Skid-mounted hydrogenation device for new energy automobile

A technology for new energy vehicles and hydrogenation devices, applied in motor vehicles, road vehicles, transportation and packaging, etc., can solve the problems of inconvenient transportation, unfavorable product investment recovery, large floor space, etc., and achieves simple and efficient operation and use. and the effect of enhanced use, easy transportation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

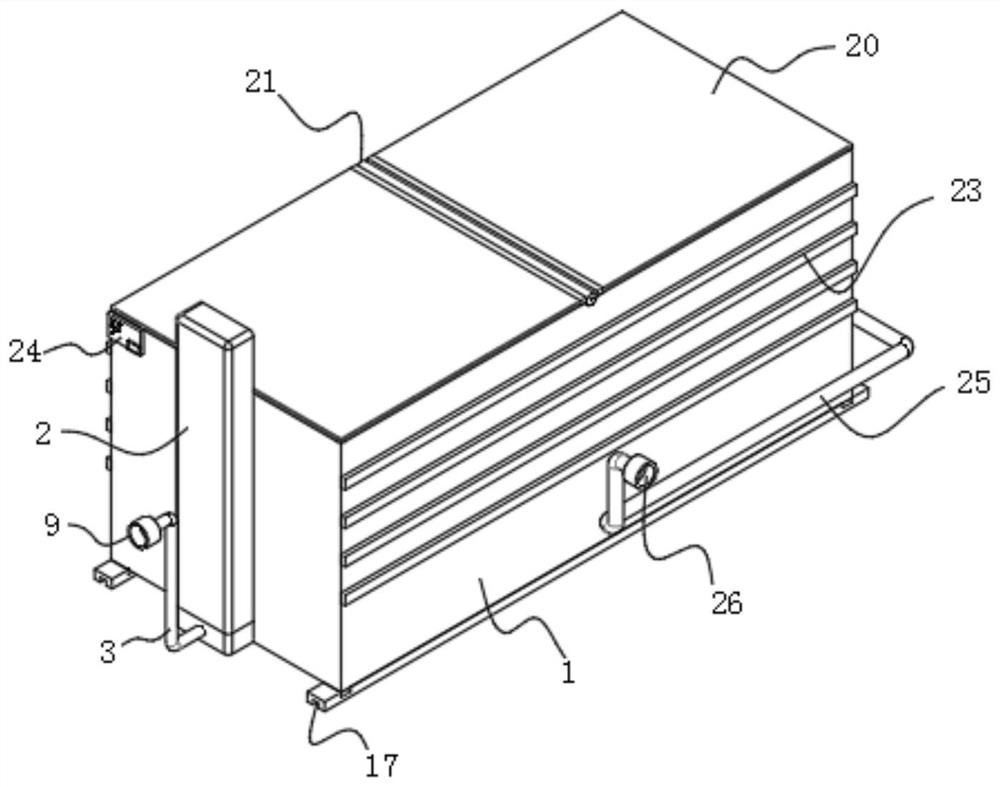

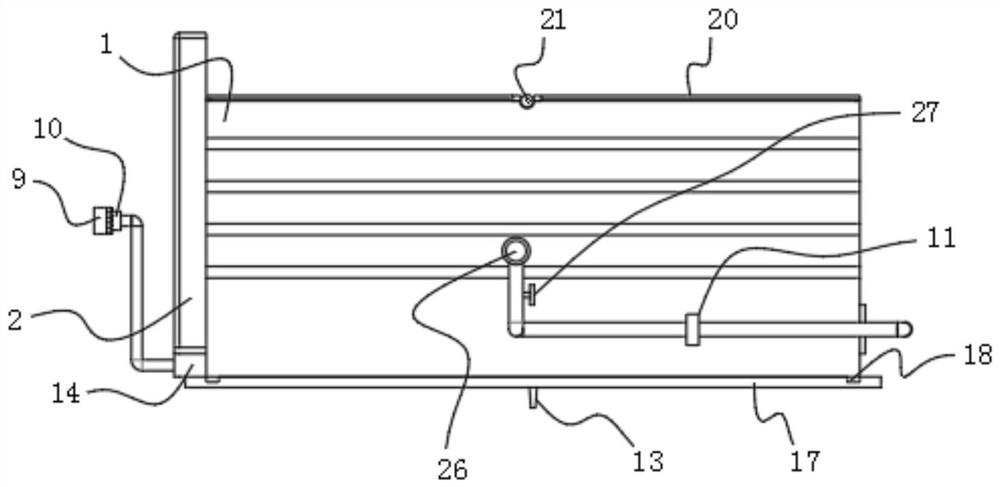

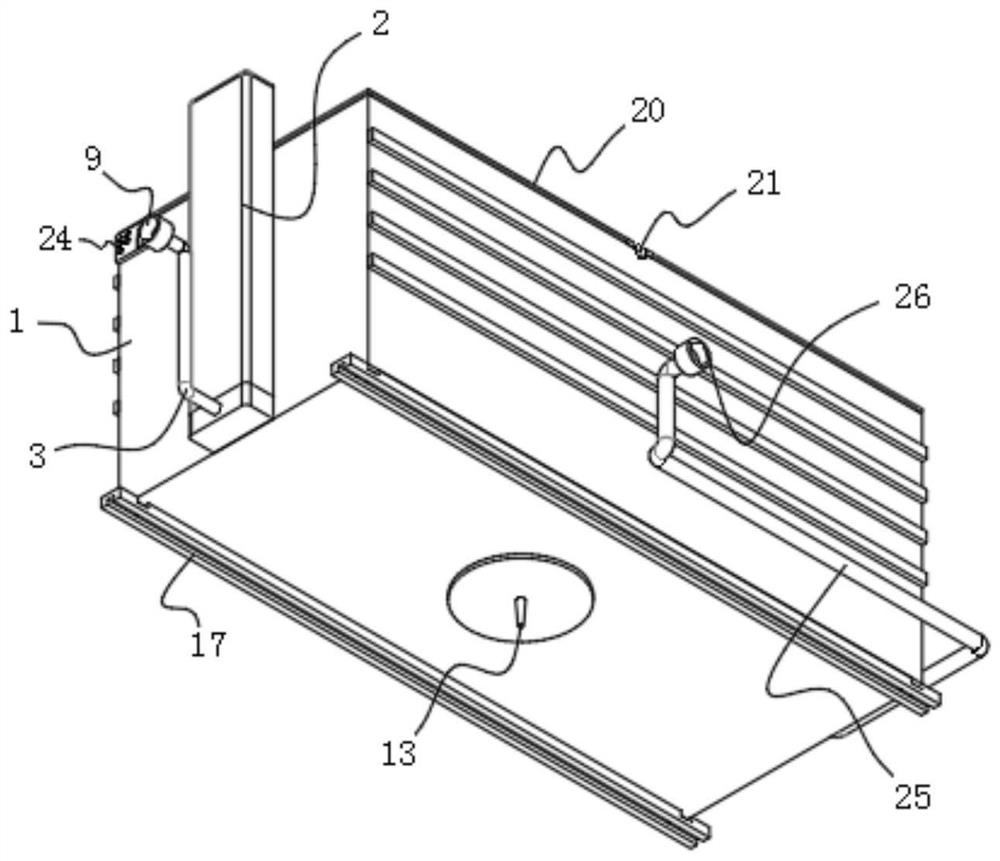

[0029] Please refer to Figure 1-7 Shown: a skid-mounted hydrogenation device for new energy vehicles, including a box 1, a hydrogen unloading column 2 and a second hydrogenation pipe 25, a hydrogen unloading column 2 is installed on one side of the box 1, and the hydrogen unloading column 2 The output end is connected to the box body 1, the second hydrogenation pipe 25 is installed on the other side of the box body 1, and the first hydrogen storage tank 4, the second hydrogen storage tank 5 and the third hydrogen storage tank 6 are respectively arranged inside the box body 1 A cold air pipeline 16 is connected between the first hydrogen storage tank 4 and the second hydrogen storage tank 5, the second hydrogen storage tank 5 and the third hydrogen storage tank 6, and a compressor 7 is installed on one side of the first hydrogen storage tank 4 , the output end of the compressor 7 is connected with a cooler 8, the output end of the cooler 8 is connected with the cold air pipeli...

Embodiment 2

[0031] Please refer to Figure 1-7 As shown: the outer surfaces of the first hydrogen storage tank 4, the second hydrogen storage tank 5 and the third hydrogen storage tank 6 are connected with the first hydrogenation pipe 15, and the combined use of the two sets of hydrogenation pipes can improve the hydrogenation of the hydrogen storage tank. Adaptability, according to the actual use requirements, carry out separate hydrogenation or integrated operation, the first hydrogenation pipe 15 side is connected to the second solenoid valve 12, the second hydrogenation pipe 25 side is connected to the first solenoid valve 11, Independent self-adaptive control is performed on the hydrogenation pipe. The grounding pin 13 is connected to the bottom of the box body 1 to improve the electrostatic protection effect and enhance safety. The bottom end of the box body 1 is equipped with an installation slider 17. There is a buffer post 18 connected between the cabinets 1, and the slider 17 is...

Embodiment 3

[0034]It should be noted that the present invention is a skid-mounted hydrogenation device for new energy vehicles. During operation and use, the long hydrogen tube vehicle is connected to the hydrogen unloading column 2 through the gas unloading pipeline 3, and the hydrogen unloading column 2 uses a meter 14 After metering, it is compressed by the compressor 7 and stored in the first hydrogen storage tank 4, the second hydrogen storage tank 5 and the third hydrogen storage tank 6 respectively, wherein the first hydrogen storage tank 4 is a high-pressure tank and the second hydrogen storage tank 5 is a medium-pressure tank, and the third hydrogen storage tank 6 is a low-pressure tank, which fills each gas storage tank group in sequence according to the high, medium and low-pressure tank groups, and the stored hydrogen passes through the first hydrogenation pipe 15 and the second hydrogenation pipe 25. Fill the vehicle. When filling the hydrogenation pipe, take gas from the tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com