Novel tread rubber with pattern and preparation method thereof

A tread rubber and pattern technology, which is applied to tire treads/tread patterns, special tires, road vehicle tires, etc., can solve the problems of wear resistance decline and achieve improved safety, ultra-high wet skid resistance, Create a convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] A kind of preparation method of the tread rubber of a kind of novel self-contained pattern of the present application, comprises the steps:

[0050] The first step, the preparation of the anti-wet skid foam rubber unit A, controls the rotor speed of the internal mixer to 40-80RPM, the temperature is 130-150°C, and the pressure of the top bolt is 30-50N / CM2. The specific process includes the following steps:

[0051] (1) Add foam rubber to press the top bolt, and keep masticating in the internal mixer for 120-180 seconds;

[0052] (2) Add materials other than accelerant, sulfur and foaming agent to the top bolt, and press the top bolt for 120-180 seconds;

[0053] (3) After air-cooling the prepared mixed rubber for 1-2 hours, add accelerator NOBS and accelerator DTDM to the open mill. The temperature of the open mill is required to be 55-75°C, and practice 8-15 times.

[0054] (4) After air-cooling the prepared mixed rubber for 2-4 hours, add sulfur and foaming agent to...

Embodiment 1

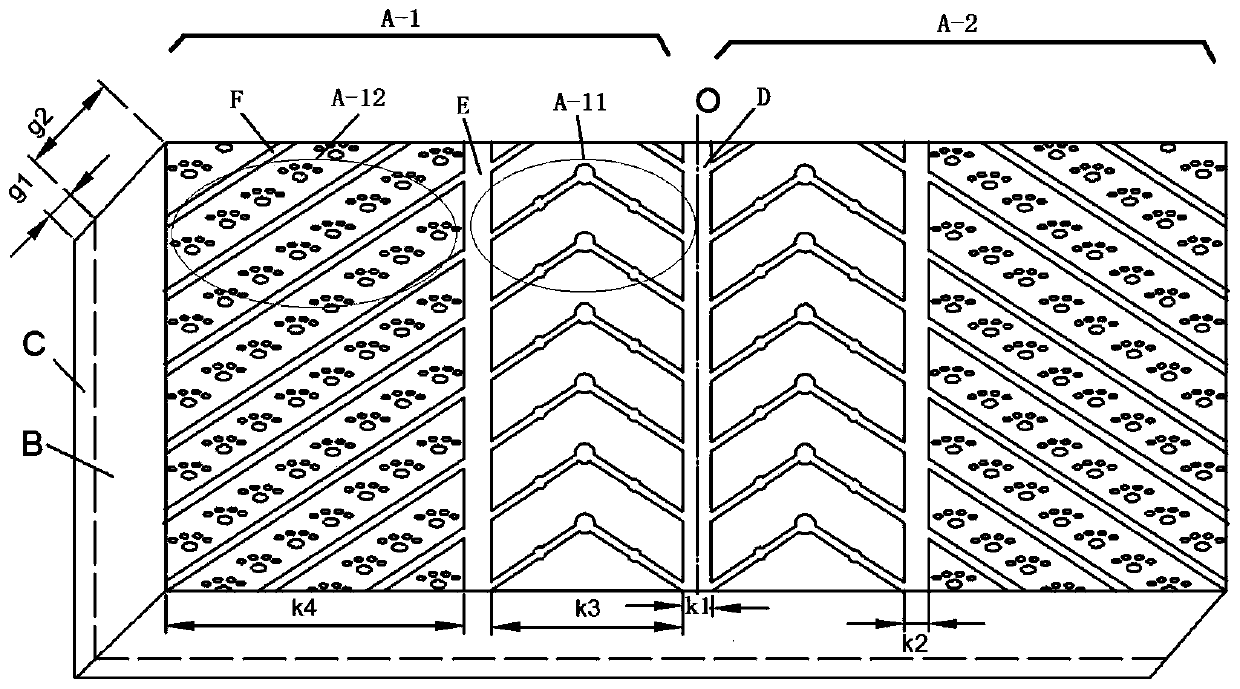

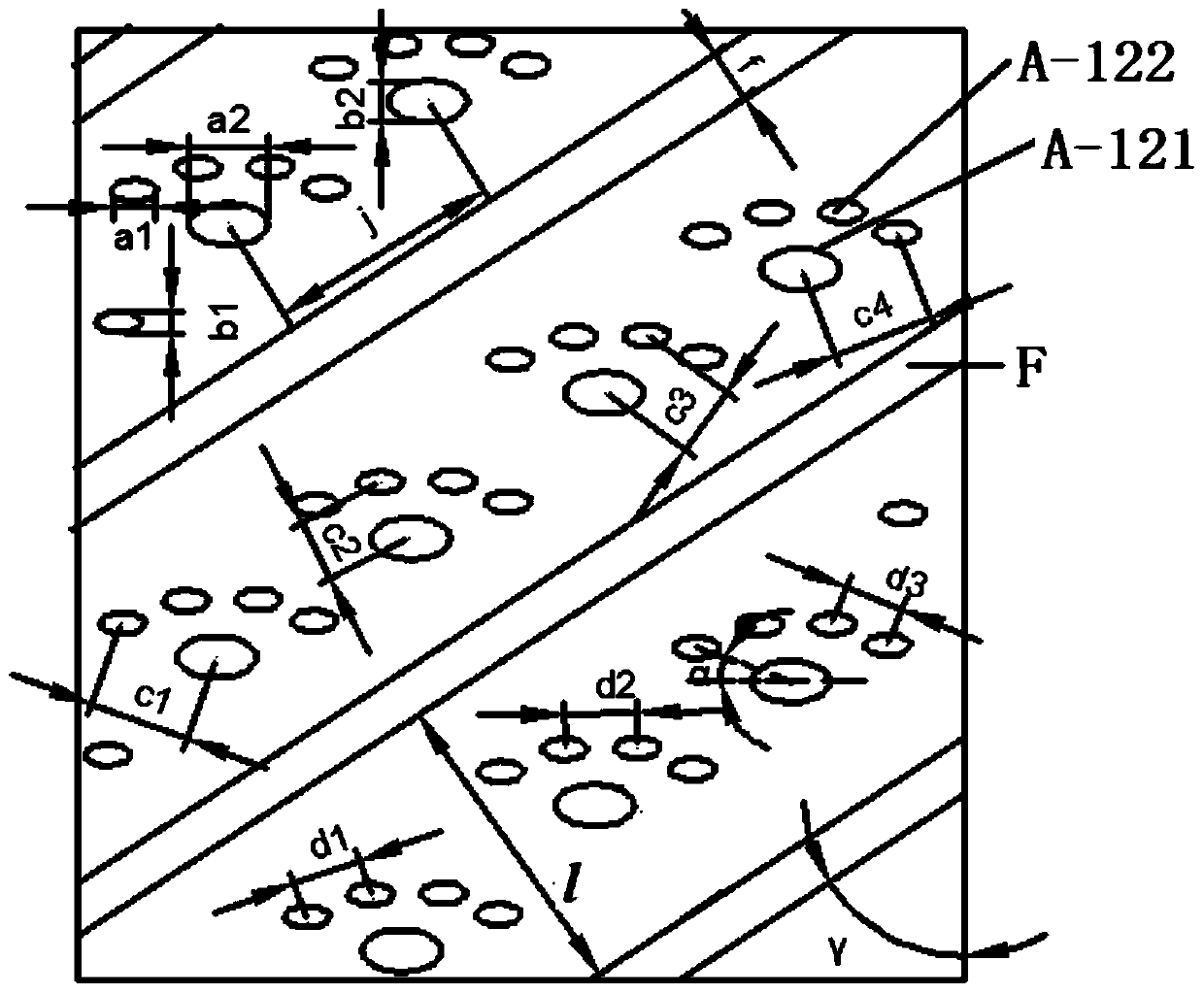

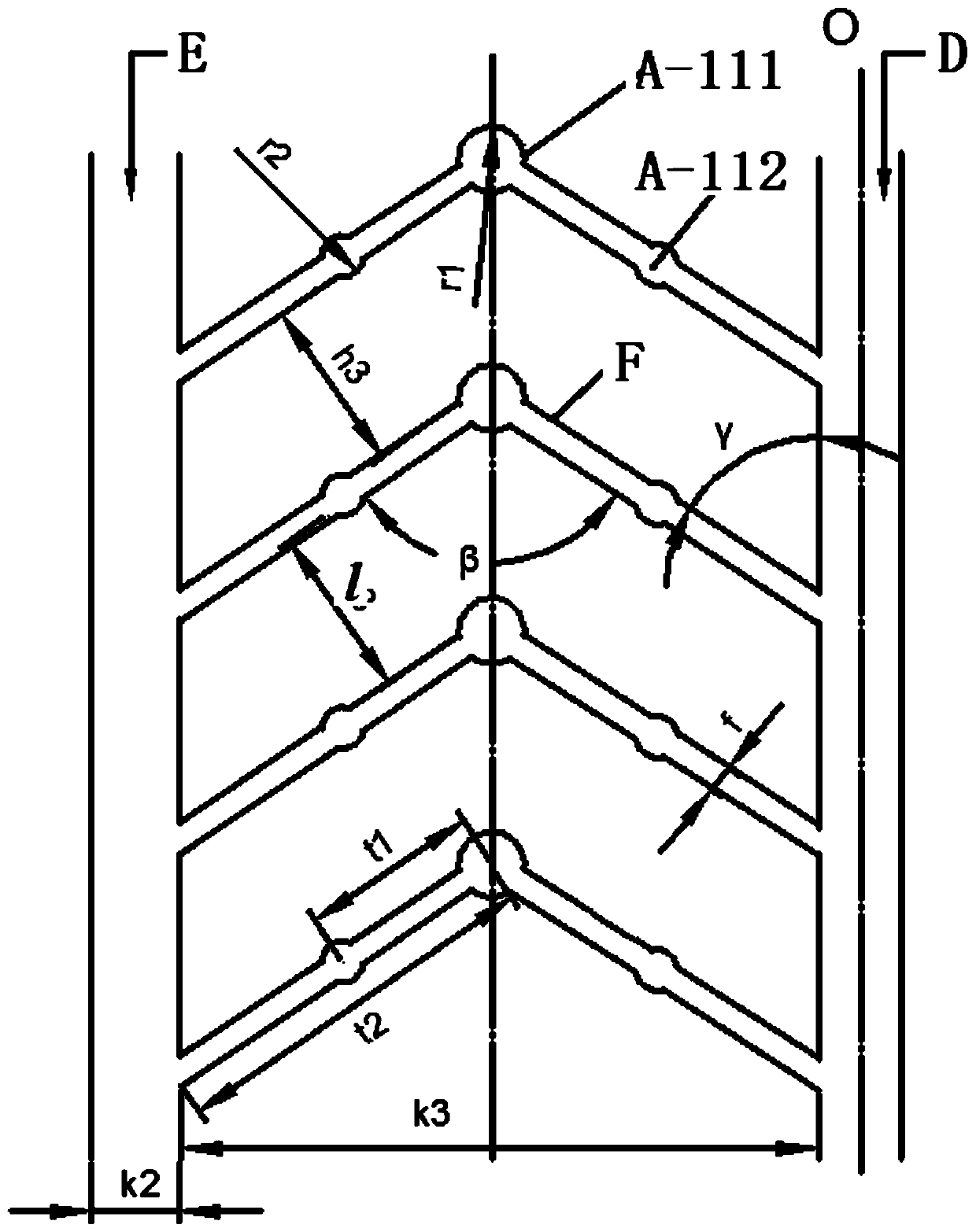

[0066]Embodiment 1, as shown in the figure, a new type of tread rubber with its own pattern, including anti-wet skid foam rubber unit A, high wear-resistant rubber unit B and tear-resistant rubber unit C, the anti-wet skid foam rubber unit The foam rubber unit A and the high wear-resistant rubber unit B are complementary, and the tear-resistant rubber unit C is located at the bottom of the anti-wet skid foam rubber unit A and the high wear-resistant rubber unit B, and the anti-wet skid foam rubber unit A Embedded in the high wear-resistant rubber unit B to form a pattern, the pattern formed by the anti-wet skid foam rubber unit A includes a mirror-symmetrical first pattern structure A-1 and a second pattern structure A-2, the first The pattern structure A-1 includes a rib pattern structure A-11 and a bionic pattern structure A-12, the strip pattern structure A-11 and the bionic pattern structure A-12 are separated by the main groove E, and the strip pattern structure A-11 and ...

Embodiment 2

[0093] Embodiment 2. The difference between this embodiment and Embodiment 1 is that the distance k3 between the central groove D and the main grooves E on both sides is equal to 150 mm; the width k2 of the main groove E is the same as that of the central groove D The width k1 is the same, which is 15mm; the radius r1 of the central circular node A-111 is 8mm, and the radius r2 of the side circular node A-112 is 4.5mm; the width f of the auxiliary groove F is 9mm central circular The length t1 of the auxiliary groove F between the node A-111 and the side circular node A-112 is 22mm;

[0094] The auxiliary grooves F located on the same side of the central circular node A-111 are parallel to each other, and the distance l between two adjacent auxiliary grooves F located on the same side of the central circular node A-111 is equal to 45mm; The length t2 is 90 mm; the included angle γ between the auxiliary groove F and the main groove E is 45 degrees.

[0095] The auxiliary groov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com