Wear-resistant and skid-resistant asphalt pavement treatment material and preparation method thereof

A technology for asphalt pavement and matrix asphalt, applied in the direction of asphalt coatings, polyamide coatings, coatings, etc., can solve the problems of reducing the service life of the pavement, cracks and network cracks, and increasing the load of the pavement, so as to reduce the interface adhesion. , good thermal stability, the effect of improving flow properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

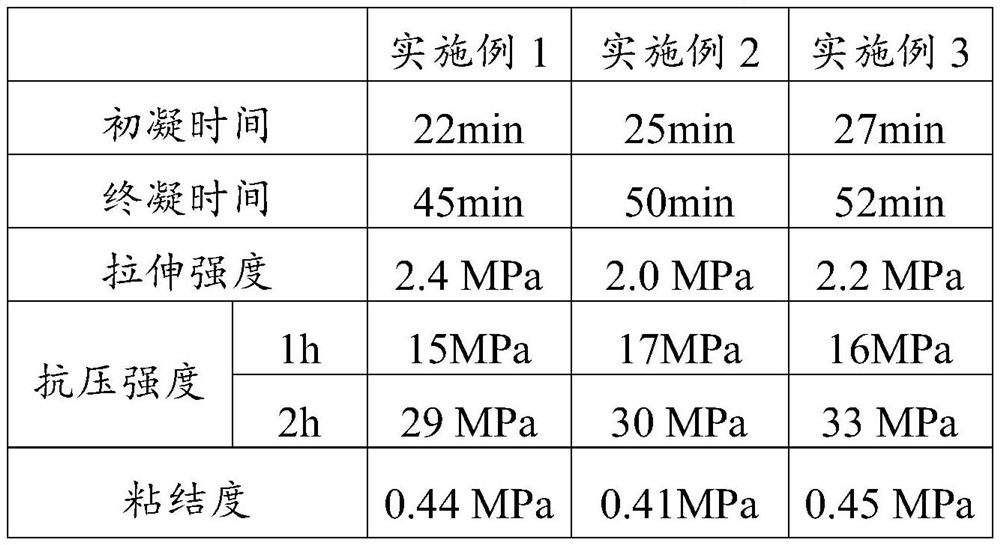

Examples

Embodiment 1

[0023] A wear-resistant and anti-skid asphalt pavement treatment material of the present invention comprises the following components: 40 parts of base asphalt, 30 parts of polyamide resin, 3 parts of toughening agent, 2 parts of friction performance regulator, 3 parts of aramid fiber, 10 parts of silicon carbide powder, 2 parts of silane coupling agent, 3 parts of epoxidized soybean oil, 2 parts of polydiethyl siloxane, 5 parts of wear-resistant carbon black, 4 parts of calcium sulfate whisker, and 7 parts of emulsifier.

[0024] The above-mentioned wear-resistant and anti-skid asphalt pavement treatment material includes the following steps:

[0025] S1: Mix the polyamide resin and wear-resistant carbon black, heat up to 85°C, and continue to stir for 2h to make the solution uniform to obtain component A;

[0026] S2: Mix aramid fiber, modified silicon carbide powder, silane coupling agent, epoxidized soybean oil, polydiethyl siloxane and calcium sulfate whisker uniformly to...

Embodiment 2

[0031] A wear-resistant and anti-skid asphalt pavement treatment material of the present invention comprises the following components: 48 parts of base asphalt, 35 parts of polyamide resin, 5 parts of toughening agent, 1 part of friction performance regulator, 1 part of aramid fiber, modified 12 parts of silicon carbide powder, 4 parts of silane coupling agent, 4 parts of epoxidized soybean oil, 4 parts of polydiethyl siloxane, 5 parts of wear-resistant carbon black, 2 parts of calcium sulfate whisker, and 9 parts of emulsifier.

[0032] The above-mentioned wear-resistant and anti-skid asphalt pavement treatment material includes the following steps:

[0033] S1: Mix the polyamide resin and wear-resistant carbon black, heat up to 92°C, and continue to stir for 3h to make the solution uniform to obtain component A;

[0034] S2: Mix aramid fiber, modified silicon carbide powder, silane coupling agent, epoxidized soybean oil, polydiethyl siloxane and calcium sulfate whisker unifo...

Embodiment 3

[0039] A wear-resistant and anti-skid asphalt pavement treatment material and a preparation method thereof of the present invention comprise the following components: 60 parts of base asphalt, 40 parts of polyamide resin, 7 parts of toughening agent, and 3 parts of friction performance modifier parts, 3 parts of aramid fiber, 15 parts of modified silicon carbide powder, 7 parts of silane coupling agent, 5 parts of epoxy soybean oil, 7 parts of polydiethyl siloxane, 6 parts of wear-resistant carbon black, calcium sulfate crystal 5 parts, 12 parts of emulsifier.

[0040] The above-mentioned wear-resistant and anti-skid asphalt pavement treatment material includes the following steps:

[0041] S1: Mix the polyamide resin and wear-resistant carbon black, heat up to 100°C, and continue to stir for 4 hours to make the solution uniform to obtain component A;

[0042] S2: Mix aramid fiber, modified silicon carbide powder, silane coupling agent, epoxidized soybean oil, polydiethyl sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com