Novel clamping buckle used for automobile air conditioning pipe

A new type of technology for automotive air conditioners, applied in the direction of pipe components, pipe brackets, vehicle parts, etc., can solve the problems of insufficient fastening of the buckle, difficulty in fixing the position, damage to the surrounding pipes, and no isolation and buffering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

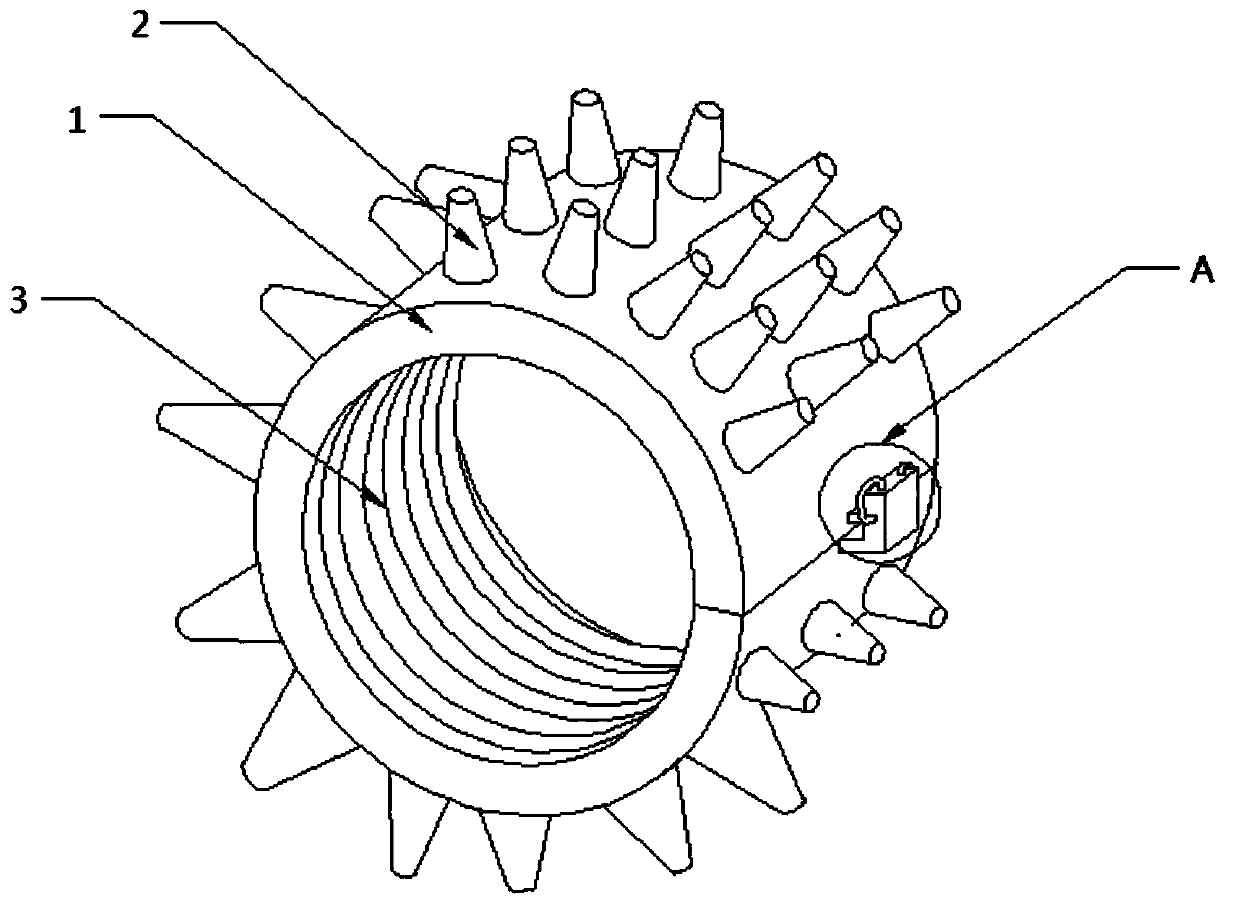

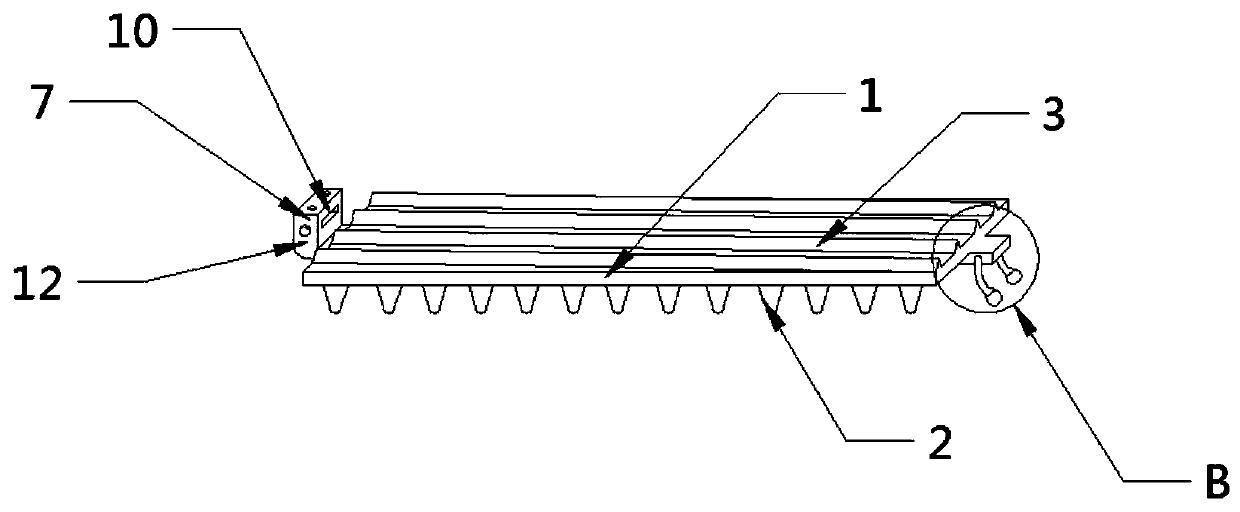

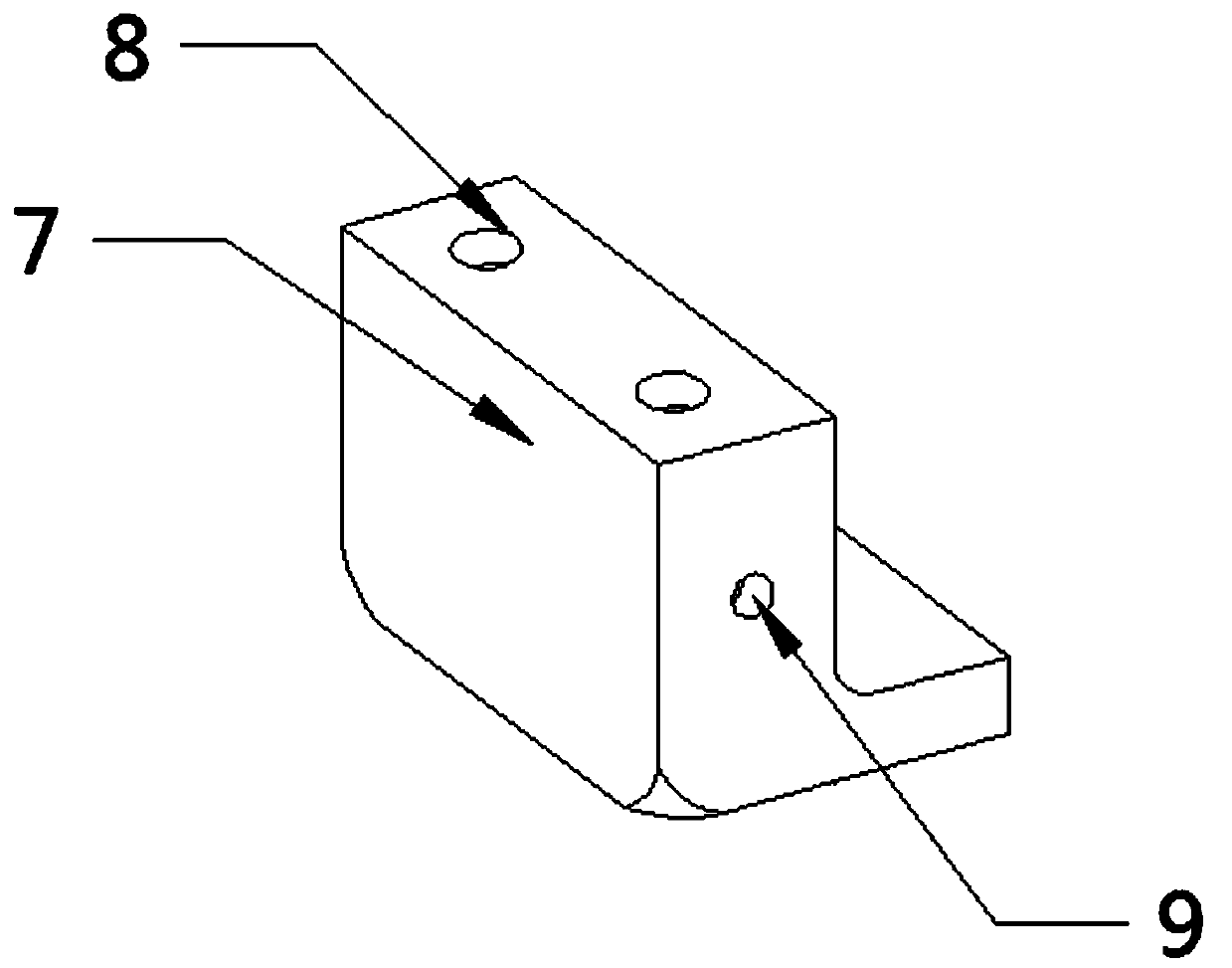

[0033] Such as Figure 1-Figure 5 As shown, the present embodiment provides a new buckle for automobile air-conditioning pipes, including a strip-shaped rubber sleeve 1 and a clip 12 installed in the middle of one end of the strip-shaped rubber sleeve 1, and the other end of the strip-shaped rubber sleeve 1. A plug-in 11 is installed at the middle position, and the plug-in 11 and the clip 12 cooperate with each other to form a ring structure of the strip-shaped rubber sleeve 1. The inner side of the strip-shaped rubber sleeve 1 is equipped with tapered anti-slip rubber strips at equal intervals along the ring of the strip-shaped rubber sleeve 1. 3. Tapered buffer bodies 2 are installed at equal intervals along the outer side of the strip-shaped rubber sleeve 1 along the ring portion of the strip-shaped rubber sleeve 1 .

[0034] By wrapping the strip-shaped rubber sleeve 1 on the outside of the air-conditioning pipe, the plug-in 11 and the clip 12 are engaged with each other o...

Embodiment 2

[0053] In this embodiment, the manufacturing method of the buckle of the automobile air-conditioning pipe is as follows:

[0054] Step 1: After passing nitrogen gas to the bottom of the polymerization tank for 25 minutes, add 90 parts by mass of deionized water, 3.3 parts by mass of disproportionated potassium rosinate soap DRS, 0.2 parts by mass of diethylaminetetraacetic acid EDTA, and dispersant MF0 in the reactor. .15 parts by mass and sodium bicarbonate NaHCO Add 0.6 parts by mass, stir and dissolve to form an aqueous phase;

[0055] Step 2: Add 65 parts by mass of isoprene IP, 25 parts by mass of acrylonitrile AN, and 0.3 parts by mass of benzoyl peroxide BPO, all of which are added to the monomer tank, stirred and dissolved to form an oil phase;

[0056] Step 3: 45 parts by mass of deionized water, 0.3 parts by mass of FeSO4 were added to the reducing agent kettle, stirred and dissolved to form FeSO4 aqueous solution;

[0057] Step 4: Control the temperature of the ket...

Embodiment 3

[0063] In this embodiment, the manufacturing method of the buckle of the automobile air-conditioning pipe is as follows:

[0064] Step 1: After passing nitrogen gas to the bottom of the polymerization tank for 30 minutes, add 100 parts by mass of deionized water to the reactor, add 5 parts by mass of disproportionated potassium rosinate soap DRS3, add 3 parts by mass of diethylaminetetraacetic acid EDTA, and add 3 parts by mass of dispersant MF Add 0.25 parts by mass and 1 part by mass of sodium bicarbonate NaHCO3, stir and dissolve to form an aqueous phase;

[0065] Step 2: Add 70 parts by mass of isoprene IP, 30 parts by mass of acrylonitrile AN, and 0.5 parts by mass of benzoyl peroxide BPO, all of which are added to the monomer tank, stirred and dissolved to form an oil phase;

[0066] Step 3: 50 parts by mass of deionized water, 0.6 parts by mass of FeSO4 were added to the reducing agent kettle, stirred and dissolved to form FeSO4 aqueous solution;

[0067] Step 4: Contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com