Method for monitoring tire pressure during corning process of automobile

A technology for air pressure monitoring and driving, which can be used in tire measurement, tire parts, vehicle parts, etc., and can solve problems such as reduced accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

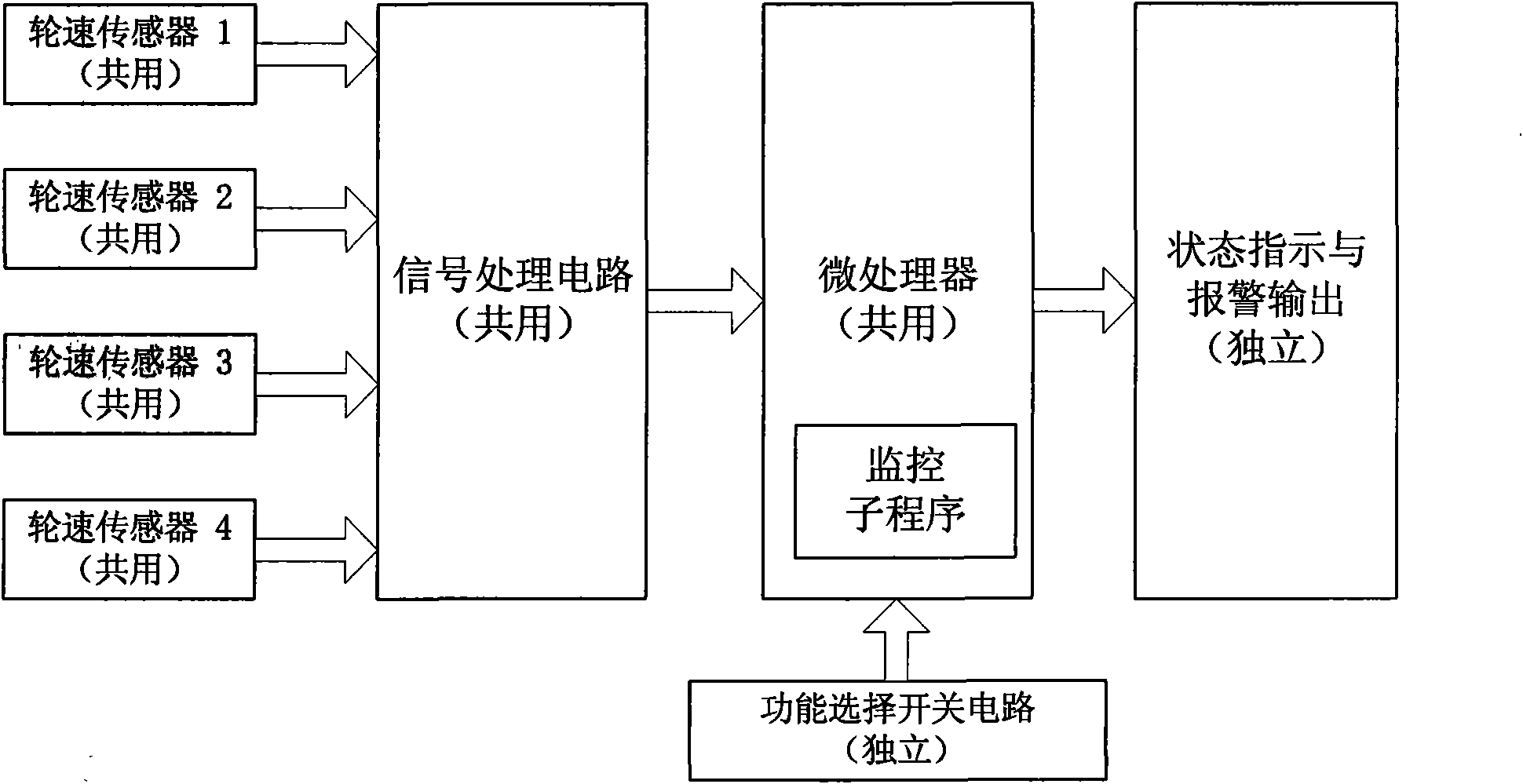

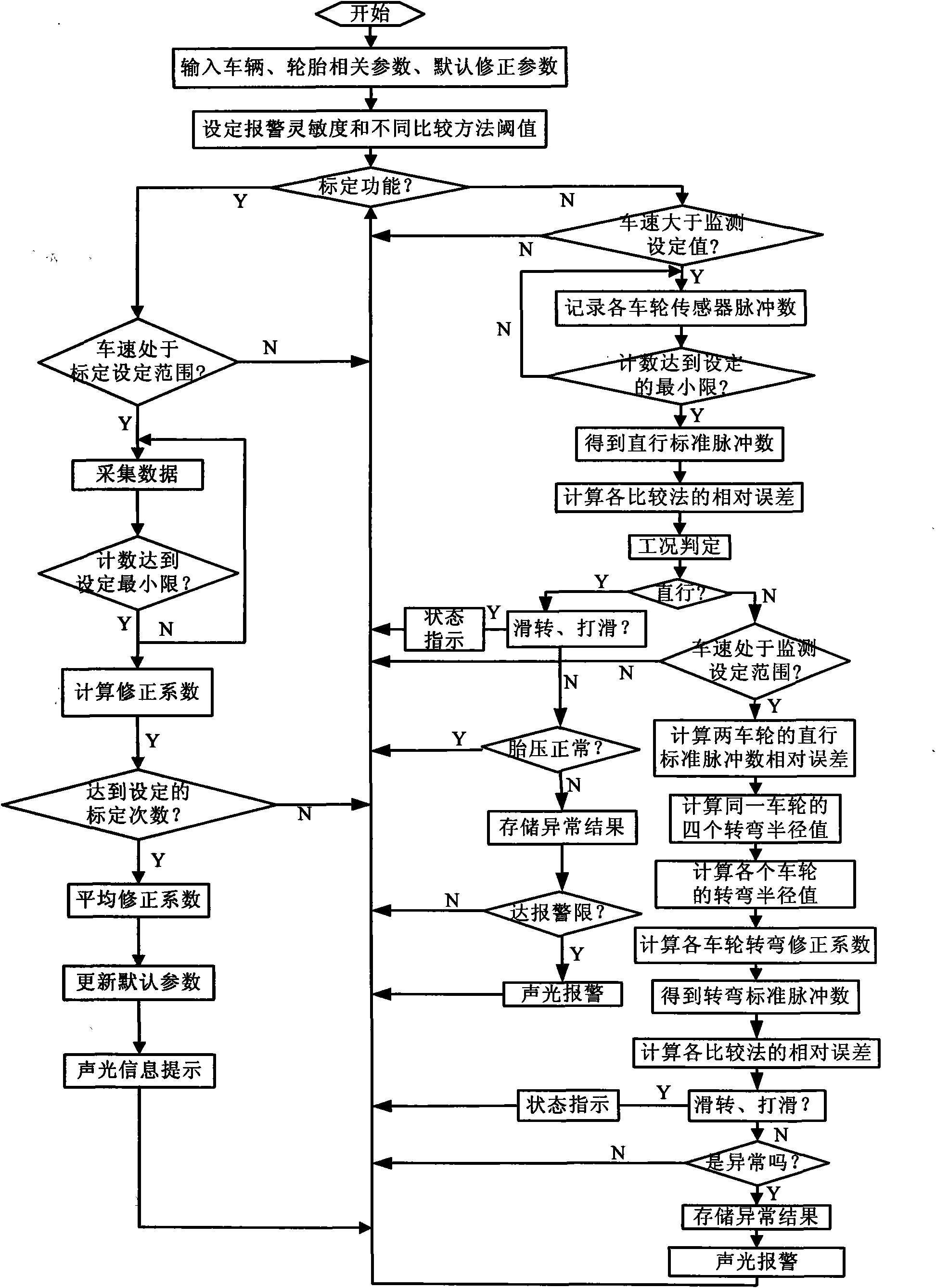

[0095] attached figure 1 Among them, when electronic control devices such as ABS, ESP, and TCS are installed on the automobile, the present invention can share wheel speed sensors, signal processing circuits and microprocessors with these devices; independently install function selection switch circuits, status indication circuits and alarm output Wait for the hardware part. The wheel speed sensor converts the rotation of the wheel into a quasi-sine signal or a square wave signal, which is sent to the microprocessor for counting after being processed by the signal processing circuit, such as shaping, filtering, and amplification. After judgment, analysis and comparison, information on working conditions such as going straight or turning, driving or braking, and whether the tire pressure of the vehicle is normal or not is obtained. When the tire pressure is abnormal, the status indication and alarm circuit will give a warning. The function selection switch is used to set whet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com