Wet-skid-resistant rubber composition as well as mixing method and application thereof

A rubber composition and anti-wet skid technology, which is applied in the field of automobile tire materials, can solve the problems of weak wet skid resistance and inability to adapt to changes in the track environment, and achieve excellent grip performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

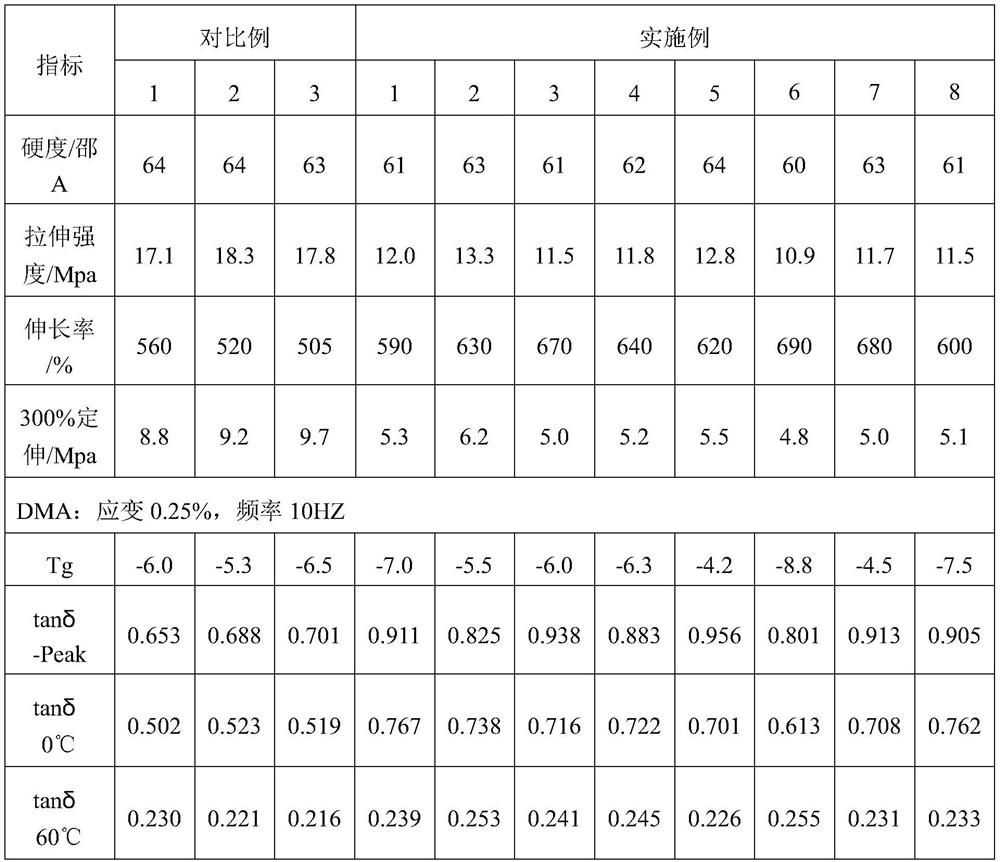

Examples

Embodiment 1

[0038] A racing tire tread rubber composition used on wet and slippery tracks, comprising medium styrene high vinyl solution polystyrene butadiene rubber 137.5phr (oil-extended 37.5phr, styrene content 25-30%) by weight , the vinyl group accounts for 50-60% of the total amount of butadiene, and the weight-average molecular weight is 100×10 4 ~150×10 4 ), fine-grained high-structure carbon black 30phr (nitrogen adsorption specific surface area is 180-200m 2 / g, iodine absorption value is 190~215mg / g), highly dispersed high specific surface silica 60phr (nitrogen adsorption specific surface area is 200~230m 2 / g, precipitation method silica, 200MP), high dispersion low specific surface silica 60phr (nitrogen adsorption specific surface area is 100~130m 2 / g, precipitated silica, 1115MP), RAE oil 70phr, hydrogenated DCPD / C9 resin 10phr (PR383, softening point 100°C), silane coupling agent 5.0phr (Si69), zinc oxide 3.0phr, stearic acid 2.0 phr, anti-aging agent 6PPD 3.0phr, ant...

Embodiment 2

[0040] A racing tire tread rubber composition used on a wet track, differs from Example 1 as follows: medium styrene high vinyl solution polystyrene butadiene rubber 137.5phr (oil-extended 37.5phr), fine particle diameter high Structural carbon black 60phr, high dispersion high specific surface silica 60phr, high dispersion low specific surface silica 30phr, RAE oil 60phr, α-methyl styrene monomer resin 15phr (SYLVATRAXX4401, softening point 85°C), silane coupling Joint agent 3.6phr, zinc oxide 3.0phr, stearic acid 2.0phr, antioxidant 6PPD 3.0phr, antioxidant RD 1.5phr, microcrystalline wax 1.5phr, sulfur 1.8phr, accelerator CZ 3.0phr, accelerator DM 1.0phr.

Embodiment 3

[0042] A racing tire tread rubber composition used on a wet track, differs from Example 1 as follows: medium styrene high vinyl solution polystyrene butadiene rubber 137.5phr (oil-extended 37.5phr), fine particle diameter high Structural carbon black 60phr, high dispersion high specific surface silica 30phr, high dispersion low specific surface silica 60phr, RAE oil 55phr, α-methylstyrene monomer resin 20phr (SYLVATRAXX4401, softening point 85°C), silane Joint agent 4.0phr (Si75), zinc oxide 3.0phr, stearic acid 2.0phr, antioxidant 6PPD 3.0phr, antioxidant RD 1.5phr, microcrystalline wax 1.5phr, sulfur 1.8phr, accelerator CZ 3.0phr, accelerator DM 1.0phr.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com