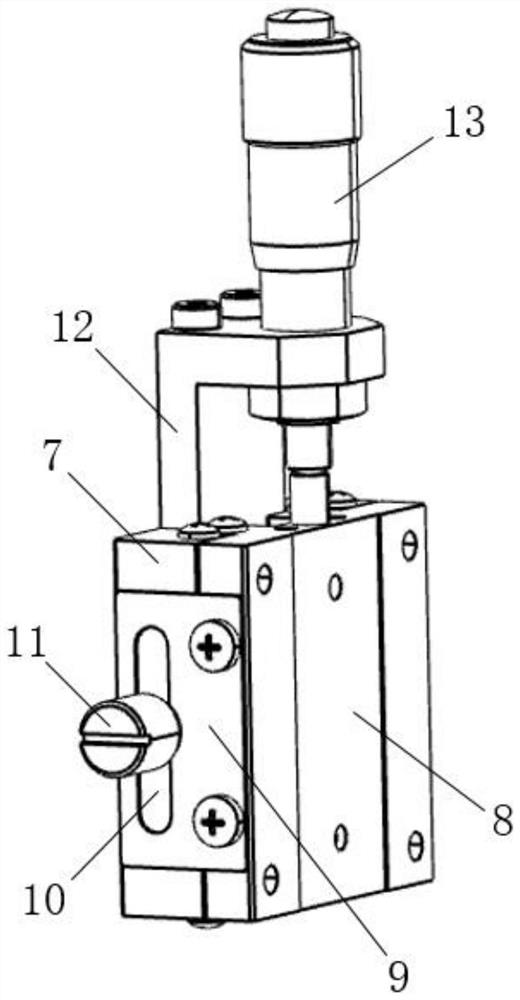

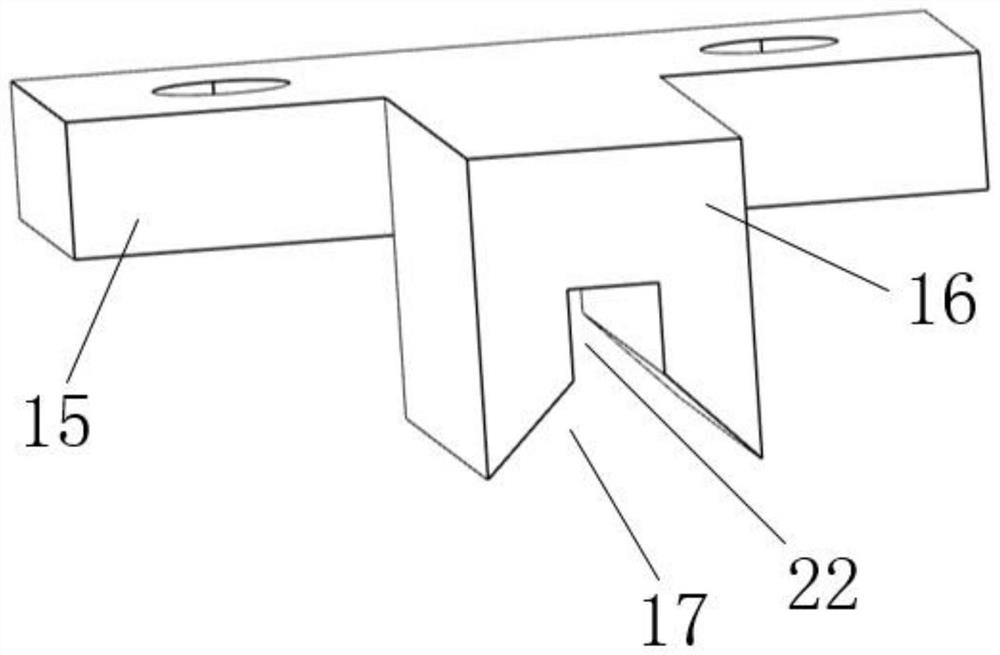

[0035] like figure 1 As shown, this embodiment provides a right-angle prism gluing and pressing tool, including a base 1, on which a vertical first sliding rail 3 is installed through a mounting frame 2 (L-shaped). A first sliding block 4 is slidably connected to the sliding rail 3; a vertical displacement table is fixedly installed on the first sliding block 4, and an upper positioning tool 5 is fixedly connected to the output end of the displacement table. The upper positioning tool 5 is driven to perform linear reciprocating motion along the vertical direction; the base 1 is provided with a lower positioning tool 6 , and the lower positioning tool 6 is located directly below the upper positioning tool 5 .

[0036] In this embodiment, the displacement table is slidably installed on the first slide rail 3 through the first slider 4, which can be adapted to right-angle prisms of different sizes; when pressing, the displacement table drives the upper positioning tool 5 to move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com