Quick die exchanging device

A fast and changing plate technology, applied in the field of printers, can solve problems such as cost increase and waste of resources, and achieve the effect of reducing development costs, fast changing models, and shortening equipment supply cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

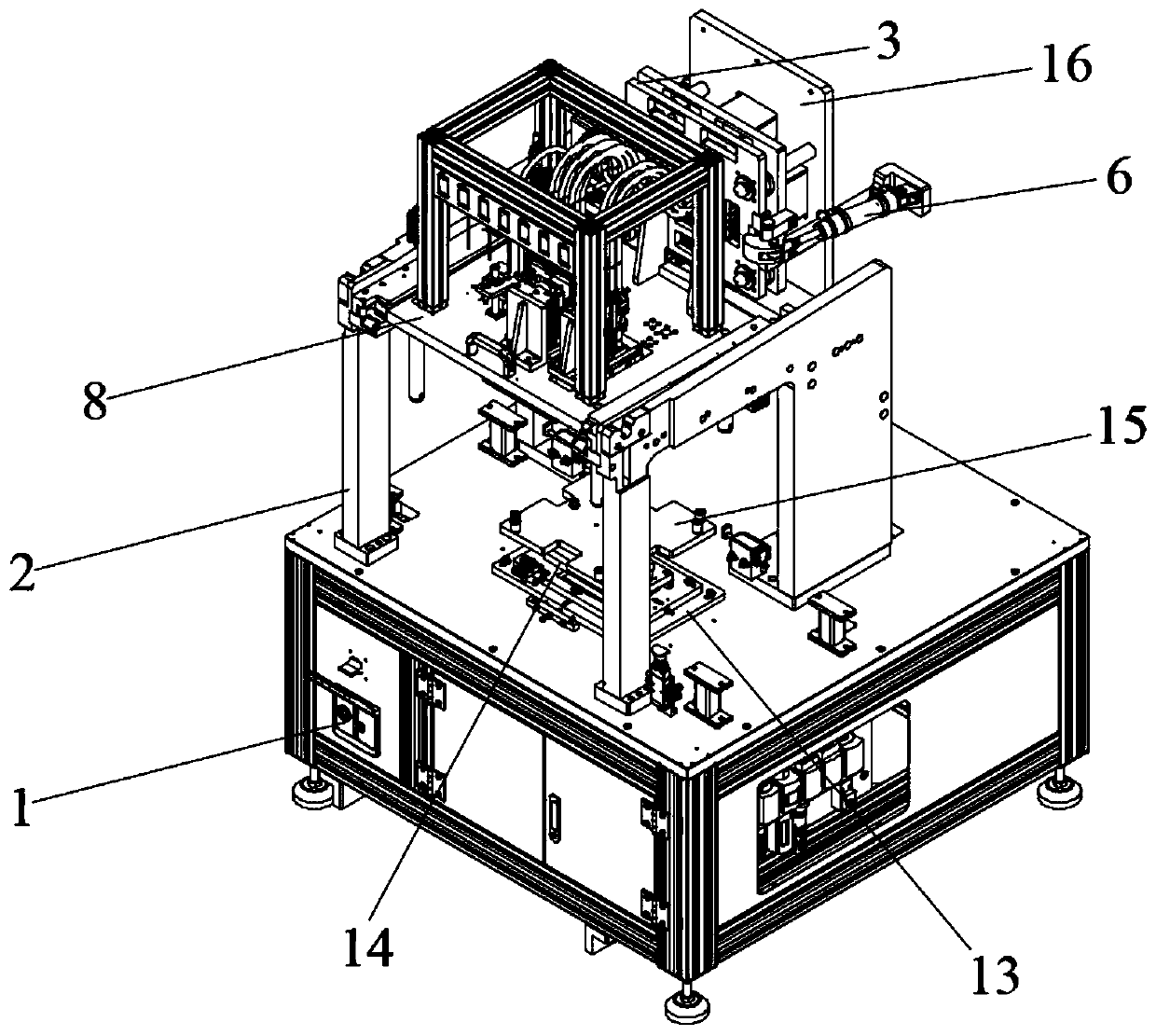

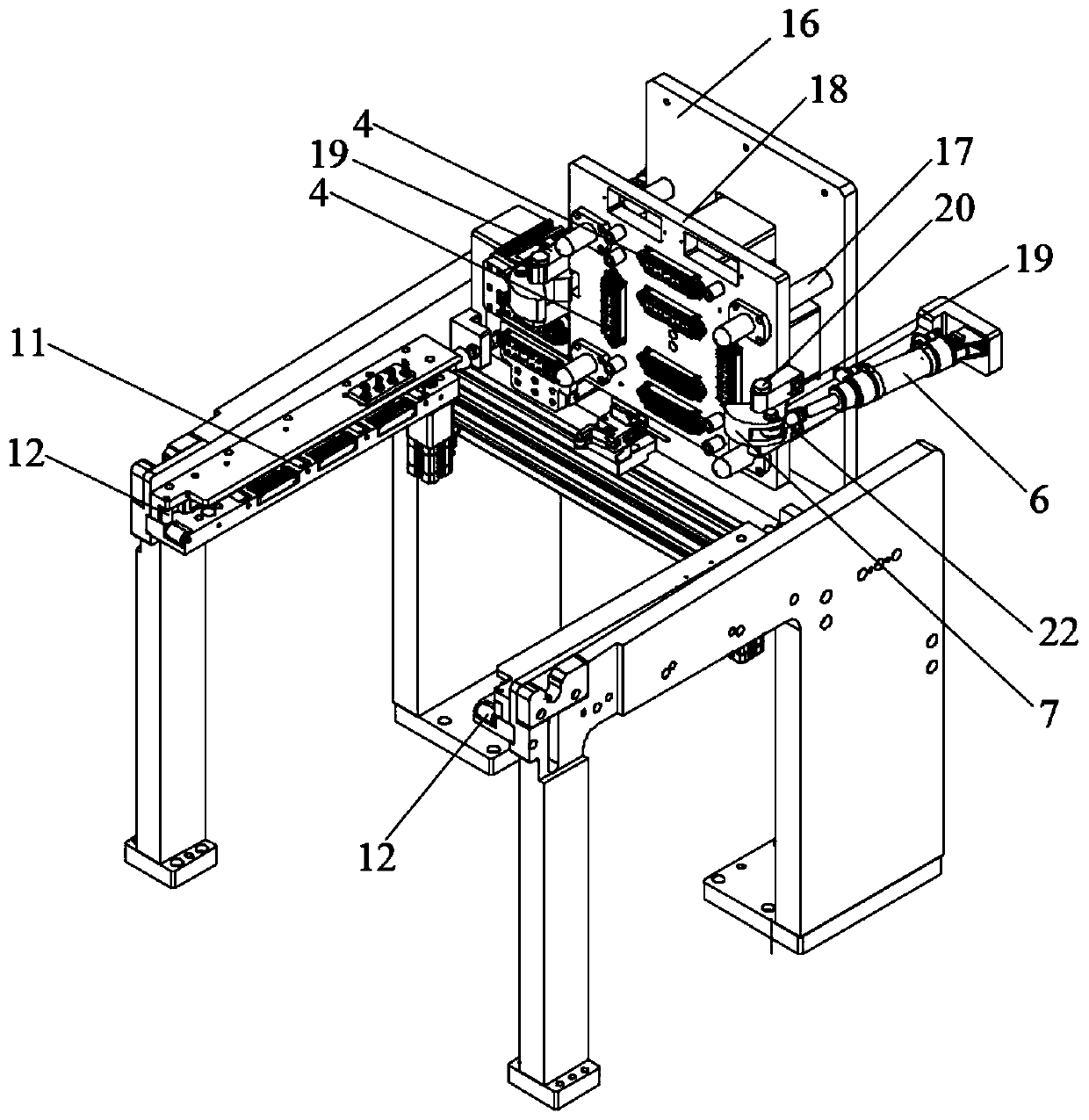

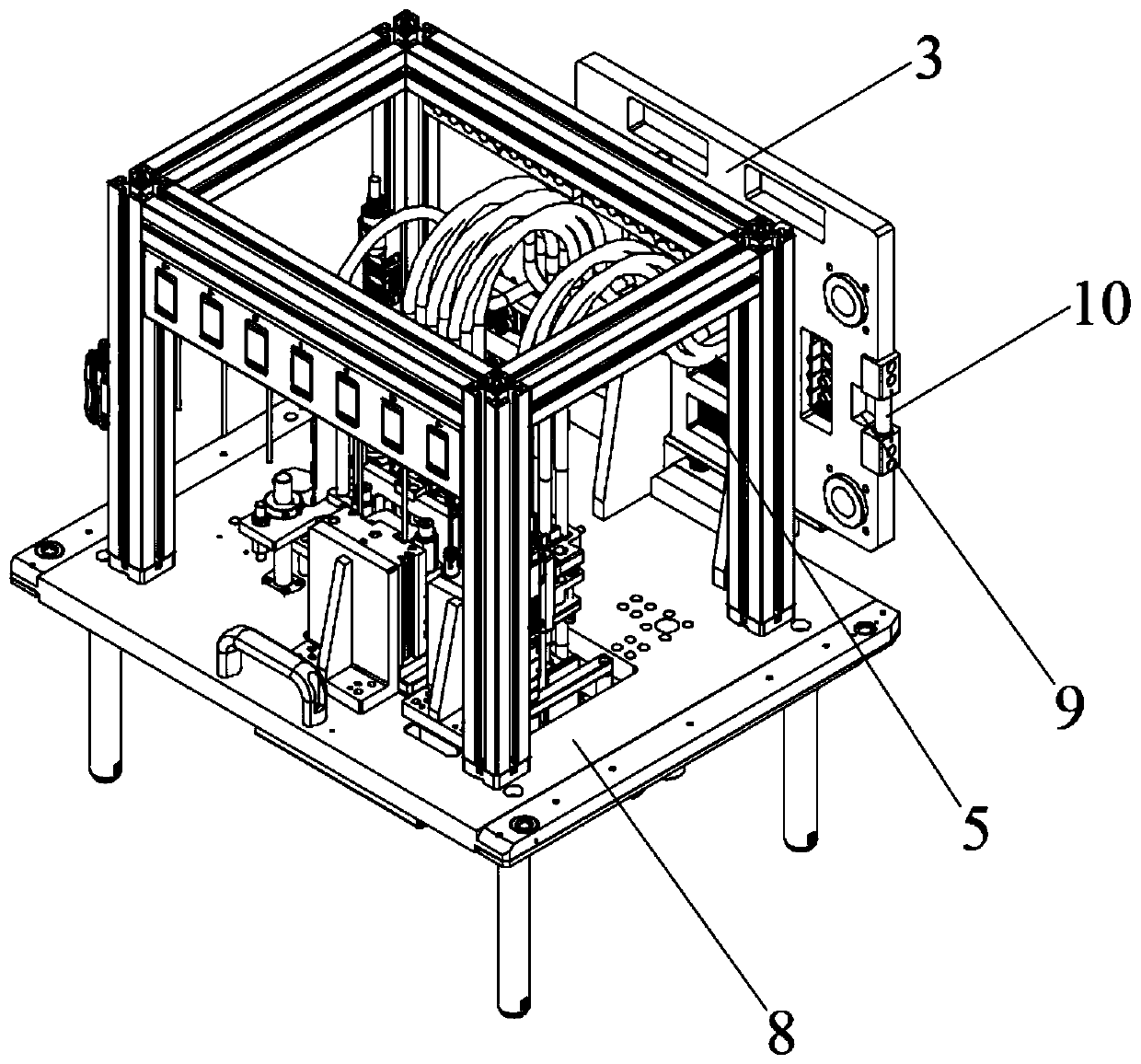

[0016] Such as Figure 1 ~ Figure 4 As shown, the present invention includes a frame 1, on which a remodeling seat 2 is mounted, and the remodeling plate assembly is assembled on the remodeling seat 2, and the remodeling plate assembly includes a remodeling plate 3, and the remodeling seat 2 is equipped with a gas electric An integrated female connector 4, a gas-electric integrated male connector 5 corresponding to the gas-electric integrated female connector 4 is installed on the changing plate 3, and a holding device is installed on the changing seat 2, and the holding device includes a telescopic cylinder installed on the changing seat 2 6. The telescopic cylinder 6 is connected with a clamping head 7, and the changing plate 3 is assembled on the changing seat 2 through the clamping head 7.

[0017] The type change plate assembly also includes a base plate 8, the type change plate 3 is fixed on the base plate 8, and is vertically arranged with the base plate 8, and the type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com