Preparation method of antiskid automobile foot mat

A technology for car floor mats and leather, which is applied to chemical instruments and methods, special positions of vehicles, vehicle components, etc., can solve problems such as inability to step on the floor, stuck brakes, and easily overlooked safety issues of car floor mats, and achieves easy cleaning. , good flame retardant performance, excellent anti-skid performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

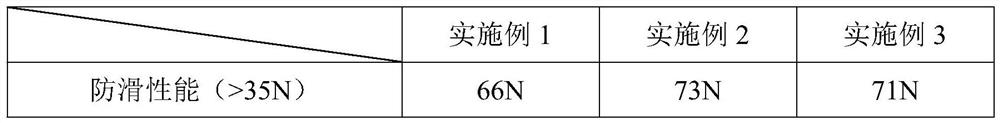

Embodiment 1

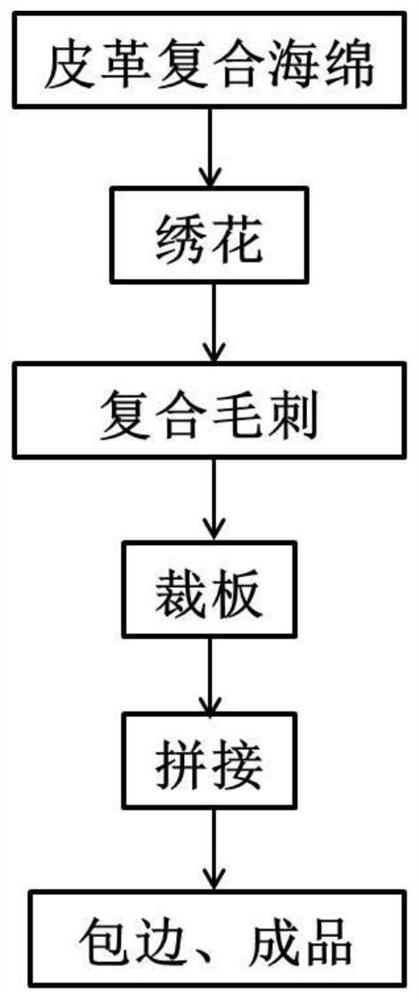

[0021] A preparation method for an anti-slip car mat, specifically comprising the steps of:

[0022] S1: Leather composite sponge: Laminate PVC artificial leather material and sponge with a hydrogel machine.

[0023] S2: Embroidery: Embroider the leather sponge layer compounded in step S1 according to the pattern design.

[0024] S3: Composite burrs: 1) Mix and granulate PE mixture (polyethylene mixture) and EVA (ethylene-vinyl acetate copolymer) on a single-screw extruder at a weight ratio of 0.54:0.28, wherein the single-screw extrusion temperature is At 120°C, polymer I was obtained, wherein the weight ratio of XPE, RPE and EPE in the PE polymer was 0.44:0.6:0.75.

[0025] 2) Then compound the polymer I and the leather sponge layer in step S2 on a roller laminating machine, wherein the polymer I is compounded on the sponge layer, the drum heating temperature is 255°C, and the polymer I is melted and bonded to the leather sponge layer, Get fur fabrics.

[0026] 3) The fur...

Embodiment 2

[0031] A preparation method for an anti-slip car mat, specifically comprising the steps of:

[0032] S1: Leather composite sponge: Composite PU synthetic leather material and sponge using a hydrogel machine.

[0033] S2: Embroidery: Embroider the leather sponge layer compounded in step S1 according to the pattern design.

[0034] S3: Composite burrs: 1) Mix and granulate PE mixture (polyethylene mixture) and EVA (ethylene-vinyl acetate copolymer) on a single-screw extruder at a weight ratio of 0.73:0.39, wherein the single-screw extrusion temperature is At 145°C, polymer I was obtained, wherein the weight ratio of XPE, RPE and EPE in the PE polymer was 0.57:0.8:0.84.

[0035] 2) Then compound the polymer I and the leather sponge layer in step S2 on a roller laminating machine, wherein the polymer I is compounded on the sponge layer, the heating temperature of the roller is 265°C, and the polymer I is melted and bonded to the leather sponge layer, Get fur fabrics.

[0036] 3...

Embodiment 3

[0041] A preparation method for an anti-slip car mat, specifically comprising the steps of:

[0042] S1: Leather composite sponge: Composite PU synthetic leather material and sponge using a hydrogel machine.

[0043] S2: Embroidery: Embroider the leather sponge layer compounded in step S1 according to the pattern design.

[0044] S3: Composite burrs: 1) Mix and granulate PE mixture (polyethylene mixture) and EVA (ethylene-vinyl acetate copolymer) on a single-screw extruder at a weight ratio of 0.69:0.34, wherein the single-screw extrusion temperature is At 135°C, polymer I was obtained, wherein the weight ratio of XPE, RPE and EPE in the PE polymer was 0.51:0.7:0.81.

[0045] 2) Then compound the polymer I and the leather sponge layer in step S2 on a roller laminating machine, wherein the polymer I is compounded on the sponge layer, the drum heating temperature is 260°C, and the polymer I is melted and bonded to the leather sponge layer, Get fur fabrics.

[0046] 3) The fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com