Patents

Literature

75 results about "Skid (automobile)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An automobile skid is an automobile handling condition where one or more tires are slipping relative to the road, and the overall handling of the vehicle has been affected.

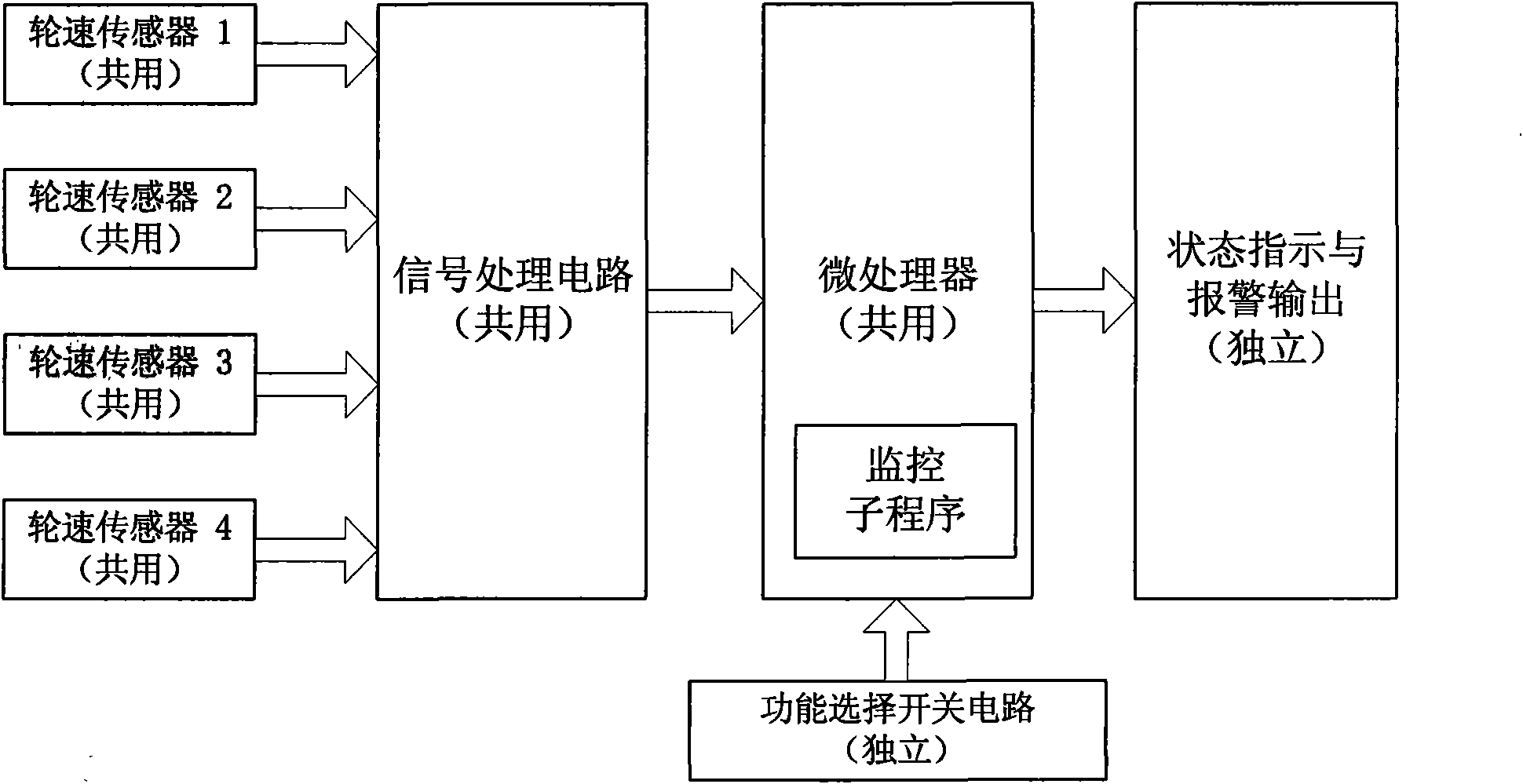

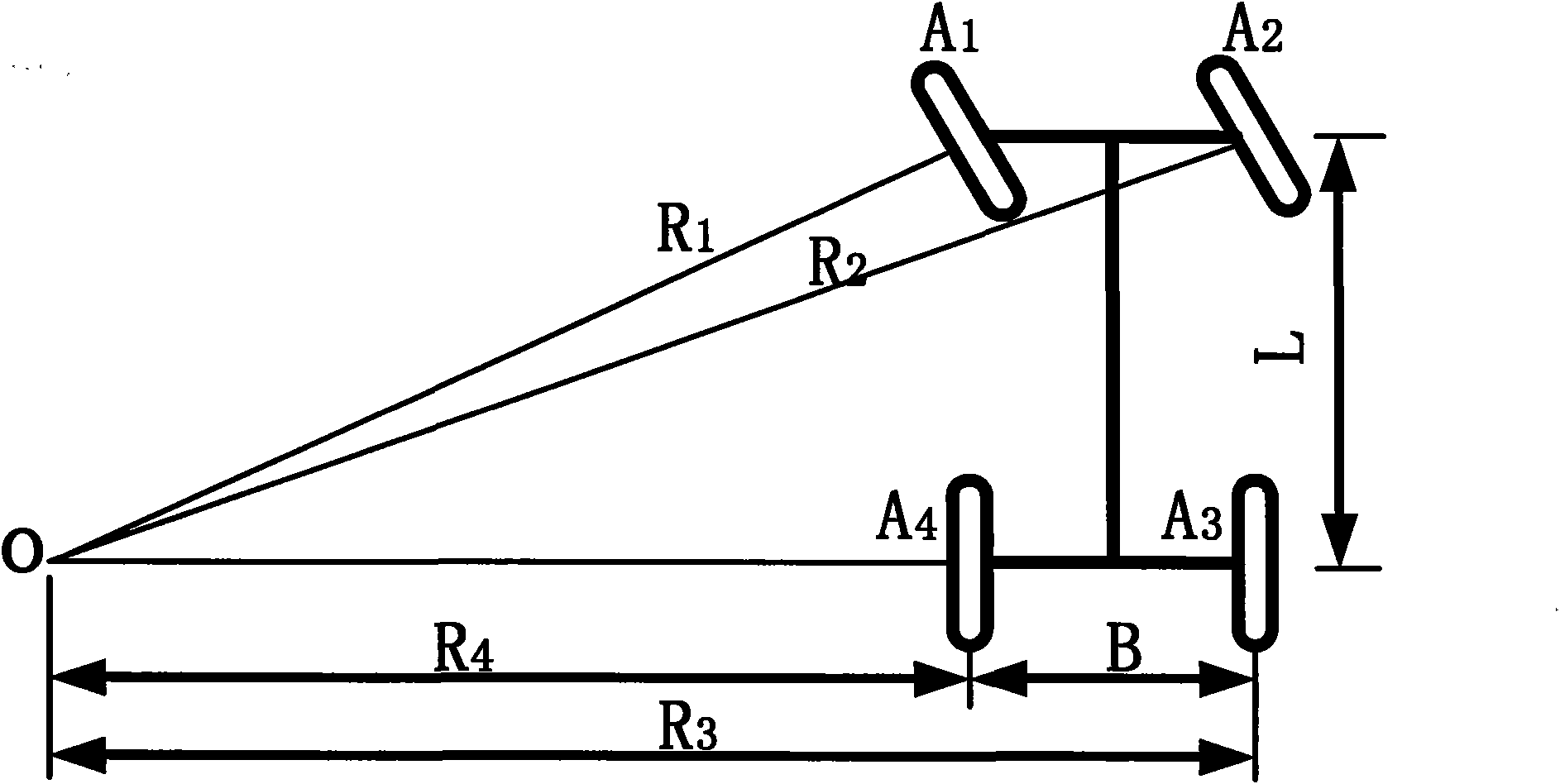

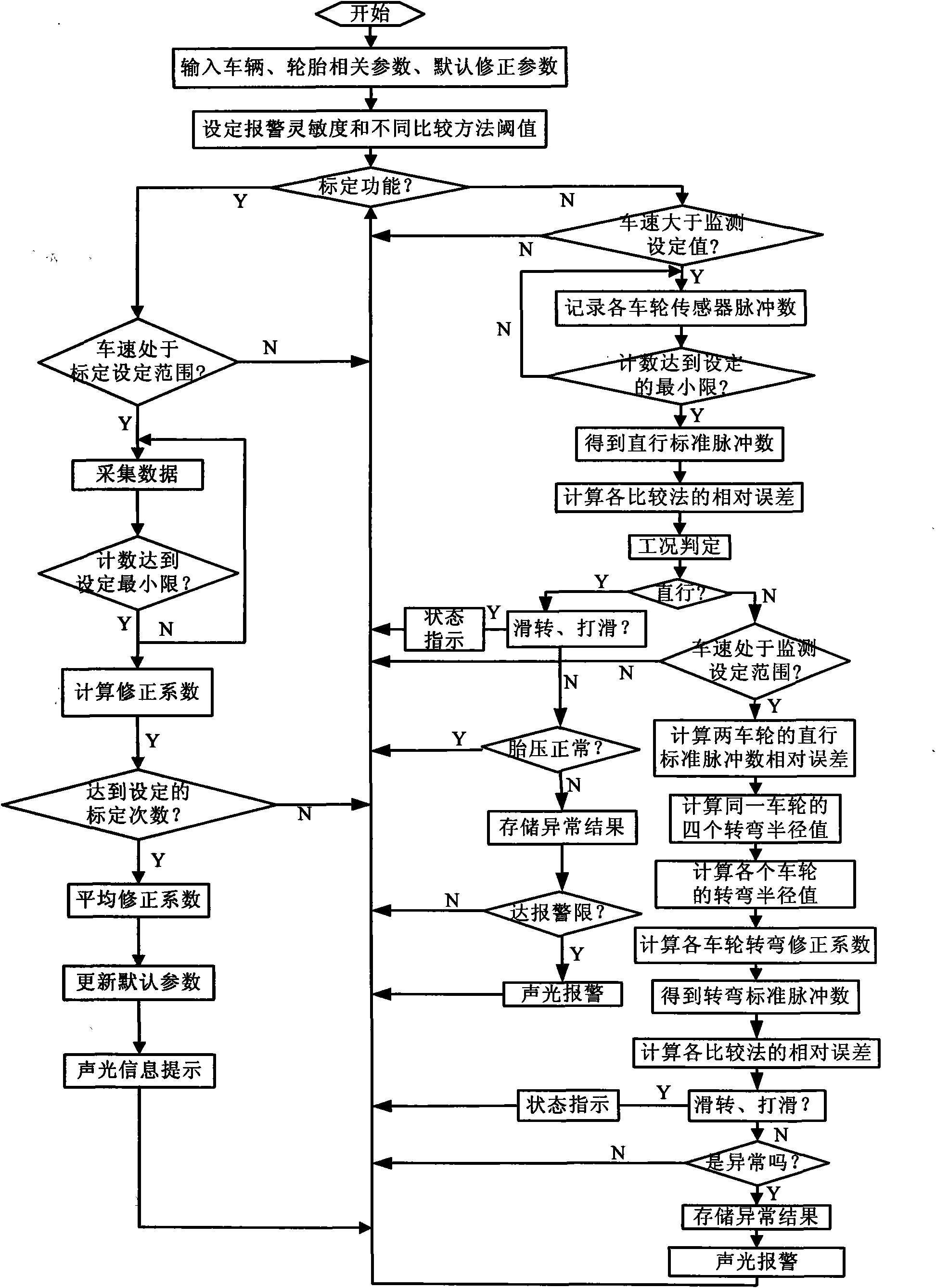

Method for monitoring tire pressure during corning process of automobile

The invention discloses a method for monitoring tire pressure during a corning process of an automobile, which is characterized by comprising the following steps: judging travel operating conditions such as corning, braking drag and skid, wheel spike driving and the like by carrying out collection, sorting, calculation, analysis and comparison on pulse signals output by all wheel speed sensors ofa travelling automobile; carrying out corresponding calculation on detection parameters (pulse number), and solving the corning diameter of each wheel during the corning process of the automobile; carrying out primary judgment on the tire pressure condition of the wheel during the corning process by comparing the corning diameter value of the same wheel; carrying out comparative analysis on the detection parameters; and finally, if the result is identical to the primary judgment, judging that the tire pressure is abnormal. By utilizing the method of the invention, the abnormal condition of the automobile tire pressure during the corning process can be accurately and effectively forecasted.

Owner:常州禄安汽车科技有限公司

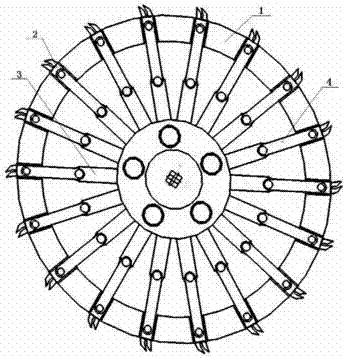

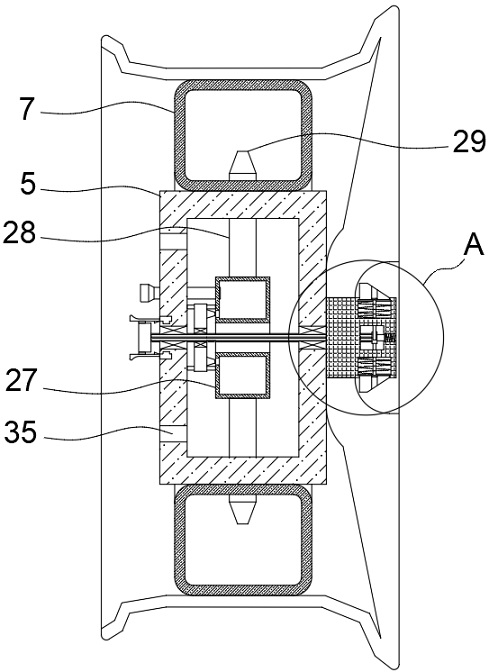

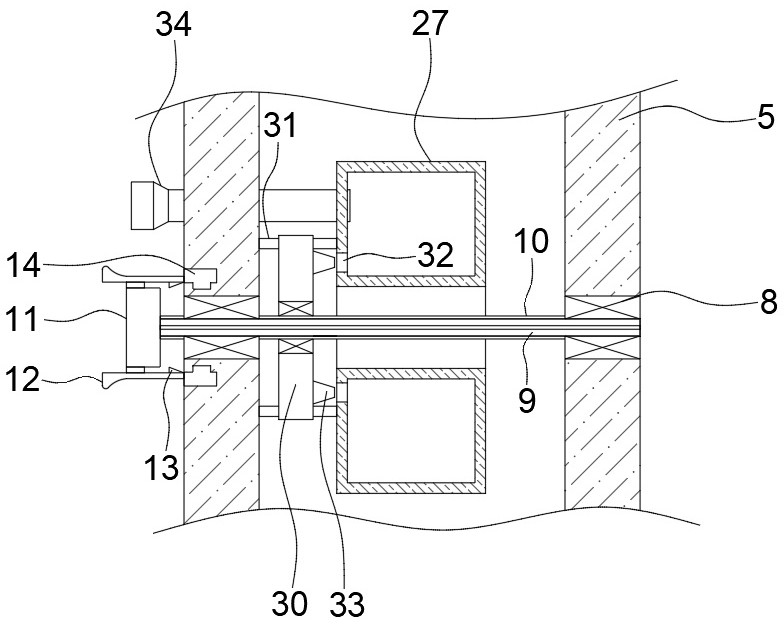

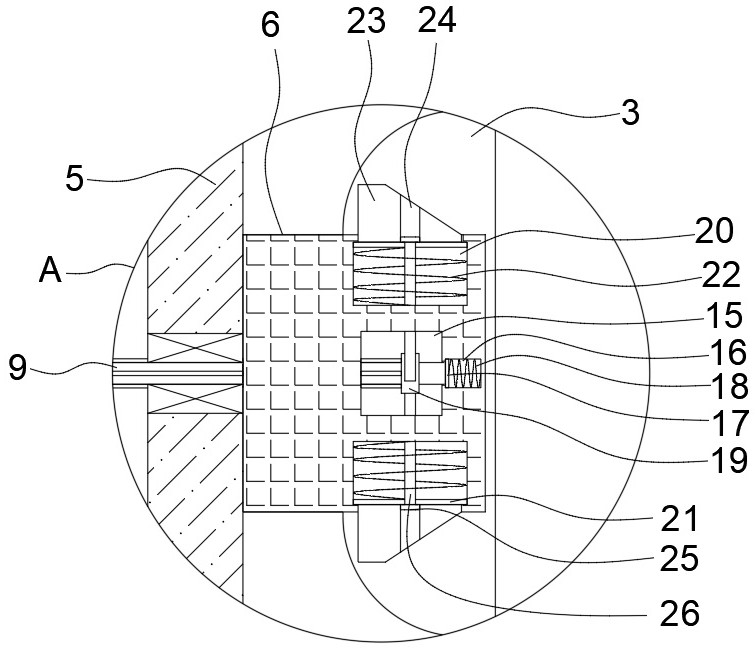

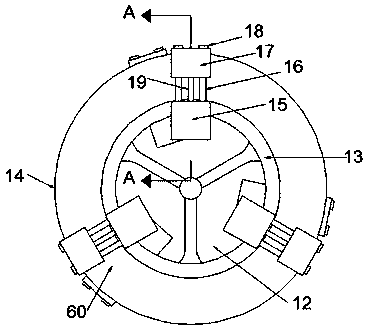

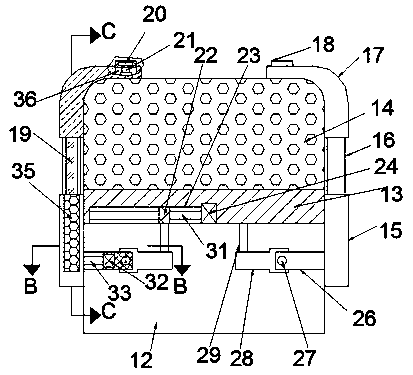

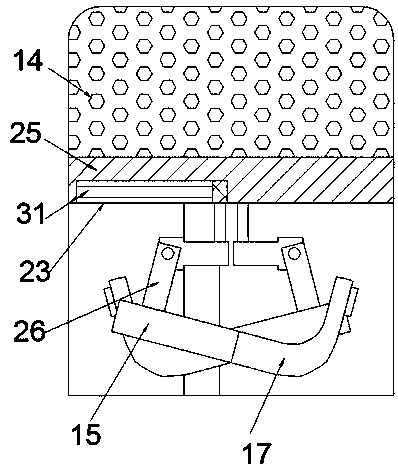

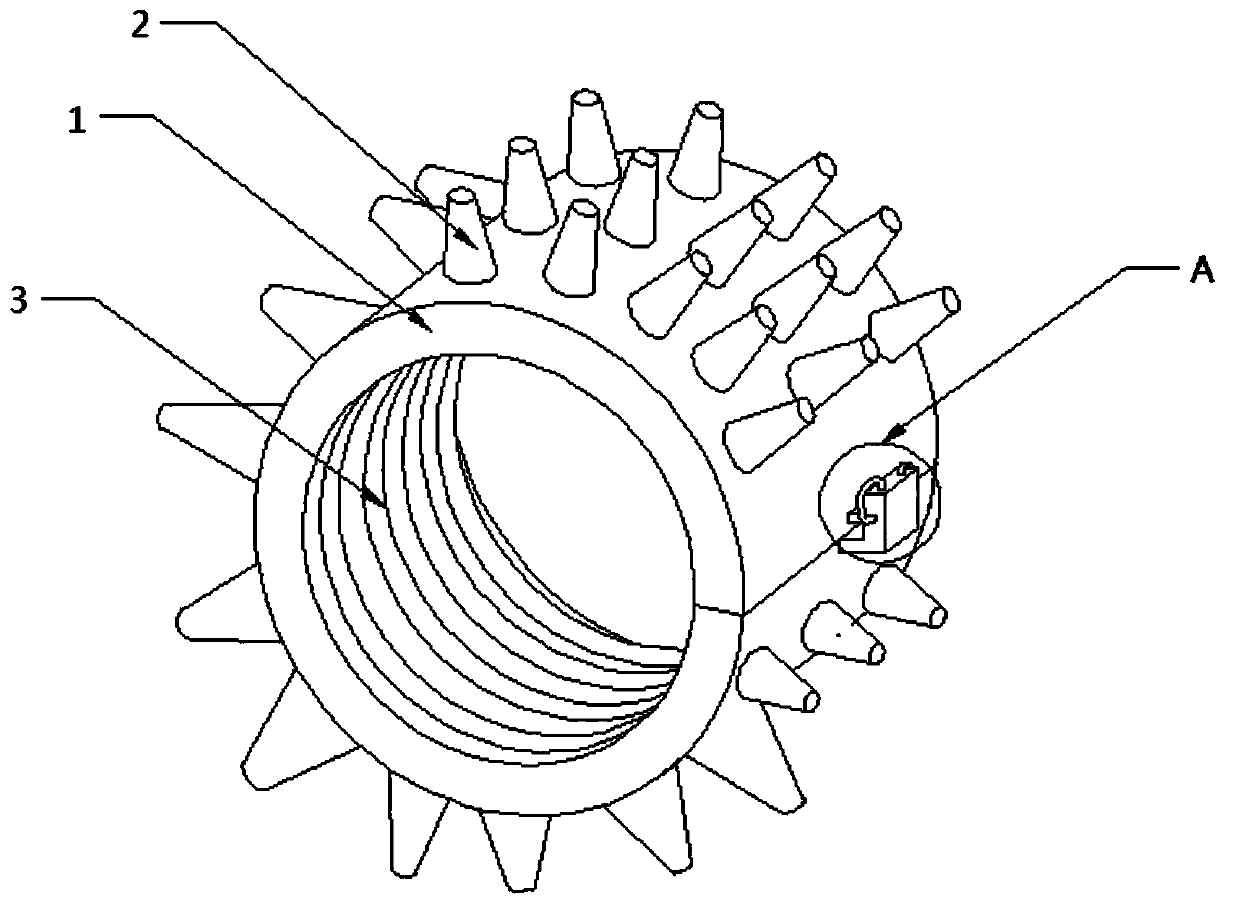

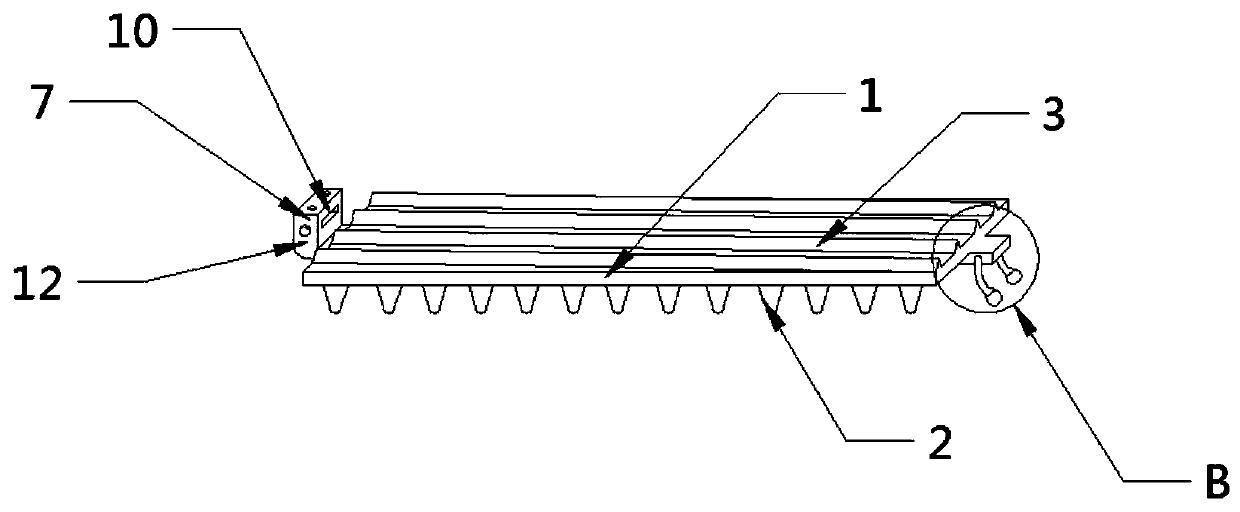

Automobile tire anti-skid system and device

PendingCN106945460AReal-time monitoring of attachmentFlexible and safe extensionWheels with spade lugsWheel speed sensorElectric machinery

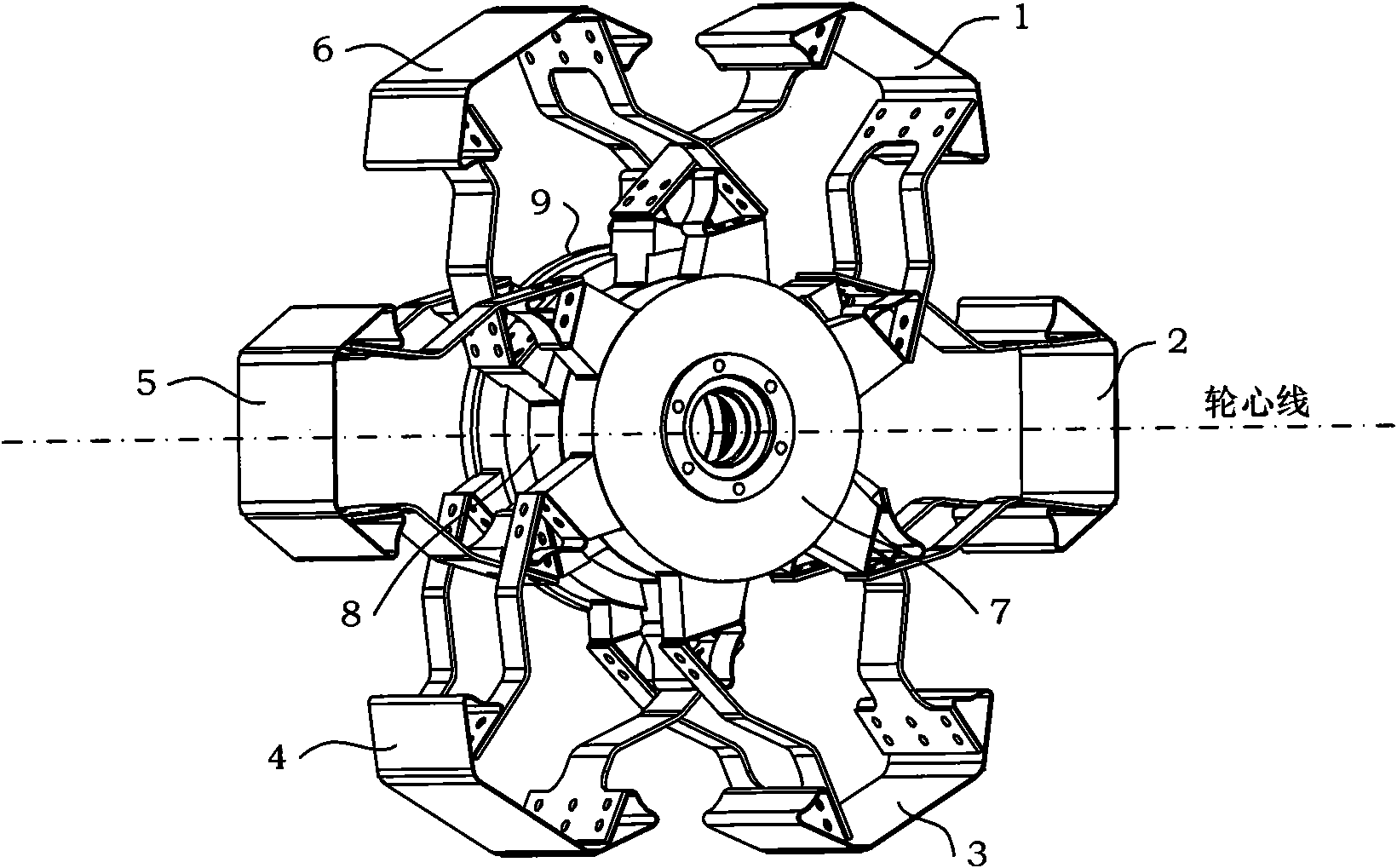

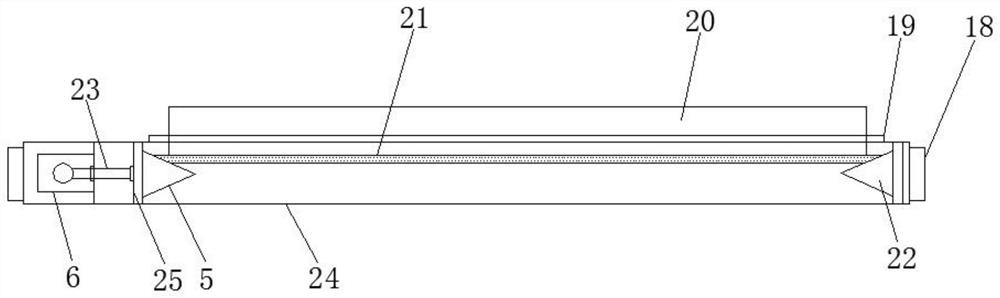

The invention provides an automobile tire anti-skid system and device. The automobile tire anti-skid device comprises the retractable anti-skid system, a drive motor (6) and a skid monitoring system monitoring the sliding friction condition between a wheel and the ground. The anti-skid system is mounted on a hub. The drive motor (6) controls stretching and retraction of the anti-skid system. The skid monitoring system comprises a wheel speed sensor and a controller. The wheel speed sensor is arranged on the hub and connected with the controller which is connected with the drive motor (6). The wheel speed sensor in the skid monitoring system can be utilized to monitor the attachment condition between the wheel and the ground in real time and transmit a wheel signal to the controller; and the operating direction of the drive motor is controlled through the controller so that anti-skid teeth can be flexibly and safely stretched out and retracted according to system needs. The automobile tire anti-skid system and device is simple in structure, convenient to mount and use and durable and meanwhile has small influence of a tire and pavement, and the service lives of the tire and the pavement are prolonged.

Owner:CHINA AUTOMOTIVE TECH & RES CENT

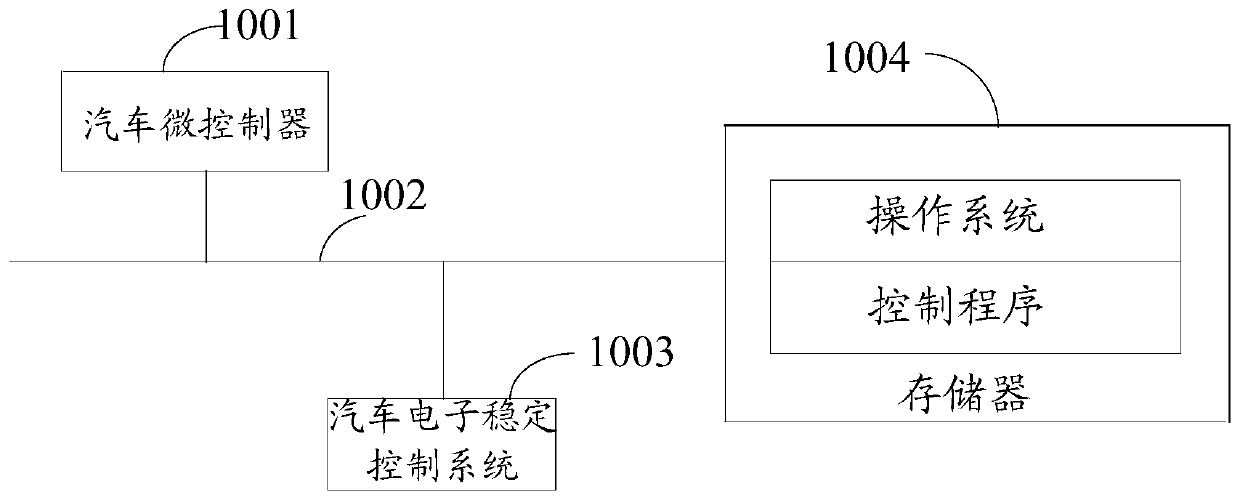

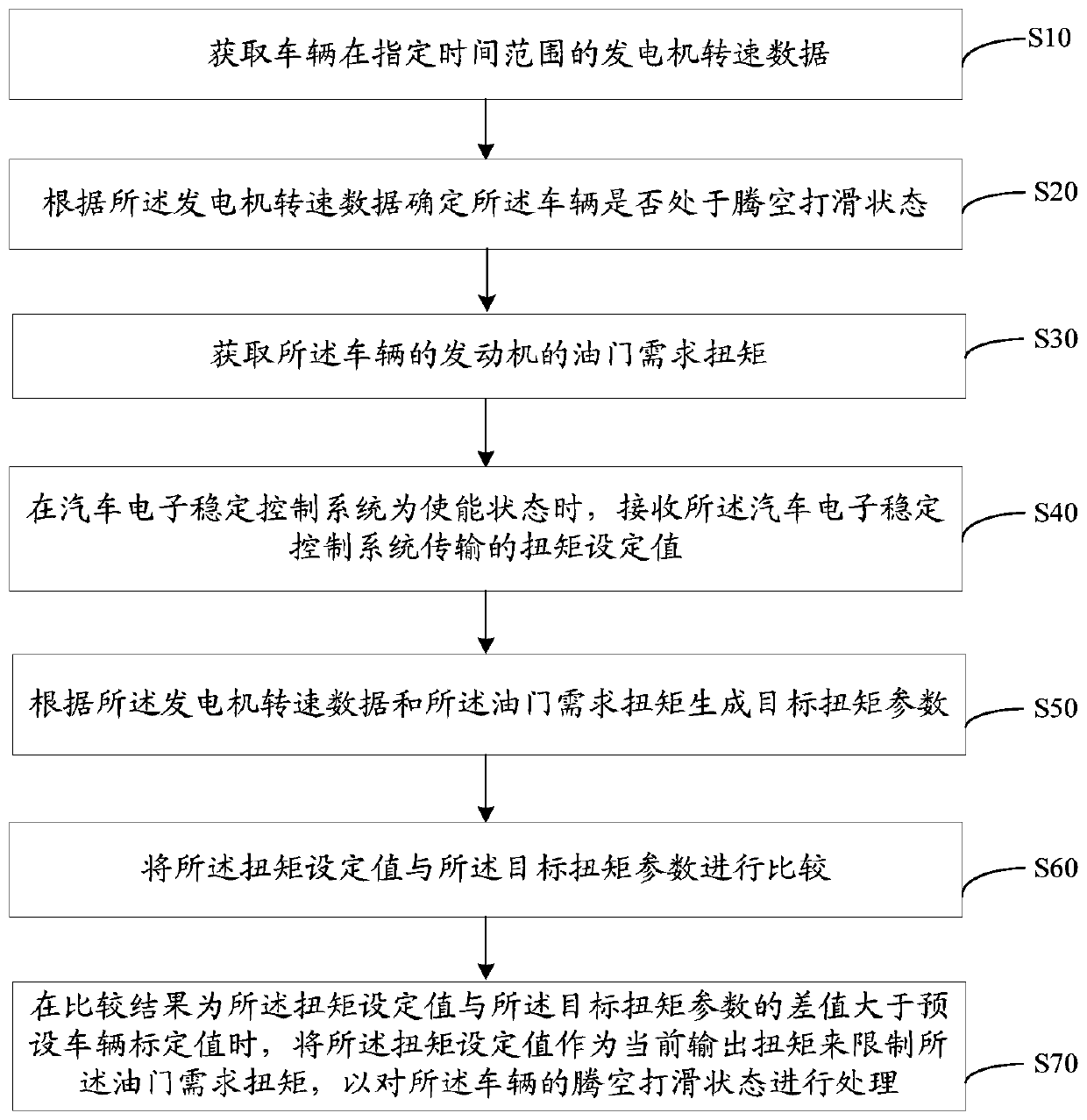

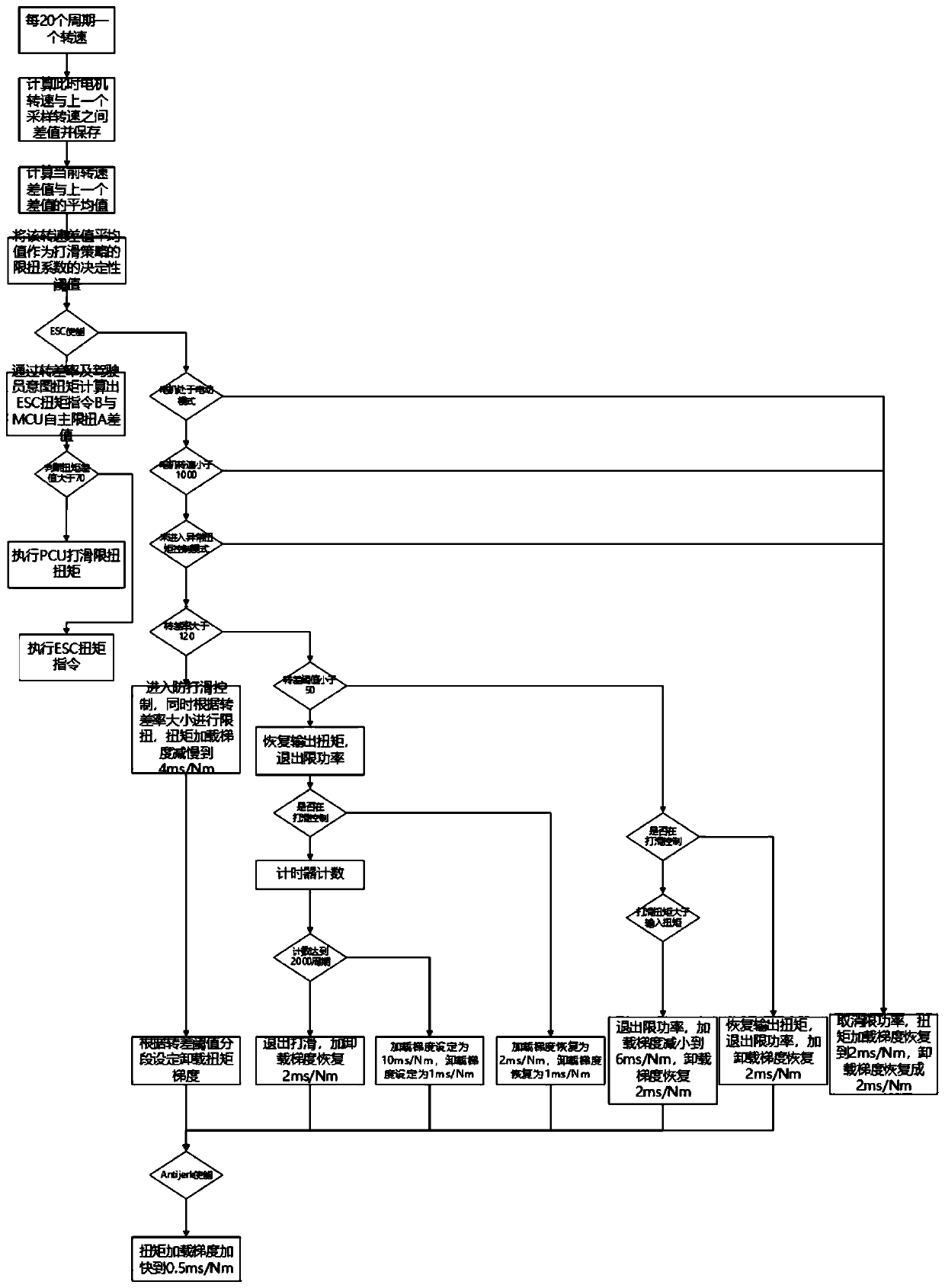

Method and device for processing vehicle skid, electric vehicle and storage medium

The invention provides a method and device for processing vehicle skid, an electric vehicle and a storage medium. The method comprises the steps of firstly, obtaining the generator rotating speed dataof a vehicle within a specified time range; determining whether the vehicle is in a skid state according to the generator rotating speed data; acquiring the accelerator demand torque of an engine ofthe vehicle; when an automobile electronic stability control system is in an enabled state, receiving a torque set value transmitted by the automobile electronic stability control system; generating atarget torque parameter according to the generator rotating speed data and the accelerator required torque; comparing the torque set value with a target torque parameter; when the comparison result is that the difference value between the torque set value and the target torque parameter is greater than a preset vehicle calibration value, using the torque set value as the current output torque tolimit the accelerator required torque, so that the skid state of the vehicle is processed, the torque response is recovered at the highest speed on the premise that the electrical and mechanical safety is guaranteed, and the dynamic property and the mechanical and electrical safety of the whole vehicle are guaranteed.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Self-adjusting automobile explosion-proof safety wheel and safety system thereof

ActiveCN109515078AImprove securityAvoid flat tiresPneumatic tyre reinforcementsTyre measurementsTweelTread

The invention discloses a self-adjusting automobile explosion-proof safety wheel and a safety system thereof, belonging to the technical field of explosion-proof tires. The self-adjusting automobile explosion-proof safety wheel comprises a hub and a main tire, wherein the main tire comprises a tread, a sidewall and a tire bead; the tire bead is clamped on the hub; a charging connector is connectedto the hub; the main tire comprises a carcass cord fabric layer; the lower end of the carcass cord fabric layer is fixedly connected to a pair of tire bead wires; the hub is fixedly connected to an auxiliary tire; skid resistance stripes are engraved on the surfaces of the tread and the auxiliary tire; the interior of the auxiliary tire is fixedly connected to a support frame; the lower end of the auxiliary tire is fixedly connected to a pressure relief valve; the air outlet end of the pressure relief valve penetrates through the auxiliary tire; the pressure relief valve is located in a support frame, can realize the automatic adjustment and pressure relief when the tire pressure is too high, can prevent the occurrence of tire burst, and gives an alarm for reminding when the tire pressureis too low. The tire pressure can be known in real time by multiple terminals through the safety system; and security incidents generated due to tire burst can be substantially reduced.

Owner:合肥名龙电子科技有限公司

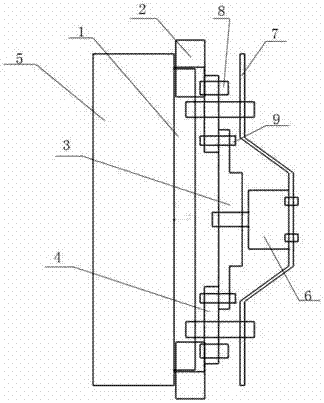

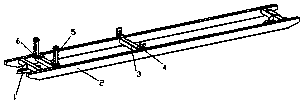

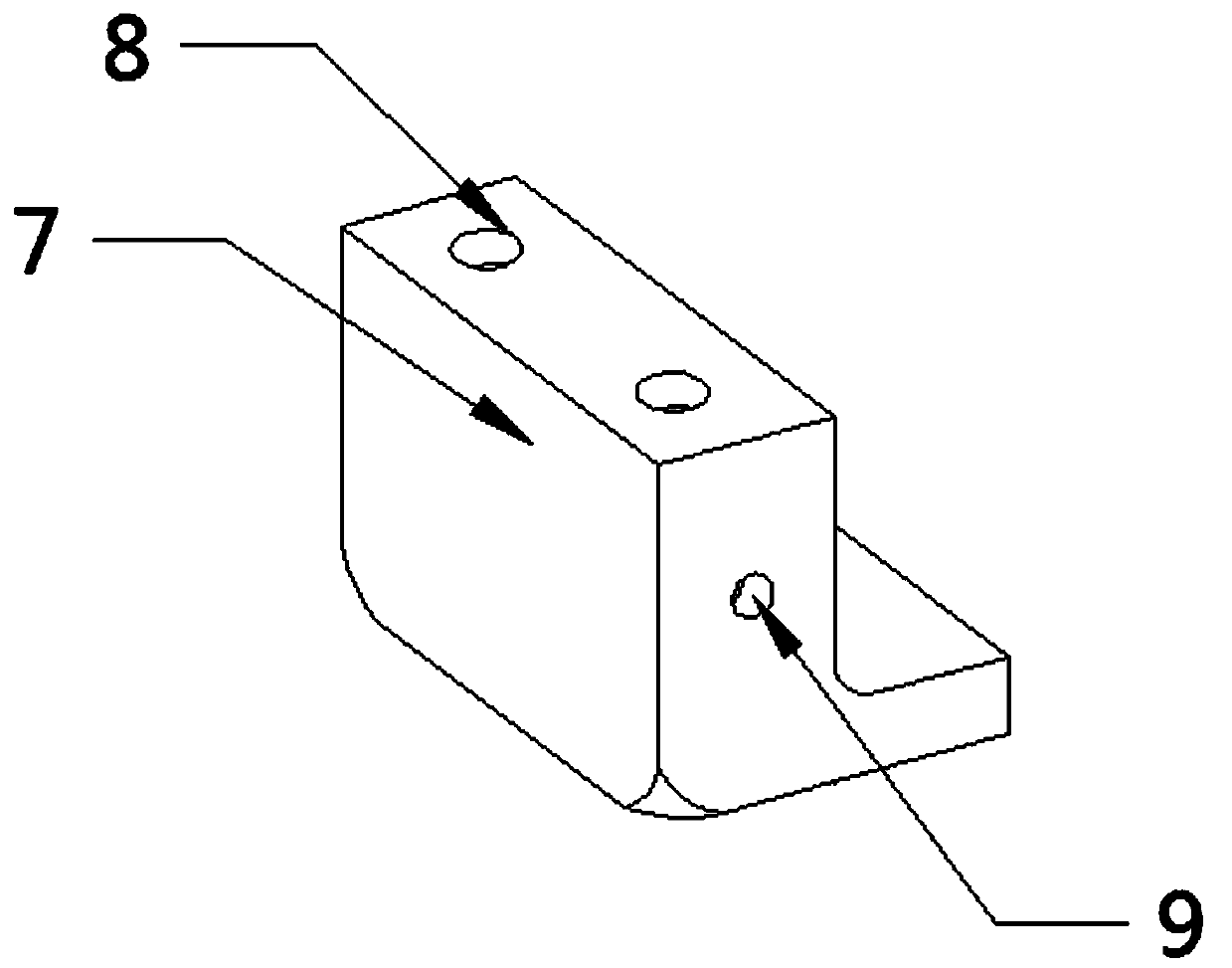

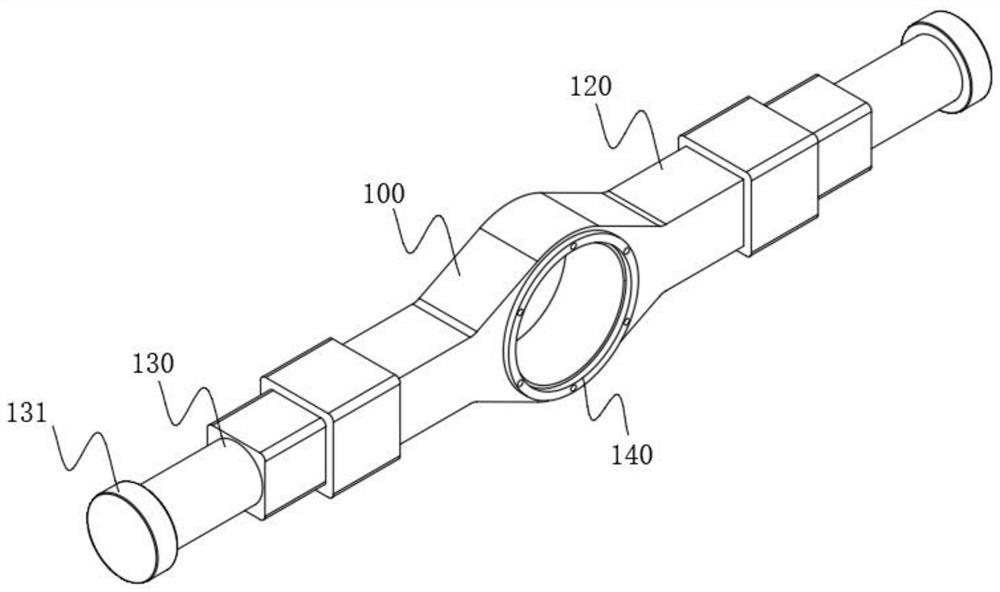

Skid for welding of automobile body

InactiveCN103433674AQuick installationFast fixationWelding/cutting auxillary devicesAuxillary welding devicesControl theorySkid (automobile)

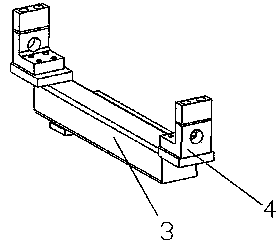

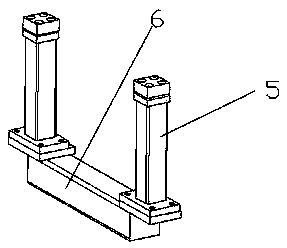

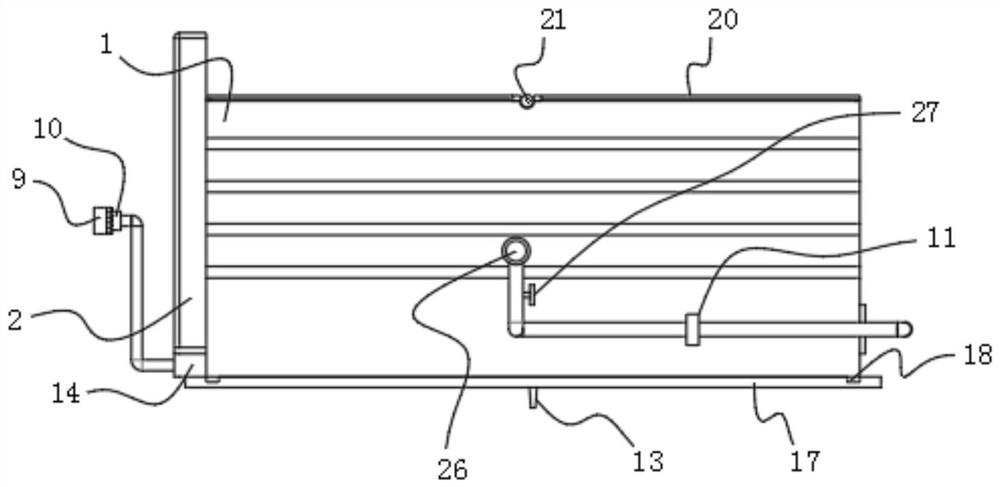

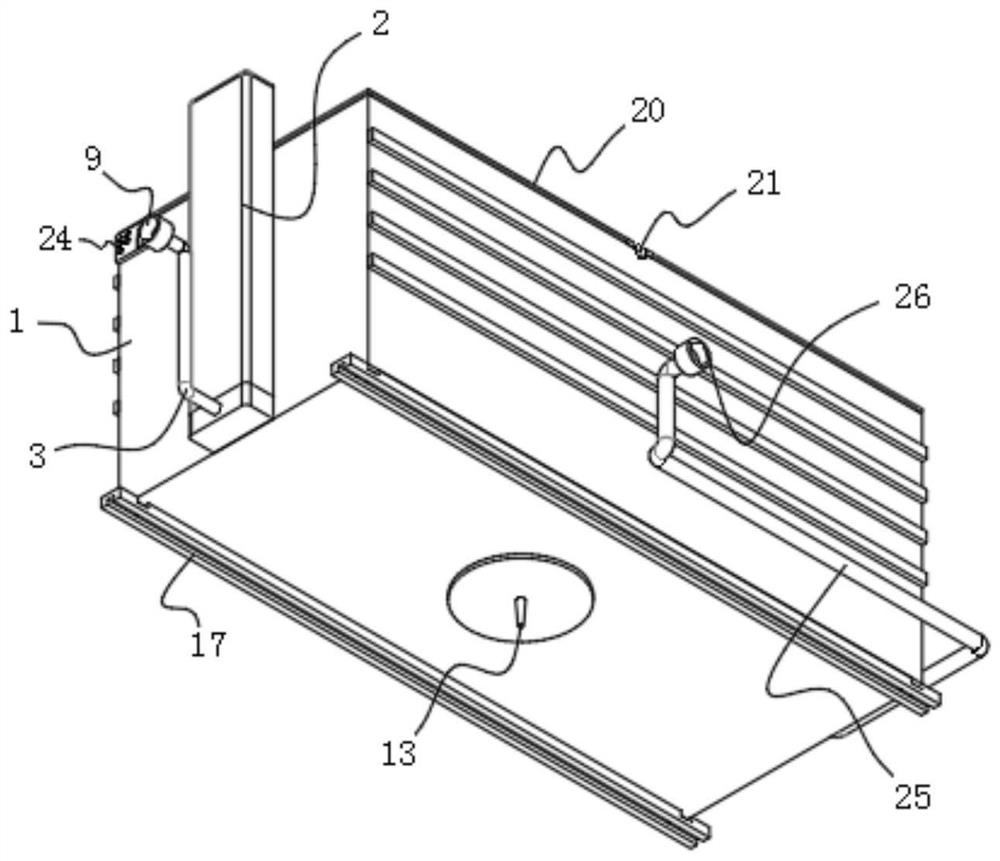

The invention discloses a skid for welding of an automobile body, and belongs to the field of welding tools. The skid for welding of the automobile body comprises a skid body, wherein the skid body comprises sliding rails, locating mechanisms, a clamping mechanism and a jacking mechanism; the number of the sliding rails is two, and the two sliding rails are arranged in parallel in the left and right direction; the locating mechanisms, the clamping mechanism and the jacking mechanism are sequentially arranged between the two sliding rails in parallel; the number of the locating mechanisms is two, and the two locating mechanisms are fixed to the two ends of the sliding rails; each locating mechanism comprises a fixing board and a locating block; the locating blocks are located at the bottom ends of the fixing boards; the clamping mechanism comprises a first sliding block and locating blocks, the number of the locating blocks is two, and the locating blocks are of an L-type structure and are symmetrically fixed to the first sliding block; the first sliding block is of a structure shaped like a reversed Chinese character 'ji', and comprises a square connection board and supporting boards, and the supporting boards are fixed to the two ends of the top of the connection board; the jacking mechanism comprises a second sliding block and square table pillars. The skid for welding of the automobile body lowers the production cost, relieves the labor intensity of operation staff and is stable and reliable in structure.

Owner:WUXI YICHEN MOLD TECH

Multifunctional vehicle with variable diameter wheels and skids

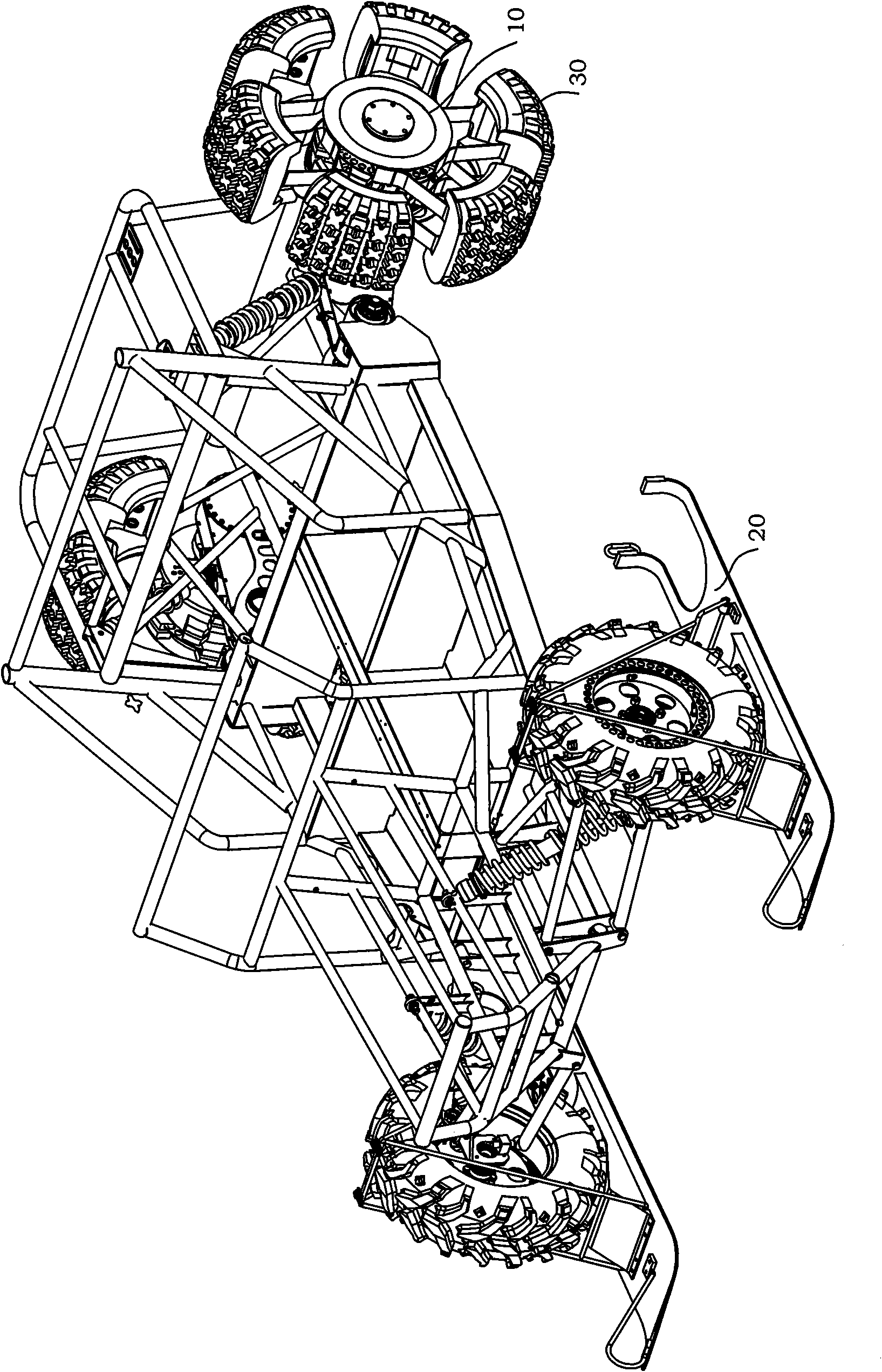

InactiveCN101927780AImprove passabilityEasy rideSledgesRolling resistance optimizationRolling resistanceIntertidal zone

The invention discloses a multifunctional vehicle with variable diameter wheels and skids. Except a basic structure of an automobile, the multifunctional vehicle also comprises the skids, a rubber baseboard and an elastic variable diameter wheel carrier, wherein the skids are mounted on the two front wheels of the conventional automobile and the variable diameter wheel carrier is arranged on a semi-shaft of the automobile; and the elastic variable diameter wheel carrier rotates a certain angle relative to a hub A and a hub C by a hub B and drives an elastic variable diameter part to rotate in a circumference direction of the hub B at the same time, so that the elastic variable diameter part is opened or folded to realize the wheel diameter variation of rear wheels of the automobile. In the invention, by adopting the combination of the skids and the variable diameter wheel carrier, the traffic capability of the multifunctional vehicle on a soft ground is improved, rolling resistance is reduced, a drive force is increased, and the vehicle body is supported by the skids in a shallow or intertidal zone, so that the vehicle body is prevented from sinking; and when the skids are dismantled and the wheel wheels are retracted to form round wheels, the multifunctional vehicle can run at a high speed on a road.

Owner:BEIHANG UNIV

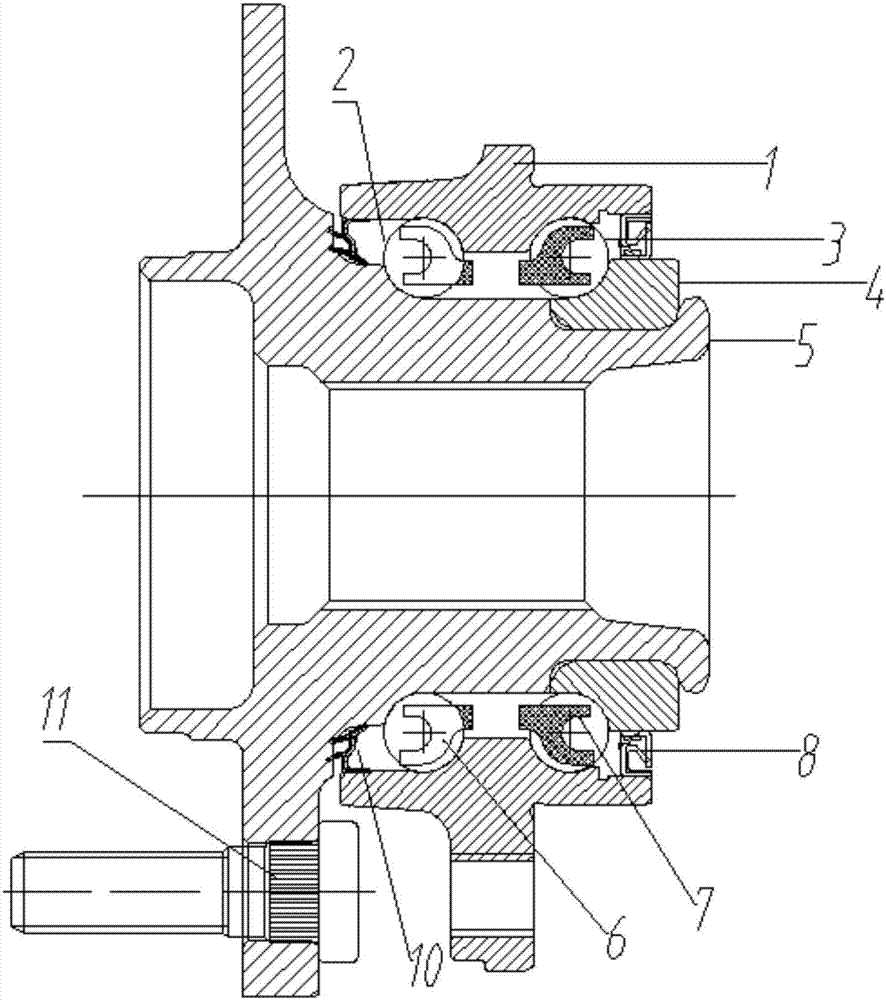

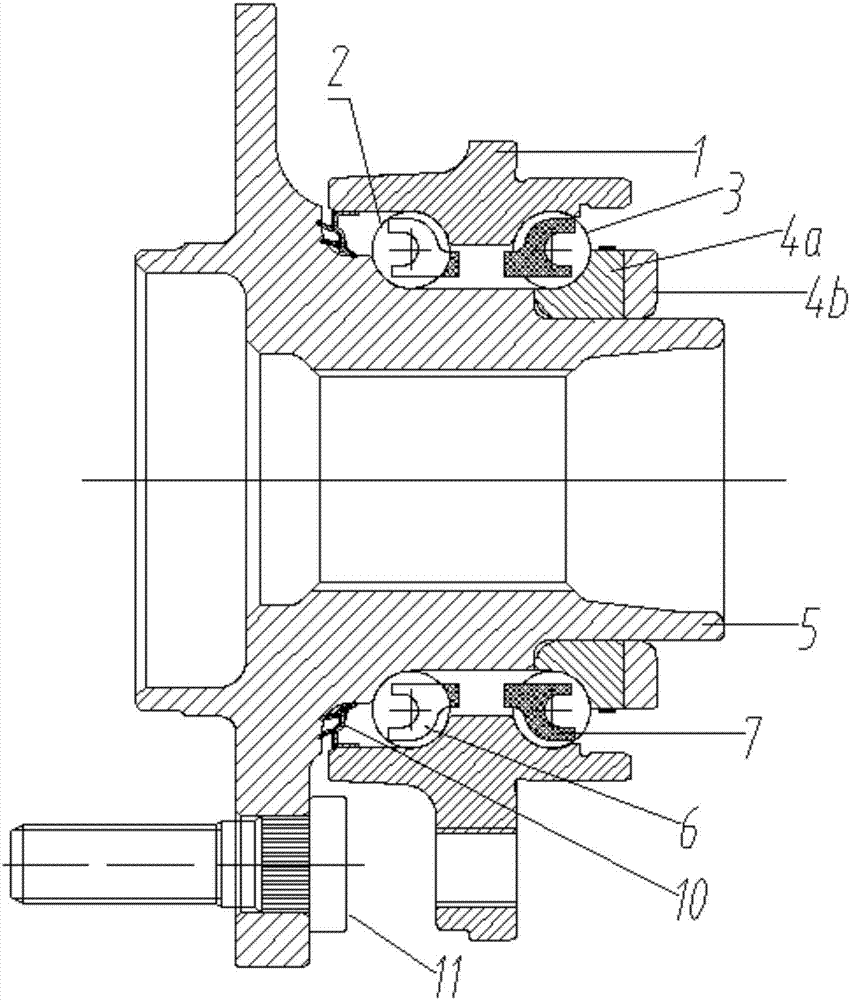

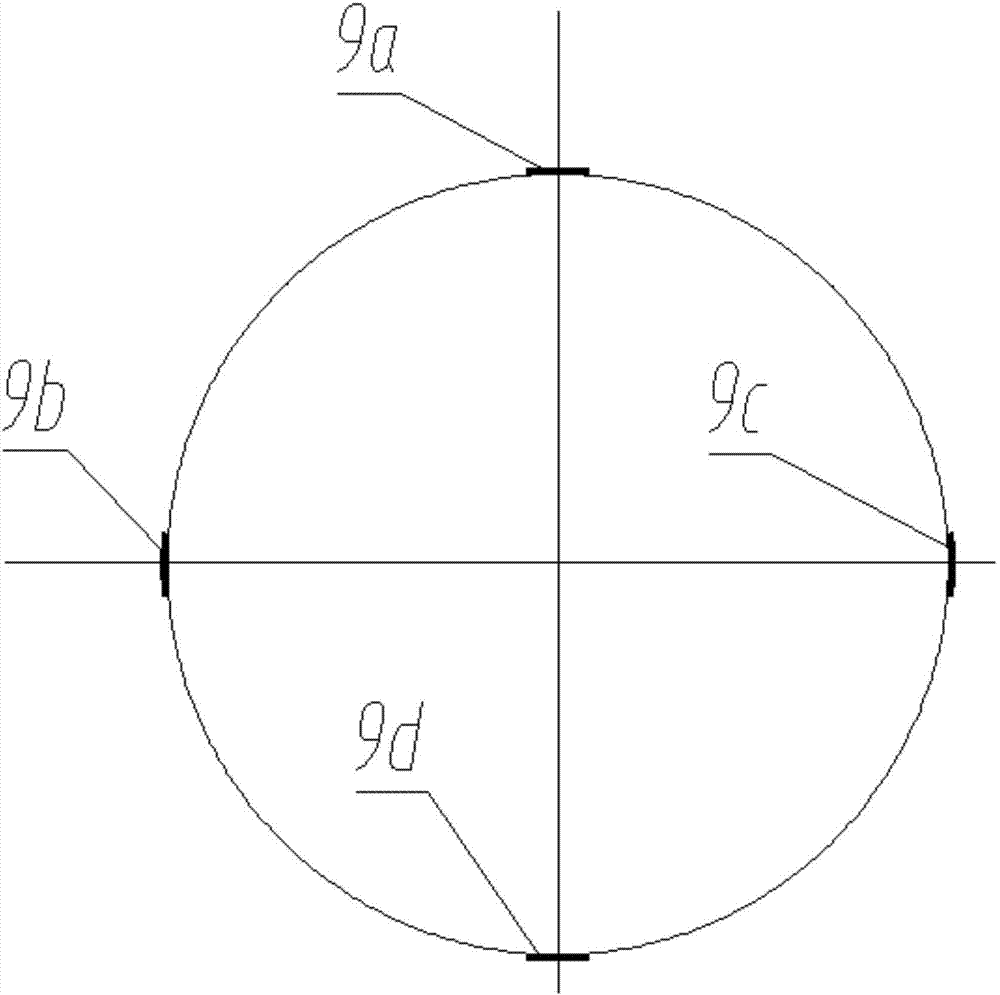

Drive hub bearing unit spin riveting pressure measurement system and measurement method

PendingCN107228725AReasonable structural designDetermination method is simpleForce measurementApparatus for force/torque/work measurementStrain gaugeAxial pressure

The invention belongs to the field of production of an automobile hub bearing unit and especially relates to a drive hub bearing unit spin riveting pressure measurement system and measurement method. The measurement system comprises an outer ring, an external steel ball, an internal steel ball, a flange plate, an external holder, an internal holder, a bolt and foil gauges. The system is reasonable in structure design and simple in measurement method, and can accurately measure axial pressure remaining on the hub bearing unit after the hub bearing unit finishes spin riveting process to determine axial pre-tightening effect under a bearing loading state, thereby preventing the problem of flange shaft rupture due to inner ring loosening and skid, and ensuring driving safety. The measurement can check reasonability of structure design of a spin riveting structure and select reasonable process parameters.

Owner:ZHEJIANG WANXIANG PRECISION IND +1

Fixture for anti-deformation machining of automobile aluminum alloy wheel

ActiveCN112192251AImprove skid resistanceWon't hurtWork clamping meansPositioning apparatusDrive shaftEngineering

The invention discloses a fixture for anti-deformation machining of an automobile aluminum alloy wheel. The fixture comprises a wheel body, wherein the wheel body consists of a wheel disk, a wheel rim, a hole groove and a center hole; a hollow column is arranged inside the wheel body; a position-limiting column is fixedly connected to the center position of the left side of the hollow column; theposition-limiting column penetrates through the center hole in a sliding manner; a rubber air bag is fixedly connected to the outer circumferential surface of the hollow column in a sleeving manner; bearings are fixedly embedded in the center positions of the left side and the right side of the hollow column; a driving shaft is sleeved with the two bearings; and the driving shaft penetrates through the hollow column. The fixture for the anti-deformation machining of the automobile aluminum alloy wheel has the advantages of avoiding deformation of the wheel rim during machining and always keeping the wheel rim in a regular round shape by utilizing the annular expansion force generated by inflation and expansion of the rubber air bag to uniformly support the wheel rim, avoiding shifting of the rubber air bag in an expansion state and avoiding damage to the surface of the wheel at the same time due to the fact that the rubber air bag has good skid resistance, and improving the machining efficiency due to the fact that the process of mounting and dismounting the fixture is simple and convenient.

Owner:薛丽

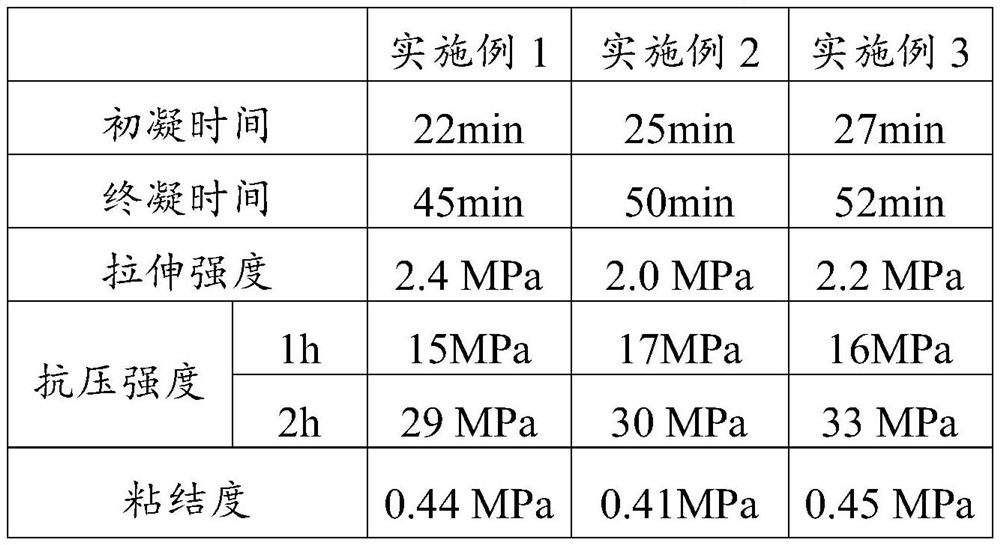

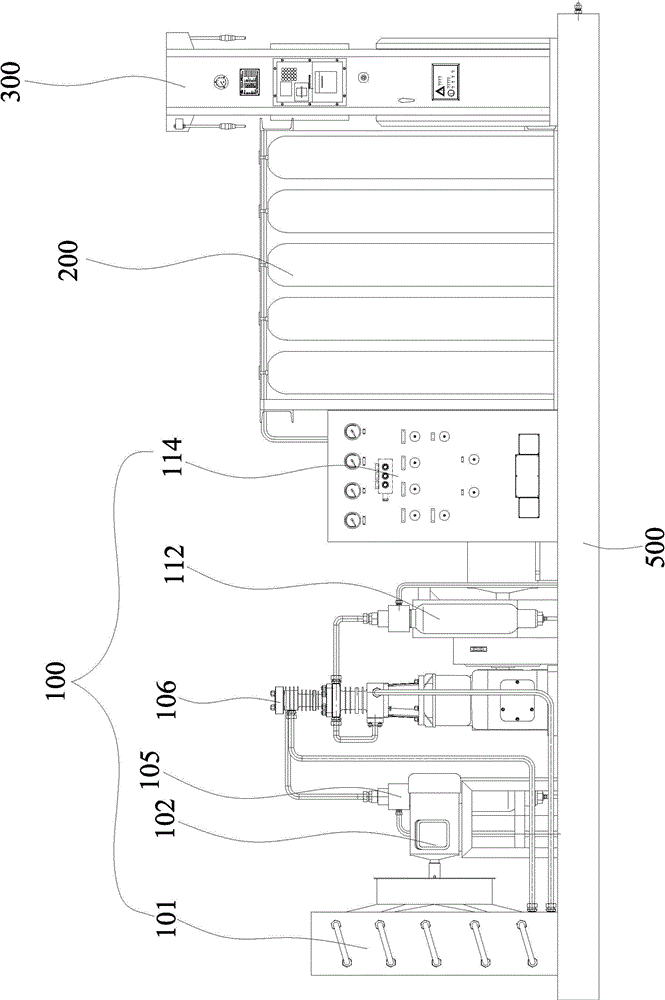

Skid-mounted hydrogenation device for new energy automobile

InactiveCN111911798AAchieve integrationEasy to transportPressure vesselsFluid handledCold airNew energy

The invention discloses a skid-mounted hydrogenation device for a new energy automobile, and relates to the technical field of hydrogenation equipment. The skid-mounted hydrogenation device comprisesa box body, a hydrogen unloading column and a second hydrogenation pipe, the hydrogen unloading column is installed at one side of the box body, the output end of the hydrogen unloading column is connected with the box body, and the second hydrogenation pipe is installed at the other side of the box body; a first hydrogen storage tank, a second hydrogen storage tank and a third hydrogen storage tank are arranged in the box body, cold air pipelines are connected between the first hydrogen storage tank and the second hydrogen storage tank and between the second hydrogen storage tank and the third hydrogen storage tank, a compressor is installed at one side of the first hydrogen storage tank, the output end of the compressor is connected with a cooler, and the output end of the cooler is connected with the cold air pipelines; and one surface of the hydrogen unloading column is connected with a gas unloading pipeline, and the input end of the gas unloading pipeline is connected with a gasinlet. According to the integrated skid-mounted hydrogenation device, key equipment is systematically integrated, transportation and installation are more convenient, and integrated and intelligent design and manufacturing of hydrogen refueling station equipment and application of the Internet of Things are achieved.

Owner:SICHUAN DIWEI ENERGY TECH

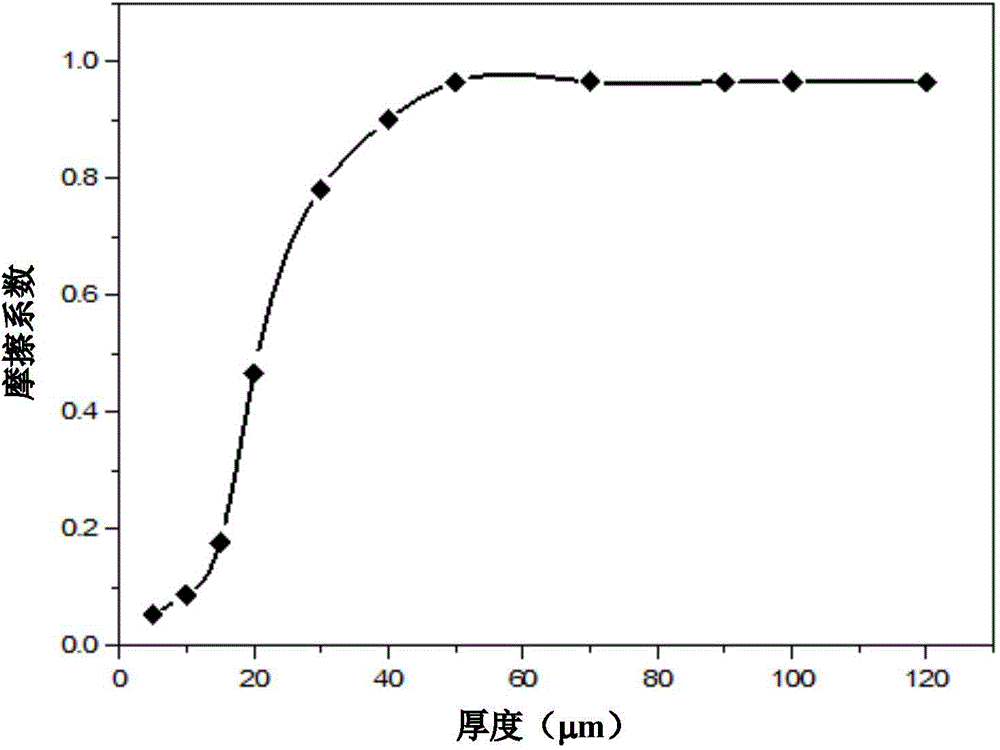

Filler-free skidproof resin paint and its preparation method and use

ActiveCN105255347AThe overall thickness is thinReduce thicknessPolyurea/polyurethane coatingsUltraviolet radiationSolvent

The invention belongs to the field of skidproof resin paint and discloses filler-free skidproof resin paint and its preparation method and use in fields of catering industry, home life and automobile industry and especially in field of food and drink pallet skid resistance. The filler-free skidproof resin paint comprises, by mass, 20-70% of elastic resin, 1-15% of a curing agent, 10-70% of a solvent and 3-30% of an auxiliary agent. The elastic resin rich in high activity groups such as hydroxyl undergoes a reaction to produce a polymer with a special molecular structure so that adhesion of the elastic resin to a base is improved, mechanical properties are improved, soft and elastic characteristics are retained and impact strength and wear resistance are improved. The filler-free skidproof resin paint is free of a skidproof filler. The coating of the filler-free skidproof resin paint has thickness of 30-100 microns, a friction coefficient of 0.90, a skidproof angle of 45 degrees, good adhesion to a base, good flexibility and elasticity, water and oil resistance, ultraviolet radiation resistance and a long service life.

Owner:旭川新材料(广东)股份有限公司

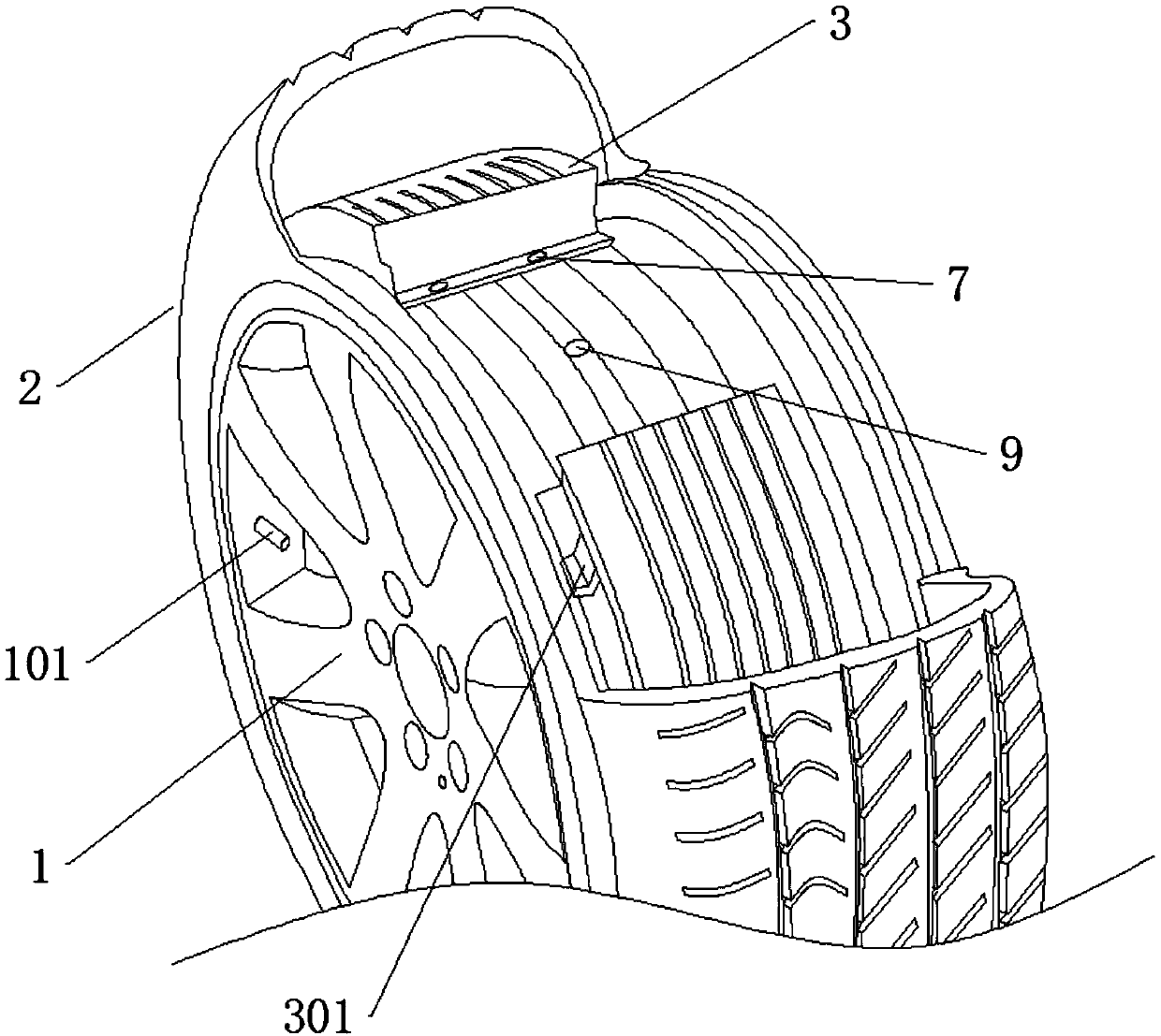

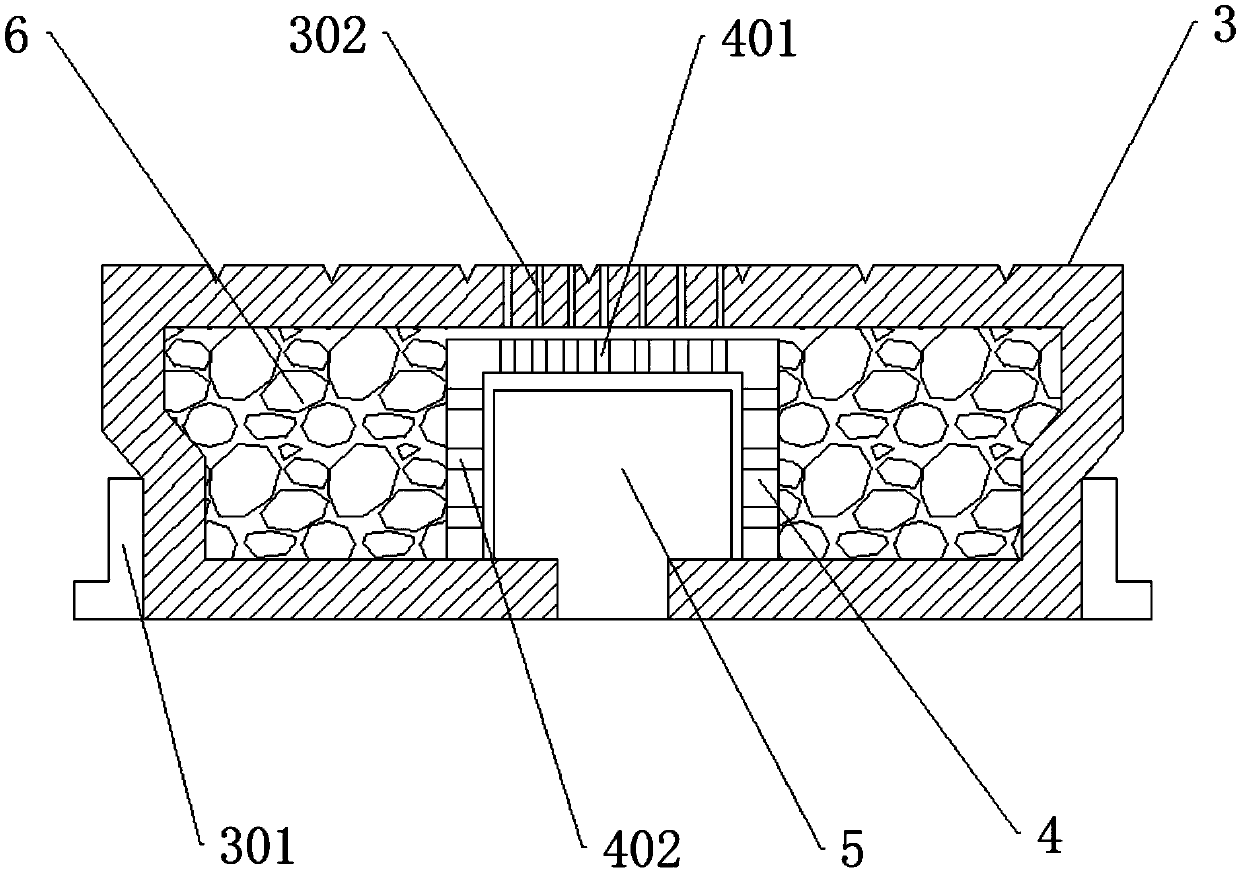

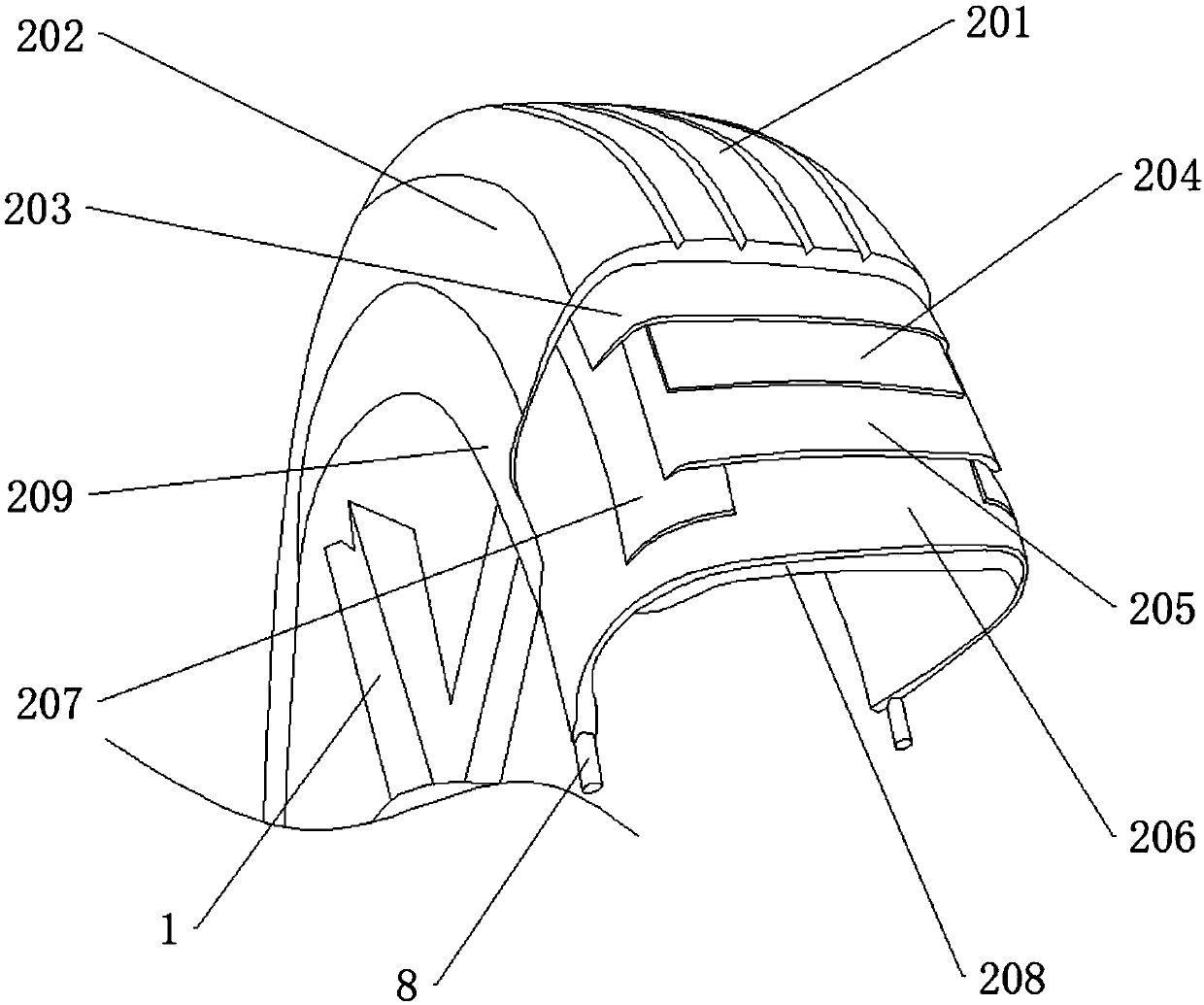

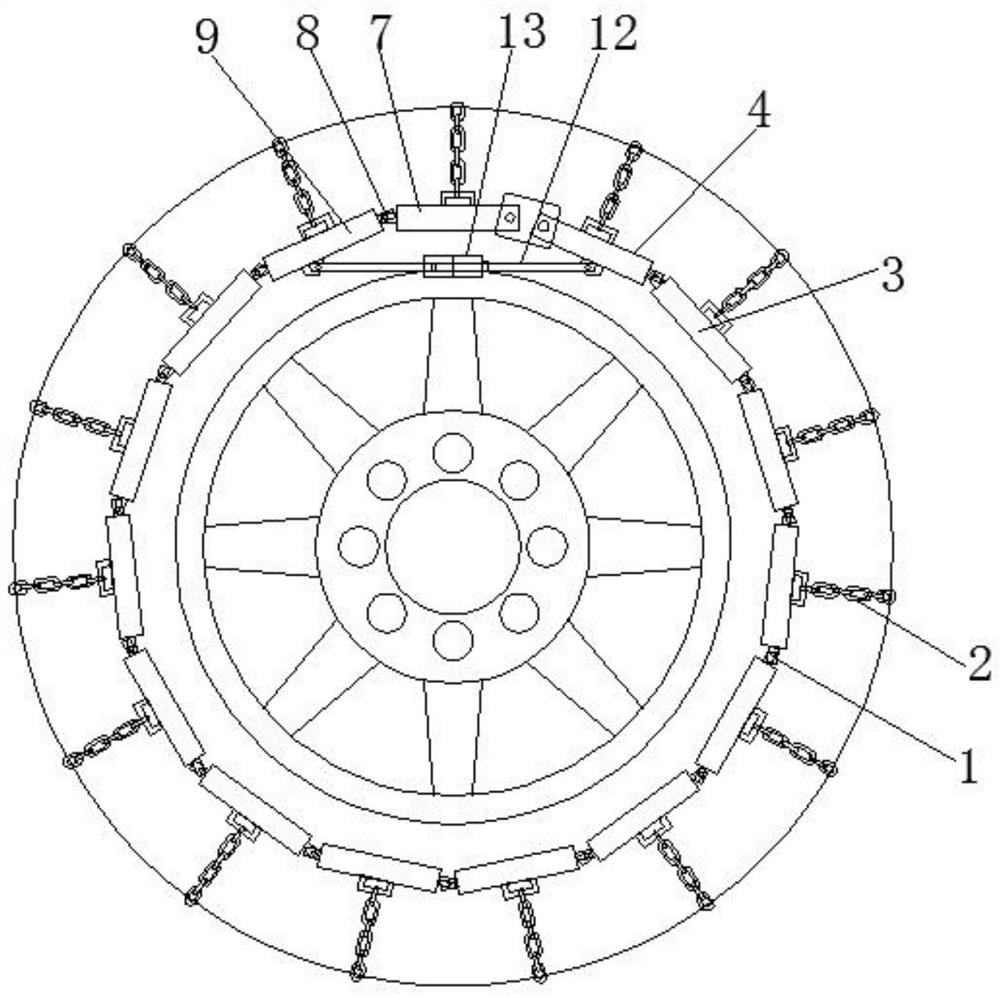

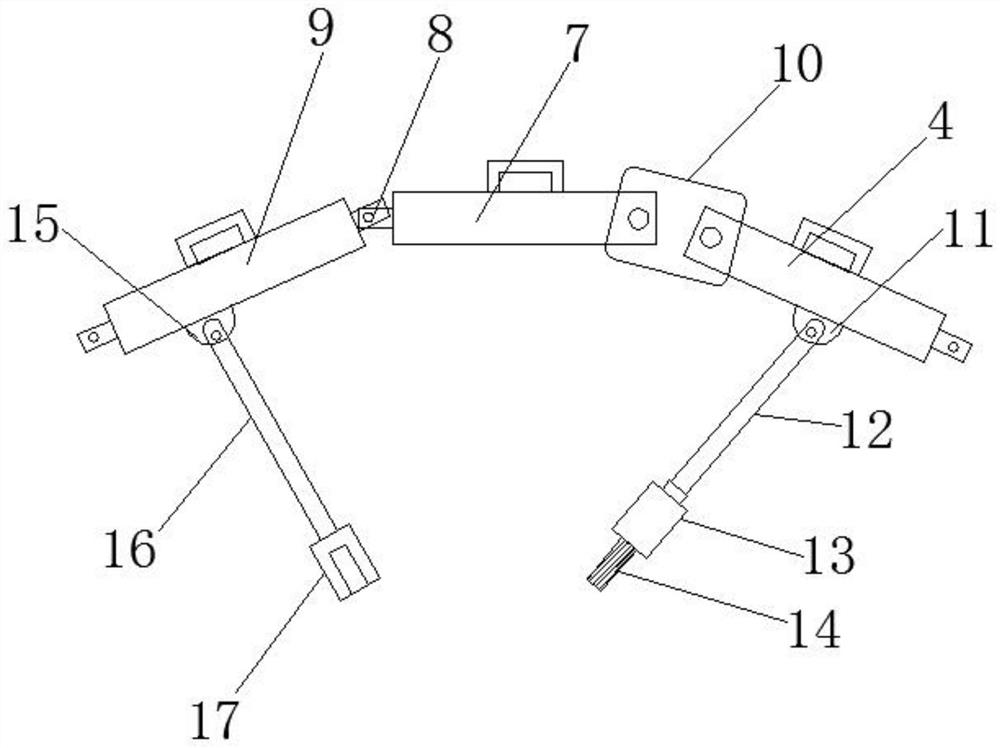

Automobile tire with antiskid chain integrated in hub

InactiveCN110884305ANo need for manual installation and disassemblyEasy to useRoad vehicle tyresRimsControl theoryMechanical engineering

Owner:SHENGZHOU CHUXUE AUTO PARTS CO LTD

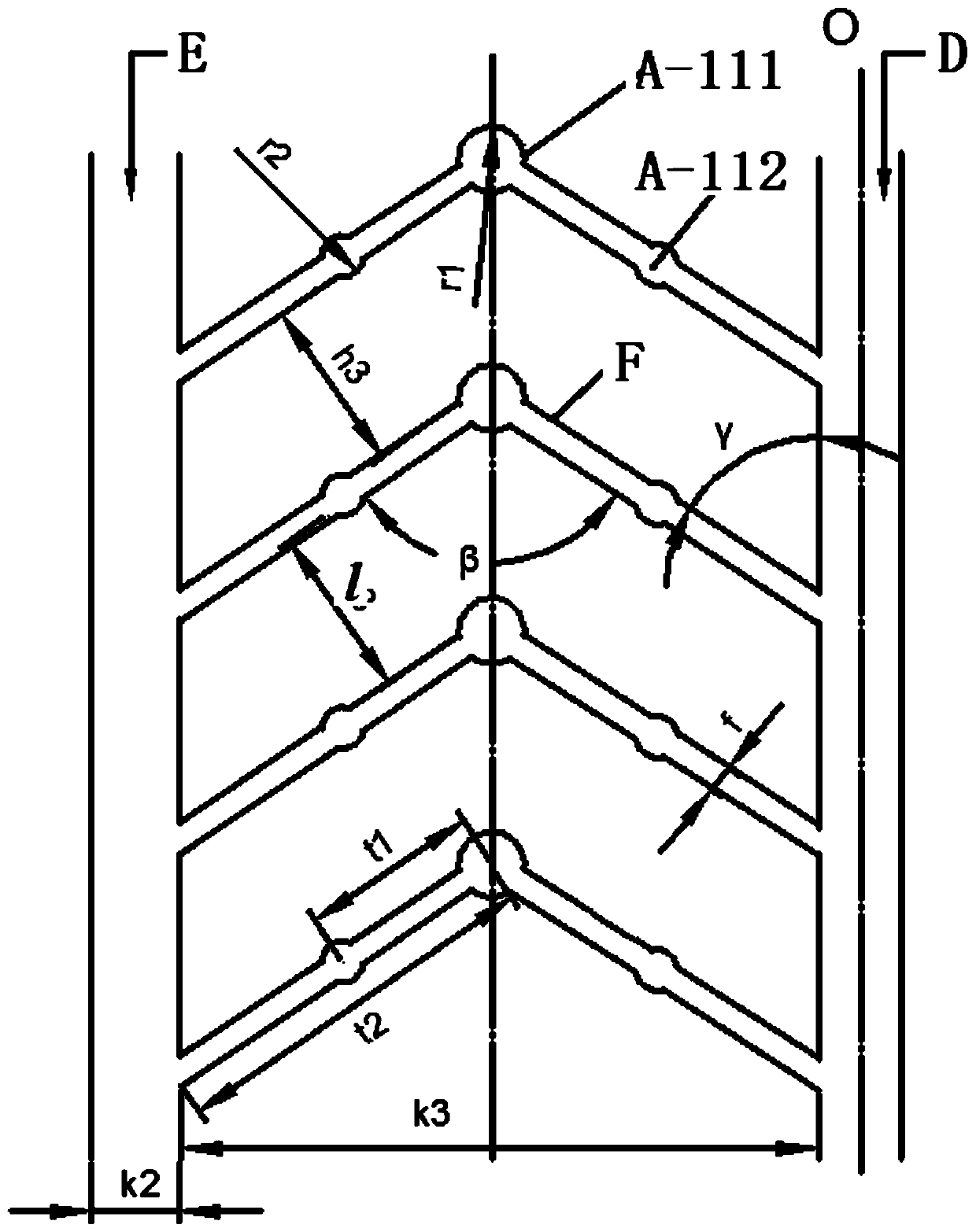

Novel tread rubber with pattern and preparation method thereof

PendingCN110861450AImprove securityEasy to manufactureRoad vehicle tyresRoad vehiclesRolling resistanceFoam rubber

The invention relates to the technical field of automobile tires, in particular to novel tread rubber with a pattern. The novel tread rubber comprises a wet-skid-resistant foaming rubber unit, a highly wear-resistant rubber unit and a tearing-resistant rubber unit; the wet-skid-resistant foaming rubber unit and the highly wear-resistant rubber unit are complementary; the tearing-resistant rubber unit is positioned at the bottoms of the wet-skid-resistant foaming rubber unit and the highly wear-resistant rubber unit; the wet-skid-resistant foaming rubber unit is embedded into the highly wear-resistant rubber unit to form the patterns; the pattern formed by the wet-skid-resistant foaming rubber unit comprises a first pattern structure and a second pattern structure which are in mirror symmetry; the first pattern structure comprises a striped pattern structure and a bionic pattern structure; and the striped pattern structure and the bionic pattern structure are separated by a main groove.The novel tread rubber is convenient to manufacture, has ultra-high wet skid resistance, and ensures good wear resistance, rolling resistance, other physical and mechanical properties and the like, and the driving safety of automobiles can be improved greatly.

Owner:JILIN TEACHERS INST OF ENG & TECH

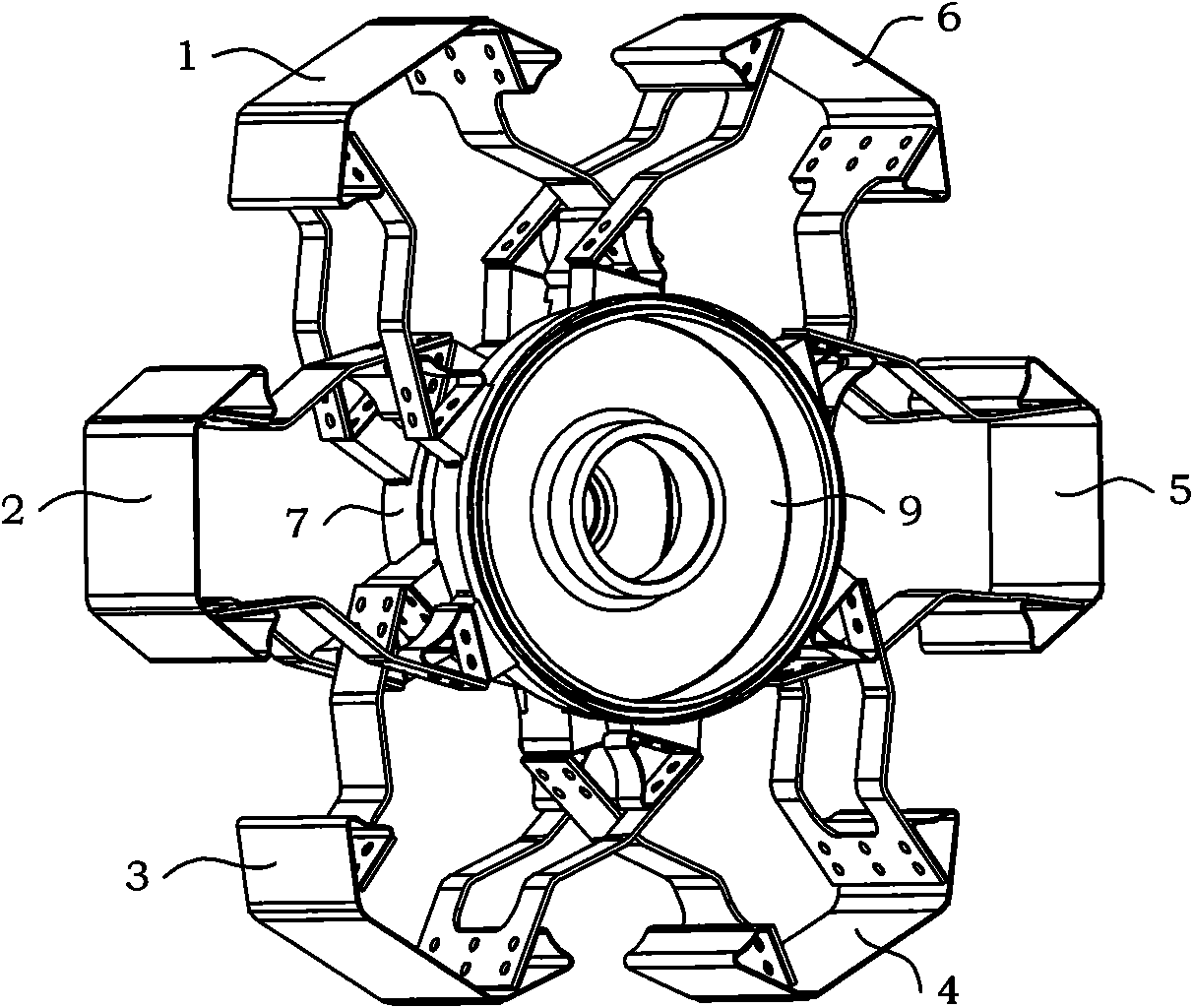

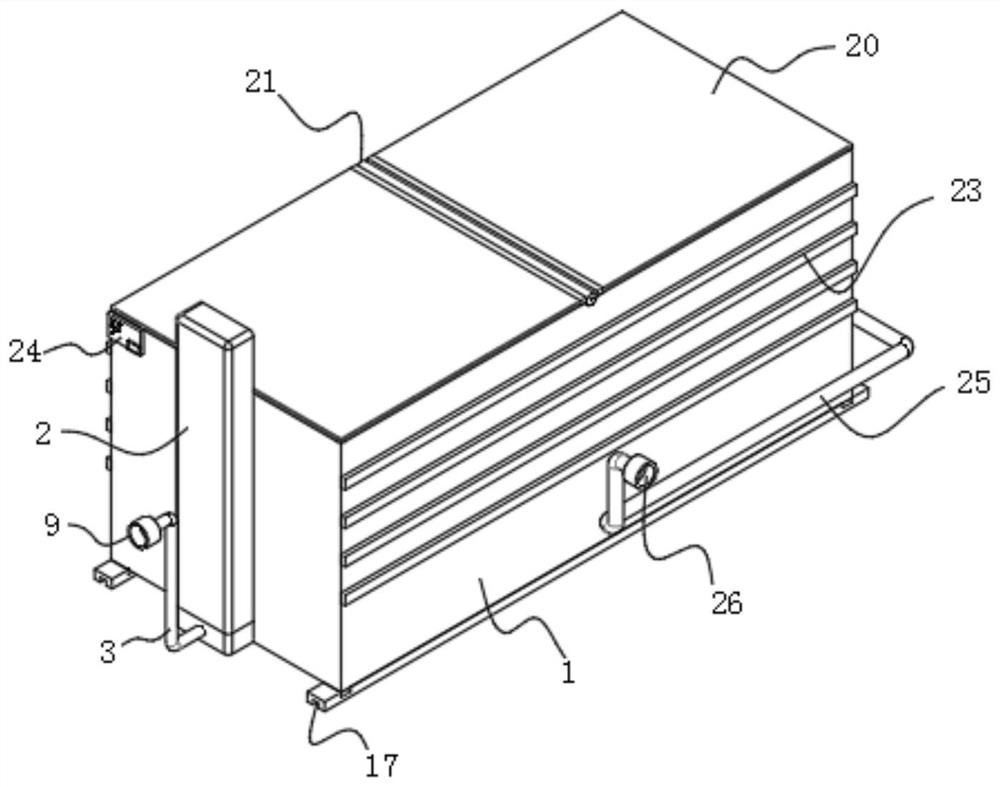

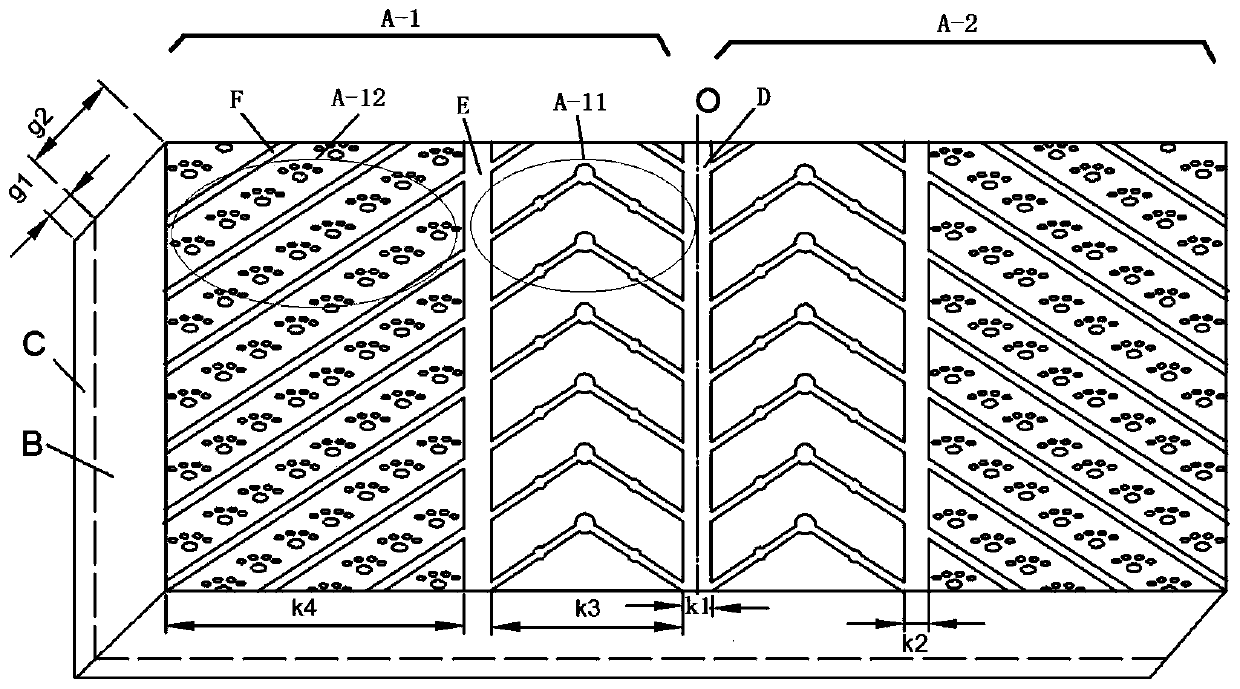

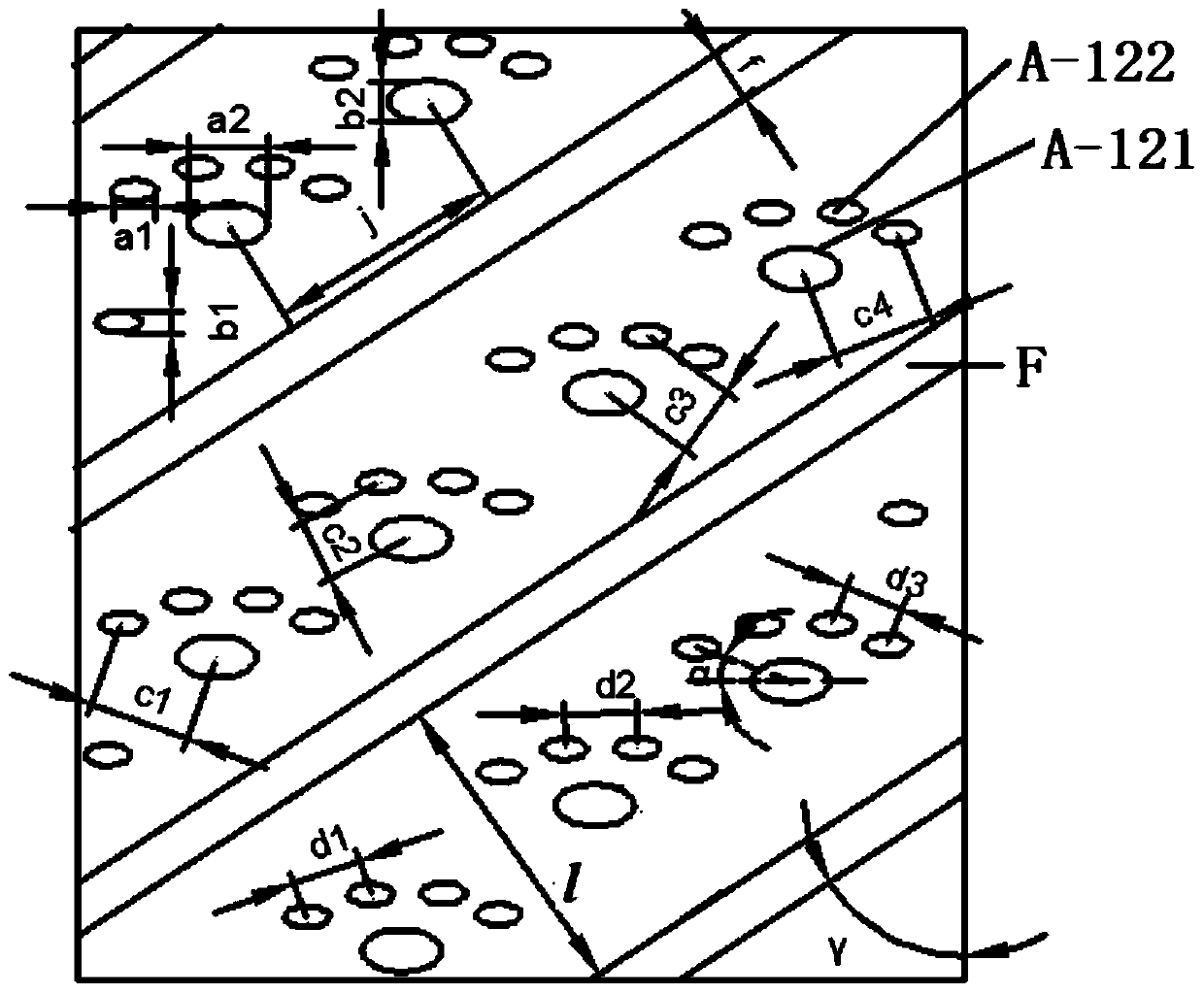

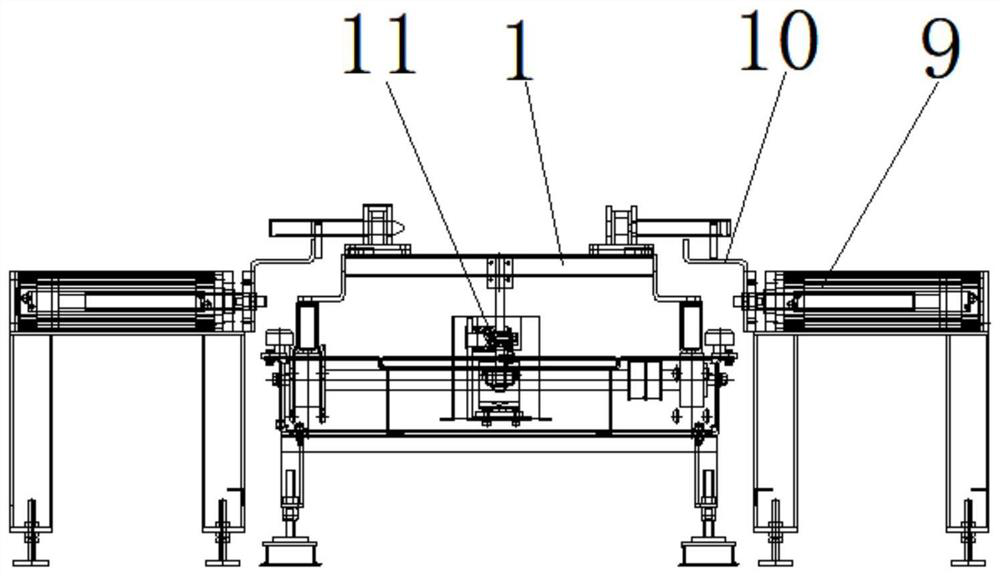

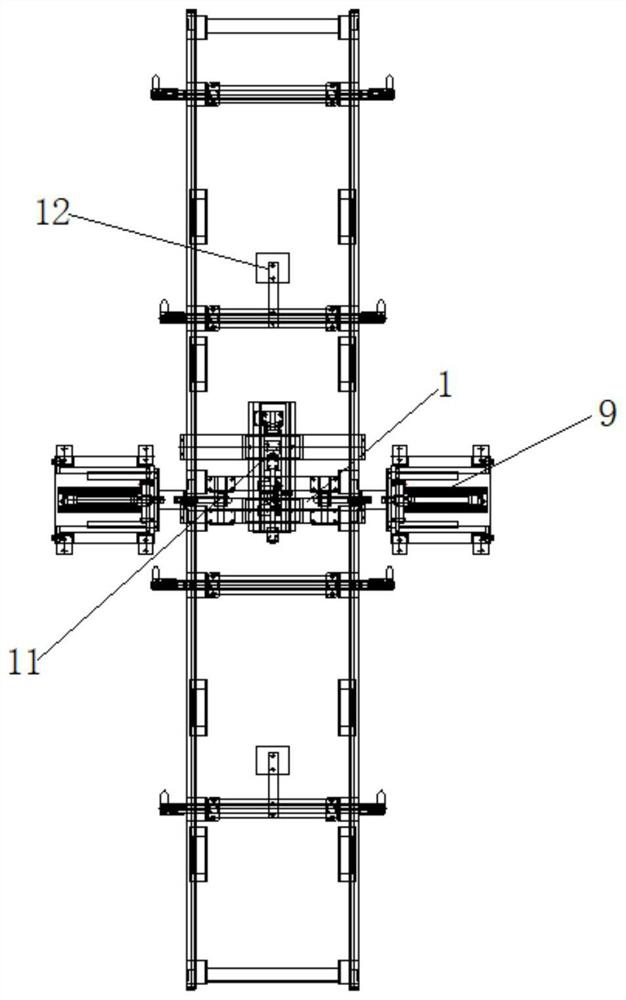

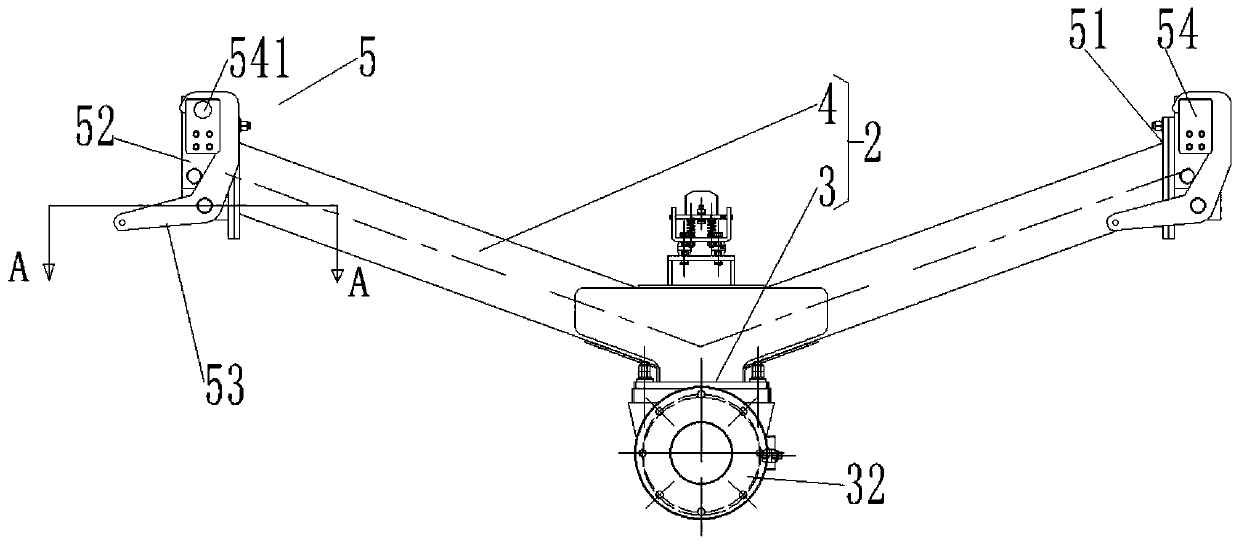

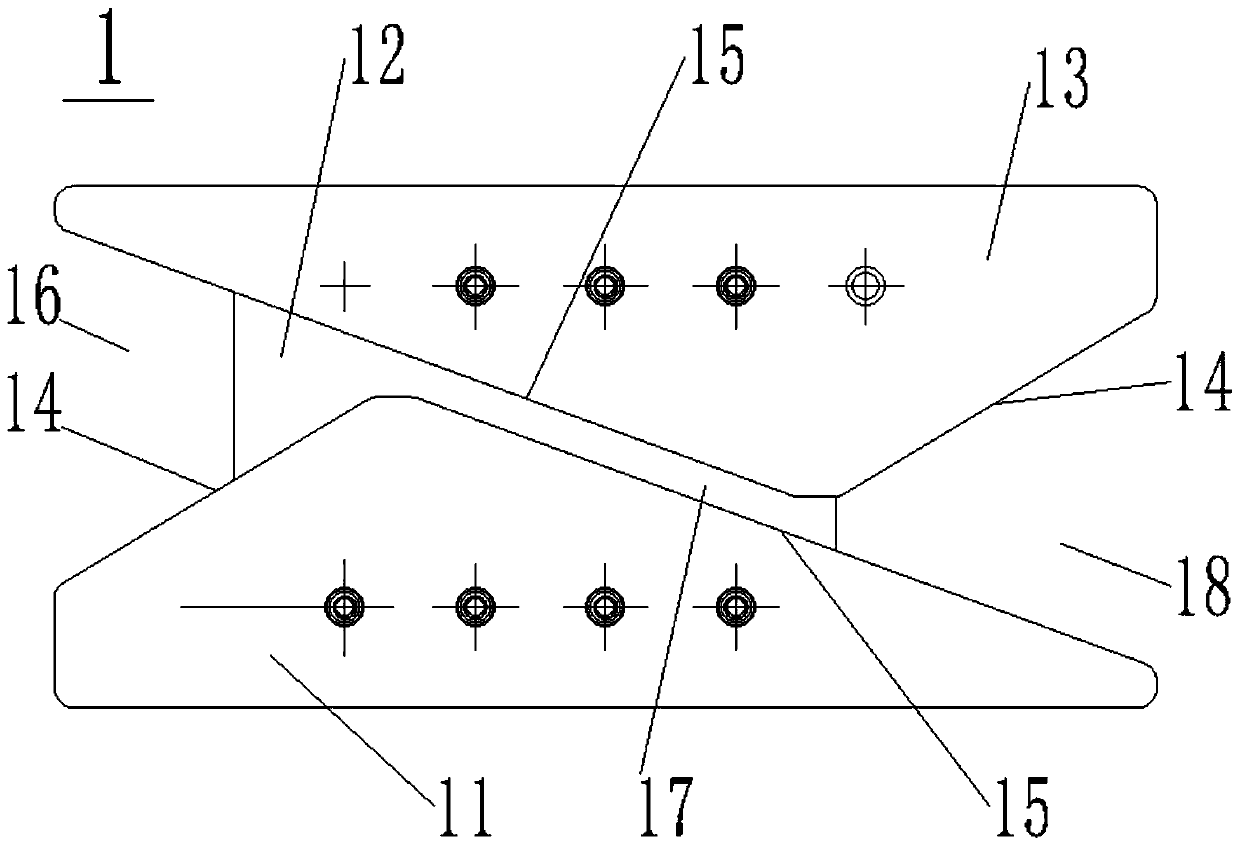

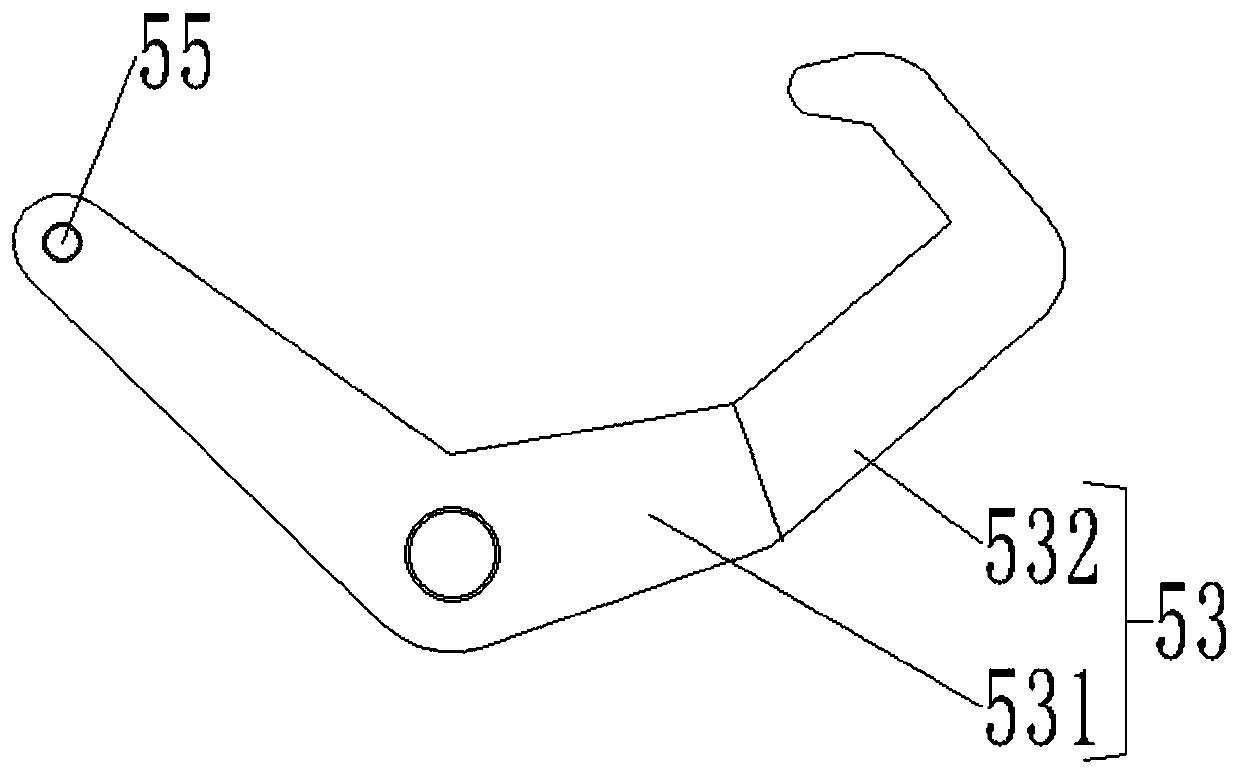

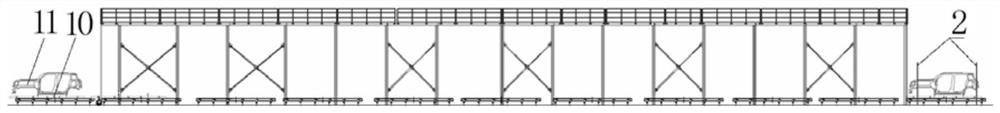

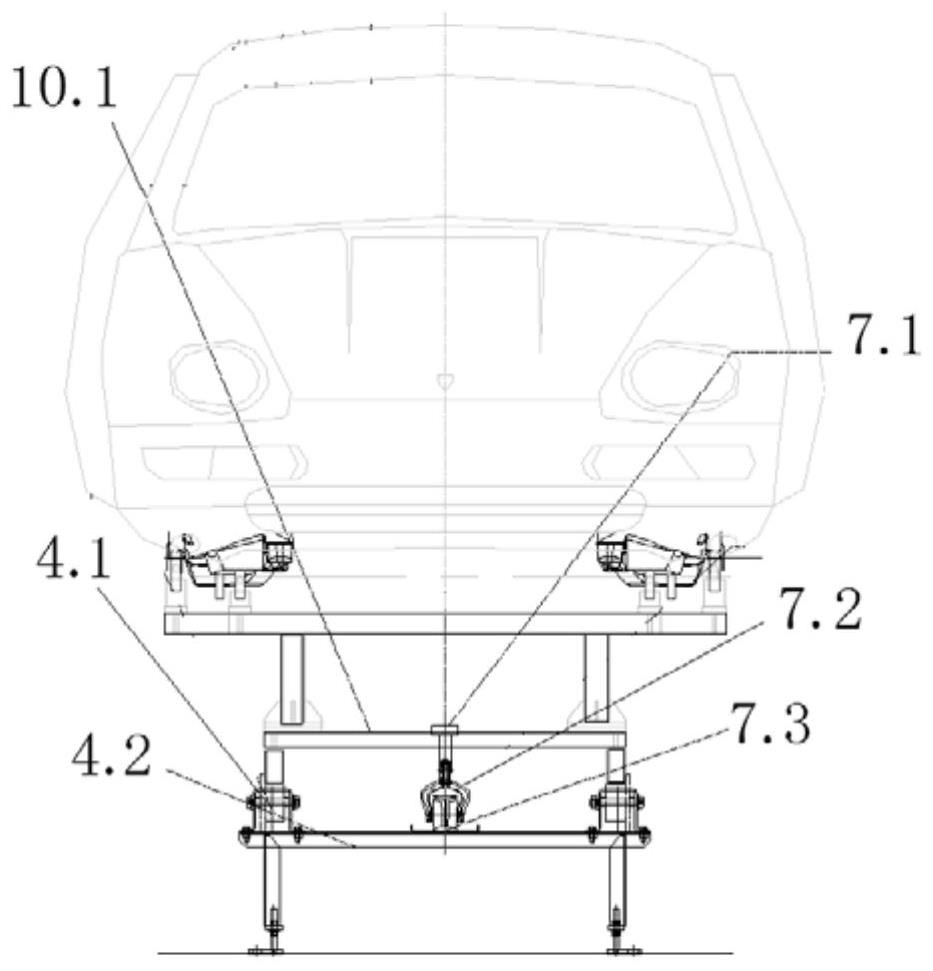

Skid and automobile production line thereof

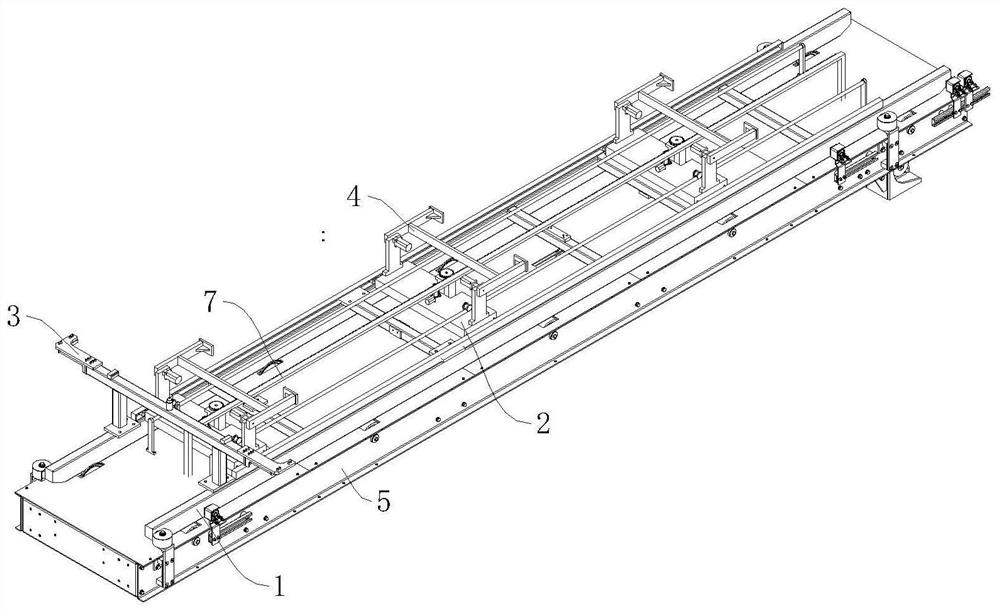

ActiveCN112046998AIngenious ideaReasonable designLiquid surface applicatorsSpraying apparatusProduction lineSkid (automobile)

The invention discloses a skid and an automobile production line thereof. The automobile production line comprises one or more than two skid units, a separating and combining mechanism and a locking and unlocking device, wherein the separating and combining mechanism is arranged on the skid units, is connected to the two skid units end to end, and is used for combining two or more than two skid units into a whole according to different production requirements or separating two or more than two combined skid units into independent skid units; the separating and combining mechanism comprises male connectors, female connectors and plug pins; the male connector is arranged at one end of the skid unit; the female connector is arranged at the other end of the skid unit; the male connector corresponds to the female connector in position; and the plug pin used for fixing the male connector and the female connector is arranged between the male connector and the female connector. According to the skid and the automobile production line thereof, each skid can serve as an independent unit, the independent skid units can be combined and separated through the locking and unlocking mechanism according to different production automobile types, and the collinear production of multiple automobile types of different sizes is achieved.

Owner:JIANGLING MOTORS +3

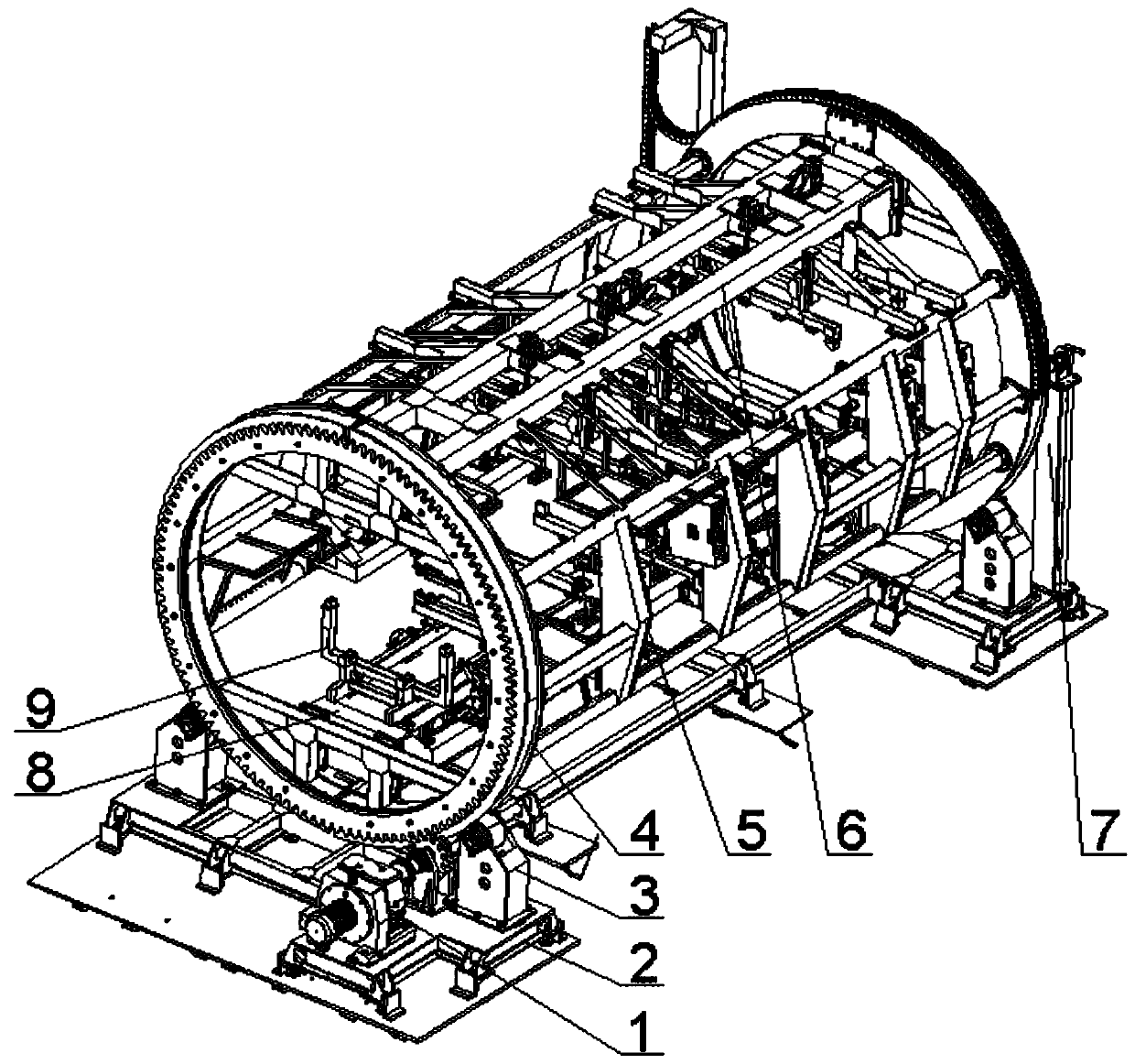

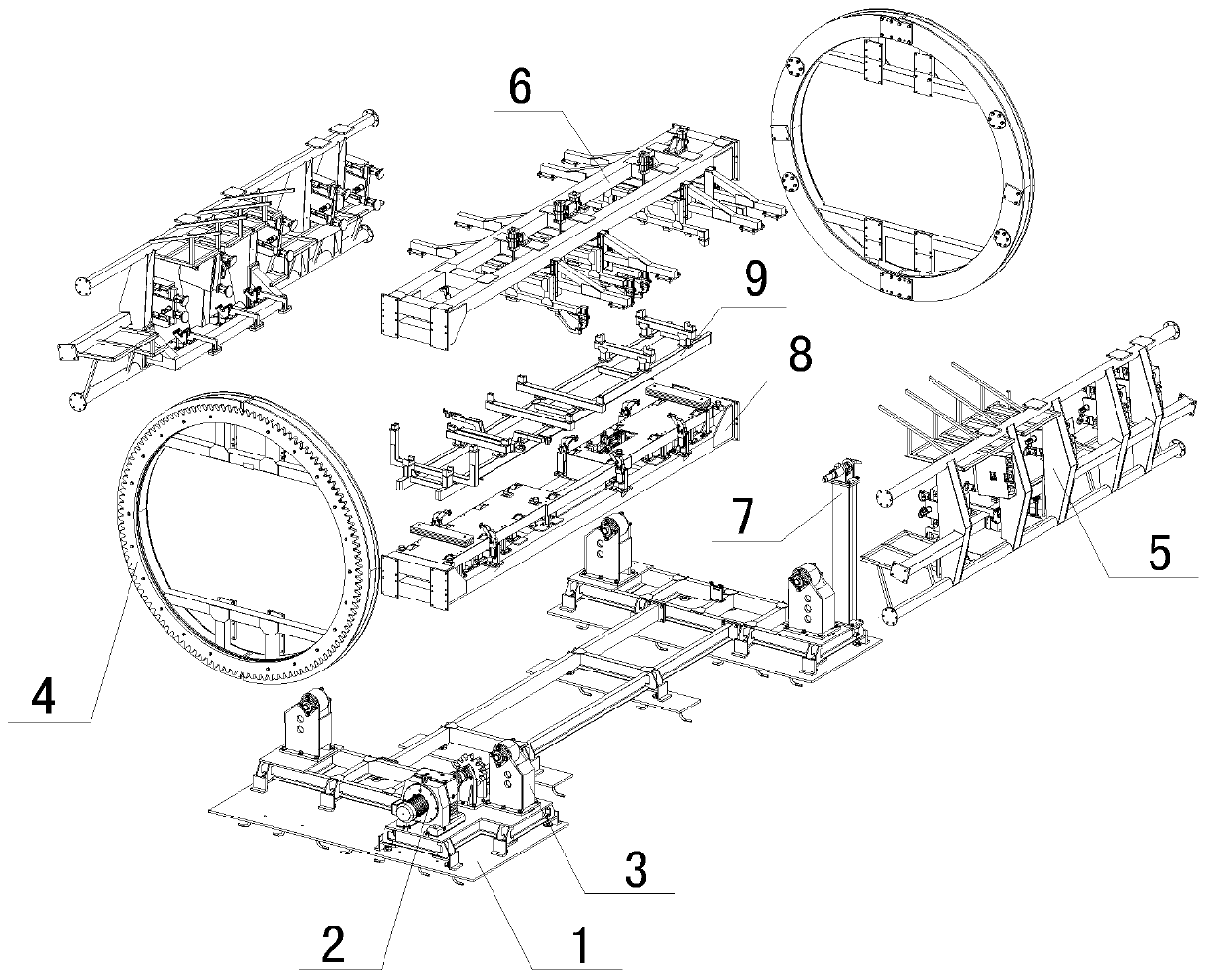

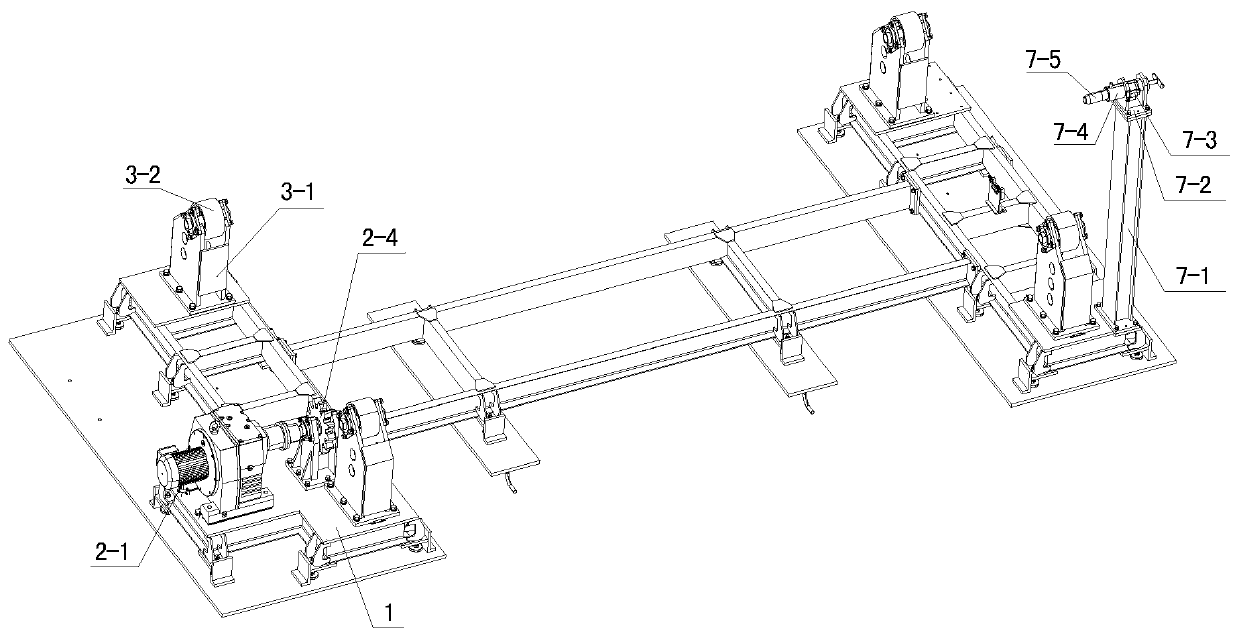

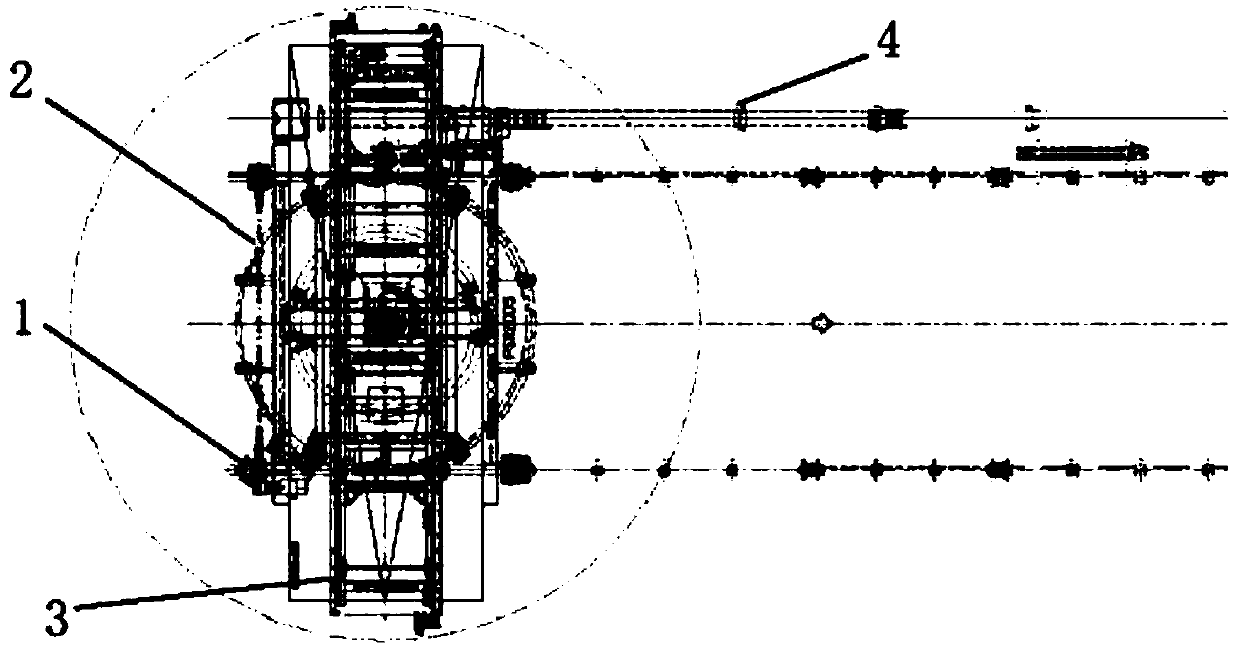

Rolling type automobile welding tool

ActiveCN110744230ASave the process of transshipmentIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineCircular disc

The invention discloses a rolling type automobile welding tool. The rolling type automobile welding tool comprises a base, the two ends of the base are fixedly provided with roller mechanisms, the roller mechanisms are provided with discs in a matching manner, a portion between the two discs is fixedly connected with a side wall clamping device which is clamped with an automobile body side wall and a top cover supporting device which is clamped with an automobile body top cover, the portion between the two discs is further fixedly connected with a fixed roller bed, the fixed roller bed is provided with a skid which is matched with an automobile body bottom plate in a limiting manner, and the fixed roller bed is provided with a skid drive device and a skid limit mechanism. The skid is matched with the automobile body bottom plate in a limiting manner, so that the skid and the automobile body bottom plate as a whole slide horizontally on the fixed roller bed to a welding position on thetool, the fixed roller bed limits and fixes the skid, and the side wall clamping device and the top cover supporting device respectively limit and fix the automobile body side wall and the automobilebody top cover. According to the rolling type automobile welding tool, the transportation mode of the welding mainline automobile body does not need to be changed, after the turnover operation is finished, the skid can always transport the automobile body on the production line along the horizontal track, so that the lifting and transportation process is saved and the production efficiency is greatly improved.

Owner:DONGFENG OFF ROAD VEHICLE CO LTD

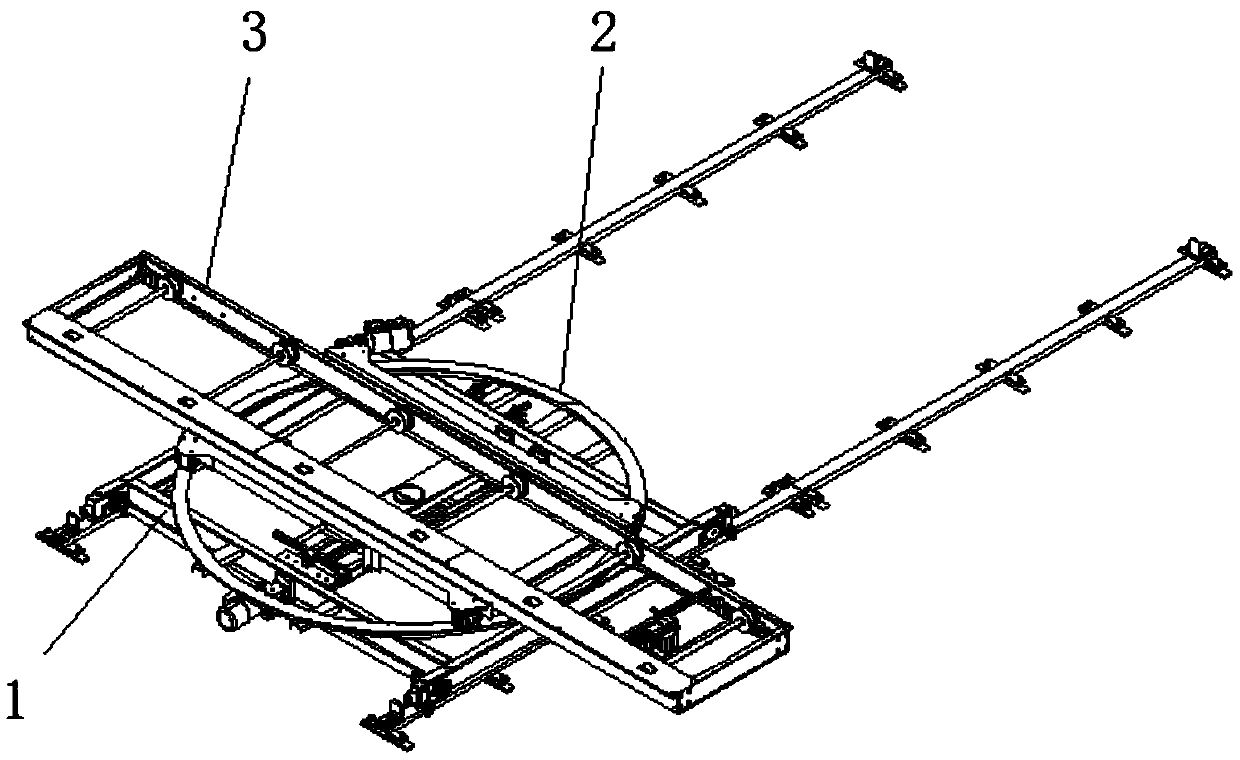

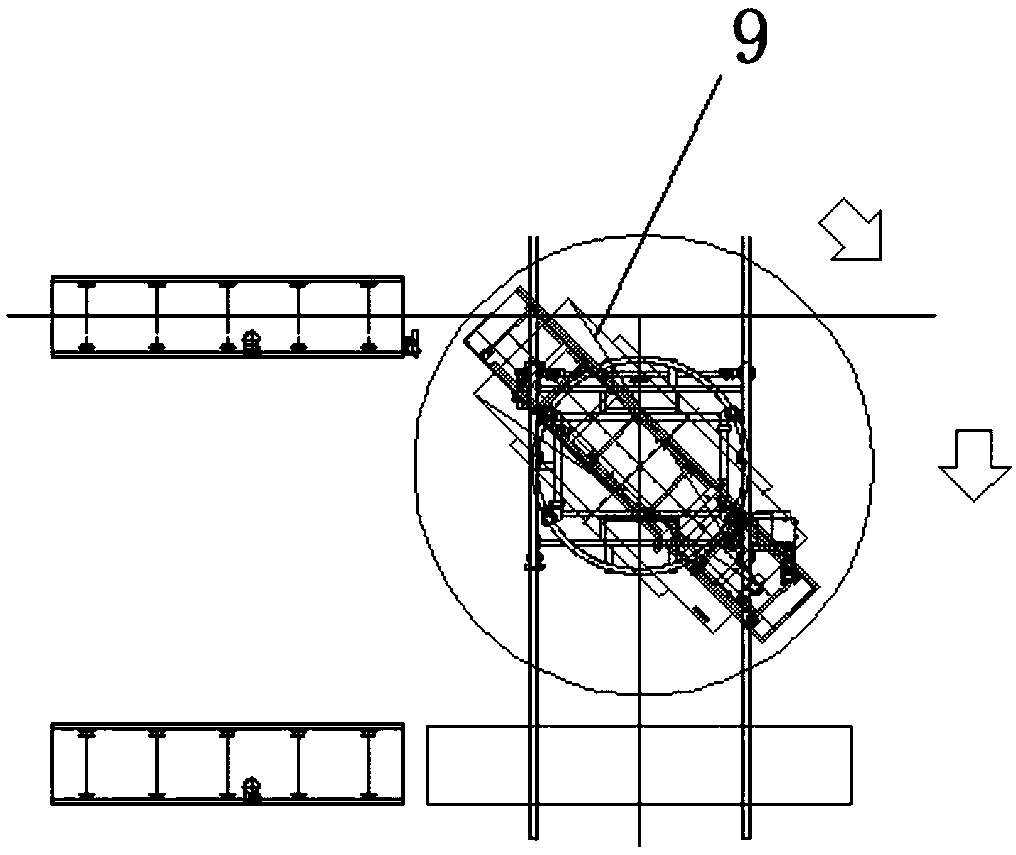

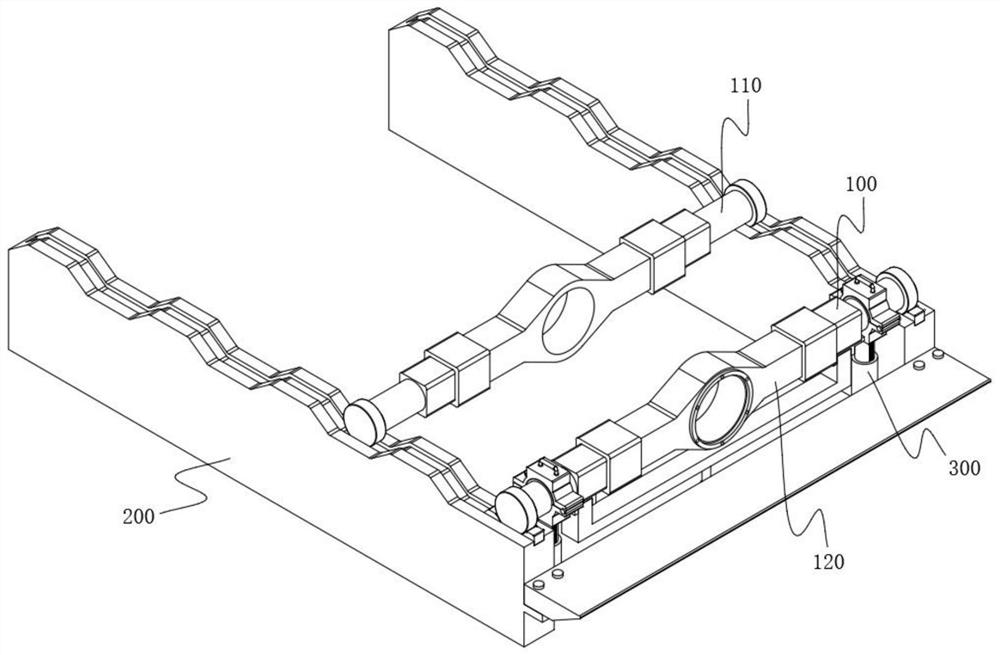

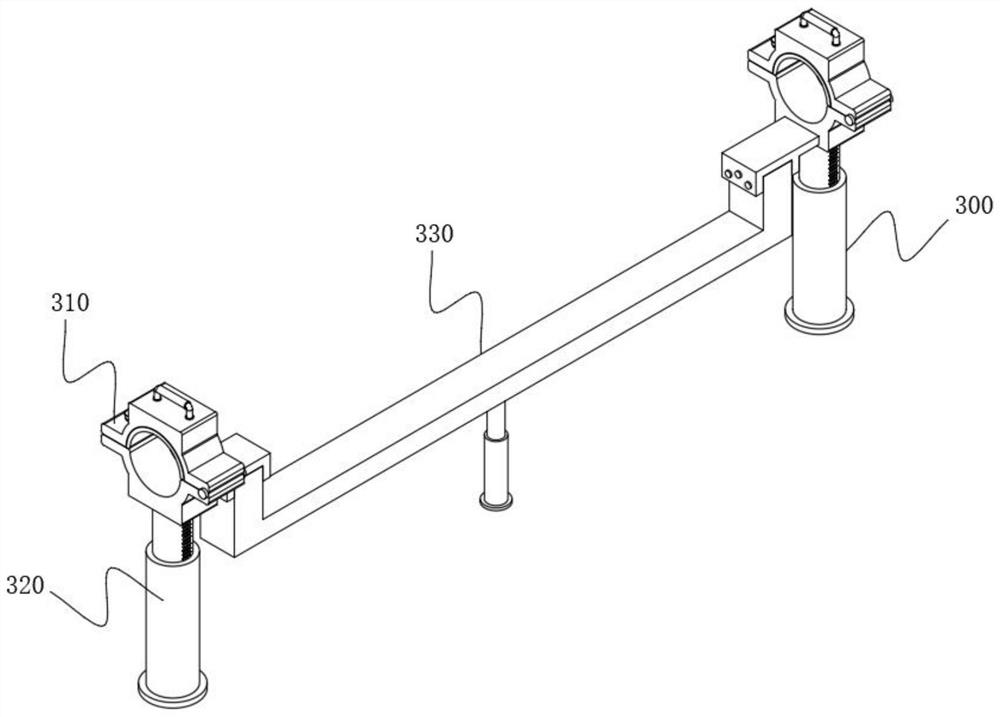

Rotary moving conveying system and skid conveying method

InactiveCN111196474AReduce conveying actionImprove delivery tactMechanical conveyorsControl engineeringElectric machinery

The invention relates to a rotary moving conveying system and a skid conveying method. The conveying system comprises a controller and a rotary moving machine; the rotary moving machine comprises a translation device (1), a rotating device (2) arranged on the translation device (1) and a conveying roller bed (3) rotatably arranged on the rotating device (2); and the controller controls the translation device (1) to drive the rotating device (2) to translate and controls the conveying roller bed (3) to rotate around the center of the rotating device (2) at the same time so as to be used for transporting an automobile body. A novel conveying time sequence is adopted, on the premises that a motor is not replaced and the type of conveying equipment is not changed, rotation and translation arecombined into a whole by changing logic control of the controller, that is, the conveying mode of moving while rotating is adopted, the conveying actions are omitted, and the conveying takt is improved.

Owner:BEIQI FOTON MOTOR CO LTD

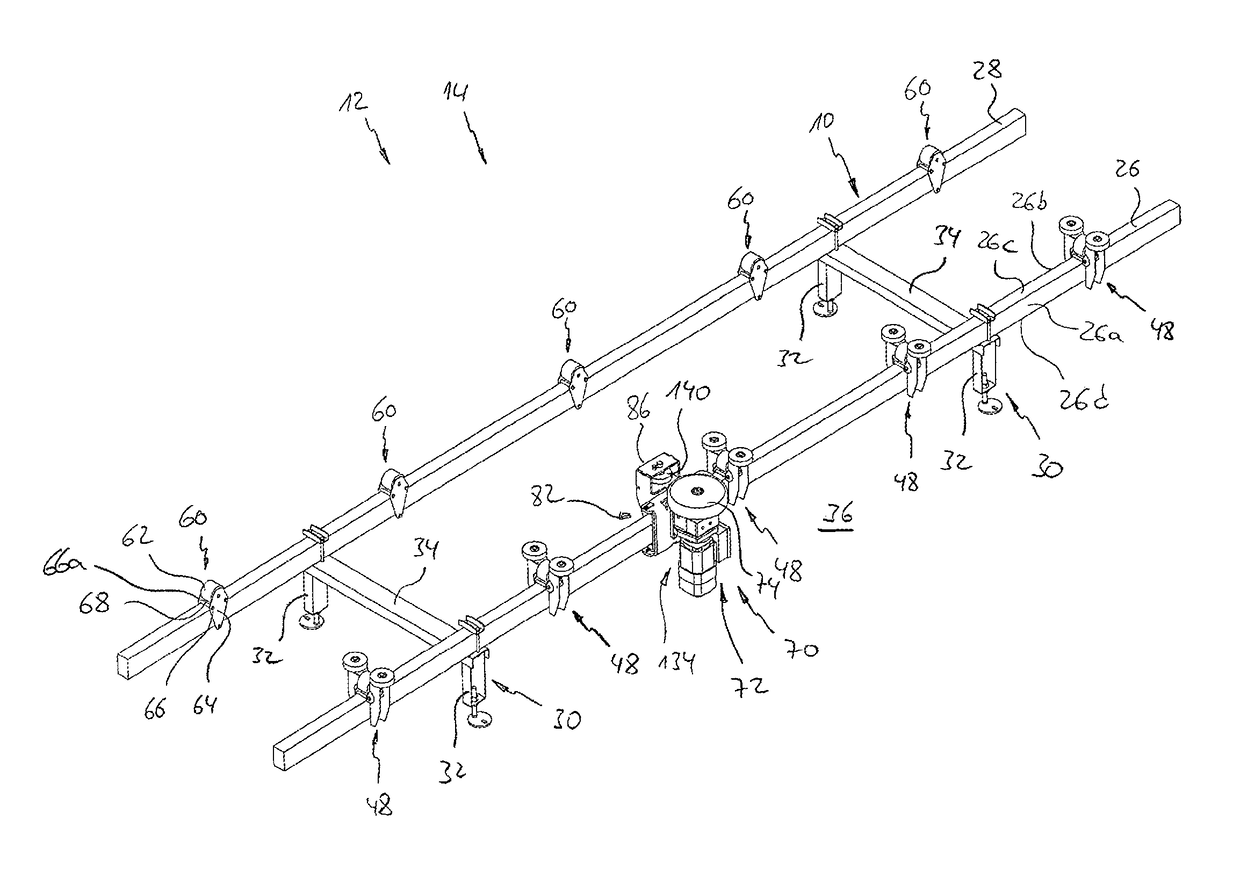

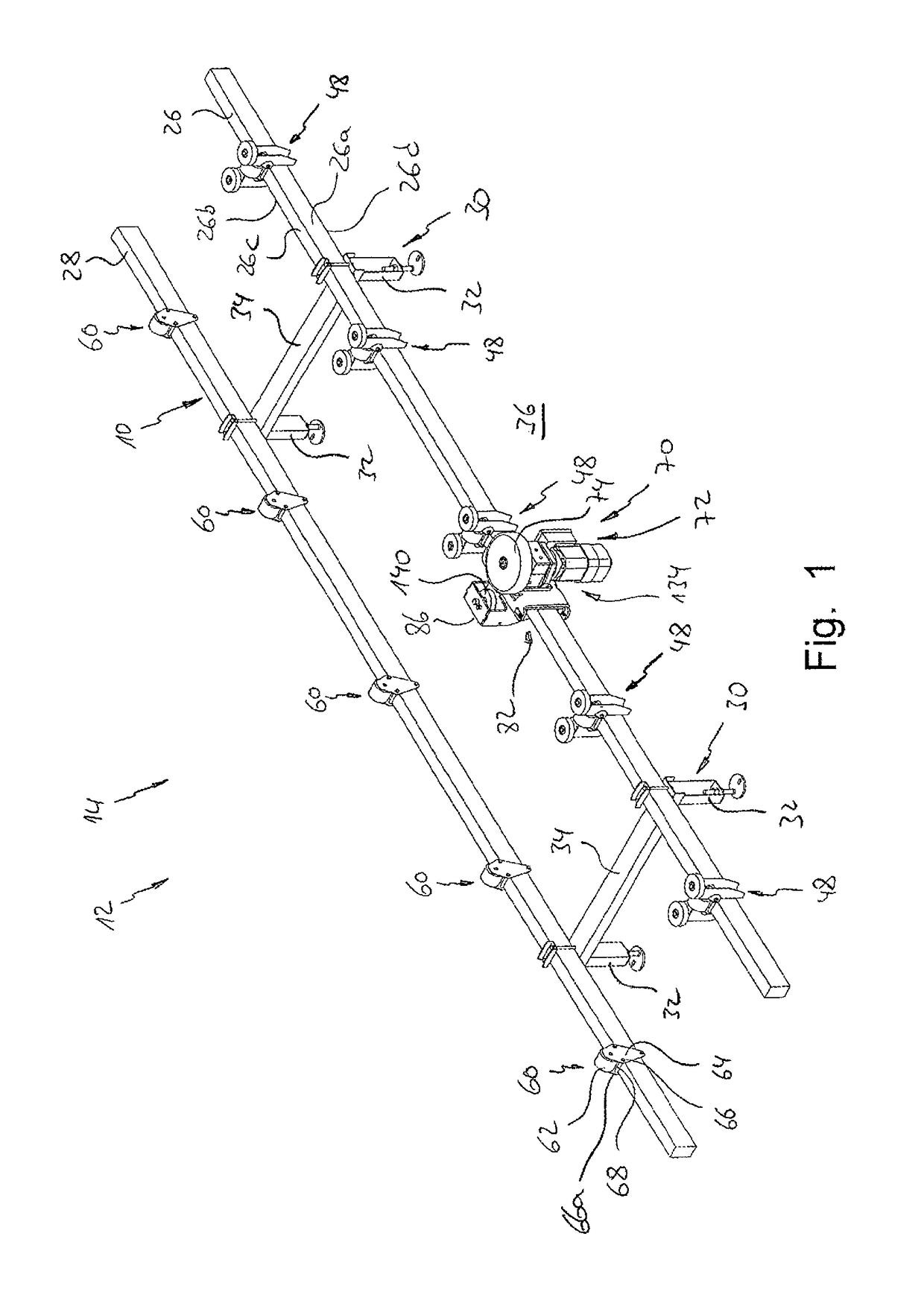

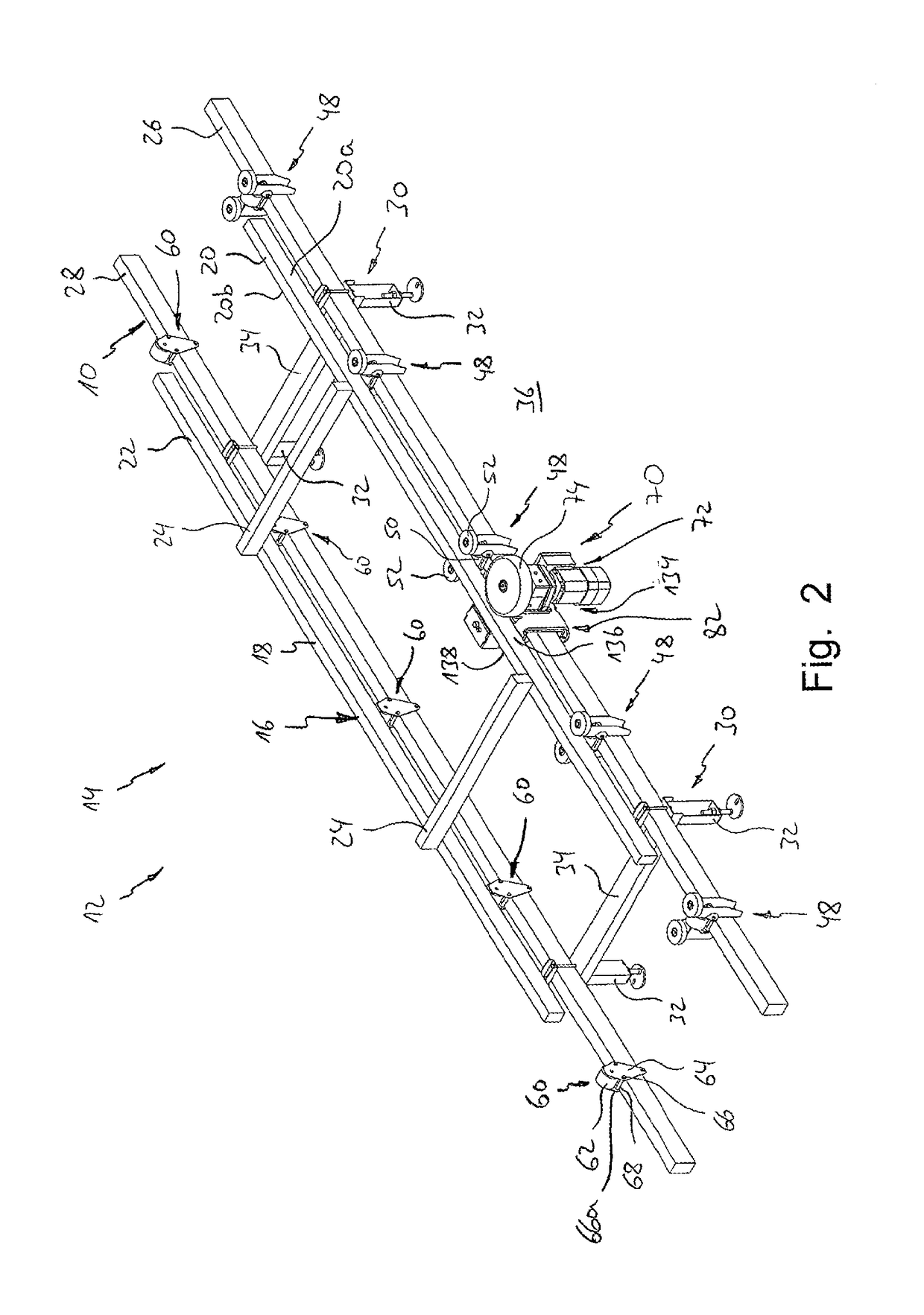

Conveyor device for transporation structures

InactiveUS10124958B2Improve system flexibilityFitting of the drive module is facilitatedRollersMechanical conveyorsSlide plateAuto industry

A conveyor device for conveying transportation structures, particularly transportation skids in the automobile industry, having a conveyor path that is formed from a plurality of path units arranged one behind the other, each of the path units having two parallel longitudinal profiled sections. A drive system for said transportation structures is provided that has at least one drive device which, when said conveyor device is in operation, is arranged on at least one of said longitudinal profiled sections. The drive system includes at least one drive module which can be detachably secured to the longitudinal profiled section by means of a drive-securing device.

Owner:EISENMANN SE

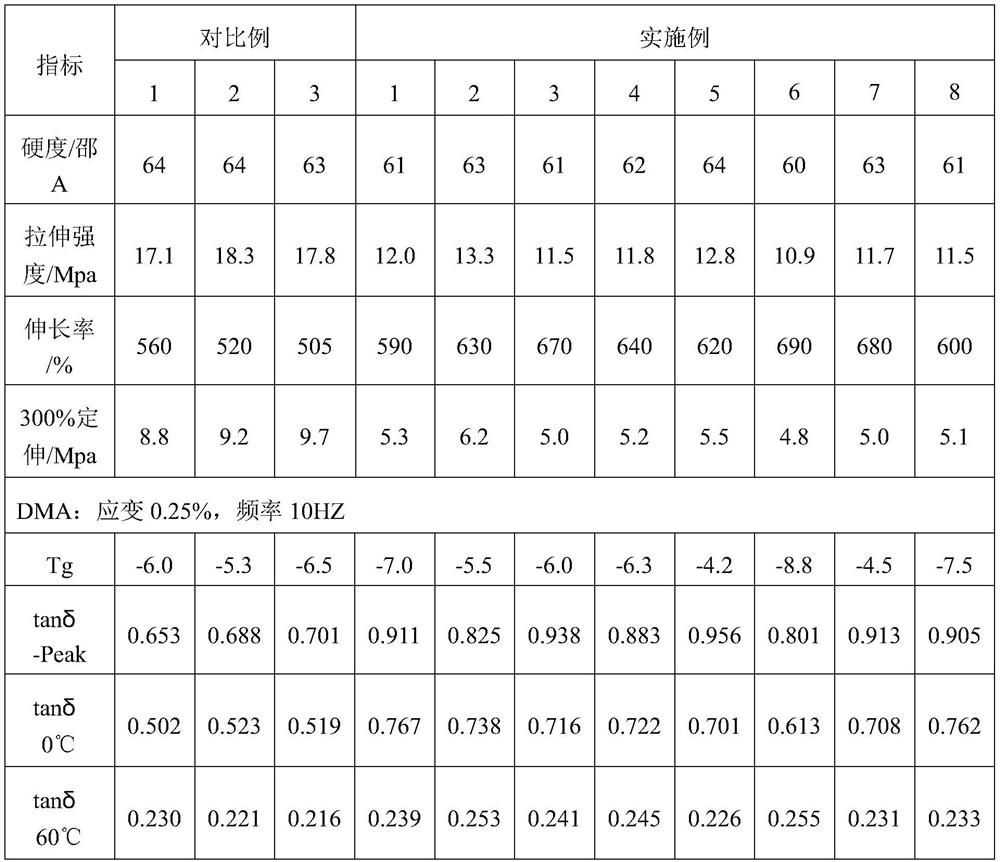

Wet-skid-resistant rubber composition as well as mixing method and application thereof

The invention provides a wet-skid-resistant rubber composition as well as a mixing method and application thereof. The wet-skid-resistant rubber composition is prepared from the following components in parts by weight: 137.5 parts of oil-extended solution polymerized styrene-butadiene rubber, 30-60 parts of carbon black, 30-60 parts of white carbon black with a high specific surface area, 30-60 parts of white carbon black with a low specific surface area, 2-6 parts of a silane coupling agent, 40-90 parts of environment-friendly oil, 5-20 parts of functional resin, 2-5 parts of zinc oxide, 1-3 parts of stearic acid, 4-9 parts of an anti-aging agent, 1-2.5 parts of sulfur and 2-5 parts of an accelerant. Through special design of a formula system in the invention, the wet-skid-resistant rubber composition is used for tire tread rubber used for wet slippery racing tracks, so tires are allowed to have excellent gripping performance in different rainy-day racing track environments such as wet pavements and waterlogged pavements, and an effective solution is provided for coping with the varied rainy-day racing track environments in automobile racing competitions.

Owner:SAILUN GRP CO LTD

Antiskid chains for automobiles in rainy and snowy weather

ActiveCN109050183BProblems that affect the effect of useEasy to installNon-skid devicesSnow chainsEngineering

The invention discloses an automobile rain-snow weather skid-proof chain, including a first head end connecting rod and an auxiliary connecting rod, one side of the first head end connecting rod is rotatably connected with the second head end connecting rod through a rotary connecting piece, the end of the auxiliary connecting rod is rotatably connected with the end connecting rod through the auxiliary rotary connecting piece, one side of the end connecting rod is fixedly connected with a mounting piece through bolts, one side of the mounting piece is fixedly connected with a first head end connecting rod through bolts, the bottom end of the end connecting rod is fixedly installed with an end fixing bracket, the inner side of the end fixing frame is rotatably connected with a rotating connecting rod through a rotating shaft, The end of the rotary connecting rod is rotatably connected with a screw seat through a bearing. The invention is provided with an inclined skateboard, a triangular pressing block and a fixed triangular block, thereby avoiding the problem that the anti-skid degree of the anti-skid chain in rainy and snow weather is difficult to adjust according to the pavementcondition when the anti-skid chain is used in rainy and snow weather, and influencing the use effect of the anti-skid chain in rainy and snow weather.

Owner:ANHUI TIANYU AUTO PARTS MFG

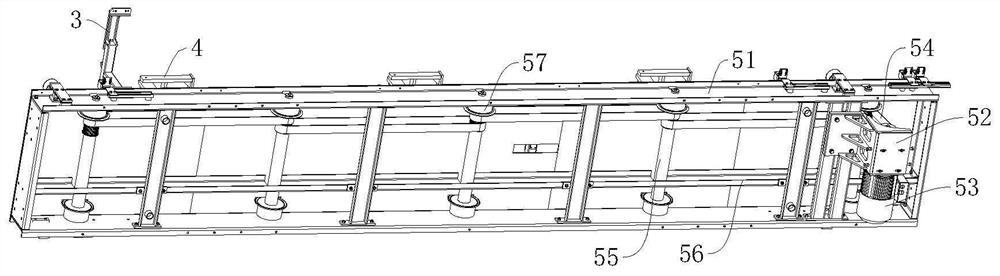

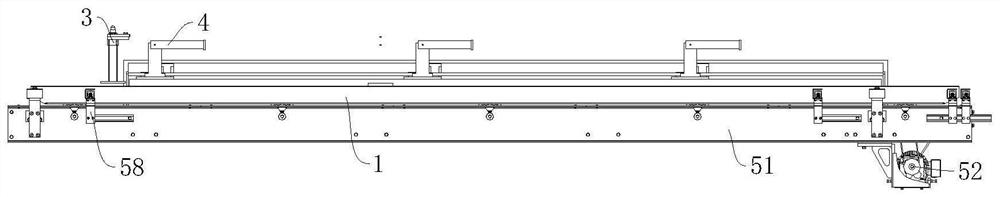

Automobile chassis finish paint conveying device

InactiveCN112298944AImprove passabilitySatisfy passabilityMechanical conveyorsRolling chassisSkid (automobile)

He invention relates to the field of automobile production, in particular to an automobile chassis finish paint conveying device. The automobile chassis finish paint conveying device comprises a skidbase, a movable carrying table, a front supporting mechanism, a movable supporting mechanism and a power mechanism, wherein the movable carrying table is arranged on the skid base in a sliding mode; the front supporting mechanism is fixedly arranged at one end of the skid base and is used for supporting a front axle of an automobile chassis; the movable supporting mechanism is arranged on the movable carrying table in a sliding mode and is used for supporting a longitudinal beam of the automobile chassis, when the movable carrying table slides on the skid base, the movable supporting mechanismis synchronously driven to move along the skid base, the movable supporting mechanism is rotationally arranged on the movable carrying table, the movable supporting mechanism is vertical to the skidbase, the movable supporting mechanism can be put down on the movable carrying table after rotating, and the height of the movable supporting mechanism after being put down is lower than that of the front supporting mechanism; and the power mechanism is arranged at the bottom of the skid base and is used for driving the skid base to slide along a straight line. According to the automobile chassisfinish paint conveying device, the longitudinal beam of the chassis can be supported by switching the states of the movable supporting mechanism, so that the passing ability is met.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

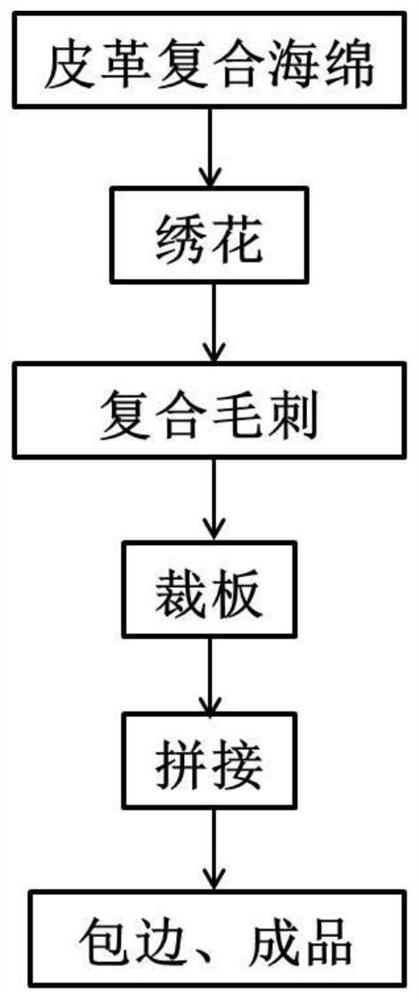

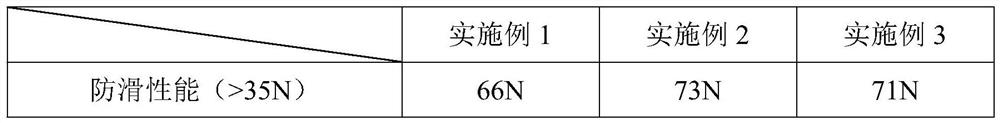

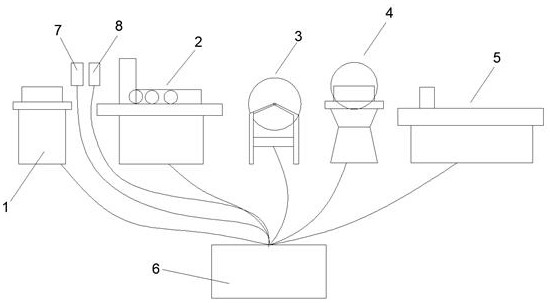

Preparation method of antiskid automobile foot mat

InactiveCN112440543AImprove flame retardant performanceEasy to cleanVehicle arrangementsLamination ancillary operationsFoot cushionMechanical engineering

The invention discloses a preparation method of an anti-skid automobile foot mat. The preparation method comprises the technological manufacturing processes of combination of leather and sponge, computerized embroidery, burr compounding, plate cutting, splicing, edge covering and finished product obtaining. The burr compounding means that a PE mixture (polyethylene mixture), EVA (ethylene-vinyl acetate copolymer) are combined with a leather sponge layer on a roller compounding machine according to a certain proportion. The anti-skid foot pad for the automobile has excellent anti-skid performance and is easy to clean, noise-proof and flame-retardant, the preparation method is simple, and the raw materials are cheap and easy to obtain.

Owner:池秀珠

Novel clamping buckle used for automobile air conditioning pipe

PendingCN110985759ASnap firmlyPipe supportsAir-treating devicesAir conditioningElectrical and Electronics engineering

The invention discloses a novel clamping buckle used for an automobile air conditioning pipe, and belongs to the technical field of air conditioning pipe clamping buckles. An inserting piece is installed in the middle position of the other end part of a strip-shaped rubber sleeve, the inserting piece is matched with a clamping piece to enable the strip-shaped rubber sleeve to form an annular structure, cone-shaped anti-skid rubber strips are installed on the inner side of the strip-shaped rubber sleeve at equal intervals along the ring part of the strip-shaped rubber sleeve, and cone-shaped buffering bodies are installed on the outer side of the strip-shaped rubber sleeve at equal intervals along the outer side of the strip-shaped rubber sleeve and along the ring part of the strip-shaped rubber sleeve. According to the novel clamping buckle used for the automobile air conditioning pipe, the strip-shaped rubber sleeve wraps the outer side of the air conditioning pipe, the strip-shaped rubber sleeve is clamped and fitted to the outer side of the air conditioning pipe through the mutual cooperation of the inserting piece and the clamping piece, skid resistance is achieved through thecone-shaped anti-skid rubber strips, damping, buffering and protecting effects on pipeline collision on the outer side are achieved through the cone-shaped buffering bodies, a rubber inserting plate is inserted into the inner side of a strip-shaped inserted opening, and a rubber connecting strip and a rubber clamping cone penetrate through a side through opening, so that the rubber clamping cone is inserted into the inner side of a clamping and fitting groove, and clamping and fitting is further firmer.

Owner:YANGZHONG HONGHUI RUBBER PROD

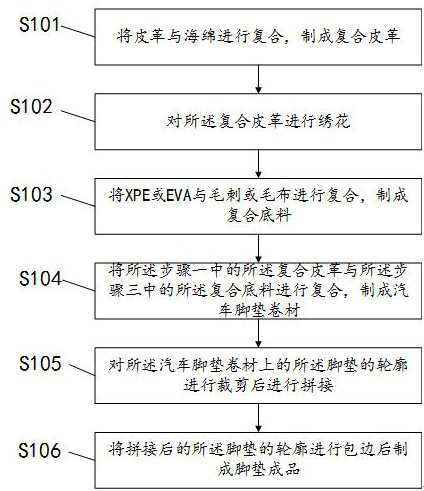

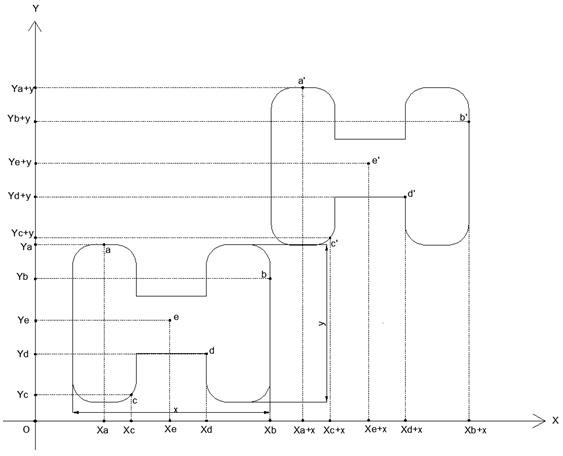

Anti-skid automobile foot mat production process

PendingCN112848631AReduce embroidery areaImprove construction efficiencyImage enhancementImage analysisFoot cushionCotton cloth

The invention provides an anti-skid car foot mat production process which comprises the following steps: step 1, compounding leather and sponge to prepare composite leather; step 2, embroidering the composite leather; step 3, compounding XPE or EVA with burrs or coarse cotton cloth to prepare a composite backing material; step 4, compounding the composite leather in the first step and the composite bottom material in the third step, and manufacturing the automobile foot mat coiled material; step 5, cutting and then splicing the contour of the foot pad on the automobile foot pad coiled material; and step 6, enabling the outline of the spliced foot pad to be subjected to edge covering, and then manufacturing a foot pad finished product. It can be seen that the outline of the foot pad is determined on the composite leather, embroidering is conducted in the determined outline, and therefore the embroidering area is effectively reduced, the construction efficiency is improved, the construction cost is saved, meanwhile, by determining the outline of the foot pad, the follow-up cutting procedure is greatly facilitated, time is saved, and the production efficiency is improved.

Owner:临沂金钰纺织品有限公司

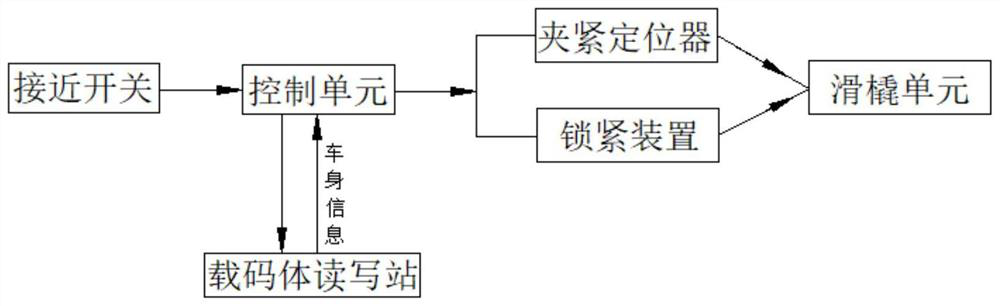

Automobile skid locking device

ActiveCN110817313AReliable lockingControl devices for conveyorsMechanical conveyorsControl theoryMechanical engineering

Owner:JIANGSU CHANGHONG INTELLIGENT EQUIP CO LTD +1

Rear axle flange ring welding device with adjusting structure and for automobile

ActiveCN112059503AReduce the difficulty of operationPrevent rotationWelding/cutting auxillary devicesAuxillary welding devicesFlangeTransaxle

The invention relates to the technical field of flange ring welding, in particular to a rear axle flange ring welding device with an adjusting structure and for an automobile. The rear axle flange ring welding device comprises a rear axle and a welding frame arranged at the bottom of the rear axle. The welding frame comprises two supporting plates, the two supporting plates are correspondingly arranged on the left side and the right side of the rear axle, the rear axle comprises a drive axle housing, a hub is arranged at the end of the drive axle housing, and an adjusting mechanism is arrangedat the position, close to the front side, between the two supporting plates. A fixing device is arranged, the drive axle housing is fixed through static friction force generated by an anti-skid pad and a bottom fixing groove, the phenomena of rotation and skid of the drive axle housing are avoided, and the operation difficulty of welding personnel during welding is reduced; and the height of thewelding rear axle is adjusted through a telescopic cross beam, so that the welding position at the bottom is flush with the face of the welding personnel, the splashing amount of welding sparks flyingto the face is reduced, and the risk that the face is scalded by the welding sparks is reduced.

Owner:CHANGDE JIAHONG MACHINERY

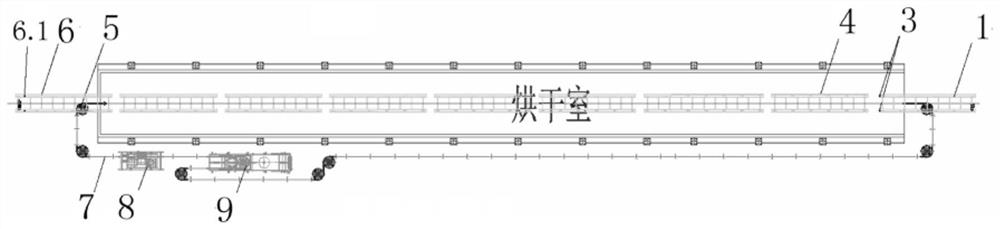

Automobile coating drying and conveying device and conveying control method thereof

PendingCN113844852AAvoid Skid Collision RiskReasonable designPretreated surfacesControl devices for conveyorsControl engineeringMachine

The invention discloses an automobile coating drying and conveying device and a conveying control method thereof. An identification sensor is used for identifying the type of an automobile body carried by a skid located on an inlet variable-speed single-side roller machine, and according to judgment of the identification sensor, whether an in-place switch directly releases or delays to release is judged; when the automobile body is long, the in-place switch delays by one station for releasing in order to avoid the collision risk of the automobile body, and vice versa; and in the process, a chain keeps running continuously, and after the in-place switch is released, a push head of the chain hooks a cross beam on the skid and takes away the skid and the automobile body on the skid, so that different distances between different automobile bodies in the conveying process are realized. Therefore, collinear production of large and small automobile types is realized, and kinetic energy loss and beat loss of collinear production are greatly reduced; and moreover, the production takt is improved, the collision risk of the skid in a coating drying furnace is avoided, and the operation is stable and reliable.

Owner:CHERY COMML VEHICLE ANHUI

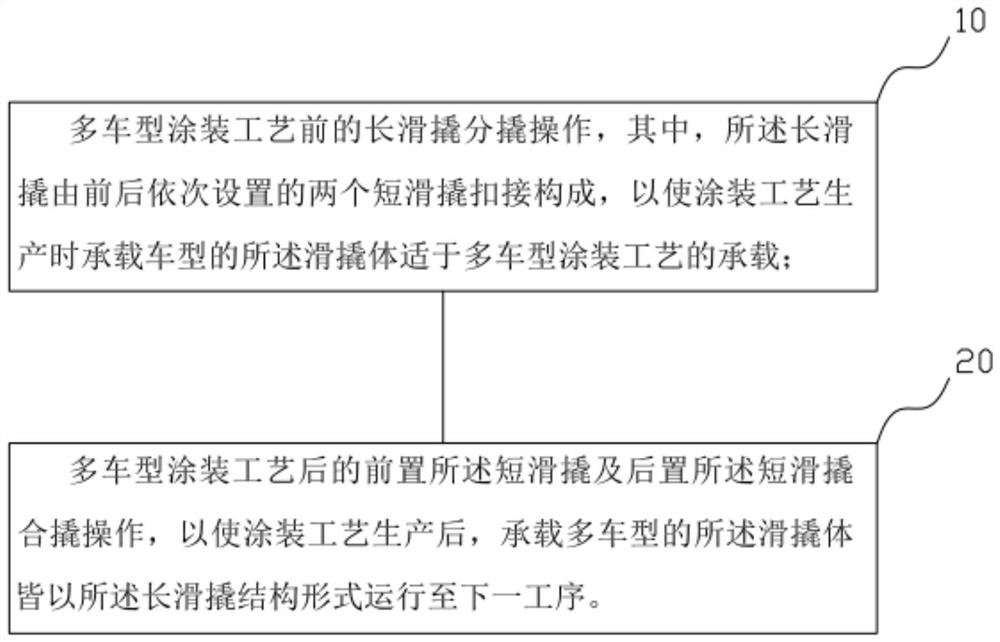

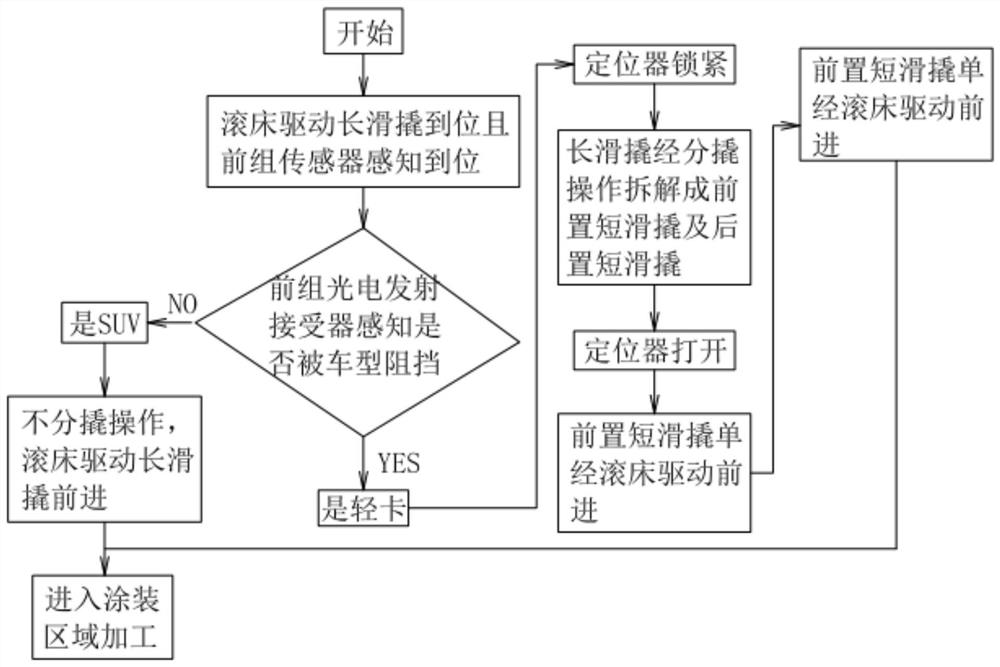

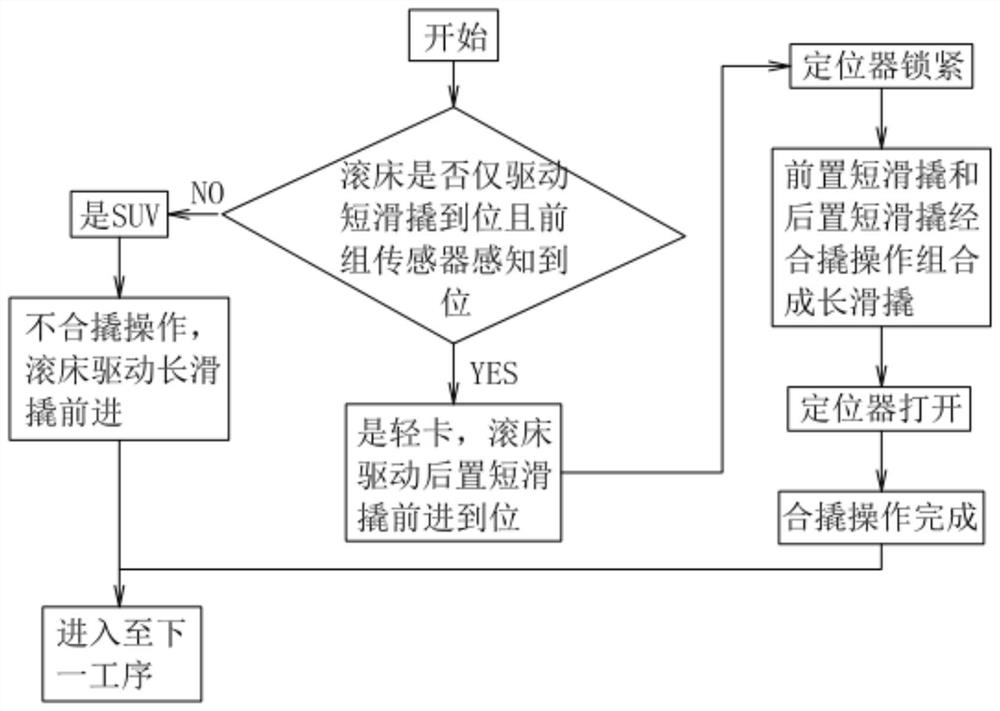

Control method of skid body for automobile coating process

The invention provides a control method of a skid body for an automobile coating process. The control method is applied to collinear production of the coating process of multiple vehicle types, and the intelligent separation and combination control method comprises the following steps that a long skid is separated before the coating process of the multiple vehicle types, the long skid is formed by buckling two short skid bodies which are sequentially arranged front and back, and therefore, the skid body for bearing the vehicle type during coating process production is suitable for bearing the coating process of multiple vehicle types; and the front short skid and the rear short skid are subjected to prying operation after the multi-vehicle-type coating process, so that the skid bodies bearing the multiple vehicle types run to the next procedure in the form of a long skid structure after the coating process production. According to the control method, collinear coating production of multiple varieties of SUV products and multiple varieties of light truck products on a coating production line is ensured, the types, the number and the storage space of carriers are greatly reduced, the carrier switching workload in the production process is greatly reduced, the coating processing production efficiency is improved, and the cost consumption is reduced.

Owner:JIANGLING MOTORS

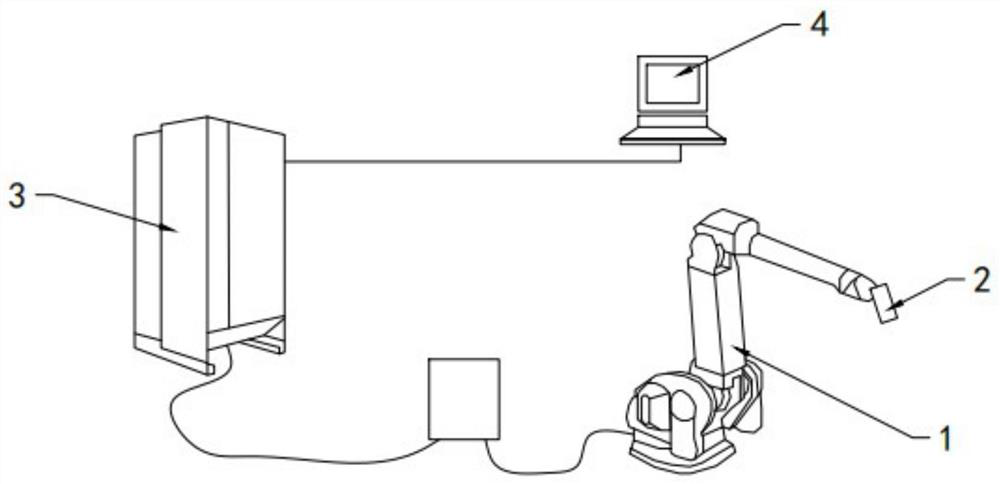

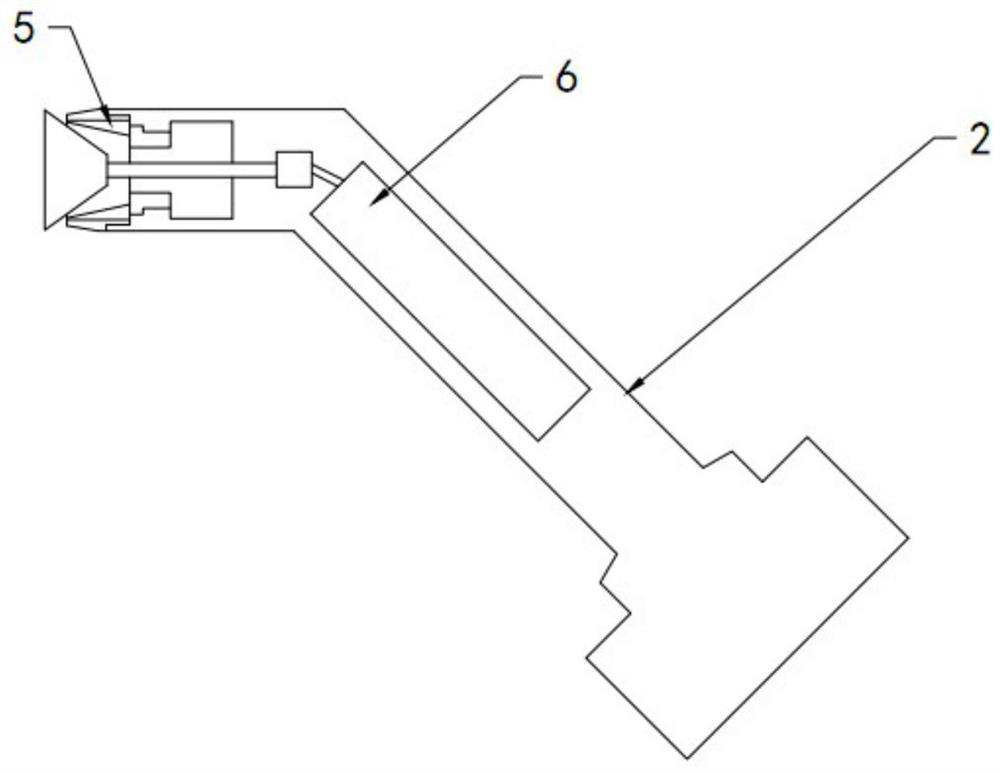

Rotary cup spraying method for primer of automobile exterior trimming part

PendingCN113019730AReduce consumptionIncrease film thicknessSpraying power supplySpray discharge apparatusEconomic benefitsCentrifugal force

The invention discloses a rotary cup spraying method for primer of an automobile exterior trimming part, and relates to the technical field of paint spraying. The rotary cup spraying method for the primer of the automobile exterior trimming part comprises the following steps that a skid provided with the automobile exterior trimming part is grounded, then a rotary cup atomizer is fixed to a robot, the robot drives the rotary cup atomizer, the rotary cup atomizer generates large centrifugal force through a cup head rotating at a high speed, high-viscosity paint is atomized, and then under the action of forming air, the atomized paint is pushed to the surface of the product; or, the electrostatic adsorption effect is added, so that the paint particles with charges are better adsorbed to the surface of the product after being atomized. Through the scheme, the thickness of a primer film of the product is greatly increased, the requirements of customers are met, the painting rate is increased to 50-70%, the paint mist amount of a spraying room is reduced, the appearance quality of the product is improved, meanwhile, consumption of the primer is reduced, and economic benefits are improved.

Owner:陈海华

Wear-resistant and skid-resistant asphalt pavement treatment material and preparation method thereof

PendingCN114752304AIncrease frictionImprove thermal stabilityPolyamide coatingsBituminous coatingsModified carbonPolyamide

The invention discloses a wear-resistant and skid-resistant asphalt pavement treatment material and a preparation method thereof. The wear-resistant asphalt is prepared from the following components in parts by weight: 40-60 parts of matrix asphalt, 30-40 parts of polyamide resin, 3-7 parts of a flexibilizer, 1-3 parts of a friction performance regulator, 1-3 parts of aramid fiber, 10-15 parts of modified silicon carbide powder, 2-7 parts of a silane coupling agent, 3-5 parts of epoxidized soybean oil, 2-7 parts of polydiethylsiloxane, 4-6 parts of wear-resistant carbon black, 2-5 parts of calcium sulfate whiskers and 7-12 parts of an emulsifier. The wear-resistant carbon black is added into the raw materials, so that the friction performance of a pavement can be improved, the calcium sulfate whiskers enable the treatment material to have good thermal stability, and the toughening agent can improve the toughness of the pavement when the pavement is rubbed by wheel pressure of an automobile and reduce cracks caused by temperature or stress.

Owner:广西北投交通养护科技集团有限公司 +1

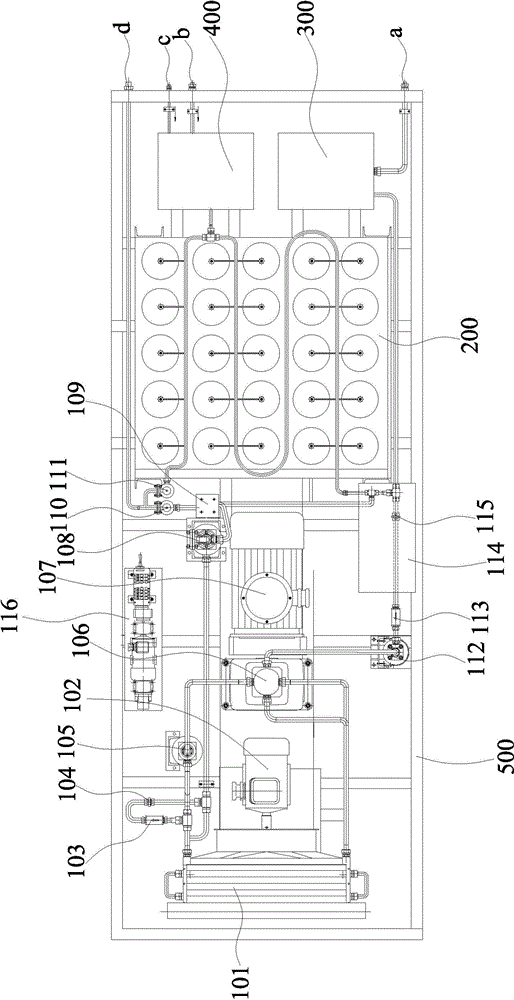

Skid-mounted compressed natural gas vehicle filling device

ActiveCN103883873BSmall footprintLess investmentContainer discharging methodsContainer filling under pressureCompressed natural gasMarine engineering

The invention discloses a skid-mounted compressed natural gas automobile air-entrapping device which comprises an air discharging column, a compressor, an air cylinder group, an air-entrapping machine, a skid-mounted body and a base, wherein an air source inlet, a medium-pressure air source inlet and a low-pressure air source inlet are formed in the base; the air source inlet is connected with the air discharging column; the air discharging column is respectively in pipeline connection with the compressor and the air cylinder group; a manual stop valve is arranged on a pipeline between the air discharging column and the compressor; the compressor is connected with the air cylinder group; the air cylinder group, the medium-pressure air source inlet and the low-pressure air source inlet are respectively connected with an air inlet of the air-entrapping machine; the air discharging column, the compressor, the air cylinder group and the air-entrapping machine are arranged on the base and are positioned in the same skid-mounted body. According to the skid-mounted compressed natural gas automobile air-entrapping device, the operations of air discharging, compressing, controlling, air storing and air entrapping are integrated, the device is small in floor space and convenient to move and use, the approval process can be finished at a time, and the device can be used as fast as possible and is particularly suitable for vehicle air-entrapping in departments such as bus stations, driving schools and taxi enterprises.

Owner:安徽鸿纳能源环保科技有限公司

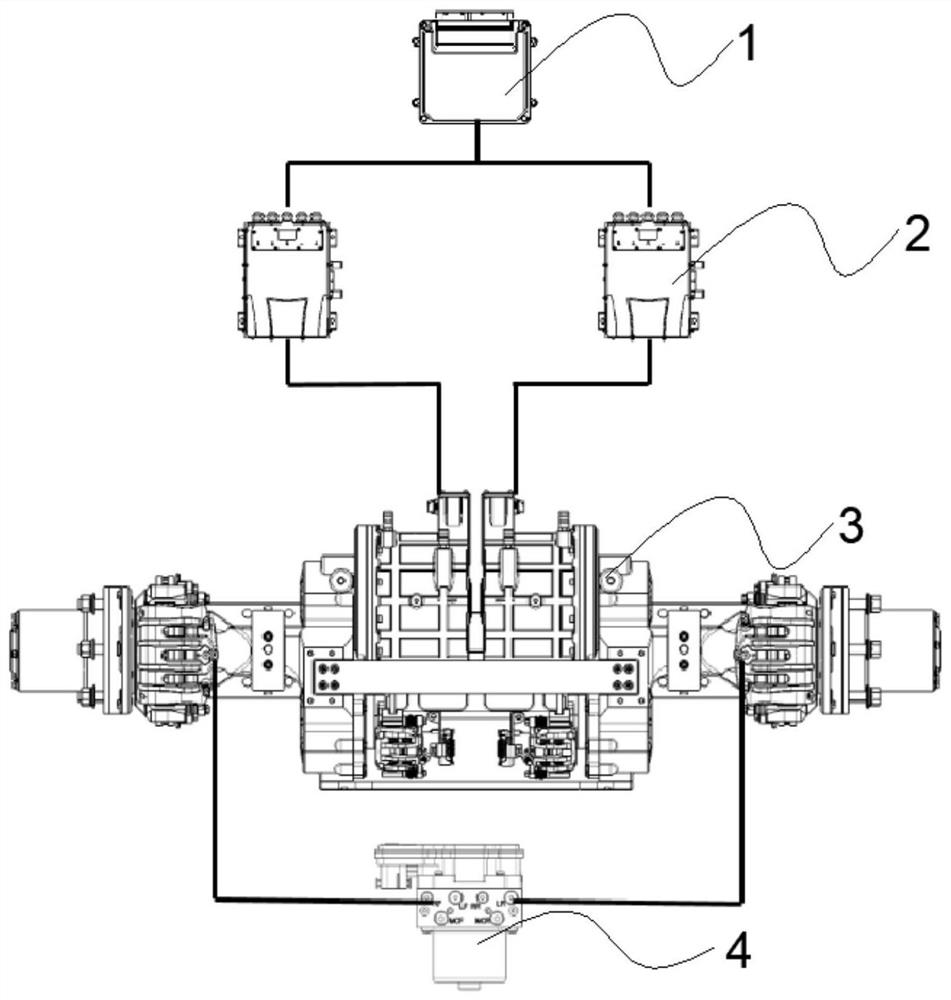

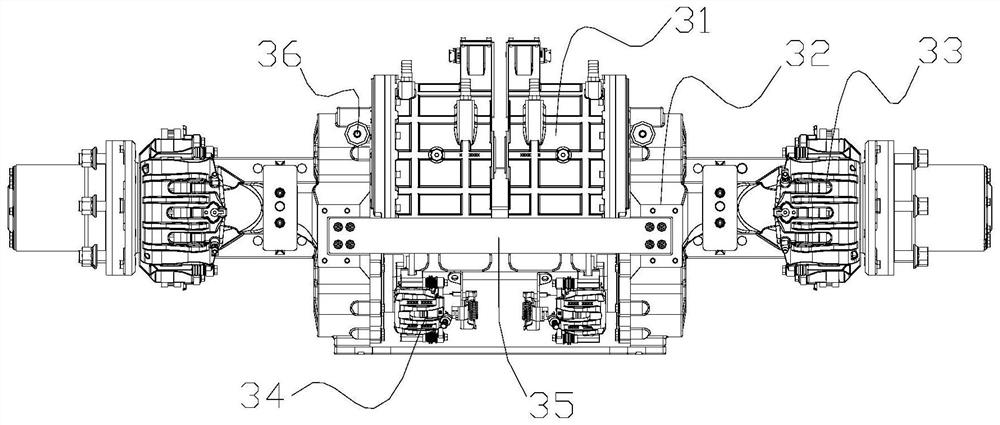

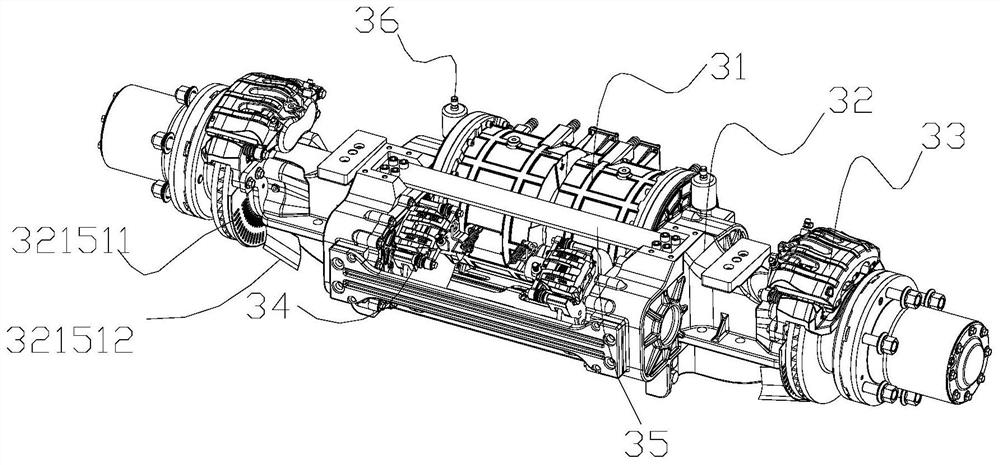

Distributed driving system suitable for plate spring suspension

ActiveCN112874284AMultiple Kinematic Control Degrees of FreedomImprove securityElectric propulsion mountingControl devicesVehicle dynamicsStabilization control

The invention provides a distributed driving system suitable for a plate spring suspension, and relates to the technical field of automobiles. A DCU (Deceleration Control Unit), a motor controller, a distributed drive axle and an HCU form the system, a left motor and a right motor are independently controlled, more whole vehicle dynamics control freedom degrees are achieved, and the dynamics control performance of a whole vehicle is greatly improved. The left motor, the right motor, a left parking brake, a right parking brake and the HCU are controlled through the DCU, higher control efficiency and shorter response time are achieved, the functions of ASR (drive skid resistance), vehicle body stability control, intelligent braking and the like are better and more efficiently achieved, and the safety of the whole vehicle is improved.

Owner:杭州时代电动科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com